The installation procedure of siding requires primarily the arrangement of the frame on which it ...

|

|

The sewage clogging occurs even with the most accurate use. This is a big... |

One of the significant advantages of a private house is the ability to expand residential ... |

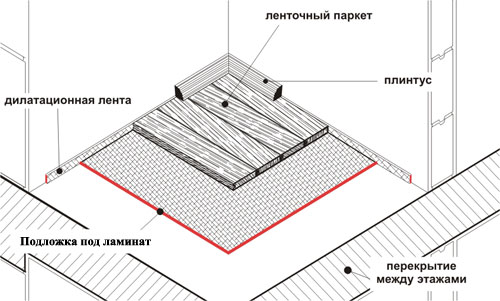

Which substrate to choose under the laminate

A cozy atmosphere is one of the main requirements for residential premises. Upon arrival home, every person wants to relax, enjoy silence and peace. However, if your restless child runs around the floor, then distinct sounds are made that interfere with a relaxing rest. And when your neighbors from below, in addition to everything, listen to loud music, then you can only dream of silence. An effective solution to this problem is the purchase of a flooring substrate. Of course, it is quite difficult to understand all the nuances yourself, but our information will help successfully choose the appropriate insulating layer.

Table of contents:

- The advantages of the substrate for the laminate

- Laminate substrate properties

- The selection of a laminate substrate

- Laminate substrate technology

The advantages of the substrate for the laminate

The flooring plays a rather important role in repair. And the choice of material for the floor should be taken seriously. Today, the most popular coatings are called laminate due to its durability, wear resistance and relative cheapness. However, buying the material itself is half the battle, since you still need to choose a substrate for the laminate.

Soundproofing

The laminate has one unpleasant feature: the sound of steps is quite loud. And for you and for neighbors. There are two reasons for this: the coating itself is thin in the laminate of the most popular thickness of 8 millimeters; As well as the floating method of laying, as a result of which a peculiar membrane that transfers sounds is obtained underfoot. To extinguish such an impact noise, when laying a laminate on the draft floors, put a substrate.

Some manufacturers into their product integrate special soundproofing systems such a layer glued on the back of the laminated floor planks. An integrated substrate is usually found in laminate 33 and 32 classes. Such a coating is very convenient to lay, but the integration of the substrate into the laminate significantly applies the products. Therefore, a more prudent solution will be the purchase of warm substrates for laminate in rolls or sheets. The noise -insulating abilities of such a material are indicated by the manufacturer on the package.

Surface leveling

In addition to decreasing noise, such an intermediate layer between the laminate and the base is able to slightly smooth out the irregularities of the screed for the flooring. It is sad that the new draft floor is not always ready to lay a laminate. In the manufacture of the screed, some changes are obtained, and such deviations are not acceptable for laying flooring.

When arranging a laminated parquet on a concrete surface in a few months in some places the so -called backlash appears. Laminate, as a rule, sags in those places where the distance between the draft screed and the floor is maximum. Even if a gap formed several millimeters, the irregularity during walking will be noticeable anyway.

Therefore, it is required to ensure additional alignment of the base. To do this, we need a substrate under the laminate made of polystyrene foam, which allows you to achieve a perfectly flat floor surface and hide minor changes. But you should not get too carried away with the thickness of the substrate, the thickness of which is more than 3 millimeters, is unacceptable because too thick the laminate substrate will bend in the joints of the flooring planks, and the connecting locks can simply be damaged.

Moisture insulation

Humidity adversely affects flooring. If, when arranging the floor, the process of natural drying to pay due attention, then when laying the laminate, no problems will arise. The new concrete screed should naturally dry for at least one month.

In any case, it will not be superfluous to carry out a simple dough for the readiness of the base for the arrangement of the laminated floor. Throw a plastic bag on the floor in the evening, and check in the morning if the evaporates appeared on it, then the screed is not yet ready to lay the laminate. The laminate substrate is able to maintain a microclimate between the flooring and the draft floor and protect the surface from technological moisture from cement or concrete.

Thermal conductivity

Thermal conductivity is especially important when using the floor heating system. Laminated flooring has the heat -insulating properties in itself. Laminate and warm flooring substrates are also heat insulators. Thus, the underfloor heating system is under two layers of thermal insulation, which reduces the efficiency of heating.

Think, in this case, it is not necessary to bear the cost of buying and installing the floor heating, as well as pay for the consumed electricity. The laminate substrate has high heat -insulating properties and is able to provide good heat insulation.

Laminate substrate properties

So, the need for laying under the laminate of isolation material is not subject to doubt. It remains only to choose a substrate. High -quality roller and leaf substrate are not too cheap, however, according to the masters, the savings on this material can end with unpleasant consequences up to the bloating of the laminate. In this case, you need to find a compromise by finding out what qualities a substrate should have for the laminated floor.

A special insulation material that does not allow direct contact of the laminated floor with a draft base must meet the following requirements:

- be neutral to interact with alkaline materials;

- have bactericidal properties;

- perform the function of thermal insulation;

- differ in high moisture resistance;

- not to promote the propagation of rodents and harmful insects;

- provide an opportunity to remove microvntilation condensate;

- reduce the load on the laminated floor.

The selection of a laminate substrate

Which substrate to choose, because there are many varieties of this material on the market? First of all, it is necessary to proceed from the state of the black base of the floor. If the screed is in a normal state and corresponds to the established tolerances, then you can safely take a two -millimeter substrate. In the case when the concrete has small flaws, it is recommended to buy a three -millimeter substrate for the isolate laminate.

On the building materials market, such types of substrates for laminated floor are presented: polyethylene foam, substrates made of extruded polystyrene foam, combined, bitumen substrates with a cork and cork materials. It is a mistake to believe that it is worth buying a substrate of exactly the manufacturer as the laminated floor. This is of fundamental significance.

Polyethylene substrate foam

Ponopoliethylene substrates are very popular, because they are highly moisture resistant, good heat -insulating properties, are not infected with different fungi and bacteria, they are not interesting to insects and rodents. It is convenient and easy to work with such material, it is economical and gives little waste. It is not rarely that the film has an additional layer of metallized film. Foil substrates under the laminate using aluminum are also available.

However, in addition to advantages, polyethylene substrate foams have disadvantages. They do not retain their shape well and can sag over time. In addition, such isolation material is afraid of ultraviolet radiation.

Cork substrates

A cork substrate is a good insulation material and is an excellent basis for a floating floor. It is known as an excellent heat insulator, is not subjected to mold and rot. The material is available in rolls and leaf performance. It is used as a heat insulator in warm floors and a substrate for floating floors. Saves its linear dimensions and technical properties throughout the entire service time.

The high cost of cork films makes it inappropriate to lay it for inexpensive laminated floors, which have a short period of useful operation. The disadvantage of the cork substrate for the laminate is that when used on the bottom of the laminate, condensate can form.

Bitumen-industrial substrates

Bitumen-industrial films are made on the basis of craft drinks with the addition of bitumen, after which it is covered with cork chips on top. Camping sprinkle is made of pieces, 2-3 millimeters in size. To everything, such a substrate perfectly absorbs sounds and thanks to bitumen prevents moisture penetration.

Bitumen-industrial substrates provide air exchange at the proper level, level pressure and prevents the formation of condensate. The material is useful when it is planned to lay the expensive and durable type of laminate. With a low -grade cheap laminated floor, this coating is inappropriate to use.

Foam policemen

An extruded polystyrene foam is often used as an isolation layer for a laminated floor. Such a film is the optimal solution from the position of resistance to load. In addition, it aligns the irregularities of a concrete foundation well. Thanks to these qualities, a substrate under the laminate made of extruded polystyrene foam can be used for a room that is intensively used.

Effective absorption of vibrations and stresses guarantees an increase in walking comfort. Polistyle foam insulations well -laminated floor and, thanks to the closed structure of its cells, is characterized by high moisture resistance. The material initially has a high density, so it retains its own elasticity and thickness for a very long time.

Combined substrates

Synthetic combined substrates are quite in demand today, in the production of which polystyrene foam and polyethylene are used. The most famous example of such a material is the well -known Tuplex substrate. The combined film is a kind of sandwich, where balls of polystyrene balls are arranged between two layers of polyethylene with different characteristics.

The material is sold in rolls and has a thickness of about 2-3 millimeters. Due to its design, the film can ventilate the space. The upper layer, made of high pressure polyethylene, prevents the penetration to the base of the moisture floor, if water suddenly gets to the coating. The thin lower layer passes moisture from the draft base to the granules, and from there, due to the technological clearances, it is removed out.

The advantages of a combined substrate are its flexibility, strength and ability to maintain the original thickness, as well as leveling defects in the draft floor.

Special substrates

Special insulation material can reduce transit noise with maximum efficiency or extinguish the sounds of steps. Thanks to the creation of natural ventilation, the material is able to remove moisture that it fell under the flooring. The use of special substrates reduces the laying time of the laminated floor by 2-3 times due to a mounted moisture resistant membrane. Special substrates in many respects have good characteristics, but are highly worth it.

Laminate substrate technology

When laying a substrate under the laminate, professional skills, work experience and special tools are not required, but you need to carefully comply with certain rules. First of all, the operational qualities and durability of the laminate depend on the literacy of the work. With the correct laying of the substrate for the flooring, you and your neighbors will not remember each other!

Preparatory work

If the screed is concrete, stone or cement, then you need to put a layer of polyethylene film on it for the purpose of waterproofing, and then proceed to laying the substrate. The thickness of polyethylene should be slightly larger than an ordinary plastic bag - close to 0.2 millimeters. The upper layer of the laminated floor is covered with a protective film, which protects the coating from moisture, therefore the lower surface should not remain without protection.

Before laying the substrate, the base must be thoroughly vacuumed. It must be dry without fail. The substrate can be cut with ordinary scissors or a construction knife, measured lines are applied with a pencil or marker using a ruler. To achieve the maximum smoothness of the surface, you can not make several layers of the substrate. It will be enough to take a submarine, the thickness of which is 2-3 millimeters.

If you choose a thicker backing for a polystyrene laminate for an uneven coating, then under pressure can break the locking devices of the laminate. Yes, and walking on the floor in this case will be inconvenient, as the panels bend.

Laying the substrate

The substrate is recommended to place the direction in which the laminate panels will be laid. This is done so that a piece of floor does not move out of the careless movement from its place. When laying, it is worthwhile to start a substrate under the laminate on the walls. This will ensure the safety and durability. If the material has damage, then in case of detection of damaged areas, it should be covered with an additional layer of substrate for the laminate.

If the film is corrugated, then the side of the corrugated surface must be laid down, so it turns out to be better to align the base. If the material with aluminum foil, then the side with foil should be placed up.

Thus, having selected laminate from the whole variety of modern flooring, to ensure sound insulation and smoothing out a black -based irregularities, it is recommended to buy a special submarine for laminate. Special insulation material is characterized by a number of positive properties and is presented on the market in a wide range. It will not be difficult to choose the right substrate necessary for you!

thanks!

thanks!

I know that it is very effective

I know that it is very effectively under the laminate are film warm floors. The neighbors installed themselves and have never complained in a few years. It is especially convenient when the heating season has not yet begun, and the street is already frosty. This is written in detail about this http://www.komfort74.ru/production/infrakrasnyj-plenochnyj-pol-teplotex/