The apartment from time to time needs repairs. And regardless of the volume of work, ...

|

|

Carpet The floor covering that appeared in the fifties ... |

In the process of building a house from a brick, the main issue is the type of foundation, ... |

DIY laminate laying

Modern technologies do not stand still. The traditional finishing material is replaced by innovative more attractive, wear -resistant and easy installation. One of these coatings is an adhesive laminate.

Elastic panels have many significant advantages and are highly popular among professional masters and amateur repairmen. Installation technology is quite simple, does not require special skills and the use of expensive equipment.

- Glue -based laminate: advantages and disadvantages of flooring

- What should be the base for vinyl laminate

- Important moments in laying a laminate with your own hands

- DIY laminate laying: step -by -step instructions

- Cool laminate flooring

Glue -based laminate: advantages and disadvantages of flooring

A flexible glue -based laminate is gradually gaining popularity among foreign and domestic consumers. The flooring is made of polyvinyl chloride. The shape of the panels corresponds to the classic laminate, and the laying process is significantly lightweight due to the presence of adhesive substrate.

For the production of vinyl coating, the company uses oil refining products, which ensure the stability of the laminate to the effects of moisture and UV rays.

The adhesive laminate consists of two layers:

- Upper protective polyurethane coating with aluminum oxide. The surface provides decorativeness and aesthetics of the floor, resistance to mechanical stress and wear resistance.

- The vinyl laminite substrate is covered with an adhesive composition or Smart tape.

Self -adhesive material has a number of undeniable advantages:

- High water resistance This characteristic makes it possible to lay the coating in baths, toilets, bathrooms and other wet rooms. Vinyl does not lose its shape from contact with water.

- District resistance most manufacturers provide a guarantee for up to 20 years. Vinyl coatings are better than a conventional laminate to transfer mechanical loads and abrasion less.

- Universality. Flexible material can be laid with warm floors, providing good thermal conductivity.

- The harmlessness of the coating is confirmed by quality certificates. This allows you to lay PVC fields in living rooms.

- Simplicity and speed of installation work. Experienced masters in a couple of hours are able to line up a room with an area of \u200b\u200bup to 15 sq.m.

- The possibility of repairing the finish. It is enough to remove the damaged area and replace with a new panel.

- The elasticity of the material allows you to lay out coatings under the slope. Due to the flexibility of the panels, the floor does not creak when walking.

- Vinyl fire resistance. PVC plates do not support combustion. When buying, you need to check the availability of fire safety certificate for the product.

- Aesthetics and wide selection of different colors. Coatings that mimic wood rocks are particularly popular. Some companies produce panels for an individual order for a design project.

Of course, an adhesive laminate has some disadvantages:

- Vinyl panels have a specific smell. If the material is of high quality, then it is enough to melt it in a ventilated room and leave it for one day. The smell of low -grade laminate disappears for a very long time and can provoke the appearance of allergic reactions, especially in children.

- On cheap laminate models, traces of rubber sole or rugs can remain. In addition, a change in the color of the coating after a while is not excluded.

- A high -quality flexible laminate is quite expensive.

What should be the base for vinyl laminate

A significant plus of adhesive laminate is the ability to install it on various grounds.

When laying a laminate with your own hands on a wooden floor, chipboard or plywood must be controlled so that there are no cracks on the surface, and the boards do not bend. Nails and screws are tightly driven and compared with the surface of the tree.

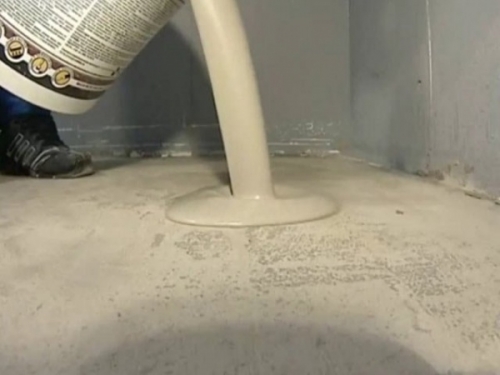

Installation on the concrete base provides for the seal of potholes and dents with putty or cement mortar. In the presence of a large number of irregularities, it is better to perform a concrete screed.

Before laying a laminate with your own hands on a base lined with tiles, you need to evaluate the condition of the seams. Deep inter -flop furrows must be treated with grout or cement.

Important! The optimal base for adhesive laminate floor from a self -leveling mixture, an even flooring of plywood sheets or a cement screed of a thin layer. The bulges and irregularities of the surface will be visible after the installation of a self -adhesive coating.

Important moments in laying a laminate with your own hands

- Before performing laying, you need to turn off the warm floor in advance. In addition, it cannot be connected within a week after the work is not allowed to prevent the coating.

- The optimal temperature regime for the time of laying and 48 hours after installation of 16-25C.

- The base for the laminate should first be treated with an antiseptic composition, this measure will prevent mold.

- The laminate should be lifted in the room where it is planned to be laid. In the cold season, adaptation takes about two days, if transportation was carried out at a temperature of less than 10, then one day is enough.

- The maximum allowable humidity level for laying laminate, according to the instructions of most manufacturers, is 60%.

- Remove the laminate out of the box in sequentially as the panels are used. This will avoid pollution of adhesive smart tapes.

DIY laminate laying: step -by -step instructions

Surface preparation

To perform installation work will be needed:

- construction knife;

- soft video or roller for rolling flooring;

- rubber hammer;

- a square, a kiyanka and roulette;

- tile crosses;

- hygrometer.

Preparatory events:

- Thoroughly clean the base of the floor to sprinkle, remove dirt, fat spots and wipe it with a damp cloth.

- Check the level of surface moisture using a hygrometer. A normal indicator is not more than 5%. If this condition is neglected, then the cool composition will not sufficiently grasp the base and over time the panel will begin to retreat. In the absence of a hygrometer, the check can be performed experimentally. Put a piece of polyethylene on the floor and fix it around the perimeter with tape. If a condensate is collected in a day from the inside of the film, then the base is not completely dry and the styling must be temporarily postponed.

- Further actions depend on the type of base and type of adhesive laminate. Flexible panels on adhesive locks can be laid on top of the old finish without special preparation. Minor differences will be blocked and will not be noticeable during the operation of the finished coating.

Laminate laying

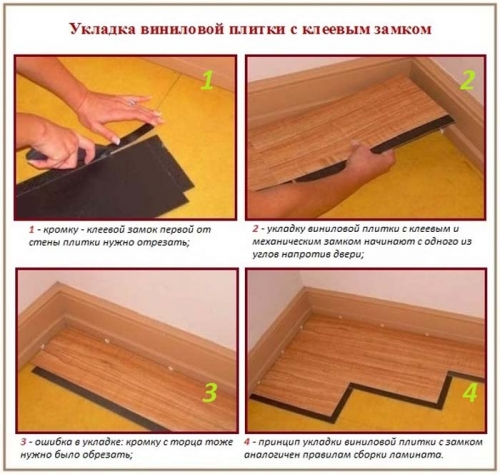

We give an algorithm how to put a laminate with your own hands:

- Prepare the panels for styling along the wall.

- Cut out 1/3 of the first bar this will give naturalness the coating. For a neat cut on the panel, you need to mark the marking, draw along the line with a sharp construction knife and pushed the lamella.

- Remove the edge of the panels and lay them out. It is important to provide thermal gaps between the laminate and the wall. To withstand the same distance, you can use tile crosses by 3-4 mm.

- Fix the panels. The upper edge should overlap on the adhesive tape of the neighboring lamella.

- Iron the joints with a roller.

- The laminate laying with the hands (instructions on the material on an adhesive basis, and not a castle) is performed without compensation clearances. The protective layer is removed from the panel and it is tightly pressed to the base.

- After placing the initial row, evenness is checked. If minor displacements are detected, the work should be redone right away, otherwise it will be difficult to fix the gap.

- The next row begins with a solid lamel. The technology of fastening the flooring does not change.

- The subsequent layout is performed with the displacement of each row.

DIY laminate laying: step -by -step instructions.

Advice. For neatly finishing the columns, heating radiators and niches, the panels are cut through the template. The pattern must be made independently to make accurate calculations, draw the circuit on the cardboard and cut out. If the template is completely suitable, then a hole in the laminate is cut out on the sample.

DIY laminate laying: video

Floor care care of glued laminate

The long service life is ensured not only by high -quality laying of the laminate, but also by timely care. Spots of various origin must be cleaned immediately using cleaning agents designed to clean the PVC laminate.

It is not advisable to use detergents for dishes and powders with abrasive components. The optimal solution is biodegradable. After applying it, you will not need to wash off the water. In addition to stains, such a cleaner fights perfectly with stains on the floor, which are especially noticeable on dark coatings.

Minor damage will be removed in one of the following methods:

- Burnts and traces of shoe sole are removed with a flannel sponge or eraser. For greater efficiency, you can add a couple of drops of vegetable oil to the surface.

- Superficial scratches are painted with a wax pencil.

- Small cracks fill with acrylic putty. When choosing a color, it is important to consider that the putty ducks in one or two tones when dried. After applying and completely drying, the plot is filled with felt.

Advice. In order not to make a mistake with a shade, it is better to first test the putty on an inconspicuous area of \u200b\u200bthe floor. If, after drying, the color of the grout corresponds to the flooring, then you can safely perform the restoration of the damaged area.

Not so long ago, an innovative finishing material appeared on the construction market. A self -adhesive laminate attracts with its operational characteristics and ease of installation, a variety of textures and shades. Many consumers are somewhat frightened by the cost. However, when the material is launched into mass production, a gradual reduction in price is expected.

Do -it -yourself laminate tips: video