The scope of the polyurethane foam is quite wide, but most often it is used in ...

|

|

Are you going to build a house, or did you start a large -scale repair? We decided to ennoble ... |

Laying tiles ends with grouting seams that have an attractive appearance and ... |

Veka plastic windows - features, characteristics, instructions, reviews

When purchasing plastic windows, first of all, you need to pay attention to their quality. After all, this is a purchase that will serve as a reliable protection from cold and noise for a long time, which means that the choice should be approached with all responsibility. For several years now, a company for the production of window systems from PVC VEKA has been in the Russian market. In the article, we consider the main advantage of this manufacturer over many others.

Content:

- About Veka

- Assortment of Veka plastic windows with photo

- Veka plastic windows design elements

- PVC profile for VEKA windows: characteristics and production

- Types of mechanisms for opening window systems

- Plastic windows

About Veka

- In the late 60s of the 20th century, Henry Laumann, one of the co-founders of Vekaplast engaged in the production of blinds, decided to radically change the main direction and opened the line for the manufacture of window systems. The purpose of the entrepreneur was to achieve the excellent quality of his products and enter the world market.

- And today, the German company Veka occupies a leading position in the field of production and development of high -quality window profiles. The main enterprise is located in the city of Zendenhorst (North Rhine-Westphalia). Products are supplied to many countries around the world.

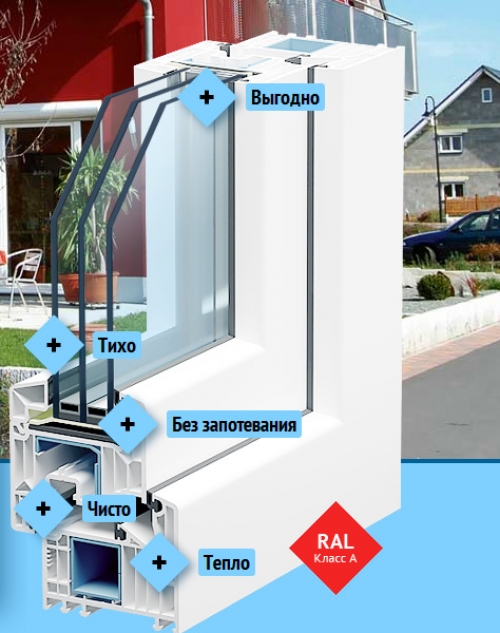

- All goods manufactured by the company comply with one of the most authoritative standards for today RAL (state committee on supply conditions). This is an independent quality assessment, which has the most stringent standards, especially toughened requirements, are imposed on the safety of window systems. RAL is not an easy quality mark, it is really proven and reliable products, which is confirmed by numerous positive reviews about Veka plastic windows.

- The network of subsidiaries of the company is widely spread throughout the continents. In 1999, the company of the century first appeared in Russia, opening its own plant for the production of window profiles and related accessories. All manufactured products have a quality mark. The important advantage of the windows made of Veka profiles is that they can be installed in houses located in the most severe climatic zones, as well as in regions with high humidity.

Assortment of Veka plastic windows with photo

The company's products are the widest assortment of specialized systems, double -glazed windows and special accessories that can solve almost any architectural problems and satisfy the needs of even the most demanding customers.

Profiled systems are presented in seven main modifications, distinguishable in the installation depth (profile width) and the number of cameras (from 3 to 6). Windows made using such profiles correspond according to the quality standard class A.

Veka Alphaline/Alfaline

Specifications:

- profile width - 9 cm;

- the width of the double -glazed window is 24-50 ml;

- the thickness of the outer wall is 3 ml;

- noise insulation class from II to IV;

- the coefficient of heat treatment is 0.94 m2S/W;

- design: folding, rotary, rotary-oxidal, sliding and strap;

- glass: ordinary, with increased characteristics of energy conservation, special and soundproofing.

This is the first window system where a six -chamber Veka profile for plastic windows is implemented, the main advantage of which is that it provides the maximum energy saving indicator.

- To improve indicators such as thermal insulation, schpip absorption and tightness, there is a three -circuit sealing system for the continuous seal in the frame and sash. The seal can have several colors gray, black and caramel and is made of silicone, thermo-elastoplast or ethylene-protopylene rubber.

- The double -glazed window is installed to a depth of 2 cm. Thanks to an increased external radius, the profile has reliable reinforcement and attractive appearance. Furniture is fixed through several walls, which ensures maximum reliability and durability. It is also possible to install components in a steel amplifier.

- Decorative crossbars, which give the glass packet the uniqueness are produced 6.5 cm or 20 cm wide and have several installation options: are glued on top of the double -glazed window, divide the double -glazed window or installed inside. In addition, there is the possibility of lamination of window glass in various color shades (up to 40 colors), both on the one hand and simultaneously on two sides.

- The windows of this configuration are recommended to be installed in office rooms, where maximum quality and reliability are required.

- This is the most reliable, but also the most expensive window profile. On average, the price of VEKA windows is alphalaine above its analogues by 10-20%.

Veka Euroline/Euroline

Specifications:

- profile width 5.8 cm;

- the width of the double-glazed window is 14-32 ml;

- the thickness of the outer wall is 3 ml;

- profile height 11.3 cm;

- noise insulation class from II to IV;

- the coefficient of heat treatment is 0.64 m2S/W;

- design: deaf, folding, rotary, rotary-oatmeal, sliding and strap;

- window systems: standard, with high heat or sound insulation, with an improved security system and balcony.

A three -chamber profile system with good insulating qualities.

- The Profile of VEKA plastic windows Euroline is made of high-quality smooth plastic, which is resistant to aggressive medium and does not require any special care.

- The design implies the presence of reinforcing amplifiers around the perimeter of the entire profile. The seal is made by a continuous contour in the wings and frame, it can be gray or black. The double -glazed window is installed to a depth of 1.8 cm. The wings can have several design options: displaced and half -interfered. Decorative crossbars are installed inside or over the double -glazed window and have a width of 4, 6, 8 or 11 cm.

Veka Proline

Specifications:

- profile width 7 cm;

- the width of the double -glazed window is 32 ml and 42 ml;

- profile height 11 cm;

- the thickness of the outer wall is 3 ml;

- noise insulation class from II to IV;

- the coefficient of heat treatment is 0.75 m2S/W;

- design: folding, rotary, rotary-oxidal, sliding and strap;

- window systems: standard, with high heat or sound insulation, with an improved security system, balcony and facade.

Windows with a four-chamber profile system that provides increased heat and sound insulation properties.

- The profile of high -quality plastic is resistant to environmental effects and, having reliable reinforcement.

- The seal is made in black and can be made of silicone, thermolastoplast or ethylene-protopylene rubber. The depth of installation of a double -glazed window up to 2 cm. The supply kit includes: expanders, connectors, decorative, enhancing and connecting profiles.

Veka Softline/Softline

Specifications:

- profile width 7 cm;

- the width of the double-glazed window is 14-42 ml;

- the thickness of the outer wall is 3 ml;

- noise insulation class from II to IV;

- heat supply coefficient 0.78 m2S/W;

- design: deaf, folding, rotary, rotary-oatmeal, sliding and strap;

- window shape: rectangular, square, triangular, arched, round or trapezoidal;

- window systems: standard, with high heat or sound insulation, with an improved security system, balcony and facade.

A profile system with five cameras and an elegant contour has various designs of the execution of the wings: displaced, half -interfered and combined.

- The profile is made of high -quality polyvinyl chloride. The double -glazed window has a sound insulation level up to 44 dB. Windows are able to withstand wind and thermal loads, as well as not change their high insulating qualities in any weather phenomena.

- The presence of a double -circuit seal of APTK or Tre, gray or black, provides a reliable density of the narthex. The double -glazed window is installed to a depth of 2 cm. The loops and accessories are fixed into reinforcing amplifiers from galvanized steel.

Veka Softline 82/Softline 82

Specifications:

- profile width 8.2 cm;

- the width of the double-glazed window is 24-52 ml;

- the thickness of the outer wall is 3 ml;

- noise insulation class from II to IV;

- heat treatment coefficient of 1.0 m2S/W;

- design: folding, rotary, rotary-oxidal, sliding and strap;

- window systems: standard, with high heat or sound insulation, with an improved security system, balcony and facade.

Innovative development, with a fairly large width of the profile, which allows for reliable heat and sound protection.

- The sash are performed in several versions: displaced, combined and half -interfered. A three -circuit seal is installed, made in gray.

- In the profile and imposal, a reinforced amplifier with a closed cross section is used, which provides additional strength and reliability, as well as the best heat resistance. To minimize heat loss and prevent the formation of condensate on the double -glazed window, the height of the fold to 2.5 cm is increased.

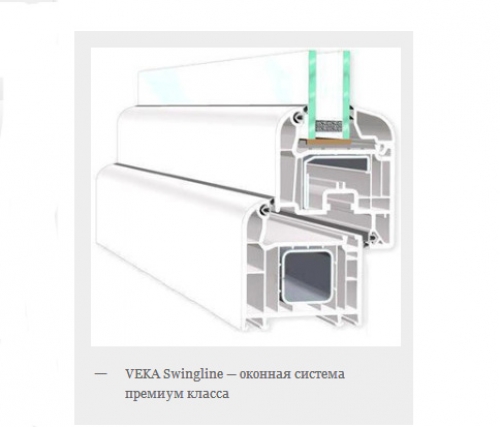

Veka Swingline

Specifications:

- profile width 7 cm;

- the width of the double -glazed window 32 ml, 40 ml;

- the thickness of the outer wall is 3 ml;

- noise insulation class from II to IV;

- heat treatment coefficient 0.77 m2S/W;

- design: folding, rotary, rotary-oxidal, sliding and strap;

- window systems: standard, with high heat or sound insulation, with an improved security system, balcony and facade.

A multi -chamber profiled system with a rounded external contour. The sash can be made in a displaced and half -mixed version.

- Between the double-glazed window and the fold there is a whole circuit of the seal made of silicone or ethylene-propylene rubber, black or gray

- The double -glazed window is installed to a depth of 2 cm. Decorative rails can be installed both inside the double -glazed window, and divide it and have a width of 5, 6, 7.5, 8.5, 10 and 11 cm. It is possible to install additional anti -ibal mechanisms.

Veka Topline/Toplaine

Specifications:

- profile width 7 cm;

- the width of the double -glazed window 32 ml, 42 ml;

- the thickness of the outer wall is 3 ml;

- noise insulation class from II to IV;

- heat treatment coefficient of 1.1 m2S/W;

- design: folding, rotary, rotary-oxidal, sliding and strap;

- window systems: standard, with high heat or sound insulation, with an improved security system, balcony and facade.

Standard five -quality window profile, having an increased heat insulation indicator.

- A comprehensive system that has 4 variants of frames distinguished in the installation height and 8 cavities with Europe, various widths (7, 8 and 10 cm).

- The frame seal is installed by a continuous contour due to the connection of imposts in a special way.

- The profile has rounded edges due to the installation of additional imposts.

Veka plastic windows design elements

As a rule, the design of plastic windows is almost identical and contains a number of the same elements.

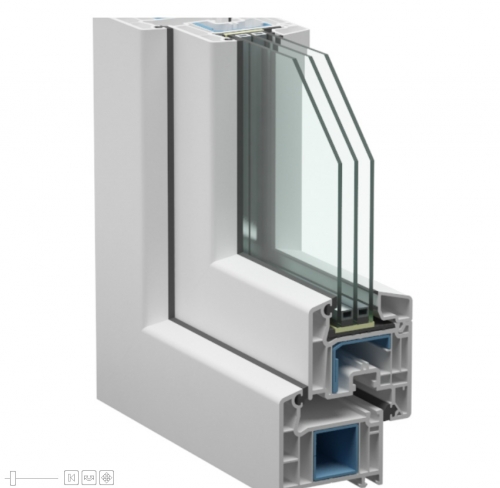

- Frame(otherwise called the profile) consists of a multi-chamber PVC profile, which is reinforced on the inside with a galvanized steel. In this case, the inside can have a different shape (P-shaped or closed rectangular). Between themselves, reinforcing and plastic profiles are connected by self -tapping screws. The frame is necessary to give the entire window design of stiffness and strength, so it should be made as high quality as possible.

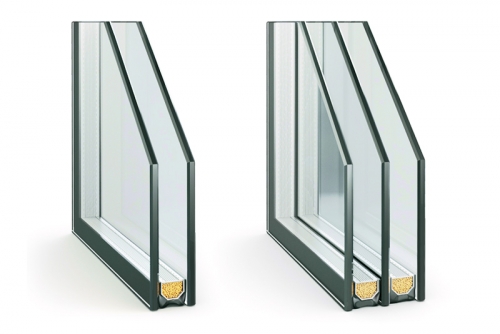

- Double -glazed windowThis is the main and largest part of the window. It consists of 2 or more glasses separated by a special frame, and among themselves interconnected by sealant. Between the glasses there is a gap filled with air or gas and each such gap is called a camera. For example, a biparting double -glazed window involves 3 glass and 2 airspace. Wheel-glazed windows can have a different width (from 14 mm to 52 mm), depending on this they have a different formula, so a single-chamber double-glazed window with a 24 mm wide assumes the presence of 2 glasses with a width of 4 mm and airspace between them in 16 mm.

- SashThis is the opening part of the window, in its design it is made in the same way as the frame.

- Rubberveka plastic windows Provide a reliable connection of structural elements and their sealing. In the Veka profiled system, the seal is installed with a special angle of inclination, at which it is practically not visible, in addition, seals of three different colors were developed: black, gray and caramel. The contour of the seal is performed without joints, due to the special geometry of the profile, due to this design, blown areas are excluded. The seal made of rubber, as it is able to withstand sharp fluctuations in temperature or is in an aggressive environment without losses of its main qualities, has proven itself.

- Furniture Under this concept, many elements of the window structure are combined. It can be mobile or deaf. As a rule, it is made of metal or plastic. Its main purpose is the connection of structural parts among themselves, as well as the opening and closing of windows. It:

- loops;

- pens;

- locks;

- covers and plugs.

- StapikThe necessary element for fixing the double -glazed window is made of plastic and has a different width. The achievement of VEKA is that this element is slightly higher than the plane of the sash, due to this innovation it was possible to minimize the accumulation of dust at the sash.

- FalzThe element on which the double -glazed window is installed. In Veka windows, it has a direct view and is placed horizontally, that is, thereby decreases the pressure of the window glass on the profile, which means that the possibility of its deformation decreases.

- ImpostFixed PVC profile, designed to connect several wings into a single design.

- StulpPVC profile, fixed on one of the wings, moves with it at the time of opening, and in a closed form serves as a connecting element.

PVC profile for VEKA windows: characteristics and production

- Polyvinyl chloride is an artificial material obtained by polymerization of vinyl chloride. Its main advantage in good refractory, high chemical resistance and low thermal conductivity.

- To obtain a window profile from PVC, softened mass is passed through a hole with the required cross section (extrusion method). The resulting substance enters the vacuum chamber, where its initial cooling occurs. Then the profile is finally cooled, marked and wrapped in a protective film.

- Veka multi -chamber profiled systems have a special appearance matte surface with a glossy gloss effect. In such plastic, small defects that are inevitable during operation are almost invisible, while it always looks spectacular and beautiful.

- At the last stage of production, profiled tapes are cut into the necessary sizes. Veka is very strictly related to the quality of its products, so quality control is carried out at each stage. So, if you do not withstand a certain temperature, then the profile can bend at the stage of extrusion.

- To verify the correspondence of products to standards, samples of finished products are sent to the laboratory, where they are checked for deformation at elevated temperature, as well as for strength from mechanical exposure. Also, the quality of welds in the corner joint is also checked. And only after that the products go on sale.

- Veka plastic profile has internal reinforcement by galvanized steel, most often a square shape. Due to this cross -section, it is possible to achieve maximum strength, and exclude the deformation of the window or sagging of the wings during the operation of the deformation of the window.

- Also, additional partitions are installed in the wings, which reliably hold the accessories (locking elements) and provide a long service life.

Types of mechanisms for opening window systems

Modern Veka plastic windows have a variety of designs that differ in shape and in opening/closing methods.

Deaf sash

- With this design, there is no way to open the window. This is the simplest and most inexpensive version of the window system. They are installed in combination with swing shutters, or separately, in cases where the premises (semi -basement rooms, warehouses, and so on) are not required. The windows themselves can have a different shape round, square, rectangular, in the form of an arch and others.

- Conditionally unprotected windows are indicated by two crossing lines (cross) or Latin letter F. The advantage of such windows is that there is no need for a large number of partitions, which means that the light -transmitted ability increases, the minus is that it is impossible to wash them from the inside (if they are impossible Not installed in conjunction with swing sashes).

Turning mechanism

- They can be opened in one specific direction to the right or left. The advantage of such a system is at a lower cost of accessories. The disadvantages include the fact that with this design, the sash has fewer cloth points with the frame, so over time can appear gaps, and hence drafts.

Folding mechanism

- The folding structure opens only on top. As a rule, such windows are installed in small rooms, where it is almost impossible to implement a rotary system (for example, on stairwells).

The rotary-oatmeal mechanism

- This design combines the rotary and folding systems, that is, the windows can open both to the right or left and from above. This is the most common type of window systems, different types of opening are implemented due to the established fittings. In addition to a simple folding option, there are micro -profile systems when a very small gap forms, which is enough to ventilate the room in the winter. Windows with such a system are a little more expensive than everyone else, but due to comfort and functionality are considered the most popular.

Sliding wings

- Such a window system provides for the extension of the wings in one of the sides along the special guides. Most often, the sliding structure is installed on balconies and loggias, where there is a small space or on glazed terraces, where it is necessary to limit the weight of the window structure. The lack of such windows in a low indicator of heat and sound insulation.

Piles

- The design involves the opening of two neighboring wings, while between nude there will be a vertical partition, that is, the stiletor is connected to one of the wings and opens with it. In such a window system, one of the wings has a rotary or rotary-oatmeal opening, and the second simply has hinges, but without opening an active sash, it is impossible to open a passive.

Plastic windows

In order for the windows to be reliably protected from adverse weather phenomena, and also performed their direct functionality, it is necessary to correctly install Veka plastic windows and properly care for them. Installation work is recommended to provide professionals so that the shortcomings during installation do not cross out all the advantages of high -quality profiles.

Care is the following simple actions.

- When washing glasses, frames, a window sill or wings, detergents should not be used, which include solid particles or chemical solvents, such as acetone. A simple soap solution or special products for PVC products and wipers is recommended.

- Do not allow the effects of heavy objects on profiles and glazing, as this can easily damage them.

- Do not touch the plastic surfaces of window systems with hot objects, do not put irons, hot pots, curves and so on.

- Vit the room to prevent fogging of double -glazed windows.

- At least once a year, lubricate the moving parts with machine oil, and the seals with the composition in which there is silicone, this procedure will extend the service life of the accessories.

When choosing and installing Veka windows, we should not forget that the quality of the entire window depends not only on the profile and glazing, but also the attached accessories. Different firms offer accessories produced in China or Turkey, but German accessories have been best established, so it should be preferred. In addition, it is very important at the initial stage to properly adjust the Veka plastic windows so that for many years they delight their owners.