Installing screw piles allows you to build a massive and strong foundation for ...

|

|

During the construction, it is necessary to approach carefully to every detail and take into account ... |

The dynamically developing Haex LLC since 1998 has launched into production ... |

DIY concrete renovation

Often, construction technology provides for concrete floors. This is due to the high technical characteristics of the components of the mixture. The finished coating is available in cost, durable and practical. It acts perfectly independently, and serves as the basis for subsequent decoration with any floor materials. However, for a number of reasons, the base is deformed and cracks appear unusable, and dust formation increases. Formed defects reduce the strength and reliability of the screed. In this connection, during the repairs carried out will help prevent further destruction. The article will consider the technology for repairing concrete floors.

Content:

- The reasons for the destruction of the concrete floor

- Preparation for the repair of old concrete sex

- Preparation of a working mixture for the repair of concrete floors

- Partial repair

- Capital repair of concrete flooring with your own hands

- The final stage of the repair of the concrete floor in the apartment

Before starting the restoration of the surface, it is necessary:

- conduct a visual inspection to assess the condition;

- identify the reasons for the result.

Based on the data obtained, the technology of elimination is selected. With small injuries (potholes, lonely cracks), it will be enough to carry out local repairs. If the area of \u200b\u200bthe site to be repaired is more than 30-35% of the area of \u200b\u200bthe entire premises, then we will talk about capital work.

The reasons for the destruction of the concrete floor

Several basic reasons are known, negatively acting on concrete coating. Conditionally they are classified into 3 groups: soil exposure; external influence; Internal factors.

- To the first point The poor -quality density of the soil, winter swelling of the earth and the close arrangement of groundwater. Such factors lead to the movements of the layer, and as a result, the destruction of the concrete floor.

- Second point It involves a negative impact on the base due to the use of poor -quality solution, as well as filling in a violation of technology. Here it is necessary to note such a common cause as a shrinkage of a house that creates some progress.

- In the third paragraph There are factors such as: natural wear of the coating, mechanical exposure (falling heavy objects) and prolonged exposure to moisture, for example, during flooding.

After analyzing this information, you can proceed to eliminate the causes. Only after that can we talk about the benefits of repair work, otherwise all the restorations carried out will be useless.

Preparation for the repair of old concrete sex

- Work begins with the release of the premises from furniture and other interior items. If there is a floor covering on the screed, then it is dismantled. All garbage and dust are removed. Much attention is paid to damaged areas. It is there that a large number of exfoliating elements accumulate.

- The old layers of primer, rust and other pollution are removed with a metal brush. Then it is necessary to perform notes on the repair site, which will increase adhesion between the material and the new concrete.

- Chips and dust formed in the process are swept by a broom. A construction vacuum cleaner will show a good result in cleaning. The surface must be treated with degreasing impregnation or primer.

The degree of damage to the coating determines the complexity and type of subsequent work. If financial resources allow, then you can carry out a major overhaul of the concrete surface in order to significantly extend the operating period of the floor.

Preparation of a working mixture for the repair of concrete floors

- To eliminate shallow potholes and cracks, you can use a solution with the addition of PVA prepared at home. First, 1 part of glue with 4 parts of water is diluted. Then, the diluted PVA is poured into the prepared dry cement-sand mixture (1: 3) until the optimal consistency is reached.

- More serious problems are solved by applying building mixtures. In such compositions, for the repair of concrete floors, specially selected components guarantee the final strength and high resistance to mechanical damage.

- The shut -shaped powder composition is thoroughly mixed with a mixer. The use of such equipment will make the process better. The finished solution deeply penetrates the structure of concrete and forms a single monolith with the original surface.

Partial repair

In case of damaged areas of small areas, you can do with local work. Cosmetic repairs are subjected to:

- recesses;

- cracks, various depths and widths;

- hair gaps (web);

- minor irregularities.

Despite small defects, you need to immediately start work. The smaller their size, the easier it is to put the surface in order. An increase in existing cracks will lead to their growth, and as a result of the deformation of the flooring.

Lowering potholes

Usually they appear due to long -term finding furniture or bulky equipment in one place. Often the causes of the appearance are a mechanical effect, for example, the fall of an object from a height.

Elimination technology

- With the help of the tool, the defect expands and deepens. This is done in order to exclude the ability to leave weakened pieces of concrete on the site. The recess is cleaned and primed. Filling is made with an epoxy mixture or adhesive composition.

- The solution is pierced several times with a metal pin. It is important to remove air voids and evenly distribute the mixture in the resulting recess. Horizontal alignment is performed by a wide trowel or construction rule. After drying, the site is grinded.

- If the depth of the potholes is over 5 cm, the solution of the solution of the solution is slightly different. Here the mixture should be poured in several stages, in order to avoid the formation of cavities.

Repair of cracks in concrete floors

This kind of flaws appear due to the shrinkage of the structure or foundation. Temperature changes, improper proportions of the concrete, and the absence of reinforcing elements can lead to deformation.

Elimination technology

- With the help of a perforator or hammer with a chisel, the gap expands both in width and depth. Carefully inspect the adjacent zone for hidden defects, which after a while will lead to repeated surface repair.

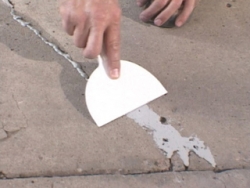

- The groove cleanses of fragments of concrete and dust. For processing, polyurethane primer is used. The mixture is laid in the crack, and then aligned with a spatula or level.

- In the presence of cracks in large widths on both sides, auxiliary grooves are made with a grinder. They will serve for laying metal captures, the distance between which should be 25-30 cm. All recesses are poured with solution.

Lining the web

This kind of deformation cracks can appear during the excessively rapid drying of the solution. They do not conceal dangers, but they are quite capable of expanding over time. The web is almost invisible. Its detection is possible when wetting the surface.

Elimination technology

- It is enough to treat the so -called hair gaps with a primer and embedded with an elastic sealant. If weakened areas are observed along the edges of the crack, it is recommended to clean the excess.

- The resulting groove is cleaned of foreign interspersed and treated with primer solutions. For sealing, you can use the composition of your own preparation or purchase ready -made mixtures of various granularity.

Minor irregularities

As a result of pouring, you can not always get a perfectly flat floor. This is due to non -compliance with the technology of these work. The flaws appear due to neglect of the installation of beacons, improperly mixed cement mass (too liquid or thick). Therefore, after drying, waves form.

Elimination technology

- The crests of the waves are removed using a grinder with a grout. The work is dusty, so personal protective equipment is necessarily used. If the processed area is large, it makes sense to contact specialized companies. In their arsenal there is equipment that, along with grinding, absorbs dust.

- The hollows are cleaned and deepened. They are treated with soil materials or diluted solvent. The recesses are filled with building mixtures, you can also use self -leveling solutions.

Capital repair of concrete flooring with your own hands

Thorough work will be needed if:

- there are extensive damage (over a third of the entire area);

- a warm floor system is installed;

- there is a desire to completely update the old concrete screed.

Such work can be carried out through the following technologies:

- laying wet screed using a standard cement-sand mortar;

- filling the self -leveling mixture, which includes plasticizers, stabilizers and fiber -fiber;

- installation of a dry screed, which includes backfill with subsequent laying of gypsum fiber sheets (GVL).

In each case, a different set of materials for the repair of the concrete floor is required.

Laying wet screed

- Repair work begins with the removal of construction debris and sipping the surface. It is necessary to remove all the exfoliating areas, which subsequently can significantly affect the strength characteristics of the new gender.

- Next, the flooring of waterproofing materials is made. A huge selection will allow you to purchase products with the most suitable properties at an affordable price. The next stage is the arrangement of beacons. Their step should be slightly less than the length of the rule used.

- The concrete solution is kneaded in accordance with the current proportions. The used ratios are completely dependent on the brand of the cement used and the desired strength of the finished mixture. Water is added until the necessary viscosity is achieved.

- Filling is carried out in small portions. This will help evenly distribute the mixture without the formation of voids. It takes about 30 days to complete drying, it is advisable to avoid any mechanical effects on the surface during this time.

Fill the self -leveling mixture

- Special compositions allow you to align with minimal labor costs. After inspection, the surface is removed by all existing detachments. In the presence of contaminants, a solution of copper sulfate is treated.

- The seams and cracks are sealed with a repair mixture. Mandatory waterproofing materials are being spread. If pouring is made on the old coating in fairly good condition, then the step with waterproofing can be skipped.

- If it is planned to fill the mixture with a thickness of more than 10 mm, then it is recommended to pre -install the profile beacons. The work begins with the far corner of the room. The solution is served in parts and leveled with a needle tool.

- After 8 hours, small effects can be exerted on the surface. For full operation, the floor will be ready after 5 days. Then they are already moving to the finish (laying of decorative flooring).

Installation of dry screed

Such a device has some advantages over wet operations. For example, it does not take time for drying, installation can be carried out regardless of the temperature regime. In addition, the floor is characterized by high indicators for noise and thermal insulation.

- First, the floor is performed. A plastic film or any vapor barrier material is spread. Then lighthouse rails are installed, which allow you to adhere to the desired level. Horizontal is checked by special tools.

- Between the profiles, expanded clay, vermiculite, perlite or compuls is filled. Starting from the door, sheet material is mounted from right to left. Its divorced it is carried out in a run (at least 25-30 cm). They move along the laid sheets with caution.

- The fastening is carried out with special screws, the step of the screws should be at least 30 cm. Mastic is used for additional fixation. If necessary, you can lay the second layer of sheet material without the coincidence of joints in any direction.

The final stage of the repair of the concrete floor in the apartment

The concrete surface with its monolithic is the property of dust formation, which occurs due to various mechanical loads. Invisible particles negatively affect human health. Wet cleaning will not be able to solve this problem.

The following will help to avoid harmful effects:

- clean the surface as much as possible;

- carry out processing with a primer;

- perform painting with a material that prevents concrete detachment.

Here you can use products based on polymers that form a protective layer of various thicknesses. For rooms with minimal loads, thin-layer materials (up to 150 μm) are used by neuromlp or elakor-pa.

In residential rooms with intensive cross-country ability, elacor-ed, retro-player or soil-due are used. The protective layer of such funds is over 250 microns, which allows you to withstand high loads.

Due to the deep penetration, the concrete screed is characterized by:

- resistance to temperature changes;

- moisture resistance;

- lack of dust formation;

- high resistance to wear.

Timely noticed flaws and their immediate elimination will help increase the life of the surface. In addition, this will avoid more expensive and laborious work to restore the concrete floor. Accurate compliance with all stages of repair work will lead to an impeccable result.