A lot of requirements are presented to modern flooring, among them are such ...

|

|

Laminate is quite popular finishing material. This is due primarily to him ... |

When the life of a wooden coating comes to an end, it needs ... |

How to lay linoleum on a concrete floor

Linoleum is a strong and flexible canvas, mainly used as a finish flooring. The main advantages of the material include its excellent moisture resistance and wear resistance. It is thanks to such parameters that the product has gained such a wide popularity among consumers. The article will talk about how to lay linoleum on a concrete floor.

Content:

- Types of linoleum on the material of manufacture

- The main criteria for the choice of linoleum

- How to lay linoleum on a concrete floor

- Linoleum care

The oiled canvas was used for the first time as a floor flooring in Europe, and since then, the interest in the material has only grown up. Now practically cannot find a living quarters or a public institution, wherever this reliable and practical coating is used.

Due to the rich colors, some types of linoleum are practically not distinguished from more expensive, elite materials. You can lay linoleum on many surfaces, but at the same time it is necessary to observe a number of important conditions, otherwise even the most high -quality product will be hopelessly spoiled.

Before starting linoleum laying on a concrete floor, you should understand its varieties and properties.

Types of linoleum on the material of manufacture

Natural linoleum

It was such material that produced several centuries ago, then it consisted of rough oiled fabric, with the addition of bee wax and dye. In the manufacture of this product, modern industry uses only natural components of flax oil, wood resin and sawdust, natural dyes, lime. In addition, the canvas is additionally treated with antiseptic compounds.

Advantages:

- environmentally friendly building material;

- high wear resistance;

- strength, reliability and durability are qualities that only intensify over time;

- antibacteriality;

- good resistance to chemical compositions;

- fire resistance.

Flaws:

- no difference in a large selection of shades, patterns and drawings;

- does not tolerate negative temperatures.

A canvas is available without a base or based on plant materials: jute, hemp, flax. Also, some manufacturers produce products where the CDF plate (high-fiber sheet of high density), for example, marmoleum from Forbo, acts as the basis. It is very easy to lay such a product, since the plates are equipped with a special lock connection.

In order for the natural linoleum to serve as long as possible, it must be treated with a special tool for leaving biolinoleum - acrylic dispersion. After such processing, the flooring will shine and it is better to clean, in addition, the protective composition prevents the rapid pollution of the canvas. When cleaning, the use of alkaline drugs is prohibited, since such compounds leave yellow spots on the material.

Polyvinyl chloride or PVC linoleum

This is a synthetic product that is made of PVC-smokes and plasticizers, with the addition of chalk, pigments and bleach. The material of the baseless, on tissue, thermal insulation and soundproof bases, and a single -layer and multilayer artificial flooring is also produced.

Advantages:

- provides additional heat and sound insulation;

- differs in simple installation and easy care;

- has a wide selection of color solutions, drawings and patterns;

- small price;

- has good elasticity;

- antistatic;

- moisture resistant;

- not subject to decay.

Flaws:

- the first time has a persistent chemical smell (disappears during operation);

- does not tolerate negative temperatures;

- if the linoleum is not on the lining of the fiberglass or not on a foamed basis, then there may be a shrinkage of up to 2% when exposed to elevated temperatures;

- the material is completely synthetic, that is, low environmental friendliness;

- slight resistance to chemicals (acetone, alkalis);

- it is not recommended to wash with funds that have abrasive particles.

PVC-linoleum is produced both without the base and several of its types, for example, on foam, on tissue and non-woven. It can also be single -layer and multi -layer, otherwise it is also called homogeneous and heterogeneous linoleum.

This type of flooring is rarely used in public institutions, since the product is not resistant to abrasion. The material is available in rolls up to 20 m long, the width can vary from 150 cm and up to 400 cm, a dense PVC is a thickness of 5 mm.

Rubber (Relin) linoleum

The product with a high indicator of water resistance, flexible and elastic due to a special two -layer structure. The lower layer of the coating is made of crushed rubber and bitumen, and the upper layer of natural or synthetic rubber and colored pigment.

Advantages:

- increased strength;

- necessary hardness;

- excellent wear resistance (the coating is not afraid of even exposure to studded car tires);

- anti -slip upper layer (due to a specific stuffed pattern);

- the coating has amortization properties;

- can be operated at a temperature of -40 to +90 degrees;

- good resistance to chemical reagents;

- not afraid of ultraviolet radiation;

- long life.

Flaws:

- small selection of colors (gray, blue, red);

- expensive material.

The reign is mainly used in public places with great cross, for example, in airport buildings, in hotels and restaurants, in schools, hospitals, as well as in elevators and garages. Modern designers have chosen this floor covering for residential premises decorated in high -tech styles. The canvas is produced in rolls up to 10 m long and 1.2 m wide, a standard thickness of 4 mm.

Colloxilin (nitro -cellulose) linoleum

The composition of such a product includes asbestos, snouts, gypsum, dyes, cotton or wood cellulose (colloxilin), plasticizers, antipyre and various stabilizers. It is produced as a single -layer coating without an additional base.

Advantages:

- flexible structure;

- increased moisture resistance;

- resistance to low temperatures;

- good elasticity.

Flaws:

- high degree of fire hazard;

- subject to shrinkage;

- unstable to chemical effects;

- poorly tolerates sharp fluctuations in the temperature regime;

- the color scheme is represented by only two shades of red or brown.

Linoleum made of nitrocellulose is not intended for use in residential premises, and it is also not recommended to be used in children's institutions, in restaurants and in rooms with an aggressive environment. The product is produced in rolls with a length of 20 m, the width can vary from 100 cm to 160 cm, the thickness is in the range of 2-4 mm. Before laying such a coating, it is necessary to carefully prepare the base.

Alkyd (glyftal) linoleum

Such a product is made of alkyd resins, with the addition of wood or running flour and pigments. As a basis, as a rule, textile materials (made of flax, jute or hemp hibiscus) are used.

Advantages:

- high degree of sound and thermal insulation;

- due to the addition of antibacterial substances, not subject to decay;

- rich color palette;

- good wear resistance.

Flaws:

- fragility - during operation there is a high probability of the appearance of fragments and cracks;

- low water resistance;

- the material is unstable to reduced temperatures;

- expensive goods, due to the use of natural components.

If the front side of the product has a drawing, it is better to refrain from flooring in rooms with intense movement, as well as on the floor in kitchens and corridors. The goods are produced in rolls, the length of which is from 15 to 30 m, width 2 m, and the thickness can vary from 2.5 to 5 mm.

Not only the life of the flooring depends on the correctly made choice, but also the comfort in the house. For home repairs, they choose natural or polyvinyl chloride linoleum. Before buying the selected material, you should understand the main characteristics and properties of the goods.

The main criteria for the choice of linoleum

All premises in a house or apartment differ in functionality, so it is important to consider these features by choosing the flooring. So, for the kitchen and the corridor it is recommended to purchase floor material, the thickness of which will be at least 3 mm, while it is desirable that the linoleum has several layers, and the protective layer is a thickness of 0.25 mm. The same strong product is acquired in the children's room to avoid damage to the coating from mechanical exposure. In the living room or in the office, you should choose a coating with a thickness of 1.5 mm, and a thinner canvas, 1-1.5 mm thick, is suitable in the bedroom.

In addition to the material of the manufacture of linoleum, it varies in its purpose. In this category, 4 main types are distinguished.

- Domestic The coating thickness is 1-4 mm, this is a very soft material, with a large selection of colors and low cost, but it does not differ in a long service life, is made on the basis of polyester.

- Semi -commercial It looks like household linoleum, but has a great thickness, so most often the floors in offices and public institutions are covered with such material. It consists of three layers of the base, protective and decorative layers.

- Commercial It has high wear resistance and is intended for public institutions with a large load, does not have a large choice of color color.

- Special This material includes several types of linoleum.

- With anti -slip coating The composition includes mineral crumbs, which gives the material a relief structure.

- With sports coating - They are used on sports fields, and has a top layer of polyurethane, thanks to which wear resistance increases.

- With a bacterial coating - It is used in medical institutions, various bactericidal mixtures are added to the composition.

- With a soundproof antistatic coating It is used in rooms with increased acoustics requirements, such material also disperses static electricity, therefore it is not dangerous for electronics.

In addition, the manufacturer classifies linoleum in the following groups:

- marking 21-23 The material is intended for residential premises;

- marking 31-34 The material is intended for public institutions;

- marking 41-43 The material is intended for industrial premises.

Also, if there is a letter marking on the roll, then it can indicate the following:

- F or m low degree of wear resistance;

- P average degree of wear resistance;

- T wear -resistant material.

How to lay linoleum on a concrete floor

Almost any floor covering involves laying on a strong and even surface, and linoleum will not be an exception in this regard. In general, the prepared concrete base is ideal for the installation of this building material, since it has sufficient strength and hardness.

Necessary tools and materials:

- chosen linoleum;

- cold or hot welding (depending on the selected type of gluing seams);

- adhesive composition for linoleum;

- ruler, pencil, construction knife and scissors;

- laser level or level (to check the degree of evenness of the concrete floor);

- leveling mixture (if necessary, level the concrete base);

- primer and waterproofing composition;

- maslar adhesive tape;

- plinths and components to them.

Stages of work

- Before making the purchase of the flooring you like, you should make the most accurate measurements of the room in which the linoleum flooring is supposed. Be sure to pay special attention to the protruding angles, as well as the presence of non -removable elements. If the choice fell on a coating with a beautiful pattern, but requiring fit, then it is necessary to purchase goods 10-15 % more than required by measurements. It is advisable to buy rolls from one batch so that there is no discrepancy in the color scheme.

- The next important step is to align the concrete floor under linoleum. Since linoleum is quite elastic material, during operation, all irregularities will be very well felt, so the alignment process should not be ignored in any case.

- With the help of leveling or building levels, height drops are checked. And if there are fluctuations of more than 2-4 cm, then first the floor will have to be leveled with a special rough spin or a simple cement-sand screed, if the difference in horizontally is less than 2 cm, then you can use self-leveling mixtures.

- In the presence of individual pits or cracks, they are simply sealed with any suitable remedy, and in the presence of tubercles they are knocked down and also aligned in a single plane.

- Cement-sand screeds are dried for 2-4 weeks, bulk floors, depending on the manufacturer, they can dry from 3 days to 2 weeks. This time must be withstanded, otherwise moisture will begin to accumulate between the canvas and the concrete floor, and the coating will gradually become unusable.

- When the preparation of the concrete floor for linoleum is completely completed, it is recommended to be covered with a waterproofing mixture, since concrete belongs to porous materials that can easily pass moisture. A layer of antiseptic primer is applied over waterproofing. All work should be carried out at a plus temperature (+17-+25 degrees) and relative humidity not more than 70%. Under such conditions, the drying process will occur naturally.

- If there is a need for an additional insulation layer, then the heat -insulating material is covered on the primed base, it can be a cork insulation, a substrate for a laminate or polystyrene foam. In principle, if the choice was made in favor of a multilayer linoleum on a foamed basis, then the additional layer of heat or sound insulation is not used, in other cases it is better not to let this process, since concrete is a cold surface.

- After all preparatory procedures have been completed, you can proceed to the flooring of the floor covering itself. But before finally fixed the canvas, it should be kept in a spread state for at least a week. This is done so that the material is straightened, all available folds are dispersed, and there was no unnecessary stretching after fixing, otherwise the canvas will puff and swim. It is allowed to make a preliminary cut so that the material is conveniently located on the floor and does not bend, especially in the corners.

- When the canvas was laid, they proceed to the final cutting of the edges around the perimeter, not reaching the walls of about 10 mm, in the future this gap will be closed with a skirting board, and you can be sure that the linoleum will not collect anywhere, even if it stretches a little during operation.

- The seams are located in the direction of the light from the window. The modern technique of laying linoleum does not involve the installation of rocks at the joints, as well as the full gluing of the canvas. In order for the material to hold well and does not bend, you should in a special way glue the joints.

Tip: In places of intensive movement, it is recommended to glue the canvas to the floor, also if the area of \u200b\u200bthe room is more than 20 m2, then it is necessary to completely glue the linoleum to the base.

Ways to glue linoleum joints

The main method is two, it is hot and cold welding. The cold method is simpler and does not require special devices and equipment, it is enough to buy a tube with an adhesive composition in any construction store. While hot welding requires special tools, and sometimes only professionals can do.

Cold welding

- Ethat method involves the use of special glue in tubes, which, when contacted with linoleum, melts it to a semi -liquid state, and when the composition freezes, a strong connection is formed.

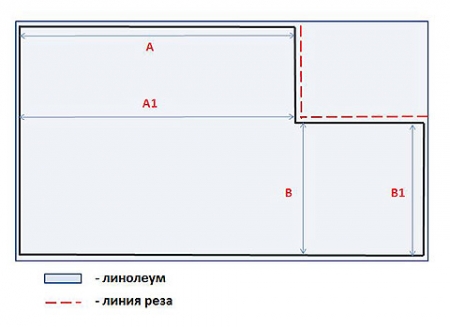

- In order to make a perfectly even seam, two joining canvases should be applied to each other with an overlap at least 6 cm. Then measure about 3 cm from the edge (so that there is an even distance on each canvas) and draw a straight line along the entire length.

- Put soft material (for example, a piece from the same canvas) under the junction of the linoleum, and then cut both parts with a construction knife with one movement of the hand. You should not rush, it is better to press the knife well to be sure that both halves are cut at the same time. When the incision is made, excess (cut) pieces are removed. Maslar tape is glued over the cut and cut into the lines formed, so that each half of linoleum has a glued edge glued with tape.

- Then, using a tube of cold welding, a special composition is filled into the seam. It is necessary to ensure that the squeezed drop is throughout the joint of the same size, about 3-4 mm. Having waited for a certain time (indicated on the tube with welding) can be carefully peeled off. The seam should not be loaded at least during the day, that is, it is necessary to limit the movement in the glued area.

- This method is most often used precisely for gluing household linoleum at home. The quality of the connection is in no way inferior to other methods, since the result is an even, strong seam, and most importantly almost invisible.

Hot welding

- This method is recommended to be used on commercial linoleums, especially in places with increased cross -country ability. For this method, it is necessary to have a special welding heating pad and add-on PVC excructions. To make the seams better solder, linoleum must be glued to the floor. It is recommended to start welding the seam, only a day after gluing. Preparation of a flat seam is also done, as in cold welding. When both strips of the canvas are prepared, you can move directly to the welding process.

- The heating pad should be held in one hand, and the bar in the other. The bar is carried out along the joint and hot air from the heating pad is directed to it. Under the influence of the high temperature, the edges of the linoleum are softened and when they conduct a clamping roller on them, they are reliably connected. After the welding, it is necessary to wait until the canvas cooled completely, then you can cut off the excess of the melted bar. To achieve a perfectly smooth and even surface, the seam is additionally polished.

At the last stage of the installation of the coating, the floor skirting board is fixed along the entire perimeter of the room. This can be a plastic skirting board with a special plug, as well as recesses for the location of the cords. Such a plinth is fixed using dowels and dowel-shurups. In addition to a beautiful appearance, the baseboard is also necessary for additional fixation of the flooring.

Linoleum care

- And the last thing to consider when choosing a linoleum as a floor covering is caring for it. First of all, wiping the canvas from dust and dirt, you should not use too hot water, it can damage the material and lead to its compression, it is also necessary to protect linoleum from the entering its surface of hot objects. If such a probability is great, then it is better to take care of this in advance and purchase a fire -resistant variety of the product.

- When doing wet cleaning, it is undesirable to use chemicals, since the coating can acquire a yellowish tint and lose shine. If the detergent contains abrasive particles, then they can damage the upper layer, from which important protective characteristics will decrease.

- To preserve pristine beauty and shine, it is recommended to use specially designed mastics and polishes for linoleum, which form a protective film on the surface, resistant to an aggressive external environment and increasing resistance to mechanical stress.

Linoleum is a universal flooring that is used in residential and public premises. He is not afraid of wet cleaning, he does not deform during operation and will reliably last a rather long time. The most important thing to choose the right canvas and conduct its high -quality installation. Do not scare the flooring on a concrete base. After all, this is the most strong and reliable surface, and if you additionally lay out the thermal insulation layer or install the warm floor system, you can be sure that even in winter cold the floor will always be warm, and the atmosphere in the house is cozy.