An international company that has been operating since 1932 produces ...

|

|

Wood is a rather popular and environmentally friendly material, so wooden ... |

The arrangement of a warm floor allows you to save well on heating. In addition, he ... |

Carpet: varieties and subtleties of production

Residents of our country with the advent of winter are faced with the problem of the cold floor in the house. This problem can be solved by installing a warm floor or covering the floor with a warm coating. True, not everyone can afford the floor. But carpet coatings have been known to humanity since ancient times. For centuries, they have acted as the subject of luxury in the dwellings of wealthy citizens. But today everything has changed dramatically! In the market of carpet flooring, the leading position belongs to the carpet carpet with an unprocessed edge. With this material, you can cover the floor in almost any room, with the exception of the bathroom, but most often it is used in children's rooms and bedrooms.

Table of contents

See also: Methods of laying and caring for carpet (article)

- The origin of the carpet

- Carpet structure

- Types of pile

- Methods for the production of carpet

- Material for the manufacture of carpet

The origin of the carpet

In 1950, the first apparatus for the production of carpets was created: at this time, engineer Kobble decided that it was possible to make a coating, often piercing the source material with a needle with a thread. After many studies with the selection of materials, it was found that with fairly frequent punctures of the thread a uniform, vill layer forms, which is somewhat similar to a regular carpet layer. Thus, the first batch of previously not known material appeared, which was not called a carpet made by a machine method, but with carpet.

Carpet is a carpet flooring. Many mistakenly believe that carpet and carpet are the same thing. Consider the differences between them. Firstly, each carpet has a clear size. Secondly, the carpet always has a finished drawing. In the dwelling, the carpet performs two functions: the heat insulator and the interior element. The floor carpet does not have certain dimensions, it can be bought different lengths, and the image on this flooring is periodically repeated. Carpet is easy to styling, and also has advantages such as great practicality and reasonable price.

Carpet structure

Carpet as a flooring consists of elements such as a pile fixing layer, the primary and secondary base. The primary base of the carpet fixes the pile and, depending on the area of \u200b\u200buse of the flooring, is weaned or not woven. The woven primary basis is made of polypropylene, and not woven is made of polyamide and polypropylene.

The threads of the pile in the primary layer are firmly fixed using a glue compound, which acts as a fixing layer and consists of dispersion material, for example, from latex. The secondary basis affects such qualities of carpet as elasticity, wear resistance, elasticity, sound and thermal insulation, shrinkage resistance and slipping. There are many varieties of the secondary basis. We will get acquainted with the most common.

Natural jute is an environmentally friendly material with a fairly large list of significant shortcomings, for example, shrinkage when moisture enters, which entails the appearance of unpleasant odor, decay, mold formation and, as a result, decomposition of threads. Therefore, the use of such a carpet is advisable only in well -ventilated, dry rooms.

The advantage of artificial jute compared to natural flooring is moisture resistance. Such material is not erased, does not change the size under the influence of moisture, does not decompose, but at the same time, after wet cleaning, it requires good drying because it has a predisposition to the formation of mold.

Foil today is practically not used in the production of flooring, because it differs a number of disadvantages. In this case, a carpet with an artificial felt is considered a good solution, which has thermal insulation and water -repellent properties. The only minus is the high price of the product.

Latex rubber gives the carpet a feeling of comfort and softness even with a small height of the pile and a slight density of stuffing. The disadvantages include the fact that when laying a rubber -based carpet tightly adjacent to the floor, and there is a very small chance of its movement without damage to the secondary basis.

Types of pile

The carpet is divided by the weaving method. There is a carpet with a short pile (up to 3 millimeters), medium -length pile (up to 8 millimeters) and high pile (above 20 millimeters). The material is multi -level and single -level. The first option has loops of different lengths, which gives the image volume. Such a carpet, undoubtedly, looks better in aesthetically, but much more problematic to care.

Velur is a type of single -level coating. The fiber does not twist with this method of production, and the tops of the villi are fluffy, the surface thus becomes pleasant to the touch and tender. If the color scheme of the material is monophonic, then it will be clearly visible dirty prints and spots. But such a coating is well cleaned.

Frieze is a carpet with a high twisted pile. The villi look curly, preserving their shape due to heat treatment. The most common type of frieze is a two -factor carpet, made of loop pile of different thicknesses. Such material tolerates crushing well. The carpet print is also popular, because any image is easily placed on it.

Scroll is a type of multi -level coating. Such a pile acts as a mixture of uncircumcised and cut loops, as well as single villi. The carpet due to such a heterogeneous coating is beautiful and interesting. Another advantage of Snweal is high wear resistance, so that the coating can be laid even in the corridor. Another type of multi -level carpet is a catwood. On the surface, islands of cut loops are formed, which are surrounded by a low loop and create the effect of volume.

Methods for the production of carpet

Since 1950, and still the technology of manufacturing carpets has not fundamentally changed. Machines became faster and more accurately, materials - better, the systematics of punctures appeared, an needle -flash technology was born, but the principle remained unchanged: the basis and creating a pile of thread. Now in production such types of carpet are being created:

- Needle -flavor carpet. The material is stitched with pile threads of a non -woven or woven base. The floor covering on the front side made in this way has a loop, for which this type of carpet is often called loop. The loops are also cut, forming a coating with cut pile. The weight of the carpet with the pile depends on the number of stitches per unit area, the distance between the needles and the varieties of the thread.

- Needle -punched carpet. In the production, needles are used in which there are ZAZUBRINA along the entire length instead of ears, which when moving up and down the fibers, as a result of which a whole canvas is formed. Such a carpet in appearance is inferior to the needle -carrying one, but is more popular due to the affordable price and its strength.

- Weaved carpet. Such flooring is made by the most expensive method, because the threads of the pile in it are intertwined with the threads of the base, forming a very complex design. The procedure is complex and long, but allows you to produce high -quality coating.

Material for the manufacture of carpet

The main material, which is necessary for the manufacture of carpet, is a fiber that is artificial or natural. And in order to get acquainted with the starting raw materials, it is worth viewing the photo of the carpet.

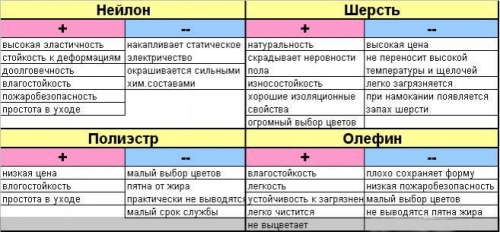

Polyamide fiber is wear -resistant and very dense material. Such a floor covering retains color and texture for a long time, the pile does not get under the weight of furniture, and does not wear out from intense walking.

Polypropylene fiber is the only material that initially has antistaticity, which allows you to forget about its treatment with antistatic, but at the same time it has a rather low fire safety and wear resistance.

The polyester fiber looks like wool, but the latter is significantly inferior in all respects.

Wool has many advantages, which include elasticity, strength, high fire safety and low thermal conductivity. The disadvantages of such warm carpet are high cost, fear of dampness and moths, as well as the accumulation of a static charge.

Acrylic fiber has an average level of abrasion, which is still lower than that of polyamide fiber products. Therefore, it is often used in conjunction with other material, which significantly increase its resistance to abrasion.

When choosing a carpet, pay great attention to its color so that the carpet coating correctly fits into the design of the room. In this matter, you should rely on your taste, but experts can give sensible tips. Due to warm shades, you can recreate a very cozy interior in the apartment, which is poorly illuminated by sunlight. You can create a calm and pacifying atmosphere due to green and blue shades. But with dark tones, be careful not to spoil the mood in the house.

Thus, carpet is classified as flooring. This material is unpretentious and durable, it will serve without losing its qualities close to 15 years. It can be placed in any room, with the exception of, of course, such places as a bathroom where damp and high humidity will reduce the useful life of the carpet by several times.