Having planned the purchase of metal doors to ourselves, we initially analyze the product, ...

|

|

The steady increase in the number of wooden buildings has become one of the most iconic phenomena ... |

Theft has long been a craft for many. On police reports most often ... |

Lining linoleum on plywood

The use of plywood as a black floor helps to quickly and efficiently align any flooring. Installation of linoleum on the floor of plywood is a great option for finishing the floor, since this process does not take much time and differs in the ease of execution. However, the installation of linoleum on the base from plywood has its own characteristics and requires compliance with a certain technology for its implementation. We will consider how to put linoleum on the plywood about how to put linoleum.

Table of contents:

- Linoleum - characteristic and advantages of the material

- Varieties of linoleum for laying on plywood

- Linoleum laying technology on plywood: Preparatory work

- How to lay linoleum on plywood: ways to lay linoleum

- Recommendations for laying linoleum on the base of plywood

Linoleum - characteristic and advantages of the material

The popularity of linoleum is explained primarily by its availability, good performance and low cost. Linoleum is the most economical and sought -after flooring, which is distinguished by good heat -insulating characteristics.

In addition, the variety of linoleum drawings allows you to use it in any room. Thanks to this, linoleum has a very wide area of \u200b\u200bapplication. It is used for flooring in both residential and public and industrial premises.

Linoleum perfectly imitates wood, stone, glass, ceramics, tiles and other materials. Thanks to this, it fits into any type of interior. Among the main advantages of linoleum, we highlight:

- Easy installation - for the installation of linoleum, special equipment or special skills in working with it, the installation of linoleum is possible even to one person;

- The ease of operation and care - this material is well cleaned of dirt, so its use is relevant in rooms with high patency, it is enough to use warm soap water to clean linoleum;

- does not need protective compositions, since parquet;

- Soft, but at the same time durable and elastic, these qualities endow linoleum with high strength to break and resistance before mechanical damage;

- Due to the fact that the life of linoleum is several decades, this material has been practical and duration of operation;

- moisture resistance, allows you to mount linoleum in rooms with medium and high humidity, such as kitchen, bathroom;

- Another advantage of linoleum is its stability over the effect of acid and aggressive chemicals;

- linoleum is distinguished by high heat and soundproofing characteristics;

- linoleum is characterized by a low sliding level, thanks to this, people who move along it are safe, so linoleum is widely used for styling in the kitchen, in the gym in public premises;

- linoleum is perhaps the most diverse material in terms of colors, it imitates other types of coating is distinguished by diverse patterns and the most unusual colors;

- Using linoleum, it is possible to equip a warm floor system;

- Affordable cost is the first factor that ensures the popularity of this finishing material.

Linoleum has a large number of advantages, but it still has certain disadvantages:

- To lay linoleum requires a perfectly even base, a black plywood floor is ideal;

- Installation of heavy furniture on a linoleum surface leads to the formation of dents on it.

However, if we compare the advantages and disadvantages of this material, it is obvious that he has much more advantages.

Varieties of linoleum for laying on plywood

Among the main types of linoleum, they distinguish:

1. The household version of linoleum - for its manufacture, a foamed polyester base is used, a strip of such linoleum in thickness is from one to four millimeters. However, this type of linoleum has a complex structure, among its advantages it should be distinguished:

- a variety of color solutions;

- high level of softness;

- moisture resistance;

- light styling;

- Available cost.

However, if this type of linoleum is highly operated, then its service life is about three years. This material is unstable in front of a large weight, therefore, due to its softness, prone to the formation of dents. This version of linoleum is recommended for use in housing premises.

2. The commercial version of linoleum is characterized by high wear resistance and duration of operation. Great for installation in offices or salons, as it involves applying any kind of emblem or drawings to it. There are two options for such linoleum:

- homogeneous linoleum;

- Linoleum of heterogeneous type.

The first option differs with a thickness of one and a half to three millimeters. A plain pattern is applied on it, its composition contains components in the form of limestone, talc and kaolin. A special coating of polyurethane is applied to the surface, protecting it from mechanical and external influences. Once every half a year, this coating needs grinding.

The second version of linoleum is heterogeneous, is highly versatile. It has a multilayer structure, it is based on the use of fiberglass. To impregnate the front part of the linoleum, PVC paste is used, then a drawing is applied to the linoleum, which is fixed with another layer of polyvinyl chloride. A substrate made of fabric, jute or foamed polyvinyl chloride is laid on the inside of the linoleum. This linoleum does not need special care and is distinguished by a long service life.

3. Linoleum of a semi -commercial type - similar to the domestic type of linoleum, but has a higher thickness of the protective layer, about 0.6 mm. The scope of its application is associated with public and passing rooms.

In relation to the type of materials used in the process of production of linoleum, it is divided into:

- synthetic linoleum;

- Natural linoleum.

The first option is characterized by ease of care, moisture resistance, good soundproofing characteristics. However, this linoleum has one drawback - the use of synthetic resins in the process of its production.

The natural version of linoleum is characterized by environmental harmlessness to human health. It is stable before wear, deformation and abrasion. For the manufacture of modern natural linoleum, linseed oil, resin, jet tissue and dyes on a natural basis are used. To ensure the protection of linoleum, a polymer coating is applied to it.

Due to the presence in its composition of linseed oil, linoleum is characterized by bactericidal characteristics, in addition, such linoleum has a high level of fire safety. It is easy to clean, does not change the colors under the influence of ultraviolet radiation. This linoleum is not used in places with increased operational load or in rooms with a high level of moisture.

Linoleum laying technology on plywood: Preparatory work

The flooring of plywood on a wooden base is performed with the aim of completely alignment. If this is not done and lay linoleum on an uneven floor, then he will soon take its shape and will also become uneven. As a result, it turns out aesthetically not attractive coating.

Even if the wooden floor is even, it can creak, and laying plywood on it will avoid this unpleasant process. Before starting work, you should determine the place on which the lags are installed, if any. To do this, one board is torn off the floor. Then, with the help of long self -tapping screws, scrolling the floor begins. Keep in mind that none of the boards should hang out. Self -tapping screws should have such a length to ensure a tight fit of each board. The distance between the concrete overlap and self -tapping screws should be at least ten centimeters. Wooden wedges or mounting foam are used to fill the cracks.

The most popular material for aligning the floor for laying linoleum - plywood from birch. For its manufacture, veneer layers glued together are used. This material is characterized by an affordable cost and good environmental characteristics. In order to align the floor with plywood, choose a material with a thickness of about one centimeter. The price of the material depends on its thickness and wood used in the process of its manufacture.

After checking and preparing the draft floor, the process of laying plywood follows. If the plywood is laid on top of the concrete screed, it is recommended to pre -waterproofing it with a plastic film.

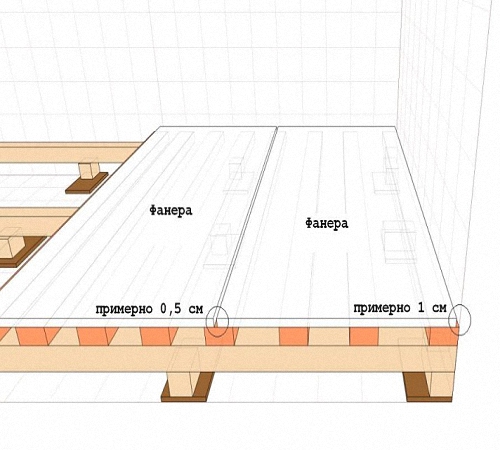

Plywood is laid on the floor both on the lags and without them. Before starting work, the plywood should be cut into sheets convenient for fixing on the floor. Large sheets are most conveniently cut into four parts. Leave small gaps between the sheets to compensate for their thermal expansion. In addition, a gap 1-1.5 cm is also left between the wall and the plywood. Fix the plywood after observing the chess order, after laying it, process the floor with a primer or primer. Using the rule, check the base for evenness.

How to lay linoleum on plywood: ways to lay linoleum

There are two options for laying linoleum on the plywood:

1. Besecleous installation of linoleum - after preparing a plywood base, follows the process of linoleum flooring. If the area of \u200b\u200bthe room is from twelve to fifteen square meters, then this styling method is the most optimal and suitable.

However, if the room has increased cross -country ability, then it is recommended to use the second way. If you lay linoleum in a large room using a flaring method, then over time, there is a risk of its deformation and swelling. In order to lay linoleum on the base from plywood with high quality and with maximum evenness, perform a number of actions:

- After buying linoleum, leave it in the room for at least a day, for its acclimatization;

- Roll up a roll in another room, the area of \u200b\u200bwhich is more than that in which it will be laid;

- in the ratio with measurements of the room, cut a fragment of linoleum for styling, leave a supply on each side, 50-100 mm;

- Roll out a cut fragment in the room so that its stock goes beyond the walls evenly from all sides;

- Starting from the central part of the room, moving the linoleum moving to the edges;

- With the help of an acute stationery knife, cut the excess linoleum, retreating one centimeter from the wall;

- To fix linoleum on the floor, use a skirting board, and on the threshold set a steel rail in the form of a spin.

2. The second option for laying linoleum will tell you how to glue linoleum to the faner, since it implies gluing linoleum to the floor surface.

At the beginning of the work, linoleum is also cut in relation to the parameters of the room. For these purposes, use a sharp knife. Put linoleum canvases on the floor, check their compliance with the shape of the room.

Bend half the linoleum, grease it with glue. To apply glue, use a special grater or a toothy spatula. Next, wait for as much time as indicated in the instructions for the glue that is applied to linoleum, lay the linoleum on the floor, giving it thoroughly. Follow the absence of air bubbles on the glued sheet of linoleum. Do the same with the second half of the linoleum, if it is planned to mount several linoleum paintings in the room, then they are indicated overlapping, and then, they are cut with a knife and welded using the method of hot or cold welding and special equipment.

Tip: When choosing the adhesive composition for laying linoleum on the base of plywood, you should not stop at the PVA chuck or compositions with a water base. Since during the operation of linoleum, there is a risk of upholding plywood and bloating. It is better to give preference to compositions intended for wooden surfaces.

Another option for gluing linoleum to the surface is the use of double -sided tape. Among the advantages of this installation method should be noted:

- simplicity of execution;

- lightness and cheapness;

- Such linoleum is easier to remove than glued with glue;

- Reliable fixation of the coating.

Double -sided tape is glued to the floor of plywood, along the perimeter of the entire room. In addition, adhesive tape must be glued to butt areas.

Recommendations for laying linoleum on the base of plywood

1. Before starting work, linoleum should be in the room for at least a day, and better two, so it will get used to the temperature and humid regime of the room.

2. Particular accuracy should be shown in the process of laying linoleum near the batteries, doorways and niches, it must fit closely.

3. After laying linoleum, if possible, leave it for one, two days, and only after the expiration of the specified period begin to operate it.

4. Cutting the linoleum in areas near the walls, leave a little reserve, since linoleum after laying gives a small shrinkage.

5. To fix linoleum near the doorway, use double -sided tape.

6. Before cutting linoleum, turn it out in the inside and twist it into a roll.

7. In order to connect two sheets of linoleum, there are two ways:

- Cold welding method - install sheets with overlap and cut the linoleum at the junction of the knife, attention - use only a sharp knife, since you need to cut two linoleum sheets at once, then apply a double -sided tape under linoleum sheets, fix them on it, apply to the surface, apply to the surface material in the form of liquid glue, it will connect the ends to each other;

- Using hot welding, a construction hairdryer is used, which warms up a special cord, which immediately fits at the junction and is smoothed by a special ironer.

thank you for the article

thank you for the article

thank you, useful and intelligible

thank you, useful and intelligible

Thank you and technological

Thank you, but technological gaps will not take a linoleum?

Roll up a roll in another

"Roll up a roll in another room, the area of \u200b\u200bwhich is more than that in which it will be laid"

and if there is no such room?