Despite the abundance of finishing materials, pasting the walls with wallpaper remains the most ...

|

|

The scope of ceramic brick is extensive. It is used for laying load -bearing walls ... |

It is no coincidence that part of the kitchen wall between the working surface consisting of a countertop, ... |

DIY laminate laying

Compared to many traditional types of finish flooring, the laminate is the youngest, modern and managed to gain popularity among consumers, thanks to the strength, the variety of shades and textures, and the simplicity of laying. Without even possessing special professional skills, everyone can independently lay beautiful floors from the laminate in their apartment: its styling is performed easily and simply, thanks to the convenient locking system of fastening spikes. Observing the manufacturer's instructions and laying technology, you can put the floors with your own hands, externally imitating parquet, a massive board or ceramic tiles and in quality not different from work performed by a professional master.

Content

- Laminate styling technology: video instruction

- Preparing the basis for laying laminate

- In what cases it is impossible to lay the laminate

- Ways to lay laminate

- Laminate laying scheme

- Laminate laying instructions

Laminate styling technology: video instruction

Make sure how simple the technology for laying laminate videos are instructions for one of the leading manufacturers:

In order for the floor covering from the laminate to serve for a long time, it must be laid on a perfectly even, carefully prepared base.

The laminate panels are necessary in advance, no less than 48 hours, add to the acclimatization room. If chips, dents and other damage are found on the packages, they are rejected.

Laminate laying work is recommended to be performed at a temperature in a room of 15-30s and relative humidity 40-70%.

The base for laying the laminate is considered normal if the depth of slopes and irregularities of the floor does not exceed 2 mm at a length of 1 m.

Directly on the base before the start of the styling work, a layer of polyethylene film with a thickness of 200 MK is laid, which protects the panels from moisture and steam.

In addition, the correct laying of the laminate involves the laying of special substrates from foamed polyurethane, traffic jams or other materials recommended by the manufacturer. The substrate performs the functions of heat and sound insulation, and is also a soft buffer that prevents the appearance on the coating of breaks and cracks.

Preparing the basis for laying laminate

Laminate compared to other flooring is most demanding on the preparation of the base: it should be impeccably smooth and smooth. As a basis for the laminate, subject to certain conditions, can serve:

- concrete;

- wood;

- linoleum;

- tile.

Preparation of a concrete foundation

On a concrete screed in a new house, laying the finish flooring from the laminate can only after its drying, that is, about 25-30 days after pouring cement-sand mixture.

When replacing the finish flooring on a concrete base, the old coating is removed and the condition of the concrete is checked. If minor irregularities and cracks are found, the base is aligned with a self -leveling mixture. If damage to old concrete is more significant, the old screed is completely removed and created again.

It is important to remember:

- A layer of vapor barrier from a plastic film with a thickness of 200 μR, an overlap by 20-25 cm and with a lowering to a wall of 10-15 cm, is always laid on any concrete base, screed or a bulk floor, and the joints are fixed with tape.

- On top of a dry screed, polyethylene vapor barrier is not laid, since this layer in it is already provided.

Preparation of a wooden foundation

Laminate on the existing wooden base of the old floor can only if it is not affected by pests and fungus. If poorly fixed floorboards are found, they are screwed to the lags with self -tapping screws. Minor irregularities and differences are eliminated with a conventional cycle. If there are very damaged boards and failures in a wooden base, they should be disassembled to the lag, align or replace.

Note:

- Both the concrete and wooden base can be perfectly aligned by laying on top of the chipboard or plywood in a checkerboard pattern.

- On the base of wood, plywood or chipboard, laying the polyethylene layer of vapor barrier is not required, but the substrate for soundproofing must be laid must be laid.

Linoleum base and tile

Considering that the basis for laying the laminate can be any sufficiently firmly fixed surfaces, smooth and provided with moisture insulation, then existing coatings from linoleum or tiles are quite suitable for this role.

If linoleum or tiles were laid in compliance with the technology on a high -quality screed, the floor of them is quite smooth, then these coatings can not be dismantled before laying the laminate. In vapor barrier, such a base does not need and, having put a substrate, you can start laying laminate panels.

In what cases it is impossible to lay the laminate

Laminate is not a universal flooring and, in order to avoid irreparable errors, it should be remembered that this material cannot be done:

- lay on carpet coatings;

- glue or attach in another way to any base of the floor;

- lay in the bathroom, bath and other rooms with high humidity;

- lay as a finish coating on a cable or matte system of an electric warm floor.

In kitchens or corridors, you can lay the laminate panels of the corresponding class -resistance class with mandatory sealing of castle systems of any type with special sealants.

Ways to lay laminate

There are the following ways of laying the laminate:

- adhesive;

- click castle system;

- lOK castle system.

The adhesive method of laying laminate panels using a spike-paz system is similar to the traditional method of laying a piece parquet board. A layer of glue is applied to the edges of each laminate panel, and then two adjacent boards-panels are tightly pressed against each other. A glue method is laid in rooms with high intensity of use, when it is required to provide increased strength of the joints and additional protection against moisture. The disadvantages of the adhesive method include the complexity of the laying process, the indiscretion of the floor structure and its fragility due to the drying of the glue during operation.

The Click castle system is the most popular and confidently displaces the other two options due to the simplicity and ease of performance. The essence of this laying system is that the spike of each panel of the next row is inserted into the groove of the previous panel at an angle of about 30, and then leaned to the floor and pressed to the snap. Then the panel is neatly driven using a bar and a hammer in the previous panel in its row until the end lock is triggered.

When laying the laminate of the LOK castle system, the panel is laid on the floor strictly horizontally with a small gap relative to neighboring panels, the spike of the laid with the groove is already laid is combined, and then carefully drive it with the help of the bar until the lock is triggered. As in the previous case, first combine the panels in adjacent rows, and then only finish the panel until the locks are combined and snap in the ends of their row.

Laminate laying scheme

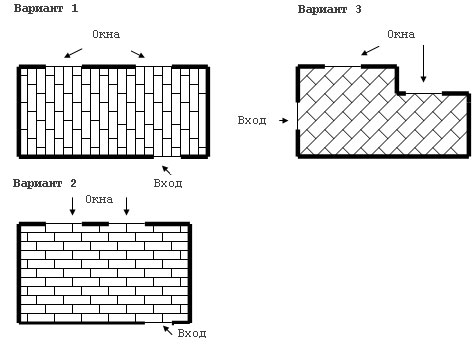

Laminate, like parquet, is most often laid in parallel to the direction of light, but depending on the design solutions or design features of the room, laying panels can be performed for any of the three options

- parallel to the direction of light;

- perpendicular to the direction of light;

- diagonally, that is, at an angle to the direction of light.

Depending on the direction relative to the light flow, the need for visual changes in the geometry of the room or the desire to focus on the design of the flooring material, one or another layout of the laminate is also selected, which are also three:

- classic;

- brick or chess;

- diagonal.

For all laminate panels laying schemes, the general condition for the strength of the coating remains the same: they are necessarily covered in the scope, that is, each panel of the next row is shifted by at least 15-20 cm relative to the adjacent panel of the neighboring row. With the help of a harmonious combination of lighting and a pattern of laying laminate, you can visually expand or narrow the room, emphasize its non -standard shape or simply create a beautiful flooring.

Classical laying scheme

The classic scheme is more often used to lay a laminate in residential and office premises, as it is the most economical. The styling according to this scheme is performed in parallel to the direction of the flow of light and begins from the closest wall. In this case, the cut part of the panel of the previous row becomes the first panel in the following. Also, trimming the panels appear when laying the last row, in the niches of heating batteries and at doorways. It is not recommended to use panels shorter than 30 cm, excluding the areas where large -sized fixed fixed furniture of the sofa, cabinets, etc. will be installed. When using a classic laying scheme, laminate waste from trimming and fitting panels rarely exceed 5%.

Brick or chess layout scheme

This laminate laying pattern resembles a brickwork, here each subsequent row is laid with a shift strictly half the panel relative to the previous one. The execution of such a three -lane pattern of flooring is associated with a large overspending of the material of up to 15%, but the strength of this gender is recognized as the highest. It is recommended to use a chess scheme when working with single -lane plain material. When laying on this scheme, panels with a two-four-lane pattern, pronounced connections in the ends of the panels can distort the overall pattern of the floor

Diagonal styling scheme

The layout of laminate panels diagonally can be considered as a type of classic laying scheme at an angle of 45 relative to the wall in which the doorway is located. The exquisite diagonal laying of the laminate is willingly used by designers for the visual transformation of the space of small rooms, creating a sensation of space and airiness in the interior, and especially good in rooms with the corner entrance door. Exaggeration of the material when using a diagonal laying scheme can be 10-15%, and in square rooms it is minimal, and in narrow and long maximum.

Laminate laying instructions

Regardless of the selected type, method and drawing of the future laminated floor, there is a universal instructions for laying a laminate, the main provisions of which accessiblely demonstrates the video video:

So, when laying the laminate between the panel and the wall, it is necessary to leave a gap of at least 10 mm, the width of which is controlled using special wedges, which are inserted before laying and removed after its completion. A gap is necessary to ensure the integrity of the coating with inevitable seasonal changes in linear size of the material.

The panels of each next row are laid with a shift of the previous one, which should be at least 15-20 cm, but can reach half the length of the panel.

Laying in the room in the room is best started from the corner, where the radiator and pipes of the heating system are located. If this point of the room is final, then when laying and achieving the last panels, difficulties will arise a radiator will become an obstacle.

When laying the laminate around the pipes of water supply and heating, holes of the required diameter are cut in the panels, but so that the necessary gap of 10 mm remains between the pipe and the material.

When laying the last row, panels of a certain width are most often required. Each panel of the last row is cut taking into account its individual sizes and an operational gap of 10 mm: the geometry of rooms is rarely ideal and the difference in the required width of two opposite panels of the extreme row can be several centimeters.

The final stage of laying the laminate is the fasteners of skirting boards and decorative thresholds in the doorways.

Important: the skirting boards must be attached to special basters, which provide uniform pressing of the laminate around the perimeter of the room.

The floor laid down according to the castle method can be operated immediately. If glue was used when laying, then it will be possible to use such a floor after a time necessary for its drying and indicated on the package.

In recent years, on

In recent years, a serious struggle for the minds and hearts of consumers has unfolded in the Russian construction market. We are talking about those who started large -scale repair or “cosmetic” finishing work in their housing, and for this purpose acquires wooden flooring (parquet, parquet board, laminate, etc.)

Everyone knows that these finishing coatings require laying on a hard, even base, with a difference not exceeding 2 mm per 2 linear meters, and their flooring on a base with high humidity is unacceptable.

In the case of manufacturing the base of the floor of wet materials (“concrete screed”, which appeared on the market recently “half-dry screed”, etc.) The result requires thorough drying-at least 30-40 days, depending on the thickness of the base. Failure to comply with the requirements for the permissible moisture of the base of the floor leads to the appearance of mold on a wooden flooring and its rapid failure. Failure to comply with building standards associated with the stiffness or evenness of the base leads to the appearance of creaks, cracks and the subsequent indifference of such a flooring.

The foregoing tasks earlier, from the mid-90s of the last century to recently, decided three sex systems competing among themselves.

Depending on the purpose of the room,:

Concrete multilayer alignment

Adjustable structures

Or a dry screed "KNAUFF".

An attempt to reduce these three technologies led to deviations from existing building codes and rules. As a result, the mass distribution of low -quality products in the Russian construction market that do not meet the requirements of modern flooring materials to prepare the base.

Sellers of this, frankly, consumer goods are disordered by the fact of reducing the service of the finishing coating, in the case of an incorrectly prepared base. Consequently, we increase the amount of investments in the arrangement of the floor, and the result “laid and forgot” can really be forgotten - the costs of such “repair” will grow exponentially.

How to spoil with your "improvement" high -quality concrete multilayer floor

Experienced builders know:

In concrete multilayer alignment is used:

technology of rough alignment of concrete screed;

technology of more accurate alignment - leveling screed;

Group leveling of the flooring of a plywood sheet 12 mm thick.

The struggle of the floors. Divorce in Russian.

Each of these layers (with a floor thickness of not more than 3-5 cm) together with work and materials will cost the consumer from 600 rubles per 1m2. For parquet coatings, the use of all three layers is required (the parquet is glued to the base); For a parquet board or laminate (covered with a floating way, with fixation around the perimeter and without fastening to the base), two layers are enough, however, to the detriment of the comfort of the floor (loss of sound and heat-insulation, the lack of protection of the finishing coating from the moisture difference).

Thus, the cost of a multi-layer concrete base depending on the quality is 1200-1800 rubles per m2. And this is not the limit!

When lifting a given floor level per size of more than 5-7 cm, this method becomes even less profitable, since its price increases significantly.

Also, keep in mind that the use of such a weighted structure is not always possible due to the growth of additional loads on the floor slab; And the screed, using wet processes, requires drying from 30 days, which is not always informed to the consumer. Nevertheless, despite the difficulty of making the foundation in this way, with mandatory observance of all of the above requirements, a parquet or laminate coating on such a floor will last for many years.

The struggle of the floors. Divorce in Russian.

The so-called “know-how” “screed in a day” proposed in the last few years in the market is a simple client’s inflation, who wants “faster and cheaper”. Such a screed is made of a small fraction of sand and cement with polymer additives, which gives the concrete mass the appearance of a dense cottage cheese until it dries. The “cottage cheese” is distributed using a special pump, and then smoothed manually. The cost is 650 rubles per m2, cheap and angrily, everyone is happy. At first sight. Misleads the consumer and the name of this method - the method of semi -dry screed. But manufacturers are silent about the need to further level this innovation in order to achieve the required difference required by the standards (a maximum of 2 mm per 2 linear meters), and the mandatory removal of moisture.

The result is no 1200 rubles per m2. Cheaper? And the same 30-40 days of stretching moisture from the screed, in front of the flooring of the finishing coating.

How to spoil with your "improvement" high -quality adjustable gender

The struggle of the floors. Divorce in Russian.

A modern alternative to concrete multilayer leveling is the floor using adjustable structures.

Two types of DNT adjustable floor - floor along adjustable lags and floor on adjustable slabs - are designed to align the floor with different initial quality.

Options are distinguished by the thickness of the adjustable screed-3-5 cm (adjustable plates), 5-12 cm or 10-17 cm or more (adjustable lags). Both of these designs with a floor lifting height (the thickness of the adjustable screed) 5-12 mm cost an average of 1200 rubles per m2, which corresponds to the cost of the base made by the method of multi-layer concrete screed in the economy version (2 layers, without plywood). With an increase in this parameter, the price, unlike the previous method, changes slightly. At the same time, plastic tilt bolts and bushings (from a polymer of special strength) interacting directly with wood (plywood or lag) are used as fixing adjusting elements. A mandatory element of the adjustable floor is plywood or DNT plate, on which the finishing coating is laid.

Attempts to “improve” the technology of adjustable floors of DNT used in the Russian market for more than 20 years have led to a change in the type of fasteners and materials from which they are made. On the Russian market there are 2 main options for "pseudo-rationalization." In one case, furniture metal hairpins are injected directly into the thread of wooden lag, and in the second they are inserted into its holes and are tightened on two sides with nuts with washers.

Advertising themselves in the regulated sex market, manufacturers of the indicated “improved” structures at a comparable price with adjustable DNT floors (1200 rubles per m2), say supposedly increased reliability of the floor design, precisely due to the use of metal studs instead of a polymer.

Fundamentals of materials science in relation to adjustable floors

These statements are not substantiated and contradict the laws of materials science. Let's look at the loads for materials more carefully.

The struggle of the floors. Divorce in Russian.

In the first version of the “know-how”, the thread in the soft tree under the dynamic load is quickly cut off with hard metal, which leads to the appearance of the backlash and the rapid loosening of the structure. In the traditional case of patented DNT technology, the plastic bolt has approximately the same characteristics in stiffness with wood and interacts with it, without violating the integrity of the connection for at least 50 years (official tests of the Mosstroy and Academy of Subtle Chemical Technologies).

The struggle of the floors. Divorce in Russian.

In the second version of the “pseudo technology”, the wood from which the lag is made, drys out of the temperature and humidity drops, which requires constant dismantling of the floor and twisting the nuts on the stiletto. If this is neglected, then a gap appears between the nuts and the tree, and the backlash of the structure arises as a whole. Now imagine how easy it is to constantly dismantle and again lay the parquet, which is attached directly to the base?!

I also want to note the adjustment of the lag using corners attached to the floor. The lag aligned along the horizon is fastened from the sides with a corner of self -tapping screws. The unreliability of this design is obvious - with constant dynamic loads on the lag, part of the load is redistributed to mounts in the form of self -tapping screws screwed into the sidewalls of the lag, at an angle of 90 degrees, which leads to their bend and loss of strength of the entire floor structure.

Dry screed Knauuff

Another type of alignment of the base of the floor, also comparable in price with floors made of multi -layer concrete screed (economy version) and an adjustable floor, is a dry CNAUF screed (1250 rubles per m2).

The small faction of expanded clay is poured in the room on the base, and is aligned by smoothing it on the surface and mandatory tamping, followed by the flooring of GVP sheets with their attachment by the junction of the junction.

The struggle of the floors. Divorce in Russian.

With a faction thickness of not more than 3-5 cm, a well-compacted fraction does not sit from constant dynamic loads. But in order to achieve the required density of the screed when tamping it, it is necessary to repeatedly water this fraction with water and use special tamping machines. Of course, in this case, the indicated screed cannot be called dry, since the moisture accumulated during tamping requires its removal, before the flooring of the finishing layer of the floor. That is, we are dealing with a wet screed again, although “dry” is written on the package.

It is important to know that with a floor height of more than 5 cm, the use of this method of alignment for wooden flooring is not at all acceptable! In places of constant loads on the bulk mixture of such a thickness, it begins to sag, which makes a parquet or laminate into the worthlessness, covered on top.

conclusions

If you do not remain in the illusions of the sweet stories “Sharash Montazh” about the builders about remarkable leveling and preparing the base of one square meter of floor for 650 rubles for parquet, parquet board or laminate, then, whatever one may say, to make a durable and reliable floor according to all the rules and standards In construction is cheaper than for 1200 rubles per m2, it will not turn out to be any of the above methods. You can use the online calculator and first estimate the cost of preparing the base for the floor.

The struggle of the floors. Divorce in Russian.

At the same time, the same competitive advantages between concrete multilayer alignment, aligning the adjustable floor DNT or dry screed “KNAUFF” are the same with a thickness thickness of up to 5 cm. The difference is very significant, that during installation of the adjustable floor, wet processes are not used. This significantly saves time. In addition, the design based on the adjustable sex has increased heat and sound-insulation properties, unlike its competitors.

But if it is necessary to raise the floor to a height of more than 5 cm, adjustable DNT floors have a serious competitive advantage in terms of price-quality ratio in comparison with other methods of high-quality leveling of the floor for wooden flooring. In this case, the use of adjustable lag technology is most appropriate.

And, of course, none of the previously used technologies will give such an ease of installation of communications and various heating systems “warm floor”, like adjustable floors - after all, they have an air gap under the coating. Hofro channels of communications and pipes of water warm floor are conveniently placed in it, and additional heat-insulating mineral slabs can also be laid to achieve maximum insulation of the room from noise and cold.

So we advise, planning to repair and replace the floor, not to succumb to the sweet speeches of sellers, but carefully study the proposals, compare and make the right choice!

Good article, a lot of new

A good article, I learned a lot for myself. The laminate of the house is still to be laid. It was useful. Thanks to the author.