A botum stone was used to build a foundation and base, and in some cases ...

|

|

If you want to quickly and with the least costs solve the housing issue, ... |

It makes sense to do the owners of apartments with problem ceilings during the next repair ... |

How to remove a screech of parquet

Surely, everyone at least once came across a problem of creaking floors, either in a public place, or at home. This attack creates simply unbearable conditions of any personal life. A sharp whistling creak informs your households not only of your households, but sometimes neighbors. Involuntarily, a logical question arises, how to eliminate the screens of the parquet. Despite the excellent operational characteristics of the wooden coating, its naturalness and environmental friendliness, nevertheless, and it requires repair. The most reliable remedy for creaking parquet is its complete replacement. But not everyone can afford such expenses at once, therefore, for temporary elimination of the creak, you can use one of the methods below.

- Reasons for the creak of parquet

-

How to get rid of a creaking parquet

- If a shield parquet is dry

- If the substrate (plywood, fiberboard) does not fit out to the base of the floor

- If there are no gaps between the wall and the parquet

- If the concrete base has significant bumps

- If the Parquet Parquet strips have sucked and gaps have formed between them

- If the Parquet Parquet strips have exfoliated from plywood or fiberboard

- If the lags are deformed

- If the parquet board rubs about lags

- If a comb or a groove broke in a parquet board

- If parquet strips go freely on nails

- If the bitumen mastic, on which the parquet was attached and exfoliated and exfoliated and exfoliated

Reasons for the creak of parquet

In order to qualitatively perform the repair of the parquet creaking and choose the right method, it is necessary to accurately identify the cause of the creak and its location. All the causes of the creaks can be conditionally divided into two categories: those that are associated with the non -compliance of the technology of laying a wooden floor, and those that are associated with poor -quality drying of parquet planks or improper operation of a wooden coating. Due to the fact that the tree is natural living material, it breathes, collects moisture from the room and gives back. If the optimal humid mode was not observed in the room or the floor laying was carried out poorly, the wood of the strips begins to deform. This leads to the appearance of creaks and even deformations of the planks.

Errors in the technology of laying parquet sex:

- Not enough even base.

- The fiber or plywood substrate adjacent to the concrete base loosely.

- Incorrect location and sizes of the lag.

- Not tightly fixed lags.

- Deformation of the lag.

- Parquet strips are fixed to poor -quality glue.

- The compensation gap between the parquet and the wall has not been completed.

- The baseboard is incorrectly fixed.

Silent or deformation of the wood of parquet planks:

- Initially, poor -quality material is undercut or overdry.

- During operation, the optimal humid and temperature regime was not observed. As a result, the parquet refers or deforms from frequent wetting, and then overdrying.

- Getting wet parquet from vapors going from below. The reason lies in non -compliance with the styling technology did not use a vapor barrier membrane.

Such a large number of reasons for the appearance of the creak obliges to know exactly what a wooden parquet floor pie in your house consists of, as well as the option of its installation and used fasteners. The method of eliminating the creak, which can be used in one case or another, depends on this.

How to get rid of a creaking parquet

In total, you can distinguish several places where the creak is formed:

- Parquet strips creak from friction against each other.

- Parquet strips rub on the substrate.

- Parquet strips rub on the nails with which they were fixed.

- The creak issues a substrate that is not adjacent to the base.

- The creak is published by the lags.

Since you have decided to eliminate the screenshop of the parquet with your own hands, then try to accurately determine the cause of the creak and choose the right way to combat it from the below.

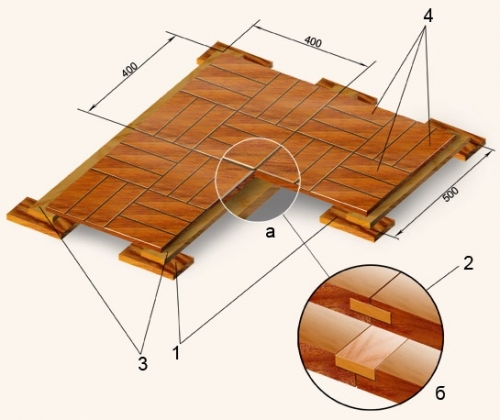

If a shield parquet is dry

The shield parquet is a square of 50x50 or 60x60 cm, consisting of wooden planks of the base and parquet strips glued to them from above. Most often, the base itself is two -layer and the ranks of the planks in it are located perpendicular to each other, i.e. If one longitudinal, then the second transverse. All layers of wood are fastened to each other with adhesive compound. Parquet shields can be quickly and easily mounted to the lags. It was thanks to convenience that in many typical apartments in Soviet times laid a shield parquet. Unfortunately, this type of parquet fails faster than classic and is practically not subject to restoration.

The shield parquet can have two troubles:

First shields do not fit the lags, which in turn have not the best geometry and are installed on elastic lining. Such a problem can be fought, although difficult. First you need to determine the location of the lag. Then fasten the shields tightly to them. In the corners of the shields, holes are made with a depth of 15 20 mm and with a diameter, like a screw for a dowel screw. Then the holes are sprinkled through the entire pie and the lag. They insert plastic spacer dowels, and then screws are screwed. The screw hat should be drowned in the Parquet Parquet for at least 15 mm. The remaining hole is plugged with a wooden cork and soaked with putty to the tone of the parquet. Of course, all this procedure must only be performed with those shields that creak.

The second due to the deflections of the shields, the layers of the planks went out and exfoliated, the boards at the base of the shields could crack or split, the boards and parquet strips rub against each other, making a creaky sound. In other words, all three layers of the parquet shield were delayed. Such a disaster, unfortunately, is not treated. If you have just such a case and you are interested in how to eliminate the creak of the old parquet, then the answer is only one replace it.

If the substrate (plywood, fiberboard) does not fit out to the base of the floor

As often happens, during construction or repair, many neglect the requirement to perform the aligning screed of the floor with cement-sand mortar. As a result, plywood is laid on a not too flat concrete floor, glued or screwed to the base, and everything seems to be good for the time being. Due to constant mechanical loads in the passage zone, the plywood is exfoliated from the concrete floor and begins to fidget and squish along it.

There are several ways to solve the problem:

Method 1. Dolling under the plywood of cement milk. In places of intensive creak, which must be determined in this way: in the place of the alleged creak, the load is 80 100 kg, if the creak is disappeared, then the place is determined correctly. In the required place it is necessary to remove several parquet strips, if they are firmly held on the basis, one of them will have to sacrifice. To do this, the parquet bar is split into three parts and removed. Then, in a substrate (faner, fiberboard), a hole of about 20 mm with a diameter is drilled. Cement milk is kneaded (1 part of cement + 1 part of the water) and poured into the hole until the solution begins to pour back. Next, the solution must be given at least a day to dry. Then the remote planks of the parquet are glued to the faner, and the split must be replaced with a new one.

In this method, you can adjust the parquet plank you can not be removed, but drill the hole through them. Then it will have to be plugged with a chopic of the same wood as the parquet, and cover with putty.

Method 2. Sloting under the plywood of mounting foam. At the place of a loose fit of plywood, a hole is drilled, into which the mounting foam is pumped into two approaches: after the first, you need to take a break for no more than an hour. Then the hole must be plugged with a cuttings and installed a load of at least 150 kg so that the mounting foam does not swing the entire floor.

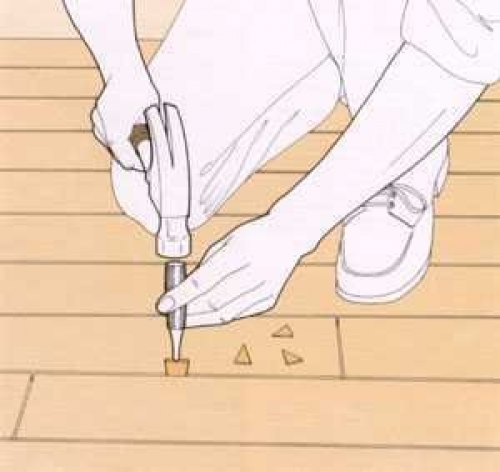

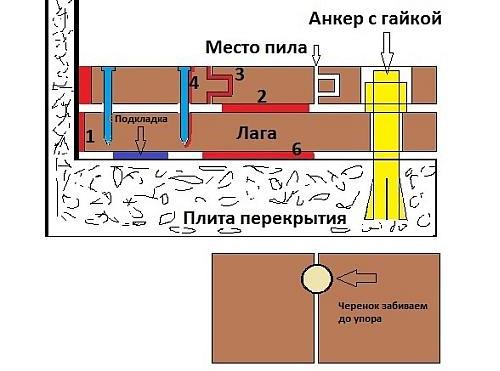

Method 3. Removing the screens of parquet with screwing parquet along with plywood to the concrete base with screws. To perform work, you will need a bars of 50x50 or 50x75 mm long as from the ceiling to the floor. One edge of the timber is sharpened in the form of a heel, the size of a five -cope coin (2 cm diameter). In the estimated place of the creak, the beam of the fifth is installed, the upper edge should rest against the ceiling. For a stronger stop between the beam and the ceiling, a wooden spacer wedges. Since initially the beam was taken with a length equal to the distance from floor to ceiling, it will not be able to become smooth, but will have some slope. It is necessary to continue to knock out the beam until it becomes smooth, and the floor will compress as much as possible to the base. If, after the procedure done, the creak in this place disappeared, then it is necessary to screw the screw nearby.

Before screwing the screw, you should check the rest of the floor for the creak. And in places where it will be found to do the same procedure with a timber. When there is no creak throughout the area, the number of necessary screws is calculated.

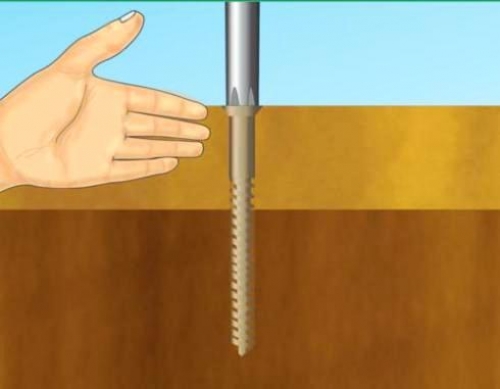

The screw should be so long to go into the concrete base of 40 50 mm, and the hat should be drowned by 5 7 mm in wood.

First, a hole is drilled with a diameter equal to the screw hat, 5 7 mm deep. Then the hole is drilled with a depth equal to the length of the screw and a diameter equal to the diameter of the plastic spacer dowel. The dowel is inserted into the hole, screwed the screw. A puck is placed under the head of the screw to ensure the emphasis in the parquet bar. The same procedure must be repeated for all places. Then all the remaining holes are covered with putty on the tree. In conclusion, spacers are removed.

I would like to note that when the script of the parquet appears, its elimination in this way is the most reliable and durable. But at the same time, the complexity of the dismantling of the coating in the future increases.

If there are no gaps between the wall and the parquet

Between the wooden floor and the wall there should always be a compensation seam of at least 15 mm around the entire perimeter of the room. If the parquet floor was mounted without observing this rule, due to the temperature and moist expansion of wood, the parquet planks begin to crush on each other, as they are obtained between the walls.

It is easy to eliminate such a defect around the entire perimeter of 15 20 mm wood and substrates. The main thing is not to be too late. There are times when, due to the wetting of the Parquet, the parquet is swollen and deformed completely without the possibility of repair.

If the concrete base has significant bumps

Perhaps this problem is one of the most difficult, as it does not imply half measures. If a floor screed was not made before laying the parquet board and the concrete base has significant height changes, then you will have to completely disassemble the entire coating to the very base. Then the surface is aligned with a cement-sand mixture, after its drying, a substrate and a parquet board are laid on top. In fact, you have to make a completely new parquet floor.

If the Parquet Parquet strips have sucked and gaps have formed between them

The reference of the Parquet planks is the result of being stacked with unimportant. The strips were deformed and now rub against each other and the base/substrate. In this case, it is possible to eliminate the creak of parquet, not allowing the planks to rub against each other and fidget. For this between the strips, wooden wedges are driven So that their upper edge does not protrude beyond the surface of the parquet. The step between the wedges is taken 15,100 cm. Then the space between the strips is sealed with putty.

If the Parquet Parquet strips have exfoliated from plywood or fiberboard

How to remove the screening of the parquet if his strips exfoliated and rub on the base? There are several effective ways.

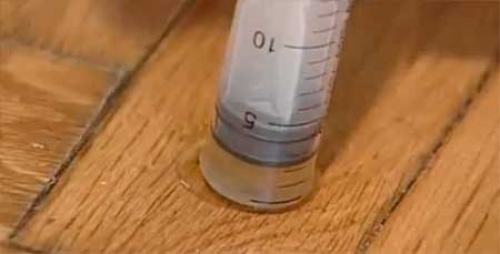

Method 1. In places where the parquet strips moved away from plywood, it is necessary to stick pieces of painting tape. If the creak area is large with tape should be placed in a step of 20 cm. Then, a hole with a diameter of 2 mm to plywood depth is made in the center of a piece of painting. The drill should break the tape, as a result, a small hole is formed. Using a conventional syringe without a needle, the hole is introduced into the hole glue. This can be a special glue for laying parquet, or there may be a different glue for working with wood, for example, PVA. Slowly, slowly, the glue pushes into the cavity between the parquet bar and the plywood. After filling the cavity, the glue must be given an hour to dry. Then the painting adhesive tape is removed, and if the glue stains remain on the surface of the parquet, they must be removed with a solvent, and then wipe the floor with a dry rag.

The glue dries for 24 hours, all this time the cargo (50 kg) should stand in the repair areas. After the glue dries completely, the holes are filled with putty on wood or wax and polished.

Method 2. Parquet strips are fixed in places hairpinsusing a pneumatic pistol.

Method 3. Remove the creaking planes of the parquet, in their place put a piece of cardboard, and fix the bar on top. In this case, you can fix the parquet both on glue and with the help of self -tapping screws, lining their hats 5 mm into wood.

Method 4. All screwed Parnish Parquet planks are screwed to the base (faner/fiberboard) with self -tapping screws. It is advisable to spill holes for self -tapping screws not evenly, but at an angle of 45. Do not forget that the hats of self -tapping screws must be shed in the floor. And put on top.

The problem described above is the simplest among all, since in extreme cases you can remove all the exfoliated parquet strips, clean the base and glue them again, but already with high -quality glue.

If the lags are deformed

The deformation of the wooden floor lag is trouble, since, most likely, the cause was the wet of wood from vapors coming from the room below. In this case, the elimination of the creak of parquet will not solve the problem. The only possible case to dismantle the parquet, check the base of the floor, lay the vapor barrier film, securely fix the lags. If the lags are deformed too much, then they must be replaced, otherwise after a short time you will encounter the problem of creaks again.

If the parquet board rubs about lags

An effective way to eliminate the creak of the parquet board, if it rubs on the lag, this is a broach self -tapping screws. The main problem to determine exactly where these lags take place, and whether there are any communications in them. It is necessary to fix the parquet board to the lag on both sides, as shown in the photo. The holes for self -tapping screws are drilled at an angle of 45, the fasteners themselves should look at each other as it were. At one board 1 m long will have to be made at least 6 mounts. Do not forget to pour the hats in wood.

In addition to this, sometimes talc or sand is covered in the cracks between parquet boards to reduce the contact of the boards and lags.

If a comb or a groove broke in a parquet board

The main task in this case to fasten parquet boards among themselves. They are used for this self -tapping screws. This method is similar to the previous broach with self -tapping screws, only in this case the screws should be short, in such a way as to connect two boards with each other diagonally. The holes are drilled with an indent from the edge of the board 1 cm, at an angle of 45, so that the tip of the self -tapping screw enters the next board for about 1 cm. The neighboring self -tapping screw should have the opposite direction from the next board in the first.

If parquet strips go freely on nails

Fastening the parquet on nails is fraught with one very significant drawback And although immediately after the installation, nothing portends troubles and everything holds well, over time, your idyll can break the terrible creak of the tree on metal.

Unlike a nail, the surface of the screw has a spiral cut, so the wood is firmly held in one position, even if there is a shrink of a couple of millimeters. To eliminate the creak of parquet planks or nail boards, it is necessary to complete the full bulkhead of the parquet and replace all nails with self -tapping screws.

If the bitumen mastic, on which the parquet was attached and exfoliated and exfoliated and exfoliated

The most extravagant way to eliminate the screens of the parquet is associated with the problem of dry bitumen mastic, on which parquet was attached in Soviet times. The bitumen mastic over time becomes fragile and crumbles, such material is not able to hold the bar. To restore its properties, you can try heat mastic using a hairdryer. Carefully heating the entire surface where the creak is observed, it is necessary to firmly press the parquet strips to the base, and for this the load should be evenly decomposed.

Another way to eliminate the creaking of parquet in this case is similar to those that have already been described above. It is necessary to perform holes in the floor, pump glue under it, and then pull the parquet boards with screws or screws.

In conclusion, I would like to recall once again that the elimination of the screens of a parquet with your own hands using the presented methods is only half measures. Do not lay another coating on top of a creaking wooden floor, for example, linoleum or cork floor or laminate. Just imagine that after some 5 7 years you will have to disassemble everything to the base, tearing the layer by layer. It is better to immediately make a full major overhaul and replace a pretty creaking parquet.