Door closers help to close the door without much effort. However, they are wrong ...

|

|

Stone cotton wool as a heater has high demand in the construction market ... |

In the process of choosing building materials for the construction of the garage, foam blocks differ ... |

How to make a wooden window with your own hands

Wooden windows are quite common in most residential buildings. This is due, first of all, by the availability of materials used in the process of their manufacture. If the window opening has a non -standard shape, then the easiest way to build a window on its own, while the master itself will choose its shape, the number of wings and accessories. We will talk about the features of the manufacture of wooden windows further.

Table of contents:

- Wooden windows - features and advantages

- Wooden windows of technology and varieties

- How to make a wooden window - the main stages

Wooden windows - features and advantages

In order to understand the features of wooden windows, we propose to consider their main advantages:

1. Aesthetic attractiveness of appearance.

On a wooden window, the structure of the wood is clearly traced from which it is made. In addition, wooden windows fit perfectly in any type of exterior and interior. Most often, in the room, wood and wooden doors are installed in the room, which harmonize well with the windows made of wood. At the same time, wooden windows have high functionality and sophistication.

Windows made of plastic have an unpresentable appearance compared to wooden structures. The tree brings warmth and comfort to the room.

2. The ability to breathe.

This function has exclusively wood. It is the tree that is responsible for the regulation of a healthy microclimate in the room. Since wooden surfaces are able to absorb moisture, with excess, and give it with a lack. In the house, with installed wooden windows, there is a comfortable and healthy atmosphere.

Windows made of plastic or other materials are prone to the formation of condensate on the windowsill or others near the lying surfaces.

Due to the fact that the tree breathes, a gradual circulation of air in the room occurs. Even if you do not open windows for ventilation for a long time, the air will be updated through microporas in the tree. After a long absence of a house, the air in the room will be fresh and updated.

3. High durability.

Despite the fact that wood is a rather vulnerable material, especially before moisture or fire, due to the presence of modern compositions and impregnations, the qualitative characteristics of the wood used in the process of manufacturing windows are improved. Modern dyes and impregnations on a moisture resistant basis provide long -term operation of wooden window structures. In addition, in the process of using wooden windows, the primacy of their appearance remains. For example, plastic windows will require replacements after ten years of operation, wooden windows do not lose the presentability of appearance and after twenty years of use.

4. High level of strength.

The tree and its quality are evaluated immediately, in the process of buying materials. The strength of plastic windows cannot be estimated, since a metal profile installed inside the structure. In addition, the option of independent manufacture of a wooden window allows you to choose a tree of the quality that is suitable for the window owner both in the material and in the operational sense. It is better to give preference to a three -layer clay beam with a minimum thickness of 70 mm. It is the use of the adhesive beam that will ensure the stability of the window before the influence of external stimuli and prevent its deformation.

5. Low level of thermal conductivity.

This property is explained by the use of glue timber in the manufacture of windows. In addition, thermal conductivity depends on the technological points of the window installation.

6. Environmental friendliness and safety for human health.

This is a condition, the most important thing when choosing wooden windows. After all, it is the tree that is a natural material that does not distinguish any substances harmful to humans.

7. Easy to repair wooden windows.

This advantage allows you to reduce the costs of repair or restoration of a wooden window. These types of windows are easy to maintain and repair.

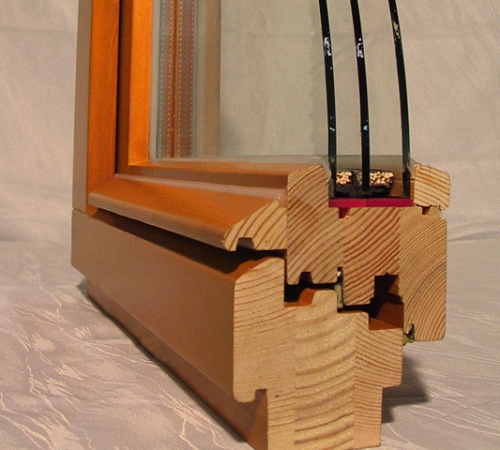

Wooden windows photo:

The installation of a high -quality wooden window opens before its owner such opportunities as:

- complete absence of drafts;

- high level of thermal insulation;

- good sound insulation;

- high attractiveness of appearance;

- selection of individual design;

- Duration of operation.

Wooden windows of technology and varieties

In relation to constructive features, wooden windows are:

- Russians;

- German;

- Finnish;

- Alumino-ruff.

The first option is characterized by the presence of one separate wooden part. It consists of one box and two wings, each of them glazed. For the manufacture of a wooden part, a pine massif is used, not a wooden beam. The minimum thickness of the wings is 4 cm. The main disadvantage of such windows is their exposure to deformation. In addition, it is not possible to achieve a complete adjustment of the sash to the window. Moisture, which is located outside the room, enters the surface of the window sill. Double wooden windows are equipped with unregulated loops and handles, so there is no ventilation mode in them.

German windows are also called European windows. Since the accessories that are installed on them are of European origin. Such a window allows you to adjust the height and angle of inclination of the sash, there is the possibility of ventilation of the window, there are locking mechanisms.

Euro -Owl includes a window box and a sash in the composition. The sash has a double -glazed window of a two -chamber type, which perfectly prevents heat loss. To open the window, it is enough to make little effort. In addition, the departure of HA with such windows is quite light, and a clay beam is used for their production, the thickness of which allows you to make a multi -circuit seal that fully protects the room from drafts.

Such windows are warm, reliability and durability. The service life of the Eurookn exceeds sixty years. This is determined by the presence of an adhesive three -layer beam, which is not inclined to drying or deformation.

There is an option to boil a wooden window using aluminum. This window is distinguished by a longer service life and does not require constant painting.

Aluminum-brutal windows involve the manufacture of the supporting part of aluminum windows. The tree closes aluminum from the outside. Thus, the strength of the structure is improved due to the presence of aluminum, and the wooden surface creates an attractive appearance and warmth of the window. This type of windows is practically not common due to the high cost of aluminum and the complexity of the work.

Finnish windows are distinguished by the presence of a wide box and two wings, which have a sequential type of opening. One simple glass is installed on the outer sash, and a single -chamber double -glazed window is installed on the inner. For the manufacture of an outer sash, both wood and aluminum are used. Two sashes are connected using a sequential opening mechanism. For the manufacture of window boxes and wings, a wooden array is used, not a clan beam. The window has an attractive appearance, although compared to German windows, loses to it in qualitative characteristics.

In addition, wooden windows are:

- Deaf - there are no sash in them, the window does not have a ventilation function, the price of such windows is much lower, since they are quite simple to manufacture, before installing such a window, you should think over the features of ventilation of the room and care for the outer part of the window structure;

- rotary and rotary-oatmeal-such types of windows have sash, opening inside the room, they are quite popular due to the optimal cost and the availability of ventilation;

- Double -leaf Impossal windows made of wood - with the help of an impost, several wings are combined into a single integral design of the window, this option is reliable, ease of use and strength;

- Spool double - the principle of opening as the previous option, only the first sash has a rotary folding handle, and the second - without a handle, the opening of the second wings is possible only if the first is closed.

In addition, Swedish wooden windows are distinguished. They represent a combination of German euro -all with a Russian window version. Such a window has an outer frame with a single glass and an inner frame with a single double -glazed window. Thus, a high level of sound and thermal insulation is provided.

Carved wooden windows are characterized by the presence of different patterns that make them more attractive.

How to make a wooden window - the main stages

Before making a wooden window yourself, you should take care of preparing all the tools necessary for this:

- glass cutter;

- screwdriver;

- electrolobian or milling mill;

- drills;

- hammer;

- chisels;

- square;

- roulette;

- ruler;

- Rubank.

Next, prepare the materials, namely:

- glued beam, pine or oak for the box;

- carpentry glue;

- stacks;

- self -tapping screws;

- dowel;

- sealant.

We offer to study the phased instructions of independent manufacture of wooden windows:

1. The construction of the box.

Depending on the size of the wooden windows, they are:

- large;

- medium;

- Small.

Before starting work, you should choose the material for the window. The most optimal and inexpensive option is pine. Since a large amount of resin is present in this kind of wood, it is the most stable before moisture and other external influences.

A more expensive, but high -quality option is oak. Although for beginners it is better to choose a pine tree so as not to accidentally spoil the expensive material. The boards should have the right drying, knots, cracks, deformations should not be present on them. Keep in mind that the box is the main supporting structure on which the entire load is entrusted.

The option of using an adhesive beam is possible, which is characterized by higher strength characteristics and a high duration of operation.

To build a frame enough boards, in size, 15x5 cm. In the workpiece, you should make a groove hole that will have the letter G and a depth of 1.5 cm. All parts are connected using carpentry glue, and then a wooden rod, a minimum length of 30 mm . It is the rod that is an element that plays the role of the latch of all components of the box.

Next, the box is installed in a pre -prepared window opening. This procedure includes drilling holes in the wall, installing dowels in them, fixing the box with self -tapping screws. To seal the junction and sealing of the cracks, installation foam is used.

2. The construction of the frame for the window.

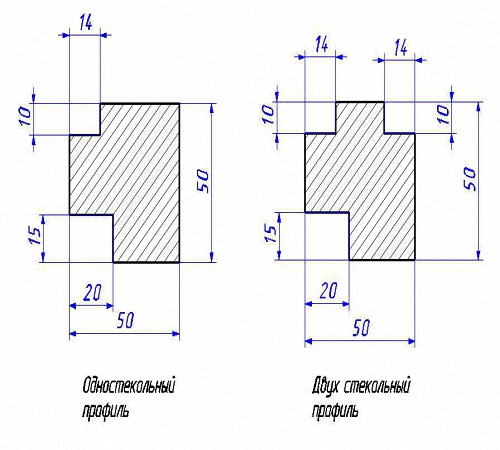

How to make a wooden window with your own hands drawings:

To create a frame, you need a bar with a size of 70x50 mm. Although it is possible to correct the thickness of the beam, depending on the size and strength of the window. The profile form is determined by the thickness and amount of glass, which will be installed in the window.

If it is planned to install a single -wall profile, then it is enough to build two rectangular grooves, otherwise, more holes will be required.

To make a profile of a certain form, the presence of an electric russian or milling cutter is required. If the glass thickness is 5 mm, then a glazing is required, 1 cm thick.

When all the details are prepared, the frame is assembled. To do this, it is necessary to cut the boards at an angle of 45 degrees. Using the prepared profile, a spit-panel connection is provided, self-tapping screws are additionally used for a higher level of fixation. Keep in mind that all hats should drown in a tree to improve the attractiveness of the appearance of the window and in order to avoid corrosion.

3. Installation of glasses.

In order for condensate to not gather in the window and there are no cold bridges, you should correctly measure the length and height of the glass that must be installed in it. The minimum error when removing measures is 1 mm.

For cutting glass, it is better to use diamond self -tapping screw, and for polishing the edges - fine -grained sandpaper.

In addition, all safety measures should be observed, namely, put on mittens of dense fabric so as not to injure hands with fragments and put on a mask that protects the eyes from dust or small fragments.

A ruler with a small margin is laid on the glass. A feature is carried out on it with a glass cutter. Next, the glass is laid on the edge of the table and broke off. The prepared workpiece is installed in the window, if it does not need correction, then the edges of the glass are lubricated with sealants and laid again. Further, the glasses are fixed with the help of graduates, on the surface of which small nails are clogged. If the width of the headaces is large, it is better to use screws for their fastening.

4. Studying the question of how to make a wooden window with your own hands should be mentioned about the final assembly of the entire structure. If the window has a large size and is divided into two parts, then first the assembly and installation of a vertical beam is carried out, then the sash with hinged loops is fixed. Handles and other fittings are installed.

The installation of the finished window in the window frame completes the installation work, its fixation with self -tapping screws, which first pass through the surface of the box, and then through the wall. To seal all the cracks, mounting foam is used, and after it is dry, the walls are plastered. The installation of an ebb and a window sill completes the work.

How to make a wooden video window:

I see no reason to bathe.

I see no reason to bathe. The reta plant that produces woods from wood sells finished profiles for small firms and even cuts in size and makes a spike puzzle. For six months now, how I closed my workshop, I sold all the machines. I first wanted to close because of the crisis, then I just dismissed the people, I sold everything at a cheap. But orders arrive 2-3 windows per week. I decided to get hooked on the start system. TBM, but there are frantic prices for a profiled beam and again to buy equipment. I got in the net and found the office that offers ready -made sets for independent assembly of windows for small firms. Delivered in 3 days and does not go expensive. It turned out to be easier to buy the finished one than to contain due to 10 windows per month. Now I wrap myself in the workshop of 20 sq. A week. In a week, it turns out to make 5-6 windows without straining myself. The profit from the window even increased - the costs became less for rent and hard workers. I think this is a way out for me. The quality seems to be normal, one thing is bad that they sell only a profile of cheap pine, all other materials only to order with a period of 10 days. I think that I’ll stretch it so far in the window market is not clear everything. It’s just a pity for 15 years he devoted to the windows.

Yes, I also bought from them. Cheap

Yes, I also bought from them. I cheaply confirm

Oshgogshgsh

Oshgogshgsh

I recommend a carpentry

I recommend that the carpentry workshop of Art Bor where high -quality wooden windows are made www.artbor.com.ua

http://www.artbor.com.ua/prod

http://www.artbor.com.ua/produktsiya/derevyannye-okna

http://www.artbor.com.ua/prod

http://www.artbor.com.ua/produktsiya/derevyannye-okna