If necessary, profile pipes are used in the construction of the canopy. Farms from profile ...

|

|

High -quality roof guarantee of reliable protection of your home from the vagaries of nature ... |

The car is not a luxury, but a means of transportation ... |

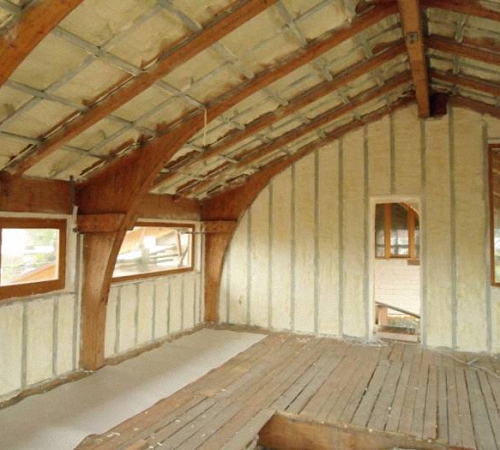

We use the blowing cotton wool correctly. Thermal insulation of the roof with your own hands

Low thermal losses, vapor permeability light weight and non -combustibility - these advantages of the double wool make it popular thermal insulation material. Due to the automation of the mounting process, the insulation rate increases eight times compared to roller materials. Find out the main secrets of working with a double wool and get valuable tips from roofing specialists.

Table of contents:

- Pros and cons of the stooped cotton wool - the characteristic of the material

- Calculation of the thickness of the insulation with your own hands

- Instructions for the installation of a double cotton wool - technology and recommendations

- DIY wool installation device

- Safety precautions for thermal insulation of the roof - methods of insulation of the roof of ecowide

Pros and cons of the stooped cotton wool - the characteristic of the material

There are three options for the blowing cotton wool in the ratio with its composition:

- basalt;

- glass wool;

- Ecowata.

Mineral or basalt wool is made using basalt rocks. The uniqueness of the composition ensures complete environmental safety of the material. Mineral blowing wool does not contain formaldehydes, is not able to form glass dust, unlike glass wool.

The basalt and glass wool of the sigh -type are made of scraps of heat -insulating plates. At the heart of cellulose cotton wool is the processed waste paper. Additional compounds of anti -riveting and antiseptic effects prevent decay and combustion of the material.

We note such advantages of a basalt -based double cotton wool:

1. Low level of thermal conductivity. Thanks to this, at home heating is used 4-5 times less heat.

2. Light weight does not load the overall structures of the building, the blowing cotton wool is used both for insulation of walls and floor, and for thermal insulation of roofing floors.

3. The material is characterized by high vaporovability and moisture repellent properties. These indicators reduce the risk of the development of fungus and mold in areas insulated with stirring cotton wool.

4. The fire safety of the building is ensured by absolute non -combustibility.

5. The basalt -body wool does not rot, it has a long service life.

Another advantage of the blowing cotton wool is the ease of its installation. Thanks to the foamed consistency, the material falls into all secluded corners. However, special compressor equipment is necessary for the installation of insulation. Automation of installation work can significantly increase the speed of laying insulation.

Superior cotton wool forms a holistic seamless structure, inside which the cold bridges are not formed. The risk of additional thermal losses is reduced. The insulation is mounted both at the stage of construction of the house and after the main finish.

High -quality stoop wool has a homogeneous consistency, fills all the voids, forming a continuous even and dense layer. With the help of a double cotton wool, pipes, building structures of various shapes and configurations are insulated.

Among the shortcomings of the double cotton wool, we note:

- the need to use special equipment for supplying material under pressure;

- By installing the blowing cotton wool on drywall structures, make sure that they are laid in two layers, otherwise they will swell them;

- Mineral and glass wool needs additional waterproofing;

- It is most often used to warm structures with large volumes, it is impractical to order expensive equipment for insulation of one wall of the house.

Calculation of the thickness of the insulation with your own hands

When performing calculations by determining the thickness of the insulation, take into account such factors as:

- the material from which the walls of the house are made;

- thermal resistance of the climatic region;

- the number of windows and doors;

- additional thermal losses;

- The composition of the insulation;

- Thermal gear.

When insulating the house with a conceal cotton with cellulose base, pay attention to such indicators - the thickness of the insulation in fifteen centimeters is:

- eighteen centimeters of mineral wool;

- forty -six centimeters of foam concrete;

- half -meter wooden beam;

- ninety centimeters of expanded clay;

- One and a half meters of brickwork.

Pullulous stoop wool is characterized by an affordable cost. The material is opposed to the formation of fungus and mold. Environmental safety allows you to use stupefied cotton wool in any for the purpose of the premises. The thickness of its laying depends on the density of the material used.

When performing calculations of the thickness of the insulation, pay attention to the resistance of thermal transmission to the material. In order to determine the value of the graduates of the day of heating time, use the formula:

GSOP \u003d (T8-T0T) Hzot

- T8 - the temperature in the house - its optimal value is from 18 to 22 degrees of heat;

- That is the average value of the air temperature;

- Zot is the number of days in which heating is used.

After determining this value, decide on the thickness of the insulation on the walls, ceiling, floor. In addition, take into account the material from which the walls are built, for brick, concrete, wood and foam concrete, the indicators will be different.

For more accurate calculations, familiarize yourself with the recommendations from the manufacturer by the number of layers, for applying a doublewater on various designs.

Instructions for the installation of a double cotton wool - technology and recommendations

Ecowata is applied with a blowing installation using a humid-cell or dry method. The first method is based on the spraying of the insulating layer: ecovy, adhesive solution, glue and special dispersion. Next, the layer is cut in a ratio with the required dimensions and dried. This method is called visual, since the specialist has the opportunity to control the filling of the frame part with cotton wool. Installation work is carried out at temperatures above +5. Drying products takes at least three days. Be sure to have ventilation, which prevents the accumulation of moisture and steam in the insulated space. As a result, the use of a wet-cell method allows you to get a coating with excellent heat and sound insulation characteristics.

A faster and simple way to use is a dry way of applying a blowing wool. The inside of the frame structure is pre -coated with a craft with paper or construction cardboard. With their help, a closed space is created. To fix this material, a plastic mounting tape or stapler is used. Next, the stooped wool is fed into the frame with a special device. In this case, the clutch of the material with the surface is less than when using a wet-cell method.

In general, we highlight the three main methods of applying a doublewater wool with your own hands:

1. Manual version - loosening the insulation with improvised tools and laying it to the surface. The quality of such insulation is at a low level. Vata is installed inward structures with maximum density. The method is relevant only with thermal insulation of small surfaces.

2. Fulfilling installations - use ecowan for preliminary loosening. The device gives material under pressure, providing its uniform spraying on the surface. The advantage of the method is seamlessness, the lack of the need for dismantling of structures.

3. The surface of the surface with a wet method - the supply of material is supplied simultaneously with water and glue. Thus, the quality of the clutch of cotton wool with the insulated surface improves. The surface is absolutely evened, rapid to solidify the material and good performance.

The stooped cotton wool has a compressed shape and needs to be loosened by special equipment for application. The blowing installation consists of such components:

1. The base platform - has the shape of an island, the inside of which is filled with a gearbox, engine and duct.

2. The basis of the mechanism is a low -fluid engine. It differs in low sound performance, minimal dust formation and prolonged operation.

3. To capture the double wool, a device in the form of a gateway is used. The fibers of the material are pushed out with a bulk hose.

4. In order to dosage pulp material, the equipment is equipped with a damper.

5. To increase the speed of the heat -insulating material, a gearbox is used.

6. In addition, the mechanism is equipped with a baking powder, loading funnel, control panel and emergency switch.

DIY wool installation device

If you rent or purchase expensive equipment for the supply of stoop wool, we recommend that you use the option of replacing it with a home -made device. In the process of working on the device, the presence will be required:

- garden vacuum cleaner, whose speed is at least 200 km/h;

- plastic capacity;

- corrugated hose, about 8 meters long, with a diameter of 60 cm;

- adhesive tape;

- electric drill with a mixer nozzle;

- Vata.

Instructions for the assembly of the device for feeding wool:

1. Disconnect one part of the vacuum cleaner and rearrange the terminals on it. This is necessary to enhance the power of the device.

2. Remove the teeth with bites that are with a vacuumber. Otherwise, the stoop wool will fall into the device, leading to its jamming.

3. Connect the corrugation with the vacuum cleaner vacuum cleaner. To fix it, use the usual adhesive tape.

4. Using a cloth cloth, make a seal that increases the tightness of the structure.

The device is ready - proceed to its use. For work, at least two people will be required. When thermal insulation of the walls is performed, in their upper part, build holes with a diameter of about 6-7 cm. Fill the plastic container with a doublewatter wool. Ecowata is struck by a construction mixer. The material will double in volume by half.

The corrugation is placed in the plastic container, not reaching the bottom by 30 cm. Use the praise ring to compact the cracks. Run the vacuum cleaner that will pick up cotton wool from the container by handing it to the wall. The device is used exclusively for insulation of the ceiling or walls. On the floor, cotton wool will not be sprayed.

Safety precautions for thermal insulation of the roof - methods of insulation of the roof of ecowide

The most important advantage of the installation of ecowan on roofing structures is the speed of work. Thermal insulation of the roof of a flat type is performed in 3-4 hours. The structure of the ecovite for insulation is distinguished by looseness and lightness. The material does not burn, does not form mold and fungus, is characterized by high indicators of thermal efficiency.

After the installation of the ecovata, it fills all the cavities and gaps without forming butt joints. Among the advantages of insulation of the roof ecowide, we note:

1. Environmental safety and harmlessness of the material. Ecowata is used for both internal and external thermal insulation.

2. High thermal insulating abilities make this material convenient and effective in use.

3. The material is not amenable to rot, the development of the fungus or mold.

4. The ease of installation and speed of work is another advantage of the blowing cotton wool.

5. Compared to roller heaters, the cost of ecovy is an order of magnitude lower.

Working conditions and individual features of the roof determine the method of using the concealwatter in everyday life. Foam for thermal insulation of the roof is less effective compared to ecowide.

Dry installation is effective in the process of insulation of the lower overlap, attic, attic and horizontal areas of the roof. The insulation in dry consistency is sprayed into metal, concrete, wooden, brick surfaces. Roof insulation is performed in two hours by two people. This method is quite fast, but less high -quality than wet wool. Previously, the wall is covered with water diluted with glue, only after that the blowing wool is applied to the surface. The result is a perfectly flat coating with higher performance.

The thickness of the stirring cotton wool in roofing areas should be at least 18 cm. Be sure to leave a ventilation gap for 10 cm. Make sure that snow does not accumulate on thermal insulation material in winter, this will lead to damage and reduce operational characteristics.

Under the roof and on the ceilings, apply the blowing wool only in a dry way. On the rafters and on the roof, it is necessary to pull the vapor barrier membrane, which is fixed with boards. Ecowata is installed through small cuts in the membrane, in the future they are sealed with tape.

Warming of roofing structures with a stupery cotton video:

the author does not understand what he writes about

the author does not understand what he writes about and what is a conceal bulk insulation.