The technology for the construction of a classic log house made of circle has been formed for centuries, and ...

|

|

After the decision has been made on the choice of finishing materials for painting, it remains ... |

No building material can boast of such wear resistance, strength and ... |

How to paint a concrete floor

Concrete surfaces, including gender, prefer not to paint, but to leave in their original form. However, even such a durable material as concrete is subjected to mechanical damage, chips and chemical exposure. Therefore, the concrete floor painting procedure is not just a work on refinement of the room, but a method of protecting the coating. That's just to find out how to paint the concrete floor?

Content:

Concrete floor protection

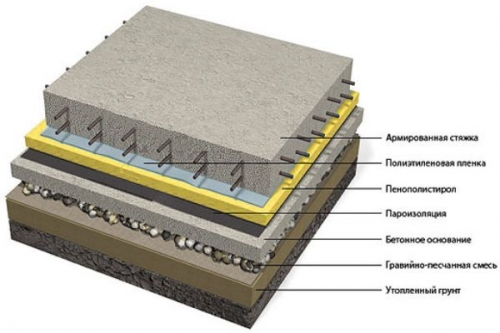

Concrete floors today are most often built in industrial or commercial buildings. But at the same time, they can be seen in home workshops, garages, cellars, outbuildings and pantries. Although concrete itself is able to withstand under adverse conditions of use of large loads, it still requires protection.

Concrete is characterized by a large porosity, a low level of tensile strength, therefore, when exposed to external factors, it wear out on its unprotected surface, peel, after which characteristic dust occurs. This happens most often in cases of use of low -quality concrete, impaired laying technology, improper mixing the mixture, and the use of poor cement.

To protect the concrete surface, it is customary to use special compounds. In addition to decorative properties, the painting of the concrete floor provides its protection against destruction, the influence of aggressive media and abrasive wear, gives additional properties such as hygiene, anti -slip, decapitability, antistatic, smoothes various defects in chips, cracks, shells and caverns.

Choosing paint for concrete

For staining the concrete floor, alkyd and epoxy paints are usually used, which differ in unique anti -slip and antistatic properties, as well as great resistance to chemicals. The epoxy must be prepared, mixed and tinted before use, alkyd should not be prepared for operation. But before working with alkyd paint, the concrete surface should be primed, epoxy paint does not require this.

In addition to paints, soil mixtures are widely used, which are designed to transform a very neglected floor. Toning impregnations give concrete a bright color coating. Polymer compositions are able to hide all defects and level the surface, the use of special putty allows any concrete coating to make monolithic. Glitter and flocks that do not burn out over time will help to ensure additional decorativeness of the floor.

When choosing which paint is better for a concrete floor, it is recommended to consider the features of the room. For example, in production places where mechanical damage or shock types of loads to the surface is often possible, the creation of high reliability is required. In this case, it is best to use wear -resistant paints.

For thin -layer civilian -purpose bulk coatings, varnish for a concrete floor or polyurethane enamel is chosen. For finishing the floor in garages and processing concrete elements of landscape design, means are used, which are designed to cover different production facilities, which are based on solvents and epoxy enamel.

To paint a concrete floor in a living room, it is necessary to take a composition with a water base. To process the surface on balconies and in corridors, it is better to buy two -component polyurethane elastomers. If the water resistance is needed, give preference to one -component polyurethane dyes. Next, consider the advantages of each type of coloring composition for the concrete floor.

Epoxy paint

Epoxy paint is a very strong and durable coating that extends the useful life of the floor and guarantees a presentable appearance. Such paint is quite resistant to external influences and various chemicals of acids, alkalis, fuel and lubricants, salts solutions, has waterproofing properties, withstands large loads and perfectly adheses concrete.

The epoxy does not abrupt and does not yellow, even if you cover the concrete floor in hangars, production workshops, car repair workshops and parking lots. You can use this paint in open areas, as it is resistant to atmospheric phenomena, and in closed rooms. Another advantage of this paint is the possibility of applying it directly to a fresh, insufficiently dried concrete.

The most important disadvantage of epoxy paint for the concrete floor is its two -component: before use it needs to be mixed. Some problems can occur with repeated staining. In addition, if you want to change the color of the concrete floor to another, it will be quite difficult to do.

Acrylic paint

Acrylic paint for a concrete surface is an aquatic composition based on acrylic resin with the addition of different polymers. Such paint prevents the destruction of concrete due to corrosion, creates a protective polymer film on the surface, which prevents various mechanical and chemical influences.

The coating, which is formed by acrylic paint, is quite reliable and durable, moisture -resistant and waterproof, so with its help you can paint the floor in the garage, basement, on the balcony and stairs.

Apply acrylic paint is simple and convenient. To do this, you can use a brush, rollers or a sprayer, and unlike epoxy paint, one layer is enough, although you can cover with two layers for more confidence. The time of complete drying is 12-14 hours.

Polyurethane enamel

Polyurethane enamels, as a rule, are two -components, however, this does not affect their high quality. They are designed to finish the concrete floor outside and indoors. The advantages of paint are in its high atmosphere, efficiency, environmental friendliness, high hiding capacity, excellent indicators of chemical and mechanical strength, and the formation of a perfectly smooth glossy surface.

Apply polyurethane enamel at a temperature of at least 5 degrees above zero and humidity of at least 75%. Since the paint is two -component, for starters, the first component is thoroughly mixed, and then the second is added to it. It is advisable to stain the concrete floor in two stages: apply a thin homogeneous layer without straits and smudges, re -paint, but no later than a day after the first color of the concrete floor.

The main drawback of polyurethane enamel for a long time drying for 2 - 14 days. We explain such a significant range of time with these points: the paint does not stick after two days and you can walk along it, the flooring after a week finally acquires mechanical resistance, and after two weeks chemical resistance.

Polyurethane primer

If you do not have paint for the concrete floor, then you can simply primer the surface with a polyurethane composition. The primer can be used as the only protective coating, as well as to process the coating before direct application of finish paint. Primer are polyurethane and epoxy.

Polyurethane primer is able to ensure reliable filling of small pores of concrete, its diluting and hardening, as well as excellent adhesive coating abilities. This substance is resistant to gasoline, detergents, chemicals, fats, oils and atmospheric precipitation.

After the name, polyurethane primer is used before staining with polyurethane enamel, because they have almost identical compositions. However, the paint can only be used 12 hours after the end of the flooring work. The advantages of this primer in the convenience and ease of application, a decrease in the consumption of the finish coating, and the improvement of adhesion of the finish layer.

Epoxy primer

Epoxy primer is suitable for processing a concrete surface before applying epoxy paint on it. But it is also customary to use this primer as an independent coating, which ensures the closure of all pores and cells in concrete, as well as diluting and strengthening the floor surface.

Advantages of epoxy primer, water resistance, waterproof, improved adhesion of the finish coating, resistance to mechanical wear and chemicals. Before applying epoxy primer, the concrete surface must be sanded and garbage and dust from it are removed. You should know that for 20-30 minutes the material is able to lose its qualities, so you need to apply it quickly enough.

Painting of a concrete floor

You have already familiarized yourself with the purpose of each composition and learned the price of paint for the concrete floor, and also found out which is better to use for the painting of a concrete floor. It doesn’t matter what you chose paint for the surface, the technology of its application is always the same. First, you need to prepare the base by cleaning from dust and pollution, then grind the surface of the concrete and packed all the irregularities, but only after that you can apply paint. Remember that concrete floors are usually customary to cover in several tricks - from 2 to 4 layers.

Surface preparation

The operational properties and durability of painted concrete floor depend primarily on the quality of surface preparation. Make sure for a start in the absence of dirt, garbage, old paint, spots of varnish and combustible materials on the floor, as well as bitumen. Traces of such fluids will be removed using detergents. Water on the concrete floor should not be collected in a drop.

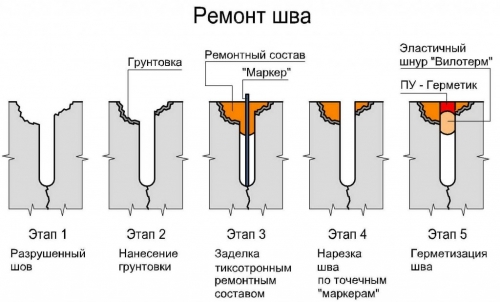

It is also necessary to remove concrete crumbs from the floor. After that, you need to close up and plunge all the existing pits, and then grind with the help of special grinding machines. Such a procedure can improve the adhesion of the paint layer and base.

To get rid of dust, you can use a vacuum cleaner or a regular mop. As practice shows, all concrete floors are equally dusted. To prevent this process, it is necessary to blame the concrete coating and process the upper layer. Disgaming is carried out using different compositions of polymers, which protect the floor not only from the presence of dust, but also from abrasive exposure and abrasion.

Strengthen the concrete surface with impregnating types, which are called tops. These substances are presented in the form of dry mixtures from quartz, cement and other fillers, as well as plasticizers and dyes. Similar toppings can also be used with decorative intentions, so that your concrete floor will become glossy and smooth.

The composition of the tops clogs the pores of the concrete floor, preventing the penetration of harmful components into the surface and ensuring the stability and strength of the concrete structure, facilitating operation, which significantly saves cash on the care of the coating. This tool is usually applied to the surface 7 days after its installation. The use of strengthening purposes will increase strength and disclose the coating by 5 years.

The primer of the concrete floor

To ensure high -quality adhesion of the concrete floor and paint, it is previously recommended to cover the surface with a primer. There are many varieties of this tool (Belyux Aqua, Grid), which can be used in air and in closed rooms. These are acrylic fast -drying materials, which are quite resistant to oils, gasoline, hydrochloric solutions, chemical detergents, mineral compositions and water.

To apply a primer, it is customary to use foam rollers, allowing to distribute the composition well on the floor surface. Apply a primer like this. The composition is mixed, if necessary, diluted up to 3% of the mass of the primer itself. It is recommended to add quartz sand to the substance to avoid the occurrence of the effect of the slippery floor - up to 10% of the mass of the primer.

The primer must be applied in 1 or 2 layers on a dry, clean coating with rollers, a spray or brush. It is recommended to use the composition at a temperature of 5 40 degrees above zero and relative humidity of 85%.

Surface painting

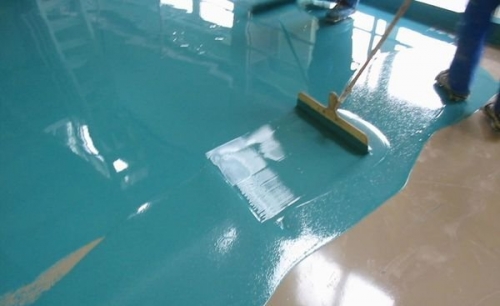

You have already decided how to paint the concrete floor, now you need to decide which tool in the work - a roller, brush or spray. The choice of staining option will depend on which the coloring composition was chosen. The paintwork is applied with a sprayer in one layer, which is able to replace 3 layers, which is applied in the usual way. Such a technique for applying paint is quite simple, economical and takes little time.

When using the sprayer, remember, with its help you can process the main part of the concrete surface, and other inaccessible places and angles will have to be painted with an ordinary painting brush. The thickness of the paint is only 0.2 millimeters.

Acrylic paints and enamels are applied to the surface of the floor with rollers. Suitable for this are wide, which have a short pile - simple facade and velor rollers that allow you to apply paint evenly and quickly. To make it convenient to work, it is worth fixing rollers on long handles. To paint the corners, use narrow small brushes.

The painting of the concrete floor is performed at a surface temperature of at least plus 5, the air temperature in the room is not less than 10 degrees above zero and humidity not more than 80%. Water polyurethane paint in the process of work does not emit flammable and smelling substances. The containers and tools fall off with water.

It is allowed to paint fresh or wet concrete, but not earlier than 5 days after pouring. When painting the concrete floor, it is first of all customary to apply strokes in different directions, then the paint is rubbed on the surface. The layers of the coloring composition should not be too thick: the thin layers dry faster and look better.

The creation of thicker layers leads to a long time of drying the coating. Make sure that the previous layer is completely dry, and only then proceed to applying the next layer of the paintwork. The application of the second layer is allowed only after 24 hours.

Drying floors

After the procedure for staining the concrete floor, it is recommended to wait for the coloring composition to completely dry. This process should occur at a moisture content of 70-80% and air temperature plus 18-20 degrees. Only after 3 days mechanical loads are allowed, but if the conditions from the presented are different, then the process of drying the concrete floor can stretch for a longer period, or occur faster.

The duration of the drying of the coating also depends on the conditions under which the paint was applied. For example, if the coloring substance was applied to fresh concrete, then the drying period will increase significantly. Under normal conditions, the polymerization of the coating finally occurs approximately on the seventh day, when the maximum indicators in mechanical and chemical stability are reached. Therefore, do not rush to use the surface as quickly as possible, let it dry completely so that it acquires proper wear resistance.

Thus, concrete paint is able to increase the strength of the coating, protect it from dust and increase the waterproofing of the screed. But all this is achieved only if the correct choice of the coloring composition is made. In addition, the sequence and competent performance of all stages of painting of the concrete floor is of great importance.

I am engaged in the cleaning. I would like it

I am engaged in cleaning. I would like to get more information. How can you call you?

good floor

good floor

http://pigment-vl.ru/catalog/

http://pigment-vl.ru/catalog/special-coatings/dcor-201/

Emal Dvor-201

Compound for concrete floors

high waterproofing property;

high mechanical and chemical resistance of gasoline, washing solutions;

Resistance to periodic effects