So that in the garden house it was warm and comfortable in any weather, it is recommended to install ...

|

|

Monolithic arbolite is one of the most economical building materials ... |

Due to the widest range of materials for the arrangement of the roof, which today ... |

Heater Izorok: characteristics, installation instructions

High energy efficiency of buildings against the background of rise in price and obvious saving of energy resources is the need of our time. For these purposes, there are many methods and one of them is insulation. The choice of quality material here plays an important role. New production lines made it possible to release high -quality materials intended for insulation of the enclosing and building structures. The article will talk about the heater.

Content:

- Izoko characteristics

- The use of heater iso short

- Brands and purpose of insulation insulation

- Installation of insulation insulation

- Cement screed of the floor with insulation tape

- Insulation of the external walls of frame buildings

- Insulation of the walls of frame buildings from the inside

- Dry method of floor insulation with an iso

- Warming of inter -story ceilings isoran

- Insulation of flat roofs isoran

- Stove insulation strokes of rocky roofs

- Insulation of the wet facade with an isoCom

- Ventilated facade with an iso

All manufactured products under the brand of Izorok meets all world quality requirements and is one of the leaders of thermal insulation materials. The excellent operational properties of insulation in combination with an affordable price provide it with wide use in the construction of new and repairing old premises, increasing their energy efficiency.

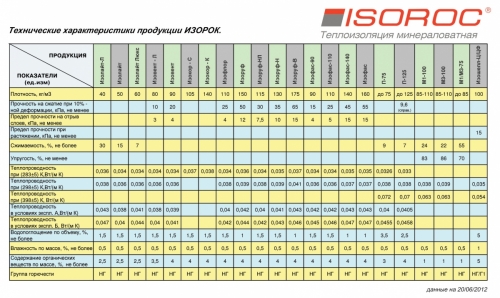

Izoko characteristics

For the entire line of heater, an isoque, which has many varieties of material, is characterized by the following properties.

- Low thermal conductivity. The presence of a large number of air pores in the Ministry of Pilts allows you to accumulate and maintain heat in the walls of buildings and reduce energy costs.

- High level of sound insulation. Mineral -free insulation due to a structure consisting of small fibers has excellent soundproofing properties. Fibers with different lengths are able to effectively absorb the energy of any sound waves. Using the Ministry of Plutches, you can successfully solve the problems of sound insulation of the premises.

- Great strength. High resistance of plates of mechanical influences contributes to an increase in the properties characteristic of the insulation of sound and heat-insulating.

- Excellent deformation resistance. Heather isooro have excellent strength properties that provide strength and durability.

- Beautiful water -repellent properties. This characteristic became possible thanks to special hydrophobic additives that prevent the penetration of moisture into the material, the heat -insulating properties of the Ministry of Plutches increase.

- High refractory properties. Natural non -combustible elements that are part of the composition make it possible to maintain their original properties at the widest range of temperatures.

- Environmental friendliness of the product. All products are made of pure natural raw materials, which provides high environmental indicators of finished material. The use of mineral wool insulations of this brand Guarantee for favorable living conditions in any insulated room.

- High stability of the entire line of insulation to the destructive influence of aggressive environments.

- The water resistance of mineral wool plates makes it possible to warm them on the basis with the use of aqueous solutions.

- The high strength of the material, which is achieved during the production process, ensures the absence of shrinkage, breakdowns, deformation of sheets of insulation, and, accordingly, the high quality of the performed works.

- Resistance to fungi and microorganisms is explained by the inorganic nature of the material.

All types of insulation of the stamp iso short and stably retain the working characteristics even after the expiration of the warranty periods, which is the best recommendation for both large developers and individuals who want to qualitatively and reliably warm their housing.

The use of heater iso short

All products are diverse and includes plates for heat and sound insulation, steam and waterproofing membranes, firmware mineral wool mats. The insulation of the stroke of the stroke has a wide circle of purpose and is used in the construction of various designs, buildings and buildings of the industrial and housing stock, for their reconstruction and repair. The list may include both temporary structures and structures designed for prolonged operation.

Depending on the density of the tape, it is used for:

- internal thermal insulation of walls;

- floor insulation;

- insulation of attic structures and roofs of various buildings;

- in apartment buildings for the sound insulation of individual rooms;

- thermal insulation of various kinds of communications;

- increasing the indicators of the anti -proseismal characteristics of any structures.

Industrial products are used mainly for:

- thermal insulation of pipelines above the ground and in basements;

- insulation of pipes working with liquids with positive and negative temperatures.

For each type of work, there are its own brands of insulation, their properties and characteristics best suitable for them. In order to decide on the choice, you need to know the brand and its purpose. So it will be easier to choose the appropriate one that will guarantee the quality of work.

Brands and purpose of insulation insulation

Insulation for internal work:

- Izoleite. The Ministry of Plots are designed for insulation and sound insulation of various building structures. These designs include vertical, inclined and horizontal surfaces. Izoleight can be used in the insulation of wall frame structures, including to create partitions, like a heater in frame walls, inter -story ceilings and attic.

- Isoruf. The Ministry of Families is used as a thermal insulation layer for the equipment of horizontal structures. It can be flat roofs, multi -layer insulation is allowed. Another example of use of the thermal insulation of the floors if the black base is performed by a dry method, that is, there is no cement-sand screed. Isoruf is recommended to be used in single -layer coatings. In multi-layer insulation, two types of this insulation are usually used: the upper layer is laid by the material of the isoruf B brand, and the lower brand isoruf N. These varieties can also be used as a heat-insulating layer in sandwich panels with a metal shell.

- Isofloor. High density mats used in construction work as an intermediate layer in reinforced concrete structures for the organization of sound and thermal insulation of inter-story floors. The same material is insulated with the floor when arranging a wet screed or bulk floor. Isofloor can also be an element of sandwich panels with a metal shell.

Insulation for external work.

- Izovent. Mineral wool plates, the brand of which is used in construction in the form of heat and sound insulation of various structures, such as layered or well masonry. The same option will be the most suitable if the work on insulation of the building is carried out using a system of hinged ventilated facades.

- Isofas. The Ministry of Plutches is recommended to be used to arrange insulation of the external perimeter of the walls of the building, if the work is carried out with a wet method. Izofas and isofas 140 plates are used mainly as the thermal insulation of the facade, where plastering is used. Stamps of Isofas 90 and 110 - respectively, in cases where the plastered layer is thick. Plasting is carried out using a steel reinforcing grid.

The most popular among the private construction of the insulation plate iso -50 (density 50 kg/m3) and isoor 75 (density 75 kg/m3). On average, their cost is 350 rubles/packaging. They are suitable for internal and external works

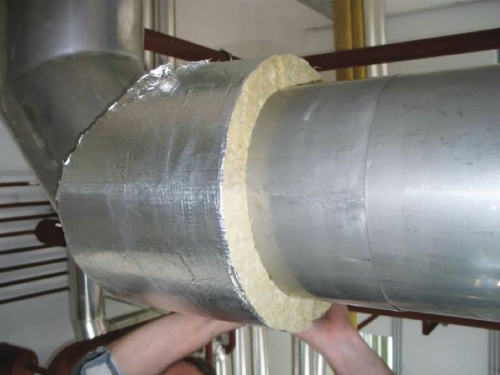

Technical thermal insulation of isoor. These products are represented by firm mats and thermal insulation cylinders.

- Izorok M1-100, M2-100. This is a heat and sound insulation material, the scope of which includes insulation of building structures of various types, as well as industrial equipment used at the temperature range from- 180 and to impressive +700 C. Another version of the insulation of the M2-100 firmware, except for all, are produced. On a metal grid. And the last representative from this line - the MATS M3-100 - have an additional coating from another thermal insulation material of the fiberglass.

- Izoshell - c and isochell - Tsf. Foil of thermal insulation cylinders and semi -cylinders are designed to insulate technological pipelines. The working temperature range is from -180 to +400C. The price of insulation of this brand ranges from 400-500 rubles/packaging.

Installation of insulation insulation

To perform insulation with the help of stoves, strokes of different types of surfaces have their own rules. For most technologies, it is necessary to use steam and waterproofing in order to maintain the quality of the insulation. To ensure the best indicators, the use of products of the same company is required.

Cement screed of the floor with insulation tape

- Before starting to lay the insulation, it is necessary to remove the obsolete flooring, clean the old screed from the contaminants located there, fill the cracks and cracks, align the entire surface, lay the waterproofing material, then the mats of the isoor, which should be placed back to each other, so So that there are not even minimal gaps between them. Then the waterproofing layer is again laid, and a reinforcing mesh is placed on it, on which the cement screed is poured.

- If there is a room under the screed in which it is warm and humid, for example, a sauna, then there is a need for additional vapor barrier, which in this case is located under the sheets of insulation. If below is a cold and wet room like a cellar, then vapor barrier is located on top of the insulation.

Insulation of the external walls of frame buildings

- In wall structures of this type of stove, stoves have established themselves in the best way. The highest quality is insulation when it is performed by two layers of material.

- A crate of wooden slats with a width of 5 cm (in thickness of mats) or a metal profile is mounted on the walls. The distance between them is equal to the length or width of the insulation.

- Laying is carried out in such a way that the slabs located outside are overlapped by the seams of the layer of material located inside. The sheet is attached with the help of fungi screws at 5 points.

- The outer layer of insulation should be protected by a wind and waterproofing film.

Insulation of the walls of frame buildings from the inside

- As a rule, even at the stage of building the frame, the distance between the wooden racks is laid equal to the width of the insulation, that is, 60 cm.

- Therefore, there is no need to make a crate, the stroke is simply placed in 3 layers (15 cm) in these niches and is not attached in any way. On top it is fixed by a vapor barrier film, which is very stretched.

- Although it is said about the environmental friendliness of the material, when it comes to the skin of the minvata particles, severe itching begins, which cannot be washed off during the day. Therefore, it is important to use personal protective equipment and work in rubberized gloves.

Dry method of floor insulation with an iso

Floor insulation is carried out according to the following scheme:

- a layer of waterproofing is laid on an existing wooden floor with tightly laid boards. Lags are laid on top of the boards, in the gaps of which a heater is located close to them. This must be done by the meals so that there are no cracks and gaps;

- the next layer is vapor barrier. Its presence prevents the penetration of moisture from a warm room into a cold layer of insulation. This must be done in order to protect the insulation from moisture, since moisturized, it loses its initial thermal insulation properties;

- next, a draft floor is laid down the lags. It can be plywood, OSB, etc. The finish coating is placed on top of this material. It can be represented by a laminate or any other coating at the request of the homeowner.

Warming of inter -story ceilings isoran

- Mineral slabs can be insulated with inter -story wooden floors. For this purpose, they are laid between the beams.

- A layer of protective vapor barrier for insulation between rooms of different levels, but with the same temperature in them, it is not necessary to place them.

- If one of the rooms is warm, and the second wet, for example, bathroom or kitchen, vapor barrier is simply necessary. If the wet room is located at the top, then a layer of waterproofing is required.

- From the side of the second floor, the sequence of the location of the materials looks like this: the flooring of the floor, lags, if necessary, a layer of hydro- or vapor barrier, between the beams, the insulation, if you need a layer of vapor barrier, the sheathing of the board, the finishing coating of the ceiling.

Insulation of flat roofs isoran

- With a high density, a flat roof can be insulated. The base on which the insulation will be mounted is reinforced concrete floor slabs or profiled metal sheets.

- First you need to lay the vapor barrier layer. It is necessary here in order to prevent the penetration of moisture vapor into the thermal insulation layers. After all, only dry insulation can retain its properties, and the wet reduces significantly reduces its characteristics. A large accumulation of steam causes undesirable deformations of plates. It is advisable to perform vapor barrier with fewer seams and select thicker membranes to provide the highest quality protection.

- The edges of the film should be made above the insulation, in order to exclude the penetration of a couple into it. With multi -layer insulation, the joints of the plates are placed with a slight displacement. The upper layer should exceed the density of the lower.

- The latter is applied waterproofing. It is advisable not to walk on it for the preservation of the material.

Stove insulation strokes of rocky roofs

- The first step when warming the pitched roofs is the installation of a waterproofing film, which is carried out on top of the rafter system. The material is laid across the slope with an overlap, so that the upper ones are layered on the lower ones. Separate canvases are connected by a self -adhesive ribbon.

- The bars of the counterparts are stuffed on top, which provide the necessary in this case a small ventilation gap, which will pass between the roofing and the future layer of insulation.

- The stroke is installed between the two rafters of the display. This is done for reliable fixation of the elements and to ensure the best thermal insulation results. It is necessary to prevent ruptures of the heat -insulating layer or a loose adjustment to the rafters. The insulation of the isoor on the entire surface should be the same.

- The next stage is the installation of vapor barrier. The material is fixed with brackets on the inside of the rafters. The connection of the strips is overlapped. The joints are fastened with self -adhesive ribbons. The latter is installed in the ceiling. On the outside of the roof, a roofing is installed.

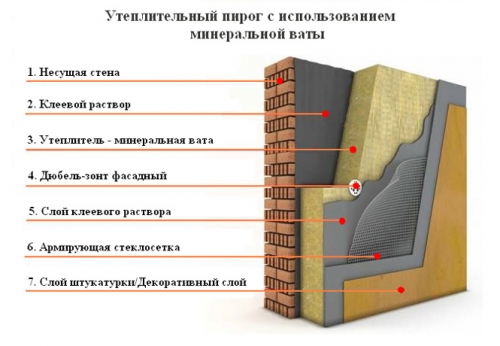

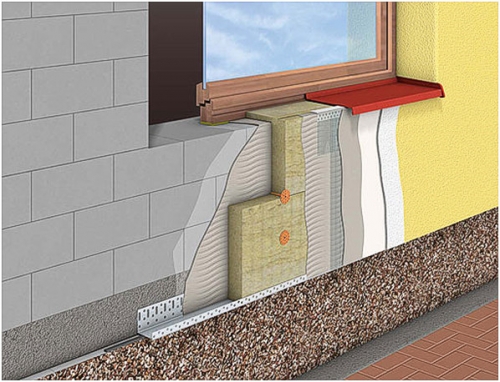

Insulation of the wet facade with an isoCom

- The outer method of insulation of buildings is more preferable as the most effective in the issue of thermal insulation of buildings. If possible, it is recommended to choose it.

- You need to start work with the preparation of the surface. It must be cleaned of all existing pollution, chatter, if any. If there are bumps, leve them. Propulate a dried finished surface.

- The next stage is the installation of a profile bar along the perimeter of the building. It is attached at an altitude of about half a meter from the level of soil. The bar is needed for the distribution of uniform load emanating from thermal insulation plates. Plates are installed on it, which are attached to the base using a dowel of nails with a wide hat. The insulation is located in rows, starting from the basement.

- Next, the reinforcing mesh, which is attached to a special adhesive composition. First, slopes, angles, etc. are strengthened. After installing the mesh, you can proceed to apply the plaster layers according to all the rules necessary for such work.

Ventilated facade with an iso

- Mineral wool plates are also used in ventilated facades. This is another option for high -quality external thermal insulation of buildings. The system itself lies in the fact that between the layer of insulation, which is attached to the wall and the decorative facing layer is a layer of air. It is needed for free outflow of moisture from layers of insulation. On the other hand, the moisture that penetrates under the cladding cannot reach thermal insulation material, since the air serves as a barrier. Another advantage of this method is that all work is performed at any temperature.

- The installation of the insulation is carried out similarly to the installation of a thermal insulation layer characteristic of a wet method. The only difference is that after installing the plates on top, the frame of the ventilated facade is mounted.

- The question of the installation of a steam and windydro-protective film remains open. Here opinions diverge. To install it or not, it is worth focusing on the installation technology provided for the slabs and systems of facades and the recommendations of manufacturers and specialists.

Mineral stoves of strokes are reliable and high -quality material. A large selection of products with different indicators and technical characteristics makes it possible to successfully use it in various fields of construction work. This is easy to work and affordable material, which both professionals and people who conduct construction on their own can appreciate. In addition, in recent years, the products are exceptionally positive reviews.