If the roof roof flows, and the patching of damaged places of tangible results is not ...

|

|

The installation of the door frame is accompanied by the installation of the door on the loops. The... |

Ceramic tiles are the best option for floor decoration. The most preferable ... |

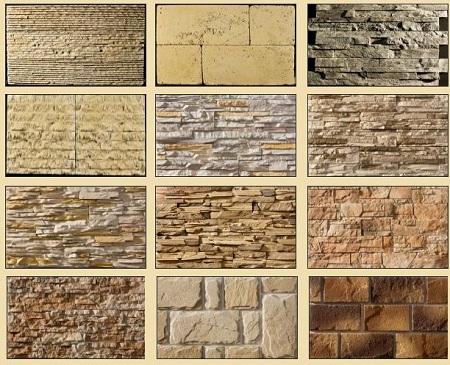

Artificial stone: for and against

Fake! Some will say about artificial stone and will be right. Yes, this finishing material is just an imitation of real natural stone, smooth and cold, but this does not force its highest characteristics at all. He is an imitation, but what! Perfectly executed, ideal, impeccable, insanely beautiful and cheap, unlike the original. Yes, the stone is artificial, but such a real, so natural and so accurately repeating color, shape and structure of natural stone that only a specialist can distinguish from one another. In this article, we will consider all the pros and cons of artificial stone, the technology of its production, as well as the types of this finishing material.

Content:

- Varieties of artificial stone

- Characteristics of artificial stone

- Artificial stone manufacturing technology

- The advantages of artificial stone

- Disadvantages of artificial stone

- What else are manufacturers offer

Varieties of artificial stone

Artificial stone can be made of synthetic stone products based on fillers from natural stone crumbs and polyester resins, clay and mineral additives (porcelain tiles), as well as from colored concrete. The first option, called agglomerate, is mainly used for facing furniture and interior items (countertops, window sills, bar racks, shells, etc.), the second and third to decorate the internal and external elements of buildings and structures. Thus, there are only three types of artificial stone, which differ from each other in their composition, the method of production and the scope of application.

An artificial decorative stone can be made of gray or white cement, sand, natural gravel or covered stone with the addition of coloring mineral -based pigments, allowing to achieve maximum similarity with natural stone. To increase the strength and bearing characteristics of the material, fibrous reinforcement is very often used. This is a special additive made of fiberglass, synthetic fibers or steel, which turns artificial stone into a kind of metal.

Artificial stone for interior decoration and for external works on buildings can imitate a variety of breeds of its natural brother: malachite, granite, onyx, marble, jasper, sandstone, etc. However, all these types can be divided into three groups, depending on the appearance, composition and area of \u200b\u200bapplication.

Porcelain tile

These artificial products are produced by vibration pressing under very large pressure. At the end of the press, the material is subjected to firing, which fixes the effect. The composition of porcelain tile includes field sparks, several varieties of clay, various mineral additives and coloring pigments.

In its appearance, ceramic tiles or glass resembles ceramic tiles, but not a stone. It is very durable and resistant to various influences and temperature changes. However, it may not withstand the invasion of smelter, which easily comes into contact with the glass.

The texture of porcelain tiles can have a variety of incarnations: it can be glossy, matte, and glazed, and embossed.

Agglomerates

The agglomerates include materials that contain polyester resin and various fillers, such as limestone, marble baby, granite. Aglomerates have a huge variety of colors and can imitate a variety of breeds of natural stones. This finishing material has high compression and bending strength, and is also able to withstand very severe frosts.

The disadvantages of the agglomerates include their photophobias, instability to abrasion and the effects of certain chemicals, as well as the inability to use them as a flooring in the installation of warm floors. In the latter case, products subjected to heating from the heating system are simply deformed and will not be suitable for further use.

The strength characteristics of the agglomerates depend on the filler. So, if quartzites are included in the composition of artificial stone, then such a product in its strength will practically not concern to porcelain tutorials.

The main scope of agglomerates is cladding furniture and interior items. The countertops, window sills, bar, trimmed with such material look as if they are cut out of a whole piece of stone, and stone crumbs that make up their composition only enhances this impression.

Artificial stone from colored concrete

The composition of such a stone includes Portland cement, sand, fillers of crumbs, expanded clay, pumhes, plasticizers, coloring pigments, reinforcing additives and hydrophobizing substances. The scope of such a man -made stone is quite large, because it can be used both for interior decoration and external.

There are few types of artificial stone, but enough to turn the interior of the house or the territory adjacent to it into a real masterpiece.

Characteristics of artificial stone

- The structuralness and integrity of the product made of artificial stone look as if they are cut out of a solid piece of stone, and their structure does not change its properties throughout the depth of the material.

- High strength tests showed that in a number of mechanical properties, artificial analogues of natural stone in its strength are practically in no way inferior to steel or iron.

- The moisture resistance of artificial stone products does not absorb moisture at all and in no way react to a change in humidity, so a fungus or mold will never start on their surface.

- Chemical resistance with artificial stone can be used even on the facades and basement floors of city buildings, which are often subjected to aggressive attack of heavy chemistry, which then talk about ordinary kitchen or garage.

- The durability of artificial stone products are not subject to erosion, as is the case with a natural counterpart, they are not afraid of wind and water, which means they will serve almost forever.

- Fire safety man -made stone is not a grief and has low thermal conductivity, which opens up wide opportunities for creative ideas. They can be faced not only with walls, but also for fireplaces, furnaces, fireproof zones, etc.

- Exceptional maintainability even if artificial stone received any damage up to the split, it can always be returned to its original appearance.

- The beauty of man -made stone products are insanely beautiful and attractive. It is difficult to achieve such a survey with natural analogues, because each stone is individual in its own way, and artificial options can be combined in the way as necessary.

Brief technology for manufacturing artificial stone

Artificial stone is made using special technology using polyurethane or plastic shapes. First, resin and filler (cement and filler) are mixed in the vacuum mixer, then this mixture is poured into forms for artificial stone, and when the composition is completely grasped and cooled, the products can be easily removed. To see this process with your own eyes, you can watch a small video video, which clearly shows how an artificial stone can be made at home.

Forms, by the way, can have a variety of sizes and drawings, which allows you to create interesting and unusual compositions: it can be a shape in the form of a sea bottom with shells, pearls and shells, a shape in the form of old blocks, from which fortresses or a round shape were built in the form wood saw. In general, the fantasy of the manufacturer is endless here and the more it manifests itself, the more income it can bring to its master.

The advantages of artificial stone

The advantages of artificial stone include:

- Easy processing

- The convenience of its transportation

- The smaller weight of products compared to natural analogues

An artificial stone is attached to a special glue or ordinary cement mortar, and in the case of cracks or chips, all these shortcomings are quickly leveled by the same solution or a small piece of material glued to the place of damage. Any special care of the surface of artificial stone is not required, however, it may be necessary to process it with a water-repellent composition if a stone that is not very suitable for use on the street is in prolonged contact with water.

Many manufacturers of artificial stone create entire collections that allow you to implement the most daring ideas and fantasies. The variety of shapes, colors and textures makes it possible to finish not only walls and floors with man -made stone, but also door and window openings, gables, corners and other elements of the design of buildings and structures.

But that's not all! An artificial stone, the price of which is much lower than for natural, allows you to use it in much larger areas, because the cost of buying material and its installation will be incommensurably lower than similar actions, but taken to natural stone.

Disadvantages of artificial stone

In fact, the disadvantages of artificial stone can hardly be called disadvantages, because it is only in some parameters inferior to its natural analogue. Man -made stone samples are less durable and resistant to abrasion, but this remark does not apply to all species, but only to the agglomerates. In addition, some types of artificial stones do not like the sun, chemicals and high or low temperatures, and individual models are also susceptible to moisture, therefore they require additional protection by processing with special hydrophobic compounds.

What else do manufacturers offer?

Manufacturers are constantly in search and are looking for new materials that can help designers and architects in the implementation of their ideas. It was in this search that the formula of the unique acrylic stone Staron was found, which is distinguished by unsurpassed hardness and strength.

This environmentally friendly, practical and trendy material created the latest standard in interior decoration. The stone is perfectly smooth, without the slightest hint of bumps or cracks, it is pleasant to the touch and looks like a product of mineral origin. But the most important thing is Staron Artificial Stone, which allows you to perform architectural and decorative objects of any size without seams from it. Thanks to seamless gluing technology, the material is easily restored and quickly brought into a state of ideal.

The progress will not stop there, be sure! There are new, even more advanced, formulas that will make it possible to improve the characteristics of artificial stone to the level of natural, and even to some extent surpass it.

Something in this article

Something in this article is a lot of advertising of industries and Beliberda. Strange, on the one hand, no one is specifically advertised, except for a particular manufacturer of acrylic stone and one seller of forms ... And this is not clear, the article itself is boring and not true, the theme of artificial stone is not disclosed at all. To make an article for the sake of clumsy advertising of two different companies is also strange ... It is clear if for the sake of one ... in general the article is strange

Don't know. I turned to the company

Don't know. I turned to the company Litka and they made me a countertop from onyx. Pretty quickly and efficiently manufactured. It’s not for a month now, but I have not found any serious defects. I leave the site if anyone is interested - http://litkam.ru/