The long -awaited summer came, and many citizens hurry to summer cottages, gardens and sites to ...

|

|

Among the large number of thermal insulation materials, mineral wool occupies ... |

The construction of any capital building is preceded by the construction of the foundation on which ... |

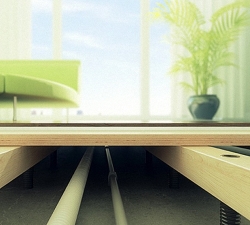

How to make an even floor on adjustable lags with your own hands

There are several ways to level floors for finishing. Among them, the main ones are screed and adjustable lags. The arrangement of the floor on adjustable lags is a less costly and fast process. We learn about how to equip adjustable floors on the lags with our own hands.

Table of contents:

- The pros and cons of the adjustable floor on the lags

- The device of adjustable flooring lag - construction technologies

- Technology for the construction of regulated sex lags

The pros and cons of the adjustable floor on the lags

Using adjustable floors, it is possible to create a perfectly even black flooring without additional leveling using cement compositions. As a system for leveling, dense material in the form of a flooring is used, on which there are mechanisms to adjust its height. It is with their help that the horizontal floor is ensured.

Adjustable lags are installed on a solid base. In some cases, the installation of the adjustable floor is necessary:

- In the process of reconstruction work in the room, while a decrease in the floor level occurs, it is not possible to set the screed, since the weight of the floor and pressure on the foundation increase;

- When completing the redevelopment, it is possible to carry out all communications in the gap between the lags and the floor;

- If the arrangement of the room that performs the function of the cinema is performed, the floor and walls in this case are high -quality soundproof;

- with a multi -level floor design.

In the ratio with the main material for flooring, two coating arrangement options are distinguished:

- adjustable floors on the lags;

- Plywood adjustable floors.

Among the main advantages of the adjustable floor on the lags, we note:

1. Compared to concrete floors, the adjustable floor has less weight, because of this it does not load the design of the building and the foundation. Such a floor can easily withstand any ceilings, especially relevant for cottages and wooden houses.

2. The device of the adjustable floor is a dry version of the finish for which you do not need to use wet solutions, and cleanliness is preserved in the room.

3. Using the adjustable floor, it is possible to align not only small tubercles, but also significant changes in height are removed.

4. Installation work is carried out quickly enough than when leveling using a concrete solution. You can align the floor in the room in one day, while you do not need to wait for extra time to dry the floor. Immediately after leveling, further work is carried out.

5. Between the main floor and lags are underground, inside which communications are installed.

6. In addition, heat and sound insulation are installed in this air gap. Thus, comfort is improved from the use of such gender in the room.

However, regulated sexes also have their own disadvantages. This is primarily a creak, which is prevented only at the stage of installation work. First of all, dust should not remain at the ceiling, a vacuum cleaner is used for these purposes. All fasteners are clogged to the end, wooden elements should fit tightly to each other. Thus, it is possible to prevent shattering of the racks.

As a result, after a certain time, still wooden surfaces begin to creak. This comes from the fact that the tree expands and narrows, changing the shape under the influence of moisture. Technologically correctly performed label installation allows you to prevent the appearance of a creak. Another drawback of this sex is that with a significant raising of the lag, the floor makes sounds, especially when walking in heels. In order to avoid such a phenomenon, a thermal insulation slabs are laid between the lags.

The process of choosing a regulated floor or concrete screed should be based on the individual characteristics of the premises in which work is carried out. When choosing adjustable lags, pay attention to such advantages as the presence of a ventilation gap and a place for laying communications, the speed of work, the lack of need to dry out the screed, etc. In order to get high -quality coating, it is necessary first of all to follow the technological parameters of the arrangement of the adjustable floor. Studying about the field on adjustable logs, we draw conclusions that this type of flooring is an excellent alternative to concrete screed.

Among the main functional features of regulatory devices, we note:

- performing the function of reliable support in the lag or plywood system;

- work as a guide element during installation of fasteners;

- A rapid change in the height of the floor in the horizontal plane.

The technology for performing work allows you to install adjustable floors of lags with your own hands without involving specialists or an additional tool.

The device of adjustable flooring lag - construction technologies

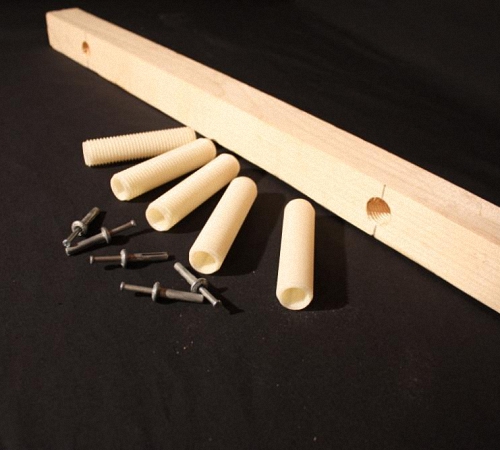

To adjust the floor, plastic supporting bolts are used, which have outer thread and dowel-gvo. Plastic bolts are installed either in the stoves or inside the lag themselves.

After installing the dry screed, the bolts and leveling structural elements on the floor are fixed. To do this, the dowel of nails is installed into the bolt. Adjustable flooring differs from ordinary ones in that they have a special screw system that allows you to quickly adjust the height of the floor. In addition, screw mechanisms perform the function of guides for the dowel-clamp. The dowel-gvo have different sizes, the choice of which is determined by the power of leveling structures and floor area. To hammer the dowel of nails, a decerator is used.

The dowel of the nails are installed if the floor is mounted on a concrete base. To fix the floor on a wooden coating, the use of screws with a galvanized coating is enough.

Simplified bolts for the adjustable floor contain a steel rod, an outer thread. The lower part of them contains elements for fixing on the surface of the base floor. The upper part of the fasteners is distinguished by the presence of the flooring of the flooring of the elements. Another option is the use of steel P -shaped details. They are fixed on the floor using screws, however, installation work in this case is carried out for quite some time and require additional physical efforts to conduct them.

Bushing -type supporting bolts are installed either on the surface of the lag or on the slabs. Therefore, it is customary to distinguish two technologies for the installation of the adjustable floor. The choice of one or another option is determined by the planned height of the black floors:

- If the floor rises more than 50 mm, then the use of standard lag is enough;

- If the size of the floor is smaller, then the use of leveling plates is enough.

In any case, using special regulatory supports, a flat surface is created on the floor. However, the differences are in the length of the supporting bolts. In addition, the holes for the screws are located according to various schemes in the first and second cases.

When choosing adjustable supports of the floor, pay attention to the height of the resulting coating. In this case, consider the height of the existing floor, add to it the communication systems that will be in the underground space. Next, decide on the option of arranging a system of adjustable lag.

Make a project of the premises, write down its entire size on a certain scale. With the help of such simple drawings, it is possible to quickly calculate the amount of material for flooring. Keep in mind that a ventilation gap should be located around the perimeter of the room, 10 mm in size. Lay on the drawing of the stove, the factory configuration in the necessary order. Designate its number on each plate, decide on the steps of drilling holes for fasteners, to determine them, consider the material to perform the finish flooring.

In order to form a perfect screed of dry type for laying tiles or linoleum, the interval between fasteners should be at least 300 mm. The maximum interval for fixing fasteners is half a meter. Keep in mind that an increase in this value leads to a non -tight fit of the plates to the floor, thus, after a while, a creak may occur.

If after the installation of adjustable lags a plank floor will form, then plywood is not installed on the aligned floorboards. The board in this case is fixed on the beam.

Technology for the construction of regulated sex lags

We offer to get acquainted with the technology of arranging a adjustable floor on the lags with plastic bushings. To install plastic bushings, adhere to such rules:

- In the process of drilling the first hole, retreat from the end part of 100 mm;

- The remains of 10 cm from each edge are divided the same under the fixation of fasteners;

- Do not forget to leave a ventilation and compensation gap between the stove and the wall;

- Install the lags in the ratio with the previously defined step in their fixation;

- The lags that are in the rows are installed in such a way that each part of the plywood rests on the surface of the beam.

Among the advantages of using this lag laying method, we note:

- the creation of a warm and comfortable atmosphere in the room;

- high floor strength and resistance before mechanical influences;

- the duration of operation and ease of caring for wooden structures;

- environmental Safety;

- ease of installation work;

- Available cost.

In order for the floor from adjustable lag to serve you as long as possible, before laying, all wooden structures are treated with antiseptic compounds and other protective impregnations.

As a material to cover the floor, boards are most often used. At the same time, the most convenient are the floor boards of a dodgy type. They are distinguished by the presence of studs-paramed joints, which form a whole and strong coating.

In the process of performing installation work, the presence of the tool in the form of:

- hammer;

- electric drill and screwdriver;

- ax and hammer;

- level;

- electric jigsaw.

Among the materials you will require lags, a sexual board, insulation, special materials for a substrate, fasteners.

At the preparatory stage for the installation of the wooden floor of adjustable lags, the basis for work is prepared. First of all, the old base is cleared of dust and garbage. In the process of laying the floor, it is not necessary to level the base, this process is performed by adjustable lags. If there are large potholes based on concrete, put them in.

Next, cut the lags of a certain size. For these purposes, an electrician is used. The size of the flooring for the floor is 5x5 or 6x4 cm. Initially, the old coating is covered with a layer of roofing material, it will provide reliable waterproofing of the floor.

Next, the floor markings are performed, and the location of the lag is determined. The lag installation interval is determined by the following factors:

- the thickness of the insulation installed on the floor;

- The thickness of the floor boards themselves.

The optimal interval for the installation of the lag on the floor is half a meter. To fix the lag, use an anchor for the adjustable floor on the lags.

We offer to familiarize yourself with the detailed instructions for arranging the adjustable floor on the lags:

1. In the bar, mark the places for fixing fasteners. Next, with the help of a pepper drill, equip holes for supporting bushings. They are fixed on the surface with self -tapping screws. The floor height is adjusted by twisting the extreme bolts.

2. The lag on which there are bushings are installed in the intended place. With the help of internal points, marking places for fixing the lag is made.

3. In order to make a hole, use a perforator. The depth of the hole should not exceed five centimeters. Install the lag and fix it using bolts fasteners.

4. In the extreme sections of the lag, using the chipper, set the dowel nails. The final clog is carried out after leveling the floor. Normal dowel nails are installed after the installation of all the lag and their alignment.

5. The locomotive screwdriver adjusts the location and height of the lag. To do this, install it in two extreme bolts. Use the level to control the action.

6. After determining the ideal position of the lags, fix the last dowel-grooves, install all other fasteners.

7. In the presence of parts that protrude above the surface of the floor, use the chisel to remove them.

Thus, the installation of each flooring element is carried out. After that, plywood or floorboard is installed on the lags. The interval between the fasteners of plywood is a maximum of 15 cm. This method of installation of the lag allows you to get a reliable and technologically perfect coating to carry out further finishing installation work.

20 squares are of interest

20 squares are of interest !!!!!!!!!!! Super! guys!

Tell me how many supports for 20

Tell me how many supports for 20 squares are needed !!!!!!!!!!!!