High -quality plastic windows from a trusted manufacturer installed with ...

|

|

What can be more useful than vegetables and fruits grown in their own area? The only way... |

The wood is the most ancient, used for building material, and ... |

Linoleum substrate: necessity, installation features

The constantly expanding flooring market is located at a certain stage of its development, associated with the steady popularity of linoleum. Consumers who make a choice in his favor substantiate this as undeniable advantages of this flooring, including the simplicity of laying, a long operational period, aesthetically attractive appearance and environmental safety. The democratic price of linoleum, leading the list of its advantages, cannot remain unnoticed. The construction school, like the market, also does not stand still, popularizing new and new trends. One of these trends was the use of shock -absorbing dampfer materials between the floor covering and the floor surface, relevant in the process of floor repair. And if the homeowners who have chosen a laminate are clearly confident in the need to use the substrates, then the masters who prefer linoleum are often not sure of a positive answer to the question: do linoleum is needed? Experienced experts also do not give an unambiguous answer to this question, but to a completely competent statement of consumers: if there is no need for it, why is it produced in such a wide assortment? Only thoughtfully shrug. To understand this issue, it is necessary to consider the main varieties of linoleum substrates, as well as the functions that they perform, after which each master will make the right choice for himself.

Content

- What is a substrate: the main functions of a linoleum substrate

- When is it necessary to use a linoleum substrate?

- Linoleum substrate: main varieties

- Read more about the cork substrate: types, technical specifications

- Laying cork substrate: Preparatory measures

- Camping substrate: step -by -step guide

What is a substrate: the main functions of a linoleum substrate

The substrate shock -absorbing dampfer building material that performs isolation functions and excludes the possibility of contacting the flooring, including linoleum with the floor surface. Thanks to this, it is a highly functional material, the purpose of which is as follows:

- Compensation of floor irregularities and alignment of the basic base. The importance of this function is due to the fact that linoleum is often placed on a concrete base, which is not always characterized by a perfectly flat surface. Even minor depressions, cracks and tubercles only accelerate the wear of the PVC cover. Using a substrate that compensates for all flaws, you will extend the operational period of the popular flooring;

- Thermal insulation functions. This functionality of the substrate is of particular relevance if under the base of the floor there is an unheated, for example, a basement, a cooling surface of the floor, as well as if the structure of the linoleum you bought does not provide for the presence of a warming layer. The substrate characterized by high thermal insulation indicators will be able to completely replace the missing thermal insulation layer. The use of a substrate as a heater is popular when arranging floors in a children's room;

- The substrate is an effective sound insulator.This property will be especially relevant for residents of apartment buildings forced to listen to sounds that are distributed from the lower floors. The substrate, bedding under the flooring, will not only muffle the sounds that come from below, but also make the room more comfortable.

When is it necessary to use a linoleum substrate?

Given the above functions of the substrate for linoleum, we list the main situations when it is not possible to do without it.

- Cold floor One of the first reasons for which the need for the use of a substrate determines. The linoleum substrate will prevent the penetration of cold from unheated lower rooms. In this case, experts recommend using a jute or combined substrate consisting of a mixture of jute, flax and wool. It is these varieties that are characterized by maximum thermal insulation functions;

- An uneven floor A common reason for using the substrate, since few can boast perfectly even floors. The substrate compensates for minor irregularities and cracks in the concrete screed, increasing the operational period of the flooring;

- The use of uninfected linoleum, another reason to recall the need for a substrate. I exist varieties of linoleum made without the use of the base. Alone, they are not able to provide a perfectly even and warm surface of the floor, and therefore, complemented by a substrate.

In all other situations, you can refuse to use the substrate, including in the case of linoleum flooring on the old flooring and laying of a more modern linoleum made on a jute or foamed basis.

Linoleum substrate: main varieties

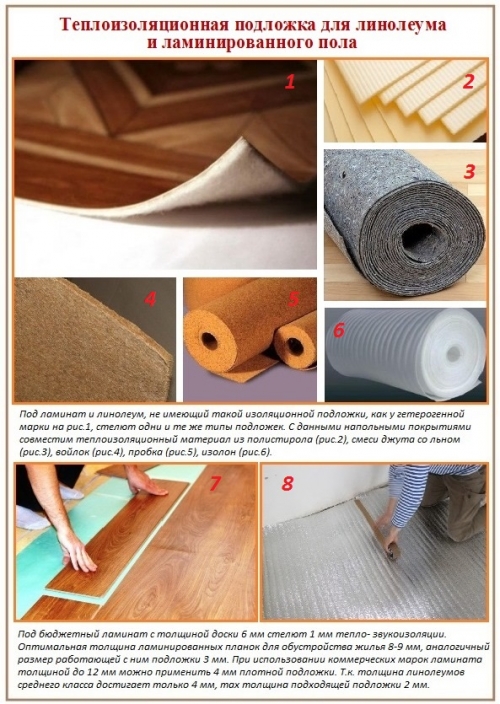

There are several varieties of linoleum substrate, which you can buy in any construction store. Consider the brief characteristics of the most common materials used as a linoleum substrate.

Cork substrate for linoleum It is a heat and soundproofing material made of crumbs of a cork oak bark compressed under the action of pressure and high temperatures in a single canvas. Completely natural material, has not only heat and soundproofing functions, but also a bactericidal effect inherent in it due to the residues of essential oils produced during the vital activity of the tree. In more detail, the characteristics of the cork substrate as the most popular material among the varieties listed below will be considered further;

Jute substrate for linoleum Another variety of thermal insulation material made from natural raw materials. For its manufacture, natural jutus fibers are used, previously impregnated with antiseptic and antipyrene, which helps to improve its fire properties and prevents decay. The jute substrate is a non -woven canvas made by punching fibers, applied to each other during the rental under the action of high temperatures (up to 1,500 degrees). Due to the fact that jute fibers material of plant origin, jute substrates are characterized by a unique ability to absorb moisture, restoring their initial consumer characteristics after drying;

Linen substrate It is made entirely of natural linen. The technology of its production is largely similar to the previous material. Thanks to the use of linen substrate, you will maintain effective ventilation between the floor covering and the floor surface, which will be the best preventive event to combat high humidity and mold. The production cycle of linen substrate at the final stage includes the processing procedure of the canvas with antiseptics, subsequently preventing the development of rot and insects;

Combined substrate, In equal proportions, containing jute, linen and woolen fibers is a reliable insulating layer with a high density (500-700 g/sq. M with a thickness of 2-3 mm). It is the best choice if you are looking for a substrate with the greatest wear resistance and high thermal insulation characteristics;

Wood -fiber or coniferous substrate is know-how in the construction market. It is produced from compressed waste of coniferous wood and is characterized by high heat and soundproofing properties. The only disadvantage that can be judged by the reviews of some consumers is an unpleasant odor that disappears shortly after the operation of a floor equipped with a coniferous substrate;

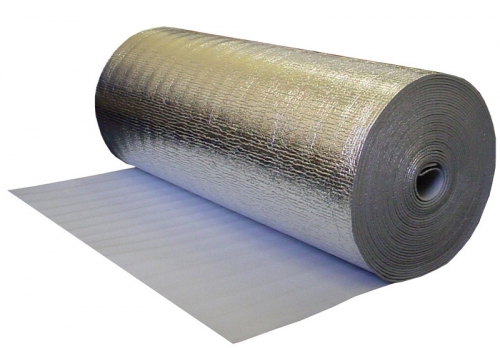

Linoleum, characterized by the most popular, due to its price, which is one of the lowest compared to other varieties of substrates. As foamed materials for the substrate, isolon and foaming, which have high thermal insulation characteristics, are used. However, experts do not recommend giving preference to the substrate of this variety, since in the case of its use, the floors acquire excessive softness and elasticity, which contributes to the premature loss of the original appearance of the coating. Over time, a foamed substrate is crushed and forms irregularities protruding on the surface of the flooring.

Read more about the cork substrate: types, technical specifications

As mentioned earlier, for the manufacture of a cork substrate, granules compressed under pressure are used, which are obtained from a cork oak bark.

There are several varieties of cork substrate:

- Classic cork substrate, in the manufacture of which only natural components are used, including binders. A distinctive feature of the classic substrate is the absence of synthetic resins in its composition, which characterizes it as one of the most hypoallergenic materials, which does not distinguish any harmful substances during operation. In addition, it is antistatic and fireproof material;

- Rubber-industrial substrate, In which rubber acts as a binder. It is advisable to use the rubber-industrial substrate in rooms with high humidity, as well as in apartments located on the ground floor of the building. In addition, the rubber-industrial substrate is chosen when the linoleum fits on the concrete screed, which has not completely dried up. This is due to its increased, compared to the classical substrate, sound and vibrational insulation characteristics;

- Bitumen-industrial substrate, for the manufacture of which a craft paper is used, saturated with bitumen, covered with compressed cork crumb on top. This coating is characterized by high waterproofing properties, but, due to the fact that in the process of combustion, bitumen emits caustic smoke, it is forbidden to use the bitumen-industrial substrate for the installation of flooring in residential premises.

Technical characteristics of the cork substrate:

- The density of the material is 200-250 kg/ cube. meter;

- The average indicator of the strength of the material per gap 2 kg/ sq. cm;

- Thermal conductivity indicator is 0.043 W/MK;

- The moisture content of the material does not exceed 7 %;

- Depreciation characteristics under the influence of a pressure of 7 kg/ sq. cm degree of compression not more than 10 %;

- The level of noise absorption is at least 16 dB;

- Deviation of size: for the width does not exceed 0.5 mm, for a thickness of not more than 0.2 mm;

- Fireglazing the material is not inclined to fire, the level of fire resistance of the S-209.

Important! A cork substrate for linoleum, the price of which depends on the thickness of the material, is made in the form of rolls and leaf panels, which differ not only in dimensions, but also by the price. If the thickness of the roll cork substrate does not exceed 2-4 mm, then for sheet panels this indicator can be 4-10 mm.

Advantages of cork substrate:

- Long-term operational period and high wear resistance of the cork substrate (the wear of the material may exceed 170-200 years). In this regard, if you plan to replace linoleum after some time, the cork substrate is so wear -resistant that it does not need replacement;

- Thanks to the porous structure, the cork substrate is characterized by low weight and high insulating characteristics;

- Simplicity of cutting and ease of installation;

- Prevents the propagation of mold and other malicious microorganisms;

- Retains the initial operational characteristics of the flooring, preventing its premature wear;

- The possibility of using a cork substrate as an independent material for decoration of ceilings and walls.

Disadvantages of the cork substrate:

- Tendency to deformation during prolonged mechanical exposure;

- Due to the low thermal conductivity, it is forbidden to use a classic cork substrate on the floor equipped with water heating. For these purposes, there is a special cork with a foil coating;

- Due to the fact that the cork substrate is a material made of organic raw materials, it is not recommended to be used in rooms with high humidity without arranging additional waterproofing. For these purposes, there is a special rubber-cork substrate made on the basis of cork granulatory modified by rubber.

Laying cork substrate: Preparatory measures

Due to the fact that the laying of the substrate must be carried out on a clean base, before its direct installation, experts recommend that the flooring of the flooring. In addition, it is necessary to pre -align the floor, since the permissible changes in its level should not exceed 40 % of the thickness of the substrate.

In the event that you carry out the installation of flooring on a wooden floor, experts recommend sheathing it with sheets of chipboard. Make sure the strength of the wooden base, and if it is not in doubt, laying the cork substrate can be carried out directly on the wooden base without arranging an additional waterproofing layer.

However, experts believe that it is best to lay linoleum on a concrete base, after its preliminary preparation. To align the concrete base, use special leveling mixtures.

Important! Before starting the installation of the flooring, check the floor surface for humidity. To do this, spread cellophane on a concrete base and fix it at the edges with tape. After 12 hours, check its condition: if there are no dews on its surface, the concrete base is completely ready to lay the flooring.

To ensure the most effective laying of the cork substrate, a few days before the installation of the flooring, bring it to the room where its installation will be carried out. This is necessary so that it acquires the temperature and humidity of the environment in which it will lie, which contributes to its more even styling. In the process of laying the coating, monitor the microclimate parameters of the room in which it will be produced. The air temperature should be not lower than +18 degrees with a relative humidity of at least 60 %.

Camping substrate: step -by -step guide

Let us consider in more detail the procedure for laying a cork substrate:

The first stage involves the arrangement of waterproofing. To do this, on the floor, polyethylene is spread out with a thickness of not more than 0.2 mm, leaving a small allowance on the walls to form something resembling a pallet. The edges of the polyethylene film are fixed along the wall with tape.

Despite the fact that in most of the construction literature the arrangement of the waterproofing layer on the concrete base is recommended, and linoleum manufacturers also adhere to this point of view, laying waterproofing makes sense only if you live on the first floor, and under you is located an unheated room, For example, a basement. The need for this measure in this case is due to the possibility of condensate formation on your side of the ceiling. In all other cases, the need for laying a waterproofing layer does not exist.

In the case of using a roll substrate, roll out a roll from one wall to the other and cut it to, in accordance with your dimensions, or cut the roll into the stripes of the width you need in advance. To connect parallel strips of the substrate, use waterproof construction tape;

If you purchase a substrate in the form of panels, lay it in a brick order, which is necessary so that the joints of the panels do not fall on each other. As in the case of a roll substrate, glue the joints between the panels with waterproof construction tape.

Important! In the process of laying the substrate, move along it carefully, and in the process of laying linoleum with no less caution, make its flooring, which will prevent damage to the cork substrate with construction tools or shoes.

Lining linoleum on a cork substrate is no different from its laying on a concrete or wooden base without a substrate.

Despite the fact that the cork substrate belongs to a higher price category compared to other types of substrates, it is characterized by a mass of undeniable advantages that cannot remain unnoticed by the masters who decided to repair the flooring.