A rather frequent element of the attic is a triangular window. To their design ...

|

|

The use of liquid foam as a heater is distinguished by a mass of advantages ... |

With independent construction, a number of problems always arise: little time, which ... |

Best glue for tiles: features and selection criteria

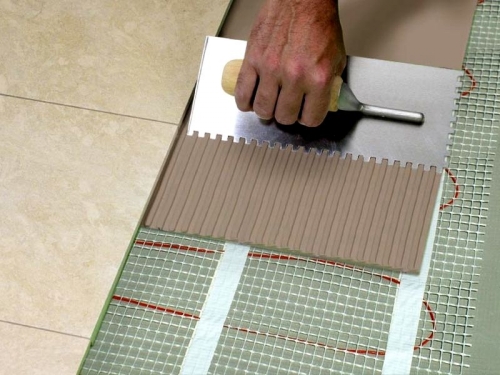

The cladding of walls and floor of porcelain, clinker, tile or ceramic tiles is one of the most complex finishing processes. Installation of tiles requires the contractor not only of accuracy and professionalism, but also the knowledge of the features of the use of various building materials, primarily tile glue.

- Basic glue requirements for tiles

- Classification of tile adhesives in composition

- Varieties of adhesive mixtures by the method of application

- Dry and ready -made mixtures: advantages and disadvantages

- Tile glue selection criteria

- Overview of glue manufacturers for tiles: characteristics and prices

Basic glue requirements for tiles

The usual concrete-sand mixture for laying tiles almost completely replaced special adhesive compounds. This is due to a number of undeniable advantages of glue for ceramic tiles:

- The concrete-sand mixture is not able to ensure the durability and reliability of the masonry.

- When performing large -scale construction, the necessary proportions of the preparation of the working solution are not always observed.

- Working with tile glue is easier than with concrete-sand mixture.

- The consumption of adhesive compounds is smaller, since even a small layer provides a sufficient coupling of materials.

- A large assortment of glue allows you to choose the optimal composition based on the type of tile, base and operating conditions of the finish.

Before you decide which glue for tiles, you need to know the basic requirements put forward in front of a high -quality adhesive composition:

- High adhesive properties. Glue should reliably hold the plates of various weights. It is desirable that the composition quickly grasps and sticks to the surfaces.

- The plasticity of the glue is responsible for ensuring that the composition does not spread along the tile and base.

- When choosing glue for floor tiles, you need to pay attention to the compositions with increased spreading. This is necessary in order for the mixture to fill all the emergencies.

- The speed of water is staining the solution. It is important that the glue does not freeze too quickly, and there was an opportunity to adjust the location of the plates.

Classification of tile adhesives in composition

Depending on the type of components of the components, tile glue is customary to be divided into such groups:

- cement -based glues;

- epoxy adhesives;

- dispersion compositions;

- polyurethane adhesives.

Cement The adhesives have an affordable cost, so they are popular among consumers. The composition of the glue includes cement, sand and polymer additives. All of the listed ingredients give the adhesive composition the necessary qualities: water resistance, plasticity, adhesion of plates with the base of the cladding and the presence of a deformation range. Before use, the solution must be diluted with water. Glue has a short period of setting, so you need to work with it quickly. The elastic characteristics of the composition depend on the type and number of polymer additives.

Epoxy adhesiverecommended for use for working with facing materials with a smooth base. This multicomponent composition includes epoxy resin in liquid form and a catalyst. Before use, you need to mix both elements, following the instructions on the package. Epoxy glue has the following advantages:

- provides a reliable coupling of materials;

- the adhesive water resistance is suitable for use in wet rooms;

- frost resistance;

- the epoxy mixture does not give shrinkage;

- glue turns into a monolithic polymer and cracks are not formed on its surface;

- porous materials when gluing are not painted.

Among the disadvantages of glue include:

- higher cost compared to cement composition;

- when working, it is important to strictly observe the proportions of mixing the components of the glue;

- in the cold, the components of glue can crystallize.

Dispersion glue It does not contain solvents, the type of composition is pasty. The dispersion glue for the tiles is reinforced, as it has increased capacities of the clutch. This quality allows you to use the composition for processing non -standard materials: drywall sheets, plastic, wooden and metal surfaces, slippery walls. The bought glue is ready for use and does not need additional preparation.

The dispersion composition is the optimal glue for external tiles, which withstands the severity of volumetric elements. Minus of such glue high cost. However, its consumption is almost half the other adhesive mixtures.

Polyurethane glue For tiles, it can be one- or two-component. The composition has the following characteristics:

- resistance to chemical compounds;

- lack of moisture absorption;

- withstands temperature fluctuations in the range from -55C to +125C;

- provides additional insulation of the base;

- lack of specific smell;

- reliable hitch of tiles with the surface of the base.

Polyurethane compounds are classified according to the method of use. Some compounds are better suited for arranging underfloor heating, while others for processing bases subjected to periodic deformation/vibration.

Varieties of adhesive mixtures by the method of application

According to international classification, glue for laying tiles is divided into 5 main categories:

- The adhesive composition for internal work belongs to the category of the most budgetary ones. Shows sufficient adhesive characteristics when fixing ceramic tiles to the bases of brick/concrete. The number of special additives is limited, so such glue is not recommended outside the room. Under the influence of high humidity and temperature changes, the operational characteristics of the glue worsen.

- Glue of increased fixation is the best glue for large tiles and natural stone. Such glue is able to withstand high tensile loads and has increased adhesion. These qualities allow the use of the mixture in conditions of non -standard temperature and dynamic influences. Before applying the glue of severe fixation, the old surface can not be cleaned (not removed the previous cladding, if it is firmly held on the basis).

- Universal type glue is most popular among tiles. Suitable for external work and decoration indoors. However, experts note that such glue may not be reliable in conditions of high humidity and temperature differences. In addition, for plates size 30*30 cm and better select another adhesive mixture.

- The moisture resistant composition is specially designed glue for the tile of the bathroom and facing the steps. The glue contains a hydrophobic modifier, which allows it to be used when laying a tile in the pool and fountains.

- The adhesive composition for attaching floor tiles has a plasticizer, which allows you to qualitatively fill the hollows and voids of the base. The ability of the glue to fuel makes it impossible to use it on vertical surfaces. According to other criteria, the glue is comparable to universal.

In addition to the listed adhesives, there are specialized compounds: heat -resistant for cladding furnaces and fireplaces, frost -resistant for external work in harsh climatic conditions

Dry and ready -made mixtures: advantages and disadvantages

You can buy glue for tiles in the finished form (in buckets) or in the form of dry composition (in bags) for cooking. What is their difference and which mixture to choose?

The basis of dry mixtures is cement. The main advantage of such glue is that it can be laid on non -aligned walls that have various curvature changes. Glue, in addition to the main purpose, acts as a leveling layer.

A significant plus of dry glue is affordable cost. With the same amount of the mixture prepared with your own hand and the glue bought, the price of the first option will be an order of magnitude lower.

To apply finished mixtures (on a polyurethane basis), a smooth base is required. However, such a composition is more durable and reliable than glue on a cement basis.

Tile glue selection criteria

In order not to make a mistake with the choice of glue, it is necessary to compare the characteristics of the adhesive, the type of facing surface and the operating conditions of the finish. Here are the main criteria for choosing tile glue:

- The operating conditions of the tile coating. For the kitchen, corridor, standard glue for tiles is a universal mixture designed to fix the plates on the walls. In the bathroom, it is necessary to use moisture -resistant glue. However, you can save and lay the cladding on universal glue, and the grout between the tiles is performed with a moisture resistant mixture.

- Type of cladding. When buying glue, it is necessary to take into account the level of the coupling of the composition with various surfaces. Dry cement mixtures are not suitable for facing a wooden base, a floor from the OSB. All types of surfaces are usually divided into simple and complex. Simple reasons include: concrete, brick, screed of cement and sand. Complex surfaces for cladding: drywall, metal, glass, plastic, as well as bases amenable to deformations or subjected to periodic vibrations. To finish simple bases, glue with a low level of adhesion up to 0.5 MPa is suitable. Fastening the plates to complex surfaces must be performed with an adhesive composition with an adhesion coefficient of at least 1 MPa.

- The weight and size of the plates. This criterion is especially relevant when choosing glue for the decoration of vertical surfaces. It is important to remember the basic rule: the larger the tiles, the greater the strength should have the adhesive composition.

Overview of glue manufacturers for tiles: characteristics and prices

The same types of glue from different manufacturers may differ in composition. When buying tile glue, it is advisable to choose goods of popular, trusted companies. The following mixtures for laying tiles have proven themselves in the construction market.

Ceresit CM-11 Dry cement mixture with additives of polymers and mineral fillers that increase adhesion. The main purpose of the installation of the elymplosive and ceramic tiles with dimensions from 50x50 mm to 400x400 mm for non -shaped bases. The cost of one bag (25 kg) is about 200 rubles. Specifications:

- glue consumption 2-7 kg/m2;

- the temperature of the base is not less than +5C;

- drying time 1 day;

- the fitness time of the cooked mixture is 60 minutes.

Ceresit CM-17 Elastic tile glue used to facing different types of surface outside and inside buildings. Application area:

- cladding of tanks and pools;

- finishing furnaces and fireplaces, provided that their surface does not heat above 80C;

- facing glazed surfaces, including without removing the old coating;

- laying tiles on the terrace, balcony, operated roof, basement, etc.;

- arrangement of heated floors.

Ceresit CM-17 is not cheap glue for tiles (price for 25 kg is about 800 rubles).

Moment Budget option for laying ceramic tiles. Designed for cladding with tiles with dimensions of not more than 30x30 mm and water heating above 3%. Suitable for cement-lime, concrete, brick and cement-sand bases.

Important! If the glue is used for facade finishes, then a special emulsion must be added to it

Clay characteristics of the moment:

- the base temperature is from +5C to +30C;

- the temperature in the room during work is about 20C, humidity is not more than 60%;

- adjustment time 10 minutes;

- the cost of glue is 125 rubles/25 kg.

Litokol Litoflex K80 Elastic highly adhesive glue with an increased period of the open layer for fixing porcelain tile. The basis of dry adhesive mixture Portland cement, inert fillers and organic additives. This is a universal glue designed for external/internal, wall/floor cladding. Suitable for fixing porcelain tiles, ceramic tiles, natural stone and clinker for stable and subject to deformation/vibrations of the base.

The consumption of glue for the tile depends on the state of the surface and is 2.5-5 kg/m2, the cost of a dry mixture (25 kg) 1700 rubles.

Keralastic (production of Italy) two -component polyurethane glue for laying stone and ceramic tiles. The composition has resistance to sliding and has a wide sphere of application:

- installation of ceramic tiles, mosaics and stone slabs over plasters, screeds, metal, PVC, wood, reinforced polyester, hyspoard, etc.; work is carried out both outside and indoors;

- laying the plates on balconies, terraces, open flat roofs;

- fixation of roofing marble, shale and composite materials subject to swelling under the influence of moisture, shifts, deformations and vibrations.

Keralastic is great for facing vertical surfaces and is able to hold large slabs. The cost of glue is 2800-3000 rubles/5kg.

Lux Plus dry adhesive composition of increased strength. Glue is used in the performance of finishing work inside and outside the room for facing the floor, walls with different materials: artificial/natural stone, mosaic, marble, transparent or thin tiles. The main purpose of laying tiles in the bathroom, saunas, baths and pools. The composition is recommended for use in places with high load loads. The price of glue (25 kg) is about 260-300 rubles.

Tiles of tile glue: video

Building store and

The store of construction and finishing materials http: // Remertvest.rf/ offers building materials wholesale and retail. Our store has a wide range of products at minimal prices, because We work directly with factories and manufacturers. We cooperate with Russian and European firms of finishing materials and have a well -established sales network, so we are always in stock building materials in bulk, and the supply of construction projects in Moscow passes as quickly as possible