Tuplex or cork - which one is the best substrate for the parquet board? This question...

|

|

Glass blocks are hollow glass bricks that are widely used in ... |

In recent years, the ceiling is gaining more and more popularity by decorative ... |

Cold roof waterproofing

The roof protects the residential building from precipitation. But how to protect the roof? The first thing that comes to mind is the finish coating. But its functions are slightly different, due to the fact that moisture can still penetrate through the roofing material. On the path of moisture by a real barrier and, in fact, the only defender of the roof from getting wet and pernicious exposure to water is waterproofing.

Content:

- The need for waterproofing cold roof

- Materials for roof waterproofing

- DIY waterproofing waterproofing

The need for waterproofing cold roof

The main task of the roofing is the protection of buildings from wind load and precipitation. If without fail, under the roof of the insulated attic, there should be three layers (insulation, vapor barrier and waterproofing), then under the roofing of an unheated attic there may be nothing at all. However, in practice, a layer of waterproofing is still mounted on the other hand.

If the water sources were only outside, then you could, in principle, do without waterproofing of the cold roof, while hoping that the quality of the roof itself will guarantee the lack of blowing, snow, rain and any leaks at 100%. With competent installation of some types of roofs, this is so.

But the problem lies not in the precipitation itself, but in their condensate, that is, drops that fall on the inside of the roofing. The likelihood that condensate will appear is increasing if, for example, engineering equipment through the attic passes. It can be fireplaces of fireplaces, chimneys, as well as various elements of heating and hot water supply systems.

No matter how effective thermal insulation, heat generation always occurs, therefore, a significant difference in temperature occurs in the attic. Depending on the various temperatures, a different amount of moisture is formed in the air, and when the warmer air is transferred to the roof, it reaches the dew point, this leads to the appearance of condensate.

Therefore, there is no doubt about the need for waterproofing a cold roof from a metal tile, which makes it possible to facilitate the process of converting the attic building into a living attic if you have such a desire. Therefore, it is not necessary to neglect the waterproofing of the roof that protects the torn space from condensing and atmospheric moisture.

In principle, in cold attics for waterproofing roofs, materials of any type can be used: anti -condensate films, diffusion membranes and ordinary films. The owners most often choose anti -condensate films, they are cheaper than diffusion membranes. And their advantage over ordinary films lies in the fact that they have a vile layer on the inside, thanks to which they can hold condensate until a certain time, until the conditions for evaporation of moisture are created.

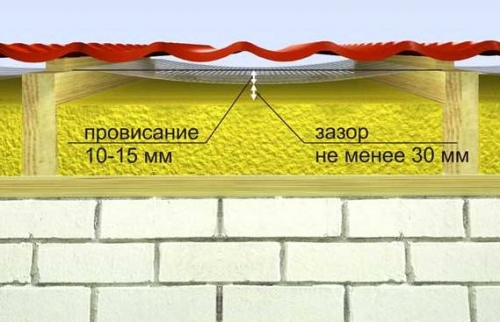

In the cold roof, the waterproofing film is installed for profiled sheets at a distance of 5 centimeters (for such a goal, an additional design is made). With this, the temperature will be leveled on the inner and outer side of the sheets. A properly mounted insulation system for cold roof will bring no less benefit in terms of reliability of the structure than the roofing in itself.

Materials for roof waterproofing

For a variety of roofs, various materials are used as waterproofing: starting from the common roofing material in rolls and various mastics, to superdiffusion membranes. Which to buy material depends on the roof of the roof and operating conditions. First of all, it is necessary to determine the roof pie, and the choice of waterproofing material for the cold roof will occur on its own.

Crystal insulation

Mastics are used as an independent type of waterproofing for flat and bulk roofs. But usually used coating insulation as an auxiliary event. Namely, in order to repair various roller roofs, the location of the displaced joints and cracks of roller material, sealing the auditory windows, pipes of pipes, additional insulation of the ridge part, ends, end parts and gluing tiles of bitumen.

For the installation of a mastic roof, it is necessary to carefully clean the base of the exfoliating parts, dust, and dirt. It is also additionally recommended to impregnate the base with a degreasing composition or bitumen primer. But mastic cannot be used in the installation of inclined roofs as an independent waterproofing.

Ruberoid

A very common and popular material for the construction of a cold roof, as it is relatively not expensive. It is used for roofs with an angle of inclination from 0 to 25%. But still, he loses rapidly his fans. The fact is that the roofing material has low durability, and after some time, all its shortcomings are manifested: bitumen material is destroyed under the influence of UV, a cardboard base decreases, integrity is disturbed, leaks begin. In addition, it is based on exclusively combustible materials.

Its new analogue with some eliminated shortcomings is the Euro -Ruberoid, which is based on non -wagging material (polyester, fiberglass, fiberglass), which is covered with a special modified bitumen composition. Such a Euro -Ruberoid has a greater durability and, accordingly, the highest price than the predecessor, but is still fuel and non -ecological. From this it follows that the use of euro -rubled in small areas for roofs is often not profitable. But if these are flat roofs, then this option is suitable.

Permamin

Permamin was once a rather popular roof waterproofer, which was used in the installation of a cold roof. It was he who came to replace the roofing material, but also lost its popularity. The reason for this is rapid aging, low strength, loss of thermal insulation characteristics, non -ecologicality. This isolation option is the cheapest, but at the same time short -lived. From this it follows that peramine can be used exclusively for temporary protection of the roofing.

Members and film

Polypropylene or PVC membranes include waterproofing films. For several reasons, such materials are gaining popularity: high indicators for waterproofing, high base strength, vapor permeability, durability (up to about 50 years).

Membranes are divided into the following species: diffusion, pseudo -diffuseum, superdiffusion and anti -condensate. Each type has its own characteristics of application and its own purpose. Well, the price of membranes, unlike other waterproofing materials, is quite high. Moreover, their cost is often proportional to the characteristics of a certain material.

Pseudiffusion membranes are a film with a fairly low level of vapor permeability - up to 300 g/m2/24 hours. Such a film can be used in order to protect the cold roof from corrugated board. There are no restrictions in this case for its adaptation. If it is used in the cake of the insulated roof, then it is necessary to make a ventilation gap between the insulation and the film. For its device, you should additionally make a crate. Because of this, the cost of such isolation can increase and amount to an amount equal to ordinary diffusion membrane.

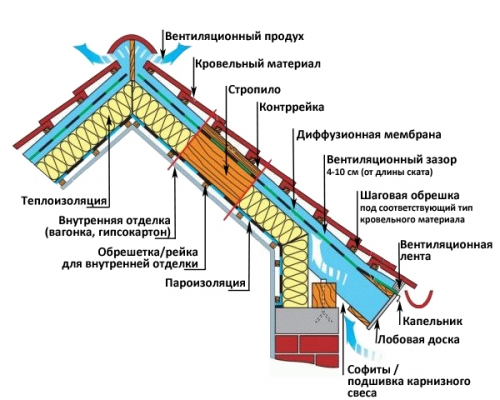

Superdiffusion and diffusion membranes are called a perforated film with high (more than 1000 g/m2/24 hours) and medium (equal to 400-1000g/m2/24 hours) vapor permeability indicators. For waterproofing of the cold roof, this vapor permeability is sufficient. The ventilation gap in the case of this film is not required. Such membranes have many advantages: can be installed directly on the insulation; Disputes steam from the inside and at the same time does not pass moisture inside; It is for a heater by wind protection, this retains heat in the undercarbon space; In an dusty environment does not lose characteristics.

However, such material forms condensate on the upper plane when the pair is removed, so it cannot be used under the roof due to what can corrode. If the finish coating is made of metal (zinc, steel, aluminum, copper), volumetric diffuse membranes are used. The layer that is in contact with the roofing material acts as a kind of separator, which absorbs and this removes condensate from the metal roofing.

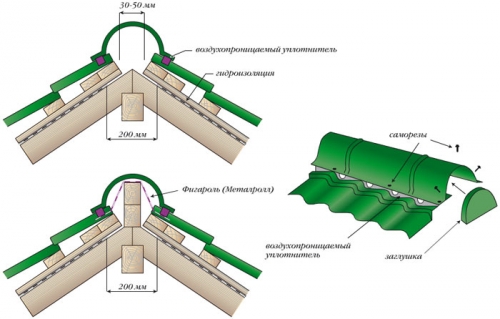

Anticandenate membranes are also used for folding and metal -based roofs. The villous carpet is on one side of the film. This side is turned out to the finish coating, as shown in the video about the cold roof of metal tiles. It is necessary to arrange a ventilation gap under insulation, since in such a protection the vapor permeability approaches zero.

DIY waterproofing waterproofing

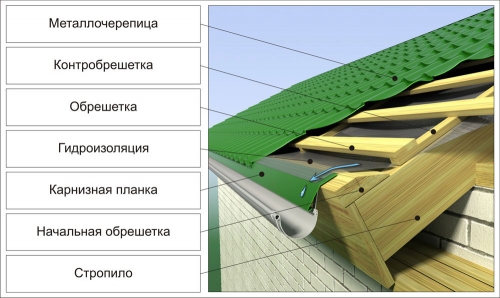

The waterproofing, which is correctly equipped, should be similar to a layer pie that needs to create a substrate. Its composition depends on the very type of substrate. Under the cold roof, this layer is as follows. The frame is laid on the rafter structures from the counterparty and crate. The waterproofing material is laid on the crate and pressed by the counter -scheme.

For the counterparty, the best material is impregnated with an anti-piren solution or an antiseptic of a rail, 4-5 centimeters wide and 2-3 centimeters thick. It is necessary to lay the labels horizontally, and vertically - the boards of the counterparty. In this case, the channels should form between the rails of the counterparty, which have a height of 2-3 centimeters. They are needed for roof ventilation. Take such a distance between the slats that the entire area of \u200b\u200bthe channels is 1/100 of the roof area.

You can get rid of steam moisture using ventilation. With a roof slope area in a hundred square meters, the area of \u200b\u200btotal ventilation ducts should be one square meter. Ventilation ducts must pass to the roof of the roof so that a vapor of moisture passes through the holes in the upper of the roof.

The procedure for waterproofing the design of the cold roof is as follows. Close the waterproofing film along the roofing cornice with sequential rows. Lay the material horizontally, while moving from the cornice to the roof skate. The width of the overflow depends on the degree of roof slope, which is in the limit of 10-20 centimeters.

The film is fixed using galvanized nails with a wide hat or brackets of a construction stapler. With tape, the place where the film is joined in order to get the complete tightness of the waterproofing of the attic. In the same way, subsequent layers of waterproofing film are laid in the same way. Their number is determined independently.

Between the rafters, the sagging of the film should be about twenty millimeters. Between thermal insulation and the film, an air pocket of 40 millimeters must remain. In order to ensure ventilation of the undercarbon space, you should make a skate on the skate, that is, the gap between the axis of the ridge and the edge of the film. The required retreat distance is 50 millimeters.

In the areas where pipes, antennas and other communications are installed, waterproofing film is fixed to closely located bars of the crate, having previously cut it. Use a construction stapler or bilateral tape. When the attic windows are decorated with a film, you should always be guided by special instructions from the manufacturer of the material. On top of the film with the interval between the bars of 10-15 centimeters, the counter is nailed.

Thus, with properly mounted waterproofing, the total service life of the insulation, roofing, and, of course, the entire roof will last. Therefore, it is necessary to treat the choice of protective material from moisture and strictly follow the technology of laying waterproofing.