No wonder the overhaul is compared with a spontaneous disaster. Think over the design before ...

|

|

More recently, no one thought about the thermal insulation of the foundation, and that's it ... |

Filling the foundation is a very important process, from the quality of the execution of which is directly ... |

Wall insulation from the inside with your own hands

To create an acceptable microclimate in your house, to protect it from drafts and dampness will help insulation of the room. Thermal insulation of the walls allows us to cut off the costs both on the heating of the premises in the winter and its cooling in the summer. After all, the insulation acts as a kind of shield that prevents the movement of air flows, protecting the structure from the effects of external factors. Unfortunately, there is far from always the opportunity to insulate the facade of the building. For example, thermal insulation of the end wall of the panel structure is advisable to carry out from the inside.

Content:

- Advantages of thermal insulation of walls indoors

- Ways to warm walls from the inside

- Wall insulation from the inside with drywall

- Wall insulation from the inside with mineral wool

- Wall insulation from the inside with a foam

- Wall insulation technology from the inside

- Preparation of walls

- Formation of the frame and installation of insulation

- Laying a steam protection layer and finishing

- Other ways of wall insulation

Advantages of thermal insulation of walls indoors

- Relatively low cost.

- Performing insulation is possible at any time of the year.

- You can insulate both the entire structure entirely, and individual rooms and even walls.

- Sound insulation of the room.

Among the positive points, the availability of independent execution should also be highlighted: this can do any owner. It is also important to know the ways of warming the walls and choose the optimal material for this.

Ways to warm walls from the inside

For thermal insulation, indoors are mainly used the same materials as for insulation from the outside. The most popular heater: polystyrene foam, mineral wool and mixed heat -insulating materials based on asbestos.

Wall insulation from the inside with drywall

Thermal insulation using drywall sheets is a simple and fast way of wall insulation. The minimum distance from the draft wall to the front surface of the plate is three centimeters. The larger this distance, the, accordingly, the more insulation will fit in the voids of the structure. This method of thermal insulation is suitable only for large rooms, since the wall in the process of installing the insulation structure noticeably thickens.

The process of insulation of buildings from the inside begins with installation of a structure of metal profiles at a distance of two centimeters from the wall. The frame is best mounted from a galvanized profile. On the sole of the guide profile, it is necessary to stick a tape to isolate the surface from contact with plaster, thereby protecting drywall from the cold transmitted through a metal profile. Then, mineral wool is laid in the cavity of the resulting frame (between the rack profiles). The air gap between the wall of the structure and drywall is already a heater. However, the use of mineral wool or foam many times increases the heat resistance of the structure.

Due to its structure and elasticity, the material perfectly fills the design. The next step will be the installation of drywall. When warming rooms with high humidity, one should not save. It is better to purchase moisture resistant drywall. At the final stage, the decoration of drywall plates with wallpaper takes place.

Wall insulation from the inside with mineral wool

Thermal insulation using mineral wool is one of the most economical options. The advantages of the mineral wool include lightness (which is very important when transporting building materials and insulation of old structures) and low thermal conductivity. The thermos effect occurs due to the occurrence of an air cushion between mineral fibers.

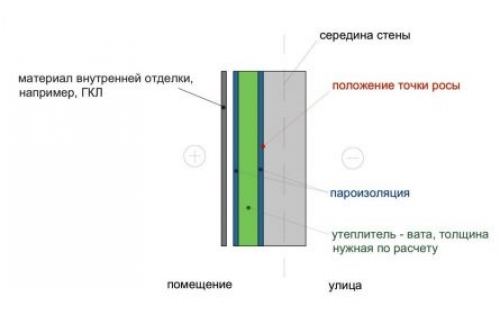

Perhaps the only drawback of mineral wool is that it is quite hygroscopic. Therefore, if you decide to insulate the walls from the inside, you will have to take care of vapor barrier in order to avoid accumulation of condensate. In order to prevent absorption through the surface of the moisture insulation, it is recommended, along with the use of the main thermal insulation material, the wall insulation from the inside with a foam. This material has an outstanding property - retains up to 97% of heat. The vapor barrier layer is applied to the frame of metal profiles after the installation of mineral wool.

Penophol is special, foamed polyethylene with aluminum coating in the form of foil, which has vapor barrier, as well as soundproofing characteristics. The polystoline membrane has small holes that allow microparticles to move moisture only in one direction. Penophol sheets have a small thickness. Thanks to flexibility, this material is easy to install. It does not require additional care during operation, which is also an indisputable plus.

Wall insulation from the inside with a foam

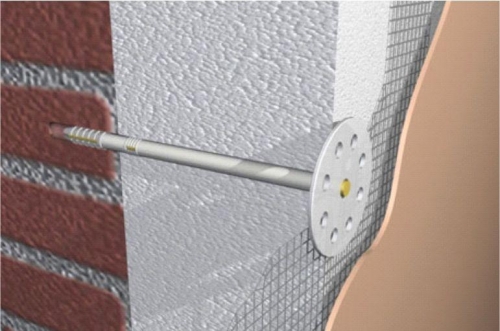

Thermal insulation using extruded polystyrene is even for beginners who do not have much experience in construction. There is nothing easier: the foam plate, which can be purchased here http://penoplex-spb.ru, are attached with glue on the wall. In this case, the adhesive composition is processed the entire surface of the plate. Small grooves along the edges of the plate contribute to a reliable fastening of the foam and improved the tightness of the joints. Extruded polystyrene with smooth edges needs additional gluing with a tape. The foam is glued and fixed with self -tapping screws.

When warming with a foam in conducting vapor barrier, there is no need, since the surface of the plate is vapor permeable. The thin layer of plaster applied to granular (for better adhesion with finishing materials and increased fire hazard protection) the surface of extruded polystyrene will protect the walls from damage and prepare for further painting or pasting with a wallpaper coating.

Wall insulation technology from the inside

The thermal insulation process takes place in several stages. The sequence of operations depends primarily on the selected material. The insulation is either glued to the inner surface of the wall, or attached to a special design.

The most common is the wall insulation scheme from the inside, in which the thermal insulation layers are located as follows:

- Interior wall decoration.

- Small ventilation gap.

- A membrane for vapor barrier.

- Insulation.

The whole process of wall insulation can be conditionally divided into several stages.

Preparation of walls

When conducting thermal insulation by mineral slabs or using drywall, it is not necessary to level the walls. It is enough to clean the walls of peeling particles of building and finishing materials, eliminate protrusions that prevent the fixation of thermal insulation materials and carry out fungicidal treatment (protection against excessive activity of room mold). Small irregularities are disguised during thermal insulation and finishing work.

Formation of the frame and installation of insulation

At a short distance from the wall, a frame of aluminum profiles or wooden beams (depending on the climate) is mounted. It should be noted that the wood is subject to drying and deformation with sharp changes in the temperature regime. The profile is attached in the vertical direction. The thickness of the frame must certainly correspond to the thickness of the insulation, and the distance between the bars or profiles is calculated depending on the size of the finishing material (for example, a drywall sheet). When warming with polystyrene, the frame is not necessary to build.

Laying thermal insulation materials begins after the assembly of the frame. In order to thermal insulation of the walls from the inside, one layer of insulation is enough. If there is a need for the installation of the second layer, then, accordingly, it will need to install an additional frame for it. Often in the field of heating batteries, the installation of insulation is difficult. In this case, a layer of foam should be laid.

Laying a steam protection layer and finishing

The vapor protection layer protects the walls from the concentration in the voids of thermal insulation material of excess moisture. As a vapor barrier, a foil film is most often used. Make sure that the brilliant part of the vapor defense layer is facing the inner wall of the room. Sheets of the vapor protection layer are mounted. To improve the effect, the joints are glued with metallized tape.

After thermal insulation is completed, the surface is sheathed with drywall and plastered, and then painted or glued with decorative panels or wallpaper. As for the choice of finishing materials, there are no special restrictions.

Other ways of wall insulation

In some cases, polystyrene is laid in space when laying walls. At the construction stage, it is also used penoizolewhich is poured into hard -to -reach places and cracks.

From liquid materials use cellulose, which is also poured under the slabs and in the intervals between brick clutches. Pulp heater has a number of disadvantages: it is a combustible and is easily exposed to microorganisms and is infected with mold. To prevent this, antipypens and antiseptics must be added to the pulp mass.

One of the simplest, but expensive ways of wall insulation is porcelain. This is a liquid pasta, which is applied both to the surface of the wall and in hard -to -reach places. To achieve the effect of the wall, it is necessary to cover with 5-6 layers of pasta, the consumption of which per 1 square meter 250 ml. This makes this type of wall insulation, although expensive, but durable.

During insulation work, unsightly heating or water pipes, additional electrical wiring is easy to hide in the niche of thermal insulation. Therefore, the insulation of walls from the inside is a wonderful occasion and improve the performance of the room, and improve the design of the room.

Water past - heat!

Water past - heat! Actor "Concrete"

Yesterday a neighbor came from below, says you fill us up! We hastily examined all the wet points of our vast odnushka and came to the conclusion that it was not us) the neighbor, having visually examined everything, went higher, we followed her. Suddenly what!

After a short search, we were on the 8th floor. The sounds of the same repairs were heard, which began every morning with a slight dispatch at 7:15 in the morning, what kind of "crazy, we thought every morning, but tried not to betray this, for we were already going to work." So, the bell to the fourth was opened to us Mehmet and repentancely admitted that he did the bulk floors, the water was poured, the toilet is a channel and the water was slightly dripped. Miracle repairmen a little dripping water flooded the entire extract of the hood from 8 to 5th floor, including our 6th. But my story is not at all about a mehmet, a neighbor and a little bit of water!

And about the wonderful tool, which once again proved its viability - the actor "Concrete". Earlier, during our - not waking, neat and fast enough, by the standards of our entrance, repair, we decided to apply an additional thermal insulation, anti -Cocal and antifungal coating on concrete, which was advised to us by Uncle Misha. To our surprise, Uncle Misha did not tell us that in addition to the reflection of the heat, with the help of ceramic vacuumed microspheres in a polymer composition, etc., a water -repellent effect (Uncle Misha, by the way a person of great mind and gold hands) soon began to warm us with a kind Warm winter, chopped nights. Fortunately, the walls stopped freezing, the corner’s apartment is old, seams, we are on the front edge, so to speak. So, in addition to all these benefits, it turned out that thanks to the additional waterproofing properties of actor concrete, the water on the riser and ventilation passed by us and went below and the protective layer removed our repairs from the intervention of Mehmet into his personal life with us!

Such technologies, Uncle Misha and actor concrete! All peaceful neighbors and brief repairs !!!