Due to its environmental friendliness, practicality and external attractiveness, finishing ...

|

|

The basement is an additional room, the construction of which is always justified ... |

A lot of requirements are presented to modern flooring, among them are such ... |

DIY handrail

In projects of modern country houses, intricate stairs and decorative parapets are often used. The manufacture of the enclosing structure is not an easy task that requires certain skills from the contractor and the availability of construction tools.

The article describes the technology of creating a wooden and metal handrails, as well as recommendations for choosing a material for the manufacture of railings.

- Stage Fences Requirements

- Design elements of the parapet

- Varieties of handrails for the stairs

- DIY handrail made from wood

- How to make a railing for a stairs made of metal

- Independent installation of a handrail in the bathroom

Stage Fences Requirements

The main function of the parapet safety of the stairs. Moreover, the structural elements are an excellent decorative element that decorates the interior or exterior of the house. The railing and handrails must be made in compliance with the norms of SNiP:

- In residential buildings, the minimum fencing height is 90 cm. For high structures, it is recommended to install a parapet of at least 110 cm.

- In public institutions and in the house where young children live, enclosing structures are mounted at least 120 cm high. An important condition for safe railings, in this case, is the absence of horizontal crossbars through which children could rise.

- The handrails should not be too wide to ensure a convenient capture when walking. Recommended thickness about 6-8 cm.

- On the handrail, the presence of burrs, sharp edges is unacceptable. At the same time, it is recommended to use not too sliding materials for the manufacture of a handrail.

- The number of parapets and the railing depends on the width of the stairwell. On a narrow staircase adjacent to the wall, it is permissible to place one fence. On a wide staircase, it is recommended to place two parapets.

- When installing a stairs in a house where there are children, it is better to mount an additional low handrail, for which the child will be conveniently held.

- The optimal span between balusters is 15-20 cm.

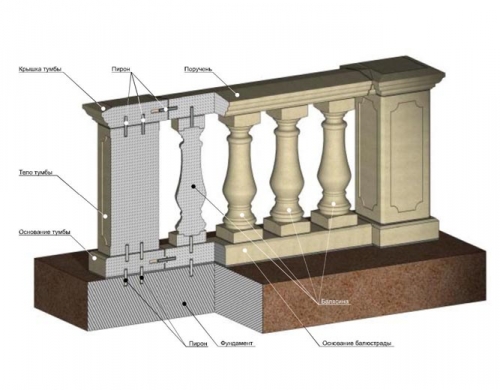

Design elements of the parapet

Any parapet equipped in a house or on the porch consists of the following structural elements.

Racks (balusters)The main node of the railing, which takes most of the load when supported. Racks are fixed to aunt or steps. Balyasins are placed on the stairs after a certain distance.

Handrails The upper bar located above the balusters. It is on the handrail that the hand falls when moving on the stairs. This element should be resistant to abrasion. Therefore, in the manufacture of a handrail for the stairs with your own hands, you must carefully consider the choice of material. It is not advisable to use spruce, fir and larch during operation, gaps and acute detachments may appear. It is also advisable to refuse pine, poplars, aspen and linden, since these breeds are very soft and abrupt quickly. Birch is not suitable when arranging a stairs in a wet room can bend under the influence of moisture.

Tumbling A powerful stand installed at the base of the stairs. The ends of the handrails are attached to the cabinet.

To give the design of attractiveness, the artistic content is often used, these are elements located between the racks.

Important! There are also wall variants of the railing, fixed directly on the wall. This design does not provide for the use of balusters and cabinets.

Varieties of handrails for the stairs

Before proceeding with the creation of a handrail and railing, you need to choose the most suitable option. All types of parapet can be classified according to the following criteria:

- manufacturing material;

- method of fastening;

- form.

Most often, the following materials are used for the manufacture of the railing:

- wood;

- metal (forged iron, aluminum, nickelled or chrome pipes);

- plastic and glass;

- concrete.

Traditional material tree. Great for arranging the staircase inside the house. The wood has a unique texture and fills the room with comfort and warmth. The material is easy to process, so making wooden handrails for the railing with your own hands can not even a professional. The additional advantages include:

- high design strength with proper calculation and installation;

- the environmental friendliness of the natural tree does not have a harmful effect on the human body;

- comfort and safety.

Important! Unlike metal, the tree does not inflame in the sun, and in frosty weather you can not stick to it. This moment is especially relevant for families with children.

Metal handrails and railing are no less popular, characterized by increased reliability and strength. Such products look good both individually and in combination with other materials (wood, concrete). Optimally suitable for arranging street fences.

Important! For the manufacture of a street handrail, only stainless metal should be used, this will eliminate the possibility of corrosion destruction and protect the original type of structure.

Among the metal handrails, forged railing for stairs are considered the most valuable and beautiful. They give the interior and exterior of the solidity and status building. A staircase with forging elements will become a decoration of any facade of the house. The only minus forging is the complexity of manufacture. It is unlikely that a masterpiece will be able to create a masterpiece on your own, and the finished product will cost expensive.

Today, PVC parapets began to be used more and more often. Such material is represented by a wide selection of textures and has an affordable cost. The advantages of plastic fences include:

- increased wear resistance, the service life is calculated by dozens, provided that the quality of the material is used;

- the ease of installation is suitable for independent manufacture and installation of handrails; polyvinyl chloride is easily bending and processed;

- a large assortment of colors and textures allows you to realize bold design ideas in the design of the exterior of the building.

Important! Given the chemical component of the material, PVC is not recommended to be used to create handrails indoors.

When designing a suburban cottage, concrete fences are often used. Durability, strength and capitalism, combined with a respectable appearance, emphasize the status of the owner of the house. Plasticity of concrete allows you to experiment and create different forms. However, working with such material, compared with wood and plastic, is more difficult. The technology for creating a concrete parapet requires certain knowledge and skills.

DIY railing and handrails for porch: video

DIY handrail made from wood

Let us consider in detail an example of creating a wooden handrail from boards. The following tools will be needed for work:

- flat grinding machine;

- a grinder and a milling machine with a nozzle for cutting a plane in the form of a semicircle;

- jigsaw;

- screwdriver;

- end saw;

- clamps;

- narrow brush;

- construction knife;

- calipers;

- a square/ruler and a simple pencil.

The necessary materials for creating a handrail with your own hands:

- wooden boards with a thickness of 2.5-4 mm, optimally 3.5 mm; It is better to give preference to oak or ash;

- wooden bars with a cross section of 20*20 mm;

- sandpaper;

- self -tapping screws for working on a wooden length of 110 mm;

- pVA glue with a large content of adhesive substances;

- painting tape;

- paper.

The technology consists in the sequential gluing of wooden boards. The number of layers will be 12. Given the fact that boards are used 4.2 cm wide and 3.5 mm thick, the finished product will have dimensions about 42*42 mm. If you need to make a larger handrail, then proportionally you should increase the width of the board and the number of layers.

Work order:

- It is enough to clean the boards on both sides with a grinder with a grinding nozzle, it is enough to remove the hillocks, the hollows should not be wiped.

- Prepare the starting black base from plywood. At the entire contour, attach the plywood strip 42 mm wide. The base should repeat all the turns and plane of the stairs. On top of the plywood, fix the newspaper paper using a painting tape. The paper is necessary so that the boards do not stick to the black base, since the plywood will be removed.

- Put the first layer of boards on the plywood, grab with clabels. The action must be repeated until the entire contour of the stairs is covered with boards. The boards should fit tightly with each other.

- Cut boards for the second layer. The size of the boards is selected, so that the boards of the upper layer are overlapped by the bottom of the lower at least 5 cm. At the end of the trim, proceed to gluing.

- PVA with a high content of binders dries very quickly, so you need to work quickly. Apply a layer of glue at once on two surfaces with a brush.

- Supremely combined and fixed with clabels. Additional fastening is provided using two bars twisted by self -tapping screws.

- The boards are compressed until glue comes out of the docking seam.

- Leave each layer for drying for at least 12 hours. After grasping the excess, cut the boards with a milling cutter, and polish the joints of the boards.

- Each subsequent layer is performed by analogy. As the work is performed, it is necessary to control the thickness and width of the handrail with a caliper. Bugrs must be polished.

Important! Each layer of wooden boards must be treated with a milling machine. As a template, a starting layer of plywood and lower cut boards.

The finish stage is processing a handrail on both sides with a milling machine with a nozzle for rounding. After that, the product will acquire a round section. Upon completion, the plywood must be removed, and the finished handrail is fixed.

Cosmetic works include:

- the putty on wood is selected to the tone of wood;

- grinding with sandpaper;

- painting and opening with varnish.

How to make a railing for a stairs made of metal

You can make simple railing for a country staircase from a metal profile. The following tools and materials will be needed:

- welding machine;

- electrodes;

- protective mask and suit;

- corner grinder, circles for polishing and cutting metal;

- level;

- metal distribution and metal profile.

The algorithm of actions:

- Determine the height of the railing and location of balusters.

- Calculate the height of the fence. The recommended value of 95 cm. However, it must be taken into account that the railing frame is located above the steps at a distance of 10 cm, and the thickness of the handrail will be 5 cm. Therefore, the size of the balusters will be: 95 10 5 \u003d 80 cm.

- Cross the metal profile for balusters and cabinets.

- Prepare the upper and lower profiles on which balusters will be installed.

- Put the frame from the profile segments and grab them with welding. Procate balusters to profiles.

- Check the evenness of the parapet and compliance with the necessary dimensions. If there are no distortions, then perform the finish welding.

- To the lower profile, weld metal racks with plates, poles length 10 cm.

- Make holes in the plates and fix the railing on the steps.

How to make handrails for the stairs with your own hands from metal. Specialists' tips: video.

Independent installation of a handrail in the bathroom

It is not appropriate to make a handrail of a bathroom on your own. In any plumbing store there are a lot of them and at a reasonable price. The main thing is to make the right choice and perform competent installation. When buying this device, it is necessary to take into account the following selection criteria.

Type of handrail. It is important to pay attention to the dimensions of the device and the degree of transformation. The use of a small handle may not be very convenient. It is better to give preference to curved or angular handrails that are operated during sunset or exit the bathroom.

Place and method of installation. If there are several screwing screws on the handle on the handle, then such a handrail is mounted on board the bath. If there is a rectangular or round flange, then the device is installed on the wall.

Important! Fasteners should be delivered with the handle, otherwise it will be difficult to choose them separately in the store.

Material of manufacturing a handrail. As a rule, the bathroom handles are made of metal or polyurethane. Products made of stainless polished steel will last the longest.

Cut the handle into the board of the bath even before the installation of plumbing. Complexation sequence:

- Apply marking under the holes from the enamel side of the bath.

- Drill holes. In order not to damage the enamel, drilling must be performed at low speeds.

- To process holes with enamel or primer, this will protect the bath from premature corrosion.

- From the outer side of the bath, install the screws, put on silicone or rubber seals on them.

- Apply and fasten the handrail for the bath.

To install the wall handrail, you will have to drill tiles. This can be done with a perforator or drill by turning off the option of a blow. You must insert a plastic plug into the resulting hole and fix the handle using screws.

Author, admit that

Author, admit that you do not sign the material is a way to avoid shame?