Installing the fence on brick pillars is distinguished primarily by good ...

|

|

Until recently, reinforcement from metal rods was considered not only the most ... |

When arranging a country household, a reliable fence and entry gates are very important ... |

Basalt wool insulation: characteristics of the material, installation features

Any house built, garage, cottage or bath need to be insulated with additional material. Various products have good heat -insulating characteristics, but we will consider basalt wool in more detail in this article.

Content:

- What is basalt cotton wool

- How to produce basalt cotton wool

- Why basalt wool is such a universal material?

- Disadvantages of mineral wool from basalt rocks

- Recommended basalt wool density depending on the type of work

- Insulation of the facade of the house with basalt wool

- Wall insulation basalt wool

- Installation of basalt wool for roof insulation

- Comparative characteristics of basalt and glass wool

- Buy basalt cotton wool

What is basalt cotton wool

The basalt insulation is the material obtained by processing rocks. This allows you to call the produced product stone, basalt, mineral. High heathelling indicators are achieved due to the fact that the air in large volumes accumulates in a felt -like texture. It does not move along the thickness of the insulation, being in a kind of trap from many fibers of very small in diameter.

The basalt threads are divided into continuous and staple types. The latter is divided by the diameter of the fiber:

- rude from 50 to 500 microns;

- thickened from 15 to 25 microns;

- thin 9-15 microns;

- super-thin 1-3 microns;

- ultratonic up to 1 μm;

- mrombon less than 1 μm.

Divide basalt wool in structure into soft, semi -rigid and hard. In order to ensure the isolation of the pipeline, a rather flexible material is required so that it adjacent tightly from all sides. A semi -rigid formation is widely used in construction. And increased rigidity indicator necessary in industrial production.

Mineral insulation in rolls and plates (mats) is produced. Among the characteristics of basalt wool, very small weight can be noted, as well as the ease of cutting the construction knife will easily cope with the task.

The material can be foil. By the way, he is very popular among consumers, not only because of his heat-saving characteristics (thanks to foil, a double level of protection is created), but for a number of other reasons:

- suitable for most rooms (residential and non -residential type), will help with installation and internal and external insulation, is used on all types of surfaces (ceilings, floors, walls). In addition, basalt insulation is used for the installation of air conditioning, ventilation systems, when installing refrigeration units;

- resistant to the decay process;

- provides additional sound absorption, steam and waterproofing;

- safe for ecology, does not distinguish substances harmful to humans;

- durable (life is limited to forty years).

How to produce basalt cotton wool

- The production of mineral wool became possible thanks to finds after the eruption of the volcano in Hawaii. The discovered thin threads from the volcanic breed became the progenitors of modern basalt fiber, obtained for the first time in the United States in 1897. Since then, it is made by processing rocks at high temperatures (1500 C). The resulting melt is stretched and formed in the thread in various ways.

- When the fibers are formed, the binding components and special impurities are introduced into them to give those operational characteristics that have already been mentioned. At the output, a product with an open cellular structure is obtained, capable of withstanding the temperature effect of up to 1000 C. The content of organics is small, and in volume from the total mass does not exceed the indicator of 3%. The finished material is formed into rolls or cut into plates. Now he is ready to work.

Why basalt wool is such a universal material?

Based on all the properties listed above, one gets the feeling that basalt wool is a material that is quite popular in construction. Why is it possible?

- Due to the close plexus of fibers that have natural origin, and the addition of connecting components has low thermal conductivity.

- The density of the threads gives soundproofing properties.

- Since the material of inorganic origin, it is not a nutrient medium for fungi, therefore, it will not be subjected to decay.

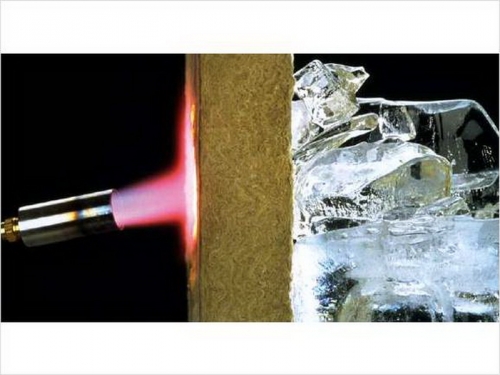

- The special strength of the fibers and their thermal stability allows us to talk about basalt cotton wool as suitable for use as fire isolation. The non -combustible Rockwall slabs contribute to the fact that in the event of a fire, fire does not spread.

- Mineral wool from basalt is vapor permeable, which means protecting the ceilings and supporting structures in the entire building from the accumulation of condensate.

- And as mentioned above, it does not emit any harmful volatile compounds or dust during operation, and it can be safely used to warm children's rooms and where people who are prone to allergies live.

- Therefore, answering the question of the possible versatility of basalt wool, the answer is unequivocal is really effective and used for many purposes environmentally friendly material.

Disadvantages of mineral wool from basalt rocks

All these operational indicators indicate the positive aspects of using this product. But, like everything in the world, he also has disadvantages.

- The structure of the material absorbs moisture well, and if this happens, it will negate all thermal insulation properties. But in order to improve hydrophobic indicators, foil described above (or lifted an additional vapor barrier layer during installation). However, the glue used in this case negatively affects the ability of basalt wool to withstand fire. The output may be the acquisition of firmware mats from basalt.

- That is, choosing the type of stone mineral wool, it should be taken into account the conditions in which it will be operated. For insulation of rooms with high humidity, it is recommended to purchase cotton wool with aluminum coating, and if at the same time it is important that the material is opposed by high temperatures, then the foil should not be glued to the base, but stitched by a galvanized wire. Hydrophobic indicators increase in a product made on the basis of foamed rubber.

- Thus, we note that the listed features can hardly be called negative properties, because solving possible problems have been found and successfully embodied, you should only carefully evaluate possible risks.

Recommended basalt wool density depending on the type of work

- If it is planned to insulate the roof under the slope, it is better to give preference to cotton wool 15 cm thick and with a density of 30-40 kg/m, otherwise the material will sink over time.

- For interior partitions, it is better to use basalt wool with a density of 50 kg/m. This characteristic is necessary to ensure noise insulation.

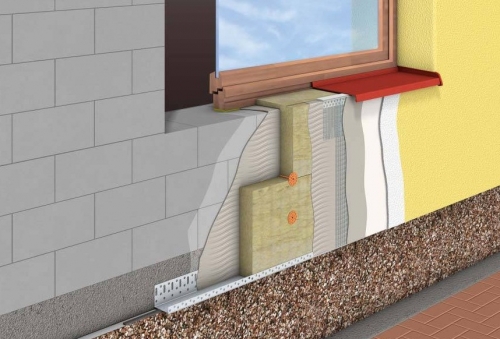

- The bearing walls are customary to warm from the side of the street. Such a decision makes a dew point where condensate, outward will subsequently form. Recommended insulation thickness of 10 cm, and density of at least 80 kg/m.

Insulation of the facade of the house with basalt wool

Installation of basalt insulation is carried out on glue and dowels with a large hat. In addition to the material and the construction knife itself, rails or metal profile will be required. They will serve to create a crate for insulation. If the density of the fibers is high from 80 to 100 kg/m, you will have to cut wood with a hacksaw.

Stages of work

- A vapor barrier film is attached to the wall.

- The bars or a metal profile are mounted in an upright position with an interval designed for a width slightly less than the dimensions of the roll or basalt wool slab. The material should be placed with a slight effort and hold on its own between the racks. Accordingly, the width of the insulation and material for the frame must match.

- The collected cells are filled with mineral wool. It plants on glue, and in addition, depending on the material of the base, additional fasteners are used:

- Dowels for concrete work, stone

- Self -tapping screws with large washers if the wall is wooden.

- For strong fixation, 5 or 6 pieces of metizes per 1 m will be required.

- A windproof membrane is covered on top of cotton wool, which is glued with tape at the joints.

- Before proceeding with the final decoration, for example, siding, experts recommend building another crate with thin rails, which will create a ventilation layer of 1-1.5 cm.

- The final stage of the cladding by the selected material.

When is reinforcement used? If multi -storey buildings are insulated with basalt wool, you need to additionally fix it. Such enhanced measures will allow you to repay the thermal expansion. To do this, simultaneously with the fastening of the material, reinforcement is carried out into the crate. A mesh is laid on a special glue over the insulation. Then it is again covered with a layer of glue. In this case, the final decoration is also possible with the help of painting and plastering.

Wall insulation basalt wool

Some rooms require wall insulation from the inside, for example, a bath. The principle of work and the sequence look as follows:

- Directors are built from the beam, between which basalt wool is attached. Her choice for this room is explained by the fact that when heated, she will not turn the steam room into a gas chamber.

- A vapor barrier layer is lined with foil. It is important that he be without visible joints. For this connection place, you need to carefully glue it with a special foil tape, ordinary tape is not suitable. The thicker the layer of vapor barrier, the better. You can fix the construction stapler, and thin wooden rails can be used as additional fixation.

- Having sheathed all this layer structure with lining, you should leave a ventilation gap.

Installation of basalt wool for roof insulation

The principle of roof insulation has no fundamental differences from the method described above:

- 1st layer vapor barrier;

- 2nd layer of minvat;

- 3rd layer additional crate. Some masters lay an additional vapor barrier or reinforcing layer;

- 4th layer final finish. Most often used hyposcarten or OSB sheets.

Comparative characteristics of basalt and glass wool

These two materials belong to the same category of insulation, for some consumers the ability to save money plays a significant role. This section is aimed at comparing two materials in order to understand whether it is worth replacing one with the other cheapness in the year.

- Unlike glass wool, basalt insulation is passive and chemical and biological parameters.

- Stone cotton wool has more elastic thick and short fibers that are not sleeping during installation.

- In terms of thermal insulation, Rockwul is significantly superior to glass wool, but in terms of the ability to extinguish sound loses.

- Glauding gives a sufficient shrinkage during operation, while the basalt analogue serves much longer .8

- Both materials are able to cause mucous membranes, therefore safety precautions: gloves, protective glasses, respirator or any analogue of it cancel. The concentration of particles in the air should also be controlled.

Each is capable of formulating conclusions on their own. But the unconditional majority of buyers who have chosen basalt wool as a heater remained satisfied with the result.

Buy basalt cotton wool

- Technonikol. This is the largest Russian manufacturing company and the supplier of hydraulic and heat-insulating materials. The corporation entered the market in 1992, and by today they have about 40 production sites in Russia, the countries of the former USSR, the Czech Republic, and Spain. The basalt insulation of this brand with a density of up to 30 kg/m and a thickness of 50 mm can be purchased at a price of 640 rubles. For the packaging (6 pcs.) A thicker mat (100 mm) with the same density indicator will be released about 700 rubles. For packaging.

- Rockwool. The main office of the company is located in Denmark, and 23 digging plants are located in 15 countries. The corporation has chosen a direction for itself, which characterizes its product is not easy as a separate product, and as a complex system, a solution in matters of thermal insulation. Packing of five mats with a thickness of 100 mm and a density of 37 kg/m will cost a little less than 600 rubles. The price of basalt wool per 12 pieces of less thick layers (50 mm) will be 530 rubles.

- ISOVER This is a French brand that releases fiberglass and stone cotton wool. In Russia, this brand has been known since 1993 and has developed private construction and technical isolation in two directions. Four 100 mm mat from this manufacturer will cost a little less than 540 rubles. About the same amount will cost 50 mm material, but there will already be 8 pieces in the package.

The above prices can vary, since most suppliers, depending on how much the goods batch are purchased, increase the price or reduce it.

- Facade basalt wool insulation will cost more. So, for example, the same Thenonikol for external work will cost from 1180 rubles. For the packaging in which the manufacturer put 3 mats of standard sizes. From this we can conclude that it is more profitable to purchase one or two large batches, and not to acquire the material gradually.

Thermal insulation of the whole house will not be cheap, but such heat saving measures will pay off with more than in the cold period.

It is better to use the material

It is better to use the material of the factory manufacture. And the polystyrene is now being made by everyone who is not lazy.

Tell me, here

Tell me, here is https://arh-group.ru/s-bazaltovaya-vata/ basalt cotton wool is suitable for insulation of the bath?