Powder painting doors is a technological process, as a result of which ...

|

|

Each owner wants to protect his house or summer cottage from penetration ... |

Modern housing, in our view, is a harmonious combination of the magnificent ... |

How to stick polystyrene

Warming with foam of residential premises has gained popularity thanks to many advantages. The reliability of such insulation is tested by history, as a result of which only a stable increase in demand for foam is observed. All the advantages of polystyrene plates are much superior to the properties of well -known traditional building materials, which is able to ensure a long life of any building, despite climatic conditions. Let's look at how to glue the foam to the wall, and what glue to use.

Content:

- Technical characteristics of foam

- The use of polystyrene as insulation

- The advantages of polystyrene

- The shortcomings of the foam

- Comparison of polystyrene with other materials

- Preparation of walls

- Necessary tools

- Glue for foam

- Features of gluing foam

- Gluing on certain surfaces

Technical characteristics of foam

Foam is one of the common materials, which is used for wall insulation almost everywhere - in mass and individual construction. The material has high technical characteristics. During its manufacture, little energy is spent, but its properties can significantly save on heating.

Standard dimensions of a sheet of foam 1 by 1 meter, 0.5 per 1met. In terms of density, the sheets are also different: the density is 15, 25 and 40. The denser the foam, the better, however, the price for it depends on this. The foam of the twenty -fifth density, which has a thickness of 5 centimeters, is designed for external insulation. The density 15 is necessary for internal insulation and gluing of the foam to wood or concrete, and the foam of the fortieth density can be used as a floor insulation, since the material of high density under the influence of additional loads is not pushed.

Foam is a material whose structure is a foamed mass. The main volume of polystyrene is occupied by air. And its density because of this is a couple of times lower than the density of the raw materials from which the foam is produced. This significantly affects the low weight of foam plates. The material has high soundproofing and thermal insulation qualities due to the large amount of gas in the structure of foam.

From different raw materials, foam of different densities with different strength is produced. The larger the foam has the density, the smaller gas volume is inside the structure and, accordingly, thermal insulation properties are lower. However, in this case, the values \u200b\u200bof the stability of the material to mechanical loads increase.

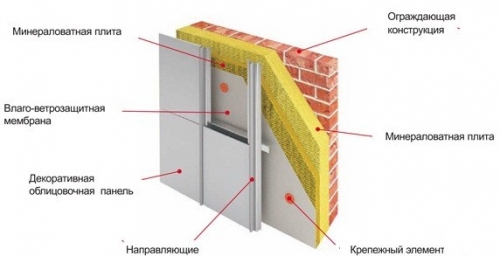

As a heater, foam sheets of different density use, which have a different level of strength. Plates with a small density are required when arranging the creation of maximum protection of the material from mechanical damage. Foam with low density is most often used as a heater with a frame installation technique - where, first of all, all loads are on the frame and the outer layer of insulation.

The use of polystyrene as insulation

As a heater, the foam has found application in such areas: for internal and external insulation of walls, insulation of floors, ceilings, foundations, basement walls, as well as attic. But it should be remembered that the use of this material for internal insulation of the walls that go outside is not appropriate. It is also necessary to find out in advance how to glue the foam.

The reason for this lies in the fact that the wall that is going out should warm up without fail due to internal heating. When laying on the inner surface of the foam wall, insulation and thermal insulation of the walls from heating from the side of the room occurs. As a result, the dew point is shifted in the gap between the layer of foam and the wall or inside the wall.

Moisture will impregnate the wall by changing the thermal insulation properties of the wall. In addition, moisture condensed inside the wall can freeze at low temperature. All this provokes a violation of heat transfer and gradual destruction of the walls. That is why it is so important to observe the technology of installation of foam and find out in advance which glue to glue the foam.

If you decide to use polystyrene as a heater, it is very desirable to insulate the walls outside the building with it. Foam is not characterized by sufficient mechanical strength, including foam with high density. In this regard, there is a need for external strengthening of polystyrene plates.

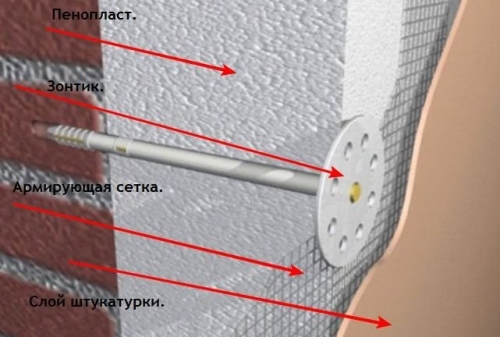

If you insulate the foundation with foam, then you need to protect the foam slabs from the pressure of the soil and the load that occurs with frosty soil tuning. And if strengthening the surface of the foam on the walls, you can do with the use of reinforcing mesh and plaster, then in the situation with the basement insulation, you need more serious protection, for example, brickwork or wooden formwork.

The advantages of polystyrene

Due to its properties, polystyrene is largely indispensable. First of all, it differs in small weight. It is carried out through foaming and further cooling of polystyrene, which in its composition is only 2% (the remaining 98% are gas bubbles). This is precisely the secret of the lightness of the foam: even a child can raise huge foam blocks.

It is known to everyone that polystyrene is easier than water, because it is always on its surface. Therefore, it is very often used for buoys indicating the place from which there is a great depth. Also, the foam is cut quite easily and easily mounted. However, it is important to know how to glue the foam to a certain surface, and strictly follow the instructions.

The fact that polystyrene has excellent stability is also very important. Plates are not afraid of direct rays of the sun, large daily temperature changes, severe frosts, high atmospheric pressure. Due to such properties, polystyrene is very in demand in the construction of residential buildings and decoration of premises.

One cannot help but pay attention to such a characteristic as heat capacity. Thanks to such thermal insulation properties, many consider polystyrene to the best insulation. The foam is inherent in low thermal expansion: stability in the temperature range from minus 180 to plus 80 degrees. Large blocks are customary to be attached directly to the walls of the house, so the heat inside the building is delayed longer.

Foam has the ability to ensure high -quality soundproofing from shock noise and the formation of complex shapes, the structure can be glued with gypsum and cement solutions, as well as mastic. Foam blocks are firewall. It can help with a fire. Of course, the fire will not completely extinguish, but, in any case, it will reduce it. Foam is characterized by a long service life.

Foam slabs can resist many chemicals. Products from this material are non -amid, do not form dust and do not have a characteristic smell. Polistyle foam is safe from an environmental point of view, because in its manufacture, gases and substances are used, which are not dangerous to the environment and humans. The polystyrene does not contain the joints of the freon row, which are harmful to the ozone shell.

It should also be noted that the polystyrene is relatively cheap material if you know how to properly glue polystyrene. This, in turn, can save on the construction and heating of the house. The material is indifferent to moisture, it almost does not absorb it. Therefore, during installation, polystyrene does not need additional waterproofing. Mold and fungus are not formed on its surface.

The shortcomings of the foam

Along with the advantages of foam, this material has some disadvantages:

- Foam is characterized by limited mechanical strength. After installation, it needs additional protection against mechanical damage.

- Foam plates practically do not pass air.

- Foam plates are easily destroyed under the influence of different paint coatings or nitro -paints. Therefore, it is important to first clarify how glue to glue the foam.

Comparison of polystyrene with other materials

The main advantage of polystyrene foam over other thermal insulation materials lies in the fact that it is one of the cheapest materials that have good insulating and mechanical properties, as well as significant structural flexibility. The installation process is simple and does not need to use qualified labor and specialized tools.

Foam is indispensable for creating insulation of various underground parts of the building, where the use of other types of thermal insulation is unacceptable due to the capillary lift of groundwater. It protects waterproofing from the harmful effects of the external environment.

If we compare the level of thermal conductivity of the foam with the rest of thermal insulation materials, then the polystyrene foam plates have a thickness of about 60 millimeters, which is equivalent to thermal insulation properties:

- mineral wate, which has a thickness of 110 millimeters;

- dry foam concrete, which differs with a thickness of 500 millimeters;

- a tree, the thickness of which reaches 195 millimeters;

- brick laying, which has a thickness of 850 millimeters;

- concrete with a thickness of 2132 millimeters.

The difference in price between glass and mineral wool and polystyrene foam is significantly less, because they compete in this regard much more closely. But these materials are characterized by low strength, which are not of the ability and tend to sag after direct laying to the place. Their other disadvantages are unpleasant sensations during installation and a tendency to absorb moisture, which sharply reduces the insulation coefficient.

Preparation of walls

Before gluing the polystyrene to concrete or external walls, they need to be cleaned of dust. To do this, you can use a spray gun. If it is not, you can use the brush and with its help to clean the surface of the walls well. If the walls are uneven, previously align them. Any uneven wall (concavity or bulge) of more than one centimeter will inevitably provoke a breakdown breakdown.

Also, the surface must be primed. It is better if a brush is used for this. This will additionally serve as cleaning from construction dust and garbage. Before gluing polystyrene plates under the window and around it, it is recommended to stick a grid, which can then be used for reinforcement. The grid with a stapler or glue is attached on the wall.

The grid is sold in rolls, so for more convenient operation, the grid can be cut with stripes of 40 centimeters close wide. The mesh should be glued so that at least ten centimeters of the grid are under the insulation, the rest of the material after gluing the foam plates can be wrapped and glued to the insulation. In this case, it must be connected to the main mesh that is glued to the foam after the gluing and beating procedure to the walls.

Necessary tools

To glue foam, it is customary to use the following tools:

- a drill with a mixer nozzle, which is needed to mix gypsum putty and adhesive mass;

- ground spatula, which is designed to apply glue;

- a small spatula as an improvised tool in the work to remove excess glue from the comb and the wall, as well as the putty rooms for a wide spatula;

- wide spatula, which serves to align the surfaces;

- a perforator that has a drill 10 millimeters for mounting fungi when fastening polystyrene;

- bucket for the manufacture of the solution;

- a wide brush for applying a primer.

Glue for foam

Before you start gluing slabs, you need to find out how to glue the foam. It is necessary to build from several main provisions, which will help determine the required type of composition. First you need to join a type of surface on which you will install the heat -insulating material.

It is also recommended to pay attention to the type of insulation itself. Other characteristics in such works are not significant. It is important that the selected glue does not contain gasoline, acetone or other solvent, which is able to enter the reaction with polystyrene.

Some works may require a procedure for gluing polystyrene sheets with each other. You can use any wet or dry type glue for this, which does not contain solvents in its composition. With the help of such substances, foam on the work surface is mounted.

Features of gluing foam

The process of gluing polystyrene foam is characterized by some technical features, which are recommended to look closely before the installation. The glue of the polystyrene foam is usually performed by applying glue heaps in 5 places of foam sheet.

If you additionally fasten the material with dowels, then you need to withstand the glued sheets as much in time as it is required to dry out the substance. After mounting the sheets, refrain from touching them, because you can move individual elements of the insulation until the glue dries.

To determine how and how to glue the foam, it is necessary to clearly indicate the scope of sheets of insulation. If you use sheets to insulate the internal space of the frame wall, then you can select the composition in random order. However, when working with the lining of external or internal walls, select the composition of the corresponding class. Outdoor sheathing needs an enhanced facade glue, which has high resistance to environmental effects.

Gluing on certain surfaces

Concrete walls are quite cold, therefore, they require when gluing polystyrene slabs of creating high -quality insulation. The most common composition for such work is foam foam, which is made on the basis of polyurethane in the mounting cylinders.

When using such cylinders, you need to purchase a special flushing that does not allow the composition in the tube to dry. The use of polyurethane substances provides the following advantages:

- Simple and quick installation;

- High -quality adhesion of thermal insulation material with the working surface;

- The possibility of processing between the stoves of the joints, if between them the distance does not exceed 2 mm.

In addition, the described foam allows you to glue the foam to the metal. The polyurethane structure with any surfaces is excellently adapt, but it is necessary to be extremely careful when it is used. The use of washing allows you to reduce the cost of buying additional cylinders, which will become necessary in the case of drying out the tanks used.

Now you know how to glue the foam to metal or concrete, and found out which glue is better to use. Follow our recommendations carefully so that the clutch is as strong as possible, and the insulation of the house is the highest quality.

Well, finally it’s clear. BUT

Well, finally it’s clear. And then they write nonsense everywhere: either polystyrene, then the dew point, then you can’t warm the beam at home, then the chemistry is harmful, although it surrounds us everywhere, it is better minvat. Thank you for explaining, I will warm the house from glued beams.

well done is clearly and clear

well done is clearly and clear

Well, what, the beam has already rotted already?

Well, what, the beam has already rotted already?