The perfect roof includes not only high -quality and expensive material for ...

|

|

Initially, the ceiling beams were by no means decorative elements of the room, they are on ... |

Properly made backlight can favorably emphasize the strengths ... |

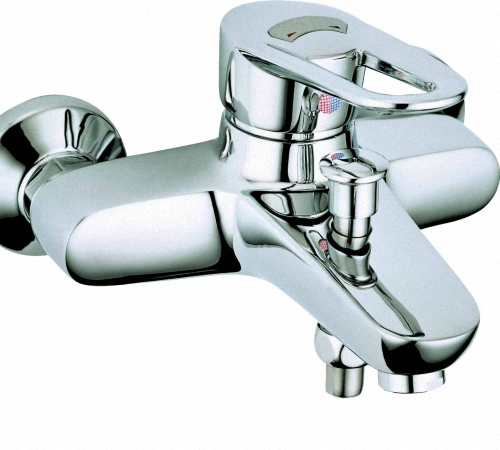

How to change the gasket in the tap

In any mixer, no matter how high -quality it is, sooner or later such a well -known problem is manifested as the formation of leaks in the tap. Even a slight sealing of water can lead to a further breakdown of the valve and flooding of the room. Of course, for each work there are specialists, and any plumber will cope with such a problem in 5 minutes. Nevertheless, in the presence of a simple tool, the question of how to change the gasket in the mixer will not become problematic even to a simple person, far from the concepts of Bamca and a crane-boux.

Table of contents

- What is a crane and how it works?

- What tools will be required to replace the laying on the crane?

- How to replace the gasket in the tap?

- Replacing the gasket in the taps with the reciprocating movement of the rod

- Replacing gaskets in cranes with a flywheel

- DIY new lining

What is a crane and how it works?

To start practice, you need to study the theory well. The mixer is a camera in which mixing of hot and cold water comes from the water supply. Then it gets to the consumer through a nose equipped with a simple mesh filter of mechanical cleaning, which provides some protection against solid particles with a size of more than 100 microns and, in addition, prevents the appearance of splashes with strong pressure.

The mixer is attached to the outputs of water pipes using threaded adapters or flexible hoses. As a rule, in most typical apartments on the pipes there is already a thread for fixing, so the installation of the mixer itself will not take much time. In order for the water to enter the user, each mixer usually has two taps-bokes, one of which serves to supply hot water, the second for cold. But recently, models with a single -stage mechanism are more common, in which the temperature and density of the water flow is set by turning and lifting the handle.

At the moment, the design of the mixer with two boux taps, which consists of the following components: is most widely used: the following components:

- the body of the mixer, in which mixing of different water supply temperatures occurs,

- pouring a rotary or cast structure through which water is supplied,

- the axle box tap supplies and regulates the flow of water from the mixer,

- the handles installed on the taps, through the position of which the required flow is set,

- rubber gaskets at the place of mounting the crane to the sink,

- laying bug cranes,

- a lung grid, which is a simple filter of gross mechanical cleaning of incoming water from rust and clogging,

- stock for fastening,

- facing nuts,

- decorative plugs. Often they have either color identification to indicate the temperature of the water flow passing through them, or an informing inscription. In addition to decorative goals, the plugs are used to close the screws of fastening the handle to the cranes.

The skins themselves are distinguished by the types:

- Cranes of the old model acting on the principle of raising or lowering the rod when turning the crane handle. According to statistics, such models more often fail, but are more simple in the repair of cranes and maintenance, and at the same time have a lower cost.

- Cranes of a new sample have in their design one control hilt connected by plates with a tap with a box. When raising this handle and its turning, water enters the appropriate position from the spout. From an aesthetic point of view, such models are more attractive and more convenient.

What tools will be required to replace the laying on the crane?

First of all, new gaskets will be required, which are desirable to purchase several pieces. Even if in the tap leaking is observed on one axle box, it is advisable to replace all gaskets. More often, leaks occur in a box through which hot water passes, since such conditions are more destructive for the rubber used. Under the influence of high temperature, the gasket begins to gradually collapse. The material for it uses a different one, starting from skin for a crane with cold water, and ending with modern options like paronite or silicone for hot water.

For a direct replacement of the leaky gasket, the following tool will be required:

- divorce key,

- screwdrivers,

- fUM-toe or Packla for winding on the thread,

- sealing gaskets.

The most popular now begin to acquire gasket gaskets, which are made by pressing the rubber mixture and adding asbestos and powder components.

A similar material is characterized by the fact that when getting wet, it increases its volume, producing effective compaction. The second advantage is the use of hot water. The operating temperature range is from -50 to +400C, so you should not be afraid of deformation of a parony lining under the influence of temperature. The last convincing argument towards her choice is the price that starts from $ 0.10 per laying.

Before starting work, it is important to remember that most of the elements of budget models of cranes are made of silumin. Therefore, when twisting taps, it is not required to make significant efforts so as not to deform the basis of the mixer.

How to replace the gasket in the tap?

To start work, you must first block the flow of water into the mixer, otherwise it is quite possible to get a whole fountain when unscrewing the crane. If the valve is tight and is not amenable to exposure, then before attaching a greater force that can lead to the appearance of cracks at the base, it is worth covering it with a cloth and watering with hot water and a temperature of 60-80C for a minute.

Roughly speaking, prepare a cup of water from a boiled teapot. When heated, the metal tends to expand slightly, so the screw connection will succumb to noticeably easier. Distinguish their methods for replacing sealing gaskets for different types of cranes.

Replacing the gasket in the taps with the reciprocating movement of the rod

When the water supply was blocked, you need to drain the residue in the system, after which the main stages of work on replacing the gasket are performed:

- on the valve with the help of a stationery knife or a small flat screwdriver, a decorative plug is pulled up, under which a bolt fixing handle is often hidden,

- using a screwdriver, the bolt is unscrewed and the rotary mechanism is removed,

- next, you need to make a visual inspection of the dismantled rotary mechanism, in which the gasket on the crane is located. To do this, with the help of a knife or screwdrivers, they are praised and removed from the structure,

- the new gasket is dressed in the place of the old

- the carving on the axle is placed by the new FUM tone after the removal of the old insulating material,

- the crane is collected in the reverse order and is checked for the relevance of the leakage problem.

If the laying is attached to the stem node with a small screw or small screws, you will have to replace the entire node. If the fasteners demonstrates traces of the effects of corrosion or is simply not removed. When the mechanism is observed by the formation of lime plaque from hard tap water, it is removed with vinegar or alcohol.

When assembling a tap, the core is screwed into the mixer, after which it is tightened with a divorce key to the stop. It makes no sense to be too zealous in twisting and attach excessive strength - otherwise the life of the core will significantly decrease.

Replacing gaskets in cranes with a flywheel

Such varieties of plumbing equipment have a protective casing in their design, which will first be removed when replacing the gasket. Under the casing and there is a nut that fixes the crane. Next are the procedures:

- with the help of a wrench, the nut is unscrewed and removed from the mechanism,

- a neck is extracted from the mixer, in which the gasket is located,

- following this with the help of improvised means, the laying is extracted and visually inspected,

- if replacement is required, then the old gasket gives way to the new one and the crane is collected in the reverse order.

It is important to pay attention to the fact that all fasteners must be twisted carefully, avoiding excessive load. In addition, the text is not in vain mentioned the need for a visual inspection. The leaks in the tap do not always arise through the fault of the gasket, despite the fact that this is one of the main reasons for their appearance. But given the price of a set of gaskets, it makes sense to make a replacement anyway, especially if this has not been completed for a long time. If the leak after assembly still makes itself felt, then it makes sense to look for the reason in the wear of the valve of the valve of the valve with which the water is supplied.

In modern mixers, ceramic sealing gaskets are increasingly used, which are highly reliable and wear -resistant, but even under the influence of high temperatures they can become unusable.

DIY new lining

Despite the fact that gaskets of any size are available in each plumbing store, some people will have a question: how to make it with their own hands? Situations are different:

- the leak appeared at the wrong time when there was no store with components nearby,

- or it has already occurred later.

In this case, you need to know that it will not be difficult to make the gasket of the skill crane.

To create it, you will need a small piece of rubber, 2-3 mm thick. It is extremely desirable if it is technical rubber - but for a temporary craft it will come down and simple. With the help of scissors, a circle of the corresponding diameter is cut out of rubber, in which the hole is later pierced with an awl. Shilo is necessary because it is very difficult to make a neat and even hole with scissors or knife.

The diameter of the gasket should be slightly large in order to provide maximum seal when shrinking. In this case, it is advisable to cut the outer angle of gasket at an acute angle with scissors so that the edges of the rubber are not deformed and not vibrated when water supply. Locks are often used by a peculiar tool for making gaskets, called survey. It is a small pipe of the same diameter in length as the required gasket. One end of the pipe is sharply sharpened, and as a rule it is advised to be sharpened with a file, and not in a machine way, since in this case steel will begin to heat up and lose strength. After the tool is sharpened, it is used to quickly make gaskets that will differ in even edges. Further, the necessary holes are pierced in them with an awl with an awl.

The specified method is suitable for those who are going to make gaskets in artisanal conditions. Otherwise, it is impractical for domestic needs. Simple rubber is quite susceptible to hot water and heat, so the deformation is accelerated. This is especially true for those mixers in which hot water enters the water heating tank.

While the average temperature of hot water in the water supply is an average of 40C, the boiler in normal mode heats water to 60C - therefore, resorting to homemade gaskets is only as a temporary solution when the problem is relevant and there are no plumbing stores nearby. Otherwise, it makes no sense to look for rubber and cut the blanks - it’s easier and cheaper to buy a ready -made gasket made of the same paronite, which exceeds technical rubber in all indicators, not to mention simple.

As can be seen from the above, the replacement of the gasket is a fairly simple operation, for which often the call masters require considerable amounts. Roughly speaking, repairs will cost no less than $ 10.