The usual bleached or covered with a water -based ceiling is already considered yesterday ...

|

|

The bathhouse or sauna has already been built, and the heat consumption is too large? ... |

During the colds on the roofs and water flow systems, ice forms, which ... |

We make a wooden floor in the garage on our own

The garage serves not only to protect the iron horse from auto -suppliers or weather conditions, but also acts as a kind of storage of very necessary things. One way or another, it spends a lot of time in it, in this regard, motorists are suitable for its arrangement with special care. Owners select material for the construction of walls and roof based on two main criteria: taste preferences and financial side of the issue. Unfortunately, less attention is paid to the organization of sexes. The article will talk about how to make a wooden floor in a garage with your own hands.

Content:

- Types of flooring

- How to make a wooden floor in a garage on an existing base

- The device of the wooden floor in the garage from scratch

Types of flooring

The most common types of floors are earthen and cement, less often wooden floorings are found. The first two options are ideal if this room is used in an intensive load on direct purpose. The floor from the boards is relevant when the vehicle is operated in the warm season or on the weekend.

Below is a brief description of the most popular types of material used to equip the floor in the garage.

Concrete

- Such floors are performed with accurate observance of the technology, otherwise, after a short time, cracks will appear on the surface that will lead it into complete unusable. Well, if you adhere to all the rules, then such a floor will last at least 20 years.

- Of the shortcomings of the concrete base, one can note low resistance to abrasive wear, which leads to dust formation. In addition, spilled liquid penetrates deep into the pores and remains there forever. A polyurethane coating can be the Savior, but its cost can be canceled the price availability of the concrete floor.

Plates

- Ceramic or porcelain tiles are characterized by both aesthetics and practicality. Their surface is simply unable to absorb liquid substances, and the upper layer of the glaze is easily washed even without the use of special cleaning compositions.

- Porcelain stoneware is quite expensive for arranging a garage. Preparation of the base, and the installation itself requires labor -intensive work. The material is recommended to be laid 2-3 years after the completion of the construction of the garage, that is, when the building is shrinkable.

- The ceramic product also has a significant minus low resistance to mechanical shock. And, as you know, the fall of various glands, especially in such rooms, is not at all uncommon.

Wooden floor in the garage

- The lowest price of a wooden floor in the garage, moreover, such a floor is considered warm. Therefore, repairing the car or performing it, lying on the back is much more pleasant.

Wooden floor in the garage photo

- Of the minuses, high absorbent properties can be noted. Do not forget that the tree is classified by resistance to decay and divided into fire hazard classes. But processing by modern protective means will extend the life of the flooring and protect it from exposure to fire.

- Of course, the floors can also be covered with special rubber tiles, which certainly are not afraid of any load. As already mentioned, the choice of coating rests against material capabilities.

- In any case, if the arrangement of the sexes is carried out on their own, then you can save a pretty decent amount for the purchase, for example, tools, spare parts for a car, hinged shelves or racks for storing different equipment.

How to make a wooden floor in a garage on an existing base

The installation of the material should be carried out on a strong base so that the work done and invested funds are not in vain.

Laying on concrete base

- A flat surface with minor defects, for example, with surface cracks and chips, allows you to mount the floorboard on top of it. The fasteners of lumber is carried out using screws and plastic dowels or anchor bolts.

- If the floor has great bumps, then it is recommended to fill the screed, which will provide not only the same level on the entire surface, but also strengthen the base.

- Before work, make sure that the cement coating has completely dried. For this, you do not need to have a special purpose device. The humidity can also be determined by improvised method, for this, a small square of plastic or a piece of film is sealed on the surface with tape.

- After a few days, the material is removed, if many large drops are found from the inside, then it is still impossible to lay the board. In this case, it is necessary to give the basis another time to dry or conduct additional measures to reduce humidity. Slight condensate allows the planned work.

- In any case, polyethylene or roofing material, which will prevent moisture in the basic base, are first spread out. Laying is carried out with steps on the walls and the width of the material of the material should be at least 10 cm. The seams are glued with tape or moisture -resistant mastic.

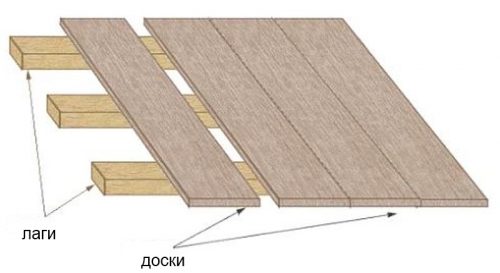

Laying on the lags

- If the surface is relatively flat, then the boards can also be mounted on the lags installed in advance. Here, a small cross section of the bar (50x50 or 40x50 mm) is fixed on the concrete base around the perimeter of the room. The same lumber is taken as crossbars. For more reliable fixation, the lags are attached to the bars using metal corners. They are installed in parallel relative to the entry/exit of the garage with a step of not more than 50 cm.

- It should be remembered here that the floor level will rise by 70-80 mm, depending on the width of the selected lumber, for example, a beam of 50 mm and a sexual board 25-30 mm. Thus, a difference is formed, the step between the floor and the entrance to the room.

Laying on a wooden surface

- It is possible to strengthen the existing plank floor by attaching new floorboards only if there is complete confidence that the design is able to withstand serious loads. If there is at least the slightest doubt, then the old coating must be dismantled.

- Here, the lag and other wooden elements are examined, the damaged parts of the frame are replaced. Under capital work, a layer of waterproofing material is laid. It is advisable to fill the space between the lags with expanded clay or dry sand, the floors will become warmer.

- The satisfactory condition of the old coating allows the fasteners of the boards, but only in the perpendicular direction.

Wood processing

It will not be superfluous to mention that wooden elements need to be processed with protective equipment. The drugs are selected individually, since some are responsible for the uniformity of shrinkage, reduce cracking, others guarantee protection against decay, and others prevent ignition.

It is worth noting that it is not appropriate to acquire miraculous solutions of 5 in 1, since one remedy cannot simultaneously protect from all misfortunes. Therefore, when going to the store, it is better to have at least basic knowledge about their classification, their destinies, the best manufacturers.

Protective compositions are divided into 3 types:

- Varnishes After drying, a transparent film is formed, which has bio -protective properties, that is, protects the surface from premature decay, and defeat by tree malls. Such coatings eliminate the cracking of the material and do not lose their original qualities under the influence of temperature changes.

- Paintsnot only give a decorative appearance, but also protect the painted elements from the short -term effect of moisture (periodically formed condensate). For processing, it is better to select paint based on organic solvents.

- Antiseptics These are multifunctional products, capable of protecting wood from biological destruction (mold formation, the appearance and spread of house mushroom). The combined version of antiseptics also has fire properties.

The coating of the lag is carried out by water -repellent agents that are characterized by a deeper degree of penetration, or antiseptic impregnations based on solvents that form a thick protective film. Preparations based on borates and fluorides are ideal.

You can use the oil analogue, only here it is necessary to make sure that the processed lumber is absolutely dry, otherwise the wet inner part of the material will contribute to the development of fungi disputes, which in turn will lead to its full destruction.

Sex boards are treated with preparations that provide effective fire protection and have copper hydroxide in the composition.

The best manufacturers

The first three included companies that produce the most effective means to protect wooden surfaces:

- from domestic manufacturers Wood healer, biox, biosept;

- foreign brands represent Tikkurila (Finland), Dulux (England), Allicator (Germany).

Folk recipes

From ancient times, the tree played an important role in national culture, so a person has always worried how to protect buildings from the harmful effects of adverse conditions. For such a long period, many effective methods have accumulated:

- silicate glue diluted with water, about 1 liter of water is taken 400 grams of glue;

- copper sulfate, is also known for its bactericidal properties (100 grams of sulfate is diluted in 10 liters of water);

- boric acid is a popular preservative. The solution is prepared as follows: 50 grams of boric acid and 1 kg of salt are taken for 5 liters of boiling water.

The device of the wooden floor in the garage from scratch

A wooden flooring in a built garage can be carried out in a matter of hours, since the lags are usually laid at the stage of building the foundation. But, if the construction was performed in a lightweight version, then more effort and time will have to be attached more.

- The zero level of future sex is determined. As a rule, the garage threshold is taken as a basis. The soil is selected by about 50 cm, more accurate calculations are made as follows: 10-15 cm will go to the sand pillow, 10-15 cm crushed stone layer, 10 cm cross-section of the beam (lags) and the thickness of the floorboard is 2.5-3 cm.

- Each layer is moistened and compacted. To do this, it is not at all necessary to use special equipment. A home -made tool is suitable here, where a square section of the board, which will be used as a sole, is attached to the end of the bar with a cross -section of 50x50 mm or screws.

- Mandatory waterproofing material with a lowerwater is lined with a slightly exceeding zero mark. The joints of the material for sealing are glued with construction tape or smeared with mastic.

- All wooden elements are treated with antiseptic and fire -retardant drugs.

- A beam of 100x100 mm is installed around the perimeter, such a cross section will help distribute the load of both the flooring itself and the weight of the car. In the corners, lumber fastening is carried out with metal corners. The level of location is checked level, if necessary, scraps of plywood or boards are placed.

- In parallel relative to the entrance, lags from the same beam are installed. The distance between them is withstanding within 50 cm, but no more. Fixation is carried out by self-tapping screws and products made of G-shaped metal.

- In the formed cells, expanded clay or dry sand can be poured.

- The floorboards located along the movement of the car are laid on top. Fasteners are carried out by self -tapping screws in two places for each lag.

Wooden floor in the garage phased video

Calculation of the material

For the arrangement of wooden flooring in a 3x6 m standard garage, you will need:

- bay of 100x100 mm 32 m;

- metal corner 32 pieces;

- floor boards 25x150x6000 mm 20 pieces;

- wood screws 4.2x65 mm 570 pieces or 2 kg.

Useful tips

- For a denser and reliable fit of the floorboards, it is recommended to drill holes under the metiz, a drill, the diameter of which is 0.5-1 mm larger than the thickness of the screw. The same applies to corner metal mounts.

- Before proceeding to the flooring of the floors, on the edges on both sides of each board should be glued, or fixed with a construction stapler stripes of roller roots.

Compliance with all the rules and technology of arranging a wooden floor in the garage will allow the repair of a machine in comfortable conditions even in winter.