Wooden windows are quite common in most residential buildings. This is explained ...

|

|

The arrangement of a warm floor allows you to save well on heating. In addition, he ... |

If you want to quickly and with the least costs solve the housing issue, ... |

Insulation of the facade by plaster

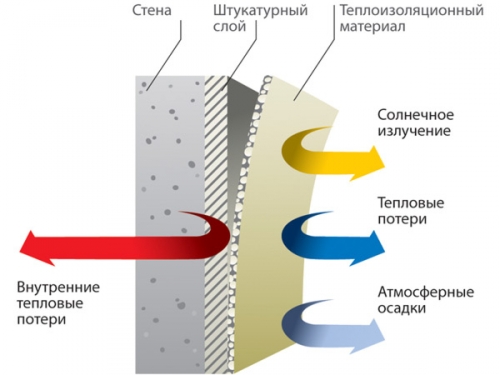

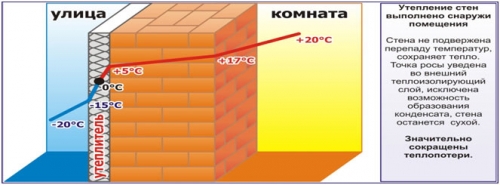

The facade of the building and the quality of its insulation is the main factor that determines the value of the heat loss of the building. With the onset of cold weather, when a significant decrease in the temperature in the room occurs, a dilemma occurs in front of homeowners, directly related to the desire to save additional heating devices, increasing the cost of heating the rooms, or to take care of its effective thermal insulation. The first option is emergency, but temporary, since it is associated with an increase in energy consumption and environmental pollution, and therefore, it cannot be used for a long period of time. With this in mind, the organization of effective thermal insulation of the building, which will reduce heat loss and increase the average temperature in the room, is the most optimal solution. There are many disagreements about the effectiveness and expediency of internal and outdoor insulation. At the same time, some masters recommend warming the house only outside, explaining this by the fact that only in this case the dew point will be in the insulation, and not in the design, which will meet the requirements for the vapor permeability of structures, while others, on the contrary, argue that it is necessary carry out both external and internal thermal insulation. The latter, in turn, add that after giving preference to bilateral insulation, the masters should know that the organization of internal thermal insulation is advisable only for walls located between internal rooms. Otherwise, thermal insulation materials located on the inside will prevent the warming and drying of the walls by means of internal heat, which is fraught with increased humidity and the appearance of mold. Thus, the most popular way to arrange thermal insulation is the insulation of the facade for plaster, the technology of which will be considered below. With the choice of the most popular insulation for plaster, we will also figure out further.

Content

- The insulation of the facade for plaster: the expediency of use

- Advantages of insulation for plaster

- Choosing insulation for plaster: Features of materials

- Features of choice of plaster: Advantages of individual varieties

- Technology for insulation of the facade with mineral wool for plaster

- Warm plaster for the facade: Features of the material

The insulation of the facade for plaster: the expediency of use

Due to the fact that construction technologies have reached almost their climax, a master who set himself the goal of warming their housing often faces the choice of the most optimal method of thermal insulation. Thermal insulation of the external walls can be provided in several ways, however, the most optimal of them is the organization of insulation for plaster, the effectiveness of which is directly determined by the choice of high -quality thermal insulation material, the type of plaster, as well as observing all the technological features of the house plaster. Most often, experts prefer to install insulation in a wet way, and therefore, this technology is called the wet facade. It involves a combination of insulation for plaster and plaster itself.

Given the fact that it has incorporated the characteristics and effectiveness of the thermal insulation material and the decorative properties of the plaster decoration of the facade of the building, which can be decorated in the classic design style. The technology of the wet facade, which provides effective thermal insulation, is characterized not only by versatility, but also to belonging to the average price range, and therefore, we can confidently say that it meets all the requirements for thermal insulation systems. Using various types of plaster, you can successfully apply this technology to organize external facades insulation. Moreover, it should be noted that the use of this technique can be carried out in the process of insulation of walls of brick or concrete, as well as wood in combination with various heat -insulating facade systems, among which special attention is paid to ventilated facade systems.

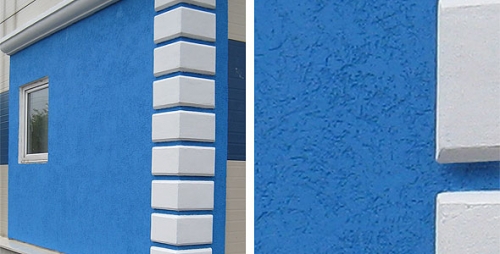

Plaster facade photo

Advantages of insulation for plaster

- Having selected as a thermal insulation technique to insulate the facade for plaster, you save a significant share of the funds that you spent on insulation and air conditioning;

- In addition, by reducing the total weight of the facade structures of the building, the estimated cost of materials and construction work is reduced in the process of building a building;

- The internal area of \u200b\u200bthe room increases by at least 3-5 %;

- An increase in the operational period of the building insulated according to this methodology;

- In the case of proper selection of insulation, its thickness and type of plaster, as well as compliance with the technological process of insulation, you will minimize the risk of temperature deformation changes in the external enclosing structures of the building;

- The use of this technology occurs in the process of thermal insulation of external surfaces from the prefabricated, monolithic or cellular concrete, as well as moisture -resistant plywood or bricks;

- In addition to thermal insulation, you can solve the problems of insulation of the interpanel seams of the building and its protective sealing.

Choosing insulation for plaster: Features of materials

If you use a technology that involves plastering over the insulation, you can give preference to any of the following thermal insulation materials:

- Mineral wool, for the production of which the waste of metallurgical toxins is used, is characterized by high vapor permeability, non -combustibility and almost the absolute absence of intermolecular chemical and biological interactions with foreign agents. This determines the absence of a tendency to decay mineral wool when interacting with a fungus and bacteria. Mineral wool is available in the form of lamella plates with a perpendicular arrangement of fibers, or simple plates that can be solid or semi -hard;

- Styrofoam, for the production of which oil products are used, is considered one of the cheapest heater. Its thermal conductivity is directly proportional to the thickness of the material. Despite the fact that it is distinguished by high thermal insulation characteristics, it is not characterized by refractoryness and resistance to mechanical influences. Foam is forbidden to use for internal insulation, since when burning it forms caustic smoke. If you prefer the foam as a thermal insulation material, the masters recommend using special separations from mineral wool, which will increase the fire safety of the system. One of the varieties of polystyrene is polystyrene foam, with plates from which it is much more convenient and easier to work, since they are easily lended to cutting and grinding, and can also be used to create complex architectural elements on facades, such as cornices, platbands or pilasters. If you prefer extruded polystyrene foam, you need to take care of organizing reliable supply and exhaust ventilation;

- Basalt slabs, for the production of which super -thin basalt fiber is used, and bentonite clay acts as a binder. The distinguishing features of this material are high heat and sound insulation characteristics, fire resistance, resistance to moisture and deformations, as well as vapor permeability. The absence of a phenol row of binders in the material of the binders of the phenol series;

- Foam -glass It is a universal thermal insulation material, a distinctive feature of which is high strength and due to these durability, low density and lack of shrinkage, as well as the ease of installation measures. All of the above characteristics of the material are preserved throughout the entire period of its operation. In addition to thermal insulation qualities, the foam glass has waterproofing characteristics, and therefore, it becomes indispensable in the process of arranging thermal insulation of foundations.

Important! It is proved that the main heat losses occur through the foundation and walls. In this regard, it is important to timely perform thermal insulation measures, choosing the most effective material that meets all the requirements for this group of goods. Such materials, rightfully, include mineral wool, the use of which will be described later.

The material most often used in private construction is mineral wool, which is recognized as the most modern material with high heat and soundproofing characteristics.

Several varieties of mineral wool are distinguished:

- GlassIt is a material characterized by a margin of strength and a high coefficient of elasticity. This variety is recommended for thermal insulation of the outer surfaces of the walls, since it differs in the lowest level of thermal conductivity;

- Stone A variety of mineral wool, the distinguishing features of which are good resistance to temperature influences (up to 1000 degrees Celsius) and high vapor permeability;

- Slag A variety of material characterized by the highest coefficient of thermal conductivity among similar heat -insulating materials. Due to the fact that when using slag wool, the thickness of the thermal insulation layer exceeds the permissible norms, this variety is not recommended for use in private construction.

Important! Mineral wool is produced in the form of plates with dimensions of 50x100 cm and 60x120 cm and a thickness of not more than 10 cm. The material is also realized in the form of rolls and mats, but this variety is not very convenient in the process of independent use.

Once again, we denote the main advantages of mineral wool:

- Absolute non -combustibility and fire safety;

- Water and vapor permeability;

- Effective sound insulation of the insulated room;

- Preservation of full air exchange.

Features of choice of plaster: Advantages of individual varieties

The next stage of work on the insulation of the facade by plaster involves the choice of plaster, stable to both weather conditions and mechanical influences. Given the variety of goods of this group, presented on the market, the following types of facade plaster can be distinguished:

- Mineral facade plaster;

- Silicone;

- Acrylic;

- Silicate.

Each of the varieties is characterized by its advantages and features, which will be discussed later.

- Mineral plaster It is a dry mixture of plaster, which must be diluted with water before use, bringing to the desired consistency. It is considered the most economical option that does not imply large material costs.

The following advantages of this variety can be distinguished:

- The durability of the material;

- No need for additional staining;

- The possibility of applying a thin plaster layer;

- Quick setting time;

- Parone resistance.

- Silicone plaster The material sold in finished form and does not require additional preparatory manipulations.

The advantages of silicone plaster are as follows:

- The ability to choose among the wide colors;

- Ease of application;

- Vapor permeability;

- Resistance to mechanical influences;

- The plastered surface is resistant to pollution and is easily cleaned in the rain.

- Acrylic plaster, similarly to silicone, is ready for use, and is a stucco mixture characterized by a liquid composition.

Among its advantages, the following should be noted:

- Quick setting time;

- Ease of application;

- Acrylic -based plastering mixture is resistant to moisture and ultraviolet radiation, and therefore, it does not bleach in the sun and is not washed off in the rain;

- Wide color scheme;

- If you plan to apply paint over the plaster, you can be sure that it will not burn out in the sun.

- Silicate plasterLike the last few varieties, I am ready for use.

Characterized by the following advantages:

- Stability to ultraviolet radiation;

- Vapor permeability;

- Elasticity;

- Resistance to high humidity and the effects of chemical reagents;

- An extensive choice of color scheme.

Regardless of your final choice, experts do not recommend giving preference to plaster related to a low price category, since it obviously cannot be resistant to mechanical damage.

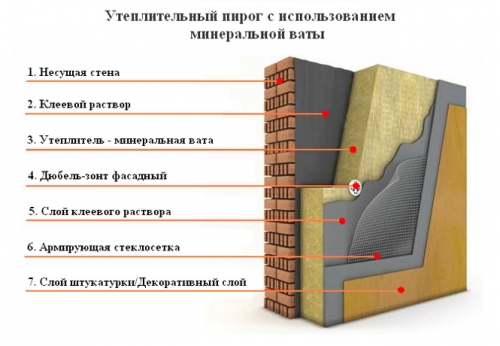

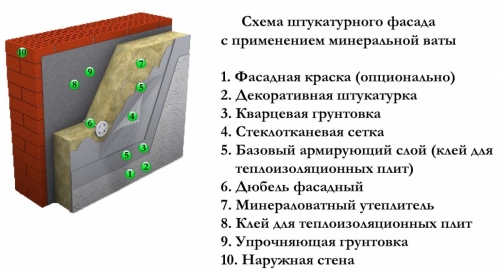

Technology for insulation of the facade with mineral wool for plaster

Construction measures for insulation of the facade by plaster include several consistent stages:

- The first stage implies the implementation of the surface of the walls and facade of the building. At the given stage, it is necessary to remove dust, pollution of various nature and oil stoops. If during the implementation of these measures you find the influx of cement, irregularity or potholes on the surface of the walls, it is necessary to align the surface of the walls. After you have eliminated all the visible flaws of the processed surface, you can proceed to the next stage;

- It involves the installation of the first plates of thermal insulation material (in this case, it is mineral wool). In order to implement it according to all the rules, it is necessary to fix the horizontal and vertical guides, as which you can use a wooden beam of a small thickness or a metal profile. The horizontal guide is fixed in the lower part of the wall at least 60 cm from the surface of the earth, for which the construction dowels are used. To fix the mineral slabs use a special adhesive composition applied to the entire surface of the insulation canvas. After applying the glue, the plate is tightly pressed to the surface of the facade;

- To increase the reliability of the mounting of the insulation, holes are made in the center and corners of the canvas, into which they insert a dowel with a wide hat and clog them. Regardless of the type of mineral wool, it is necessary to consolidate the material in this way, since in the future this will reduce the deformation of the material;

- After you have insulated the entire surface of the facade, reinforce it. It implies the application of the adhesive composition on the entire surface of the insulation and the subsequent pressing of the reinforcing mesh into it. The most optimal will be the use of fine -grained reinforcing mesh, which is resistant to moisture and alkalis;

- After the adhesive composition is completely dry, they move to the finish, for which various types of decorative plaster can be used. Even if after the reinforcement, you think that the surface is still uneven, apply an additional leveling layer. If significant defects are not detected, the leveling layer is applied along the finish layer.

Warm plaster for the facade: Features of the material

Changes that have occurred in the construction market in recent years allow us to say that insulation of the facade for plaster, the technology of which was considered above, is not the only method of insulation of the facade of the building. To date, the manufacturer offers to pay attention to the material of the new generation to warm plaster for the facade. In the countries of the far abroad, the facade of the new generation plaster is perhaps the most popular method of thermal insulation of the building. And, despite the fact that in our country this method is not so popular, more and more organizations are betting on using this particular method, which is explained by the simplicity of use and the effectiveness of warm plaster.

The construction market offers the material of various manufacturers, but not all of them combine simultaneous cost and efficiency at the same time. Moreover, some of them are intended only for internal, or only for external use. The most popular are the products of the following manufacturers:

- KNAUF;

- Heat -over;

- Varmix;

- Bear;

- Umka;

- Terraritis.

Important!

- For outdoor work, experts recommend using the following companies: Varmix, Teplover, Terraritus and Umka.

- Plastings of KNAUF and Bear firms are universal materials, and can be used for both external and internal work.

Fillers, thanks to which warm plaster acquires its thermal insulation characteristics:

- Sawdust Due to the fact that this filler belongs to the lowest price category, you often have to pay the quality of the thermal insulation properties of the material;

- Foam polystyrene, compared with sawdust, is characterized by greater effectiveness, but it is a combustible material and in the process of combustion distinguishes harmful substances;

- Perlit It is an effective, but too hygroscopic heat insulator, and therefore needs additional finish. This filler is used in the plasters of Terralite and Teperman firms;

- VermiculiteFiller, similar to perlite. Like the previous material, not toxic and not fuel, but excessively hygroscopic, in connection with which, also needs finishing;

- Foam -glass non -combustible and non -toxic filler, characterized by good water -repellent characteristics, however, in terms of thermal insulation properties, is somewhat inferior to the previous ones;

- Camping crumb Modern filler characterized by environmental safety. Thanks to the inclusion of cork crumbs in the composition of warm plaster, energy -saving and sound insulating characteristics of the material are significantly increased.

Advantages of warm plaster:

- Ease of plaster, which significantly increases the rate of application of the material;

- The possibility of making warm plaster with your own hands, in connection with which, the costs of construction work are reduced;

- If you use a warm plaster, the bear, during the work you do not need a primer, a reinforcing mesh and other additional devices;

- There is no need for additional leveling of the processed surface before applying warm plaster;

- It goes well with various types of material, and will effectively stay on any surfaces. However, to achieve the thermal insulation effect, the plaster layer is several times higher than the thickness of the polystyrene layer;

- Using this method of insulation, you exclude the possibility of the appearance of cold bridges that are formed when using metal fasteners;

- Warm plaster is of fire safety, with the exception of the one in which polystyrene foam is used as a filler;

How to make warm plaster with your own hands?

This will require the following ingredients:

- 1 part of the cement;

- The filler is vermiculite, which can be replaced with a mixture of 3 parts of sawdust and 2 parts of the paper mass;

- Water and plasticizer.

- As a plasticizer, it is recommended to use PVA glue, which must be dissolved in water, at the rate of 50 g per bucket of cement. First, dry ingredients are mixed, then add water until a homogeneous, plastic mass is not possible. After 15 minutes, it is mixed and proceeded to apply the plaster on the wall.

How to insulate the facade of the house with plaster?

- Before applying the plaster, the processed surface is cleaned of dirt and dust;

- A wide spatula is used to apply the plaster, after which it is aligned with the rule and rubbed with a grater;

- If the thickness of the total layer exceeds 2.5 cm, experts recommend sequentially apply several layers of warm plaster.

Insulation of the facade with mineral wool for plaster video

And they could supplement the article

Could you supplement the article with PIR-plate insulation information? Recently, there is a lot of talk about such insulation, and the information is quite scarce, mainly on European sites. And technology seems to be already used in full swing ...

All thermal insulation mixtures

All thermal insulation mixtures should be applied to the adhesion layer - spray. Warm plasters are characterized by reduced adhesion to the base since they are filled with thermal insulation material in one form or another. And of course, of course, all warm plasters are reinforced and decorated that protects them from moisture.

On the given (m) stage

On the given (m) stage

Write, sometimes, without reading and not

They write, sometimes, without reading and not delving into the meaning.

Here is a fragment: “Even if after the reinforcement, you think that the surface is still uneven, apply an additional leveling layer. If significant defects are not detected, the leveling layer is applied along the finish layer.”

Nothing confuses?