Ceiling finishing is troublesome and requiring certain dexterity and patience ...

|

|

Monolithic arbolite is one of the most economical building materials ... |

Any repair ends with the installation of a skirting board, without which the room will have ... |

Roofing mastic: choice

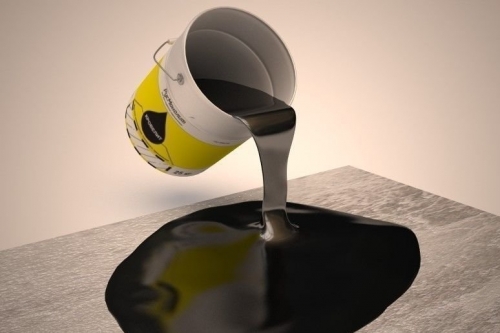

To date, there is a huge selection of roofing materials, and their number is increasing every year. But there are a number of materials whose quality is tested by the decade, and therefore, their popularity is not reduced. For example, roofing mastic remains in demand for flat or with a small slope of roofs. But its composition undergoes changes. The article will talk about the choice of roofing mastic and the method of its application.

Content:

- Properties of roofing mastic

- Types of roofing mastic

- The advantages and disadvantages of roofing mastic

- The main manufacturers of roofing mastic

- How to choose a roofing mastic

- Nuances when working with roofing mastic

- How to use roofing mastic

- The cost of a roof from mastic

The choice of materials for a flat roof is not so wide. This is a classic roofing material or modern roller materials. If in the first case the work is quite laborious and complex, then in the second expensive, requiring the use of special equipment. Against this background, the use of bitumen mastic for waterproofing the roof looks very advantageous. It is easily applied, creates a monolithic layer, and to work with it you need a minimum set of tools.

Properties of roofing mastic

- Mastic for the roof is based on bitumen, but with the addition of various related components. It is a liquid mass with a high viscosity of black and a pungent odor. It is evenly distributed over the entire surface of the roof with a roller with a long handle or brush as the main layer. Or are used for repair, applying to separate areas.

- The composition dries, subject to dry and warm weather, during the day. This is important to consider, since in most cases it needs to be applied in several layers, allowing the previous one to completely dry.

- Depending on the thickness of the applied layer, after drying, an elastic and strong film is 4-6 mm thick. It is resistant to mechanical damage, frost -resistant and absolutely does not pass moisture.

- Bitumen roofing mastic is a great option for garages and any other buildings that have a tilt of the roof of no more than 30 degrees. Since this is the only restriction in its application.

Tip: as if a flat roof was not made qualitatively, it has on the surface of convexity and deepening. In these places, a layer of mastic should be thicker, since over time water will accumulate there, gradually destroying the coating.

Types of roofing mastic

Bitumen mastic is divided into several types, depending on the composition and purpose.

- Roofing polymer mastic. It has a longer shelf life. When applied, it forms a strong protective coating with high heat -resistant and elastic indicators at high and low temperatures. They are used for wood, concrete or metal;

- mastic roofing bitumen latex. It is characterized by a shorter drying period, which is especially important during repair work. It has good adhesion with almost all types of roofing coatings. It withstands high temperatures (up to +70 C) at the same time does not melt. Numerous tests showed that the latex bitumen coating does not pass water, resistant to extreme temperatures and ultraviolet radiation;

- rubber mastic It is used when it is required to create high -quality isolation or as the main whole layer. For partial repair, it is unsuitable.

In addition, roofing mastics are divided into two -component and one -component. If the latter is already on sale in the finished form and everything that is required to work with it is simply applied to the surface with a brush, then two -component must be prepared first. To do this, it is mixed in the right proportions indicated by the manufacturer on the label. Most often, the composition of the roofing mastic implies the presence of components that, when connecting, cannot be stored for a long time. Therefore, for high -quality waterproofing, it is recommended to choose two -component compositions.

The advantages and disadvantages of roofing mastic

It is without reason that bitumen mastics are still the most popular solution if it is required to waterproof the flat roof. Especially when work is planned to be performed independently. The advantages include:

- moisture resistance. It is able to withstand high water pressure for a long period without losing characteristics;

- low cost. And the difference is not only in the price of the composition. When using it, you do not have to hire a team of professional roofers with equipment for gluing expensive roller roof;

- ease of use. It is easy to apply both a roller and a wide brush. Thanks to viscosity, bitumen mastic is evenly distributed without additional effort;

- stability to ultraviolet. Under the scorching rays of the sun, for many years, the bitumen roof will not require repair, since the generated film has high indicators of stability to UV rays. In addition, it does not oxidize and is not subjected to corrosion.

But, despite all the above positive qualities, we must also mention the shortcomings:

- the inability to do the job in one day. This is due to the fact that it is recommended to apply at least 3 layers of 1-2 mm each. And since the drying takes at least a day, the work will drag on;

- unsuitability for roofs with an angle of inclination of more than 30 degrees;

- you can work with it only in the warm season at positive temperatures.

The main manufacturers of roofing mastic

The market is presented with bitumen mastic of several dozen manufacturers. All of them are similar in composition and are in approximately the same price category. Among them, several brands can be distinguished, which have already successfully established themselves.

- Roofing mastic of Krasko. This is a domestic manufacturer whose factories are located in Moscow. They produce bitumen compositions of excellent quality at affordable prices. Most of their compositions are multicomponent. The cost ranges from 200-300 rubles/kg.

- Mastic for the roofGidrolux. The main direction of their activities is based on the manufacture of bitumen-polymer mastics. These compositions are valued for low consumption and an acceptable price. In this case, the quality of the resulting layer has excellent characteristics. The price does not exceed 350-400 rubles/kg.

- Roofing mastic Tehron. This Ukrainian manufacturer until recently was widely represented in the Russian construction market. Despite the incompetence of the packaging, this is a high -quality and reliable composition at a low price. So, 1 kg of mastic costs from 70 rubles.

- Mastic roofing techniconicol. It is considered an unspoken leader in this segment of products. It has existed for many years, during which the mastic has improved and the material has reached the world level. The price is an average of 3000 rubles/20kg and depends on the brand.

So, this company offers material:

- Eureka 41. It can be used both for creating a new roofing, and for partial repair or as waterproofing. Produced for cold and hot use;

- Technomast 21. This high -strength coating is already sold in the ready to use form. As part to the main component of bitumen, rubber, various solvents and special additives were added. As a result, the coating of the roof will be not only moisture resistant, but also elastic and heat -resistant;

- Water -based mastic 33. There are no solvents in its composition. This universal composition is suitable for arranging a new roof and for repair work;

- Aquamast. This is cold roofing mastic based on bitumen and rubber. One of the most expensive in its line, but with complete drying creates a particularly strong coating that is suitable for operated roofs. In addition, such a roof is able to withstand a larger amount of the ferro-delay cycle, which is especially important in the middle lane of Russia and in the northern regions.

How to choose a roofing mastic

First of all, you need to rely on exactly which work will be carried out and in what conditions.

- To create a partial waterproofing or for repairing individual sections of a flat roof, it is best to opt for bitumen-lakekin mastic. It has higher elasticity and fluidity, which is especially good when filling in small cracks.

- Bitumin-resistance composition also has similar characteristics. But it is recommended to use it to cover the roof with a monolithic layer or for waterproofing individual elements, such as vertical sides on a flat roof.

- But when creating the operated roof, according to which any movement is planned in the future, it is better to choose strong polymer bitumen mastics.

- For cheap repairs, for example, the roof of the garage, it is better to buy the cheapest ordinary bitumen or tar composition. Its consumption is slightly larger, and the result is not so durable, but the total cost is sometimes a decisive argument.

- If the work is carried out for the first time and there is no experience, then it is best to buy the easiest to use one -component composition. But for a more professional coating you need to buy two -component mastic.

Nuances when working with roofing mastic

But no matter how high -quality and expensive the composition of the roofing mastic was purchased, if the technology of its application is not observed, the operational period is significantly reduced. Depending on the angle of the roof, a different number of layers of mastic and special reinforcing gaskets are made:

- with the maximum permissible angle of inclination of 20-30 degrees, the pie will consist of 3 layers of the bitumen mastic itself, 2 reinforcing, and on top of 1 layer of protective paint;

- if the slope is from 10 to 15 degrees, then 2 layers of mastic are enough, also 2 reinforcing layers and on top of 1 layer of paint;

- with a roofing slope of up to 10 degrees, 3 layers of mastic are made, 2 layers of reinforcement, and gravel or crushed stone is poured on top of the layer.

Tip: In addition to independent use, roofing hot bitumen mastic can be used to fix modern roll roofs for flat roofs.

In addition to the main area of \u200b\u200bthe roof, there are several roofing elements that require the application of additional layers. So, for high -quality insulation of yends or overhangs, an additional 2 layers with reinforcement need to be applied. But in the places of the joint of flat sections with vertical (walls, ventilation boxes, etc.), it is necessary not only to apply 2 more layers of bitumen mastic, but they also pour crushed stone of a small fraction on top and they are completely replaced in it.

Mastic roofs can be conditionally divided into several types: reinforced non -targeted and combined. And also by the method of using the composition on hot and cold. Roofing cold mastic has organic solvents. This allows you to use it without heating, if the air temperature is not lower than +5 C. If such a composition also has polymer components, then this significantly improves its operational characteristics. In contrast to it, roofing hot mastic requires preliminary heating on a portable burner to at least 150-160 C.

Tip: Before applying bitumen mastic to the roof, it is necessary to correctly primer the surface with a waterproofing compound, for example, a primer.

How to use roofing mastic

- First of all, preparatory work is carried out. All garbage is removed from the surface of the roof and washed with water if possible to get rid of dust.

- Then, based on the angle of inclination of the roof, the mastic is applied either by pouring and leaving on the surface or painting with a brush.

- Depending on the selected type of composition, they work with mastic in a cold or hot way. In the second case, it is necessary to prepare a portable gas burner, which can warm up the bitumen mastic to the desired temperature and maintain it throughout all work. The thickness of the layer should be approximately 1 mm, but their number directly depends on the angle of the roof, the smaller it is, the larger they are. But it is important not to forget that before applying the subsequent layers the previous one should completely dry, which takes at least a day.

- The consumption of roofing mastic depends both on the characteristics of the hiding place and on the application method. But on average, this indicator is 1.3-1.5 kg/m2.

- For greater mechanical strength, gravel is poured onto the upper layer of mastic immediately after application and completely lifted. If the coating was made combined, it is recommended to use staining as a protective layer.

- If reinforcing layers are required, then fiberglass is used for them. You can work with it only in gloves, otherwise severe itching will appear on the hands. To level over the overlap is comfortable with a wide spatula.

The cost of a roof from mastic

Roofing mastic is a universal and multifunctional material. It not only creates a high -strength and moisture -resistant coating on flat roofs, but also saves time and money for work.

- The total cost will be significantly lower than when using modern roller materials, it is this factor that still holds these products at the peak of popularity. The mastic roof is in demand not only for work with small roofs, but also for large objects, such as shops, kindergartens and schools.

- To calculate the cost, it is necessary to proceed from the consumption of the material indicated by the manufacturer on the package. For example, Bitumen Roofing Mastic of Technonikol declares the flow rate of approximately 1.5 kg/m2. This means that one layer for a roof of 5x5 m in size will require 38 kg, which is 6000-12000 rubles, depending on the brand.

- For additional strength, it is recommended to pour gravel or crushed stone of a small fraction. 1 trailer of a passenger car is enough on a roof of this size, and 0.5 tons mean no more than 500 rubles.