Protection of window openings with the help of gratings has long become a necessity. Barring such ...

|

|

Uneven ceilings are an urgent problem of both old and new houses. If the differences in ... |

Sound insulation problems are more puzzled by residents of apartment buildings. Someone from... |

Thermal insulation materials

We decided to make their home energy -efficient in order to spend less money on its heating, or simply insulate the walls to make living in it more comfortable, but do not know what material to opt for? After all, I want it to be of high quality, not to let water, not too much weighting the structure, was vapor permeable, not afraid of fungus and mold, and at the same time preferably not too expensive, did not have negative influences on human life, but was better natural. Thermal insulation materials presented in the modern market are amazing in their diversity, among which it is not easy to make the right choice. Within the framework of this article, we will determine what characteristics to pay attention to, what advantages and disadvantages have certain types of materials and what they are made of.

Content

- Characteristics of thermal insulation materials

- Thermal insulation materials for walls

- Comparison of thermal insulation materials

To begin with, let's find out why such materials are needed and what they are.

The main function of thermal insulation material is to prevent heat loss from the isolated room, for example, in the cold season, and the penetration of heat inside in the summer. The transfer of heat is due to the movement of molecules, which cannot be completely stopped, but can be reduced. So, in the motionless dry air, the molecules move most slowly. It was this property that formed the basis of the production of thermal insulation materials, which are air, packed in various ways: in pores, cells, capsules.

Characteristics of thermal insulation materials

When choosing one or another insulating material, you should pay attention to several fundamental characteristics.

Coefficient of thermal conductivity (lambda) The main indicator for thermal insulation materials. It shows the amount of heat, which passes through the material that has a thickness of 1 m and an area of \u200b\u200b1 m2, in one hour, provided that the temperature difference on opposite surfaces is 10 C. For example, the heat conductivity of dry air is 0.023 W/(m*c) . The amount of thermal conductivity is affected by other characteristics of the material: porosity, humidity, temperature, chemical composition and others.

Porosity The percentage of air pores in the total volume of the product. It can be 50% or more. In some cellular plastics it reaches 90 98 %. Pores can be open, closed, small or large. Their uniform distribution inside the material is very important.

Humidity The amount of moisture contained in the material. This parameter affects thermal conductivity. Since the water conducts heat very well, the material saturated with wet water will not perform its functions.

Water absorption The ability of the material to absorb water in direct contact with it. A very important point for external isolation, which can be under precipitation, for internal isolation in rooms with increased humidity. If the material absorbs water, its properties will fall.

Vapor permeability The amount of water vapor passing through the material with a thickness of 1 m and an area of \u200b\u200b1 m2, for 1 hour, provided that the temperature is the same on both sides of the material, and the difference in the partial pressure of the steam is 1 Pa. This parameter affects the need to arrange additional vapor barrier.

Density The material affects its mass. It can be calculated on it how much the design will be weighted if this or that material is used to a certain thickness.

Bio resistance It determines whether the development of fungi, mold and other pathogenic flora on the surface or within the structure of the material is possible.

Heat capacity Material is important in regions with a frequent change in temperature. It shows the amount of heat, which can accumulate thermal insulation.

There are other characteristics: fire resistance, strength, frost resistance, bending strength and fire safety indicators. When choosing the material, it is also worth paying attention to them, as well as another indicator that is not directly related to a specific thermal insulation material:

Coefficient U.The ability to skip heat. Whether it is walls, ceiling or floor, depending on the materials from which they are made, can pass heat in different quantities and at different speeds. This coefficient is a combined value, the calculation of which includes all layouts used in layers and air gaps between them. On the value of the coefficient U of a particular building or design will depend on which thermal insulation material can be used, and which the thickness of this material is required.

Thermal insulation materials for walls

To date, the production of thermal insulation materials has been established, both from inorganic raw materials and organic. Consider them separately due to their different impact on the environment and humans, as well as disposal conditions.

Thermal insulation materials from inorganic raw materials

Mineral wool It is perhaps the most common material at the moment. It is made from mineral raw materials: dolomites, basalt and other fossils. The fibers obtained as a result of melting of minerals are fastened with a binder, which is often phenol -formaldehyde resin. The ease of production caused a low price for this material.

Advantages of mineral wool:

- Good heat -insulating properties.

- Practically does not absorb moisture.

- Frost -resistant.

- It can serve as additional sound insulation.

- Does not burn.

- Durable.

- Does not change its characteristics.

- Not subject to decay.

- Breathing.

Flaws:

- Not strong enough.

- Requires vapor barrier.

- Requires waterproofing.

- Phenolformaldehyde toxic substance.

- It requires special disposal.

Release form: loose cotton wool, mats, cylinders, slabs with different densities (light, soft, semi -rigid, hard).

Stone cotton wool It is made from the rock of the diabase by melting and turning the liquid mass into fibers. Such material is 99 % of the air and only 1 % of the rock. It is used to warm walls and other structures everywhere.

The benefits of stone cotton wool:

- Provides sound insulation.

- Does not burn.

- Not subject to decay.

- Prevents the spread of fire. Melts at a temperature of 1000 C.

Flaws:

- Energy -intensive production process.

- It requires special disposal.

Foam glass (cellular glass) It is made of glass powder by sintering with gasoling. The air occupies 80 95 % of the material.

Advantages of the foam glass:

- Durable. You can drive out nails.

- Waterproof.

- Frost -resistant.

- Does not burn.

- Not subject to decay.

- Durable.

Flaws:

- It does not breathe (additional ventilation is required).

- Expensive.

Perlit volcanic rock. When heated, it increases several times, which is why the production process resembles the creation of popcorn. It is used for thermal insulation from the middle of the last century.

Advantages of perlite:

- Environmentally friendly material.

- Does not burn.

- Does not absorb moisture.

- Not settling.

- Resistant to decay and influence of pathogenic flora

- It is easy to use (you can fill up or blow into the voids).

- It is disposed of composting (improves soil quality).

Flaws:

- It can be sprinkled from the voids during laying in the walls of pipes or cables.

The thermal insulation materials from inorganic raw materials also include various heat -insulating concrete: aerated concrete, cellular concrete, foam concrete. As well as concrete with aggregates: keramziton, perlito concrete, polystyrene concrete.

Polymer thermal insulation

Extruded polystyrene foam It has a whole, strong microstructure. The cells are closed, impenetrable and filled with air. Neither water nor air can penetrate from the cell into the cell.

Advantages of extruded polystyrene foam:

- Good thermal conductivity.

- Inert in relation to most substances.

- Does not absorb moisture.

- Stronger than foam.

Flaws:

- Combustible (in the process of combustion, emits toxic substances).

- Not breathing.

Polystyrene foam They are small balls fastened with each other. They can be produced both by a press and in a resident way.

Advantages of polystyrene foam:

- Inexpensive.

- Durable.

- Thermal insulation is well.

- Convenient in installation.

Flaws:

- Under the influence of sunlight yellow and break up.

- Do not breathe.

- Burning.

- When moisture is penetrated, the structure is destroyed.

Poliuretan foam It is a liquid heat -insulating material. When ingredients with air mixes, fine aerosol is formed, which can be sprayed to the surface with any geometry.

Advantages of polyurethane foam:

- Awesome elasticity of the material.

- Resistant to fungi and mold.

- You can warm uneven surfaces.

- Easy installation that does not take much time.

- It has no joints.

Flaws:

- It is burning, secreting toxic substances.

- Not breathing.

- A special installation is required for installation.

Thermal insulation materials from organic raw materials

Paper Used for insulation from the middle of the last century. Such materials are granules obtained from newspapers and other waste paper. To blow these granules in the voids in the walls, the help of specialists is necessary.

Advantages of heat -insulating materials based on paper:

- Do not burn (treated with neutral salts).

- Pour water.

- Fill the cavities well.

- Easy to use.

- They do not harm the environment.

- Prevented by conventional composting.

- Resistant to fungi.

- Do not require additional vapor barrier.

Flaws:

- The limited area of \u200b\u200buse due to the specific form of the granules product.

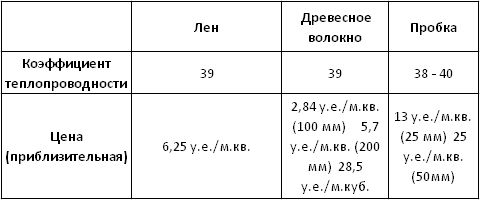

Linenit is used as a heater quite rarely, mainly those who care about the environment and their health. The reason for the unavailable distribution of materials from flax high price. Although over time predicts its decrease.

Advantages of linen insulation:

- Excellent insulation qualities.

- Do not require additional vapor barrier.

- They are disposed of burning or composting.

- Absolutely natural.

- Resistant to fungi and microorganisms.

Flaws:

- It is difficult to cut.

- An additional fire protection is needed.

Wood fiber (cellulose cotton wool)at the moment, it is considered one of the most famous organic thermal insulation materials. It is a woody material crushed to a state of cotton wool. It is produced both in loose form and in the plates. Used to blow in the cavity of the walls.

Advantages of cellulose cotton wool:

- Increased thermal insulation properties.

- Serves as sound insulation.

- Simple and convenient in use.

- Compost.

Flaws:

- Subject to decay and fungus.

- It cannot be used to insulate the hollow walls of old buildings.

- To increase refractory qualities, ammonium polyphosphate has been added.

Cork thermal insulation It is made from cork oak bark without the use of synthetic substances. The cork is another absolutely natural insulation, like flax.

Advantages of traffic jams:

- Does not rot.

- It is not amenable to shrinkage.

- Strong to compress and bend.

- Light.

- Durable.

- Inert to most substances.

- Does not burn (but smolder).

- During smoldering, it does not emit harmful substances.

Flaws:

- Processed with anticipated impregnations.

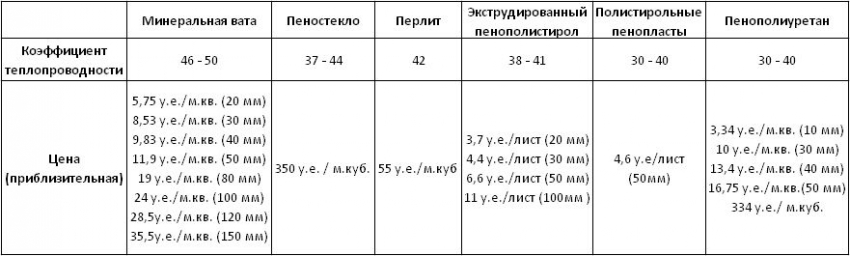

Comparison of thermal insulation materials

Before choosing material for insulation, it is advisable to consult with specialists. Based on the material of the walls, their thickness and operating conditions (climate), they will advise which materials can be suitable in a particular case and what their thickness should be. If you have not heard in the list of proposed options the material that you would like to use, specify this nuance. Perhaps this material simply fell out of the attention of a specialist, or maybe it is categorically not suitable for this design.

It is impossible to single out the unambiguously the best thermal insulation material. All of them are to one degree or another good for specific purposes. The choice depends primarily on thermal insulation properties and on personal preferences and financial capabilities.

For example, arranging an absolutely ecological house made of wood, it will be absurd to use foam -polyteral or polystyrene foam or foam. It makes sense to pay attention to natural materials: flax, paper, cellulose and cork.

In the construction of modern multi -storey buildings, polystyrene and other polymeric materials are everywhere, since their price is small, they are easy to install and have good thermal conductivity. But the influence of such materials on human life basically no one thinks. The developers are enough that the manufacturer assured the safety of the product.

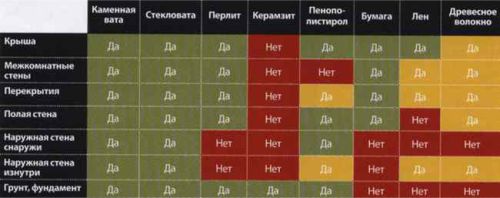

In the presented table of the use of thermal insulation materials:

Gray the color is indicated by the right choice;

Yellow The color indicates options that should be carried out taking into account fire safety;

Red Color - cannot be used.

As can be seen from the table, any of the materials presented in the article is good in its place: some are better to use for insulation of walls, other floors, third attics and roofs. Even for the heat -insulation device inside the building or outside, different materials are suitable.

Good division!

Good division! Jenzhou Technical Company Joda supplies the best thermal insulation material Aerogel thermal insulation. Airgelle thermal insulation has such excellent properties as the perfect insulation effect, sufficient strength,

It is not subject to decay, a long service life, excellent hydrophobic, practically does not absorb moisture, does not burn, prevents the spread of fire, environmentally friendly material, not containing toxic substances, no smell. Detailed information on the site: http: //www.joda-tech.ru/produktsiya/teploisolytsionnoye-odeyalo-aerogena/