How often in construction stores you have to literally get lost against the background of endless ...

|

|

The owners of suburban farms often have a need to build a bathhouse. She is... |

In order to quickly and efficiently make the roof of waterproof and persistent to ... |

Waterproofing film for the roof: Features of choice and installation

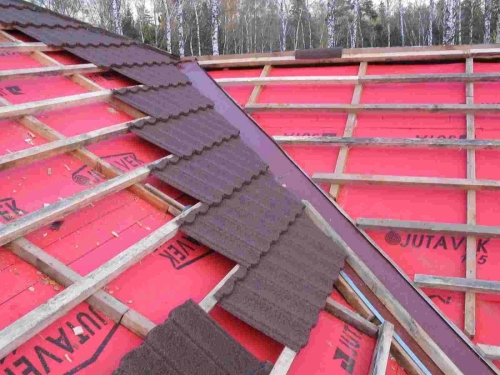

The roof of any type is subjected to the destructive effect of rain and snow. When erecting the roof, there is a need to arrange a waterproofing layer, reliably protecting the undercarbon space from the penetration of precipitation. Excessive moisture of the roof structure is opposed by waterproofing films. Consider the main types of film waterproofing, give advice on their choice, as well as describe the step -by -step installation of a roll hydraulic boar.

- Waterproofing film for the roof the purpose and characteristics of the material

- Types of a subcutaneous waterproofing film

- Review of film waterproofing of different manufacturers

- Tips for choosing a waterproofing film

- Basic requirements for the arrangement of the waterproofing layer of the roof

- How to lay a waterproofing film: installation sequence

- Notes on the installation of diffuse/superdiffuse membranes

Waterproofing film for the roof the purpose and characteristics of the material

The main purpose of the roofing is the protection of the roof from rain and snow. The level of the effectiveness of the roofing pie is significantly reduced with mechanical damage to the waterproofing layer. Moisture penetrates inside the structure, which leads to the gradual destruction of the insulation and wooden structural elements. To prevent such a development of events, they use a waterproofing film of a baking house.

In addition to preventing moisture penetration, the insulation layer protects the structure of the roof from internal condensate. Regardless of the construction material used, due to the difference in temperature conditions on the street and in the undercarbon space, condensate is formed. Film waterproofing is considered the best option for the sewing layer from moisture.

The waterproofing film is also used in the arrangement of the ventilation system. The ventilation structure can include not only a waterproofing and inter -cell circuit, but also an additional contour between the insulation and waterproofing.

High -quality waterproofing film has such properties as:

- moisture resistance;

- mechanical strength;

- heat resistance (temperature range from -40C to +80C);

- elasticity.

The waterproofing film is available in rolls. The weight of one roll is about 9 kg, length 50 m, width 1.50 m.

The characteristics of film waterproofing allow it to be used during arrangement:

- roofs;

- attic, inter -story and basement floors;

- foundations where vertical and horizontal surfaces located below or above the zero level are isolated with such material.

Types of a subcutaneous waterproofing film

Manufacturers offer several types of steam, waterproofing films:

- permamine;

- polyethylene film;

- polypropylene films;

- Breathing membranes.

Permaminused as steam and waterproofing. Parchment is impregnated with liquid bitumen, so it does not get wet. It is environmentally friendly, does not emit toxic/carcinogenic substances. When using this material, there is no greenhouse effect, since the production of parchment is based on natural components (cellulose). The material is easily laid and has a relatively low cost.

Waterproofing film polyethyleneDurable material thanks to an additional tissue or reinforcing layer. The use of the film requires the presence of a gap over the insulation. Types of polyethylene waterproofing:

- A perforated film has micro -fuels that increase vapor peripation. The operation of a perforated film has a number of features:

- with slight damage to the film, moisture accumulates in the insulation;

- in dry weather, the micro -permeability of the film is clogged;

- installation of the film on a warm roof requires the arrangement of the ventilation gap.

- Unperformed films are more beneficial than material with micro -focuses.

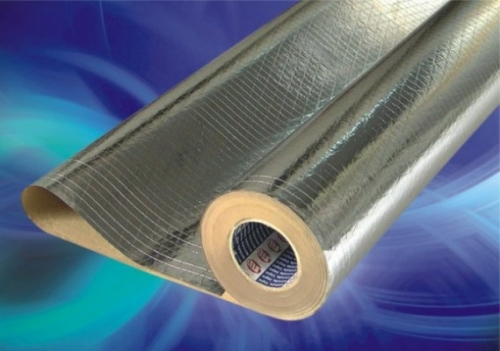

- Reinforced waterproofing films have a reflecting layer of aluminum foil. Products are indispensable for the arrangement of roofs in rooms with a high degree of humidity (pools, bathrooms, baths and saunas), as they have a very high vapor peripation.

Polypropylene The film is more durable than previous options. Such films are resistant to ultraviolet rays and can have a special anti -condensate layer.

The upper surface of the antioxidant waterproofing film is smooth, and the lower one has cellulose-shaped fibers. This layer absorbs excess moisture well. With an increase in temperature, accumulated humidity gradually evaporates.

The trim antioxidant waterproofing is more often used for metal roofs (corrugated board, metal tiles), where the probability of condensation loss is especially high.

Important! Anti -okidant film waterproofing does not have micro -focus and is breathing materials

Polymeric waterproofing films include Breathing membranes. In their properties, the membranes resemble the skin. The material has a non -woven structure that has the ability to pass steam accumulated inside the room and prevent the penetration of external moisture into the space under the roof.

The important advantage of membranes is that the waterproofing layer can be laid directly on the insulation without organizing the ventilation space.

Important! Membrane is the best option for waterproofing when converting attic cold rooms into warm attics without changing the design of the rafters

By the level of vapor permeability of the membrane, it is customary to divide into three categories:

- pseudoffed membranes (perforated sub -films, require a ventilation clearance device);

- diffuse membranes;

- superDiffuase.

Review of film waterproofing of different manufacturers

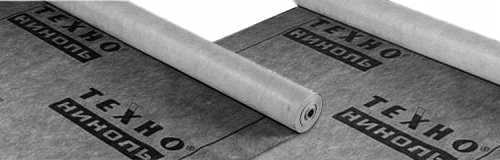

Burning -out waterproofing films are produced by a wide range of both domestic and foreign manufacturers. The construction markets have proven themselves in the construction market: Technonikol, Folder, Utacon, Ondutis, Dorken Delta-ROF, etc.

Three -layer vapor -permeable subcutaneous film Technonikoldesigned to protect against snow, moisture, dust and condensate, protruding on the back of the roofing material. The scope of vintelirable pitched roofs without insulation. Technical characteristics of the material:

- length/width of the roll 50/1.5 m (in a roll 75 sq.m.);

- vapor permeability 0.09 g/sq.m. (per day);

- strength 220/170 N/50 mm;

- UV stability 3 months;

- the cost is about 1,500 rubles/roll.

Company Folder It produces film vapor barrier, waterproofing and diffuse membranes. Among the waterproofing films, they are in special demand:

- Minima D98:

- the density of the material is 98 g/sq.m.;

- vapor permeability 30 g/sq.m. (per day);

- the load on the gap is 550-650 N/5cm.

- Standart D110:

- film density 110 g/sq.m.;

- vapor permeability - 30 g/sq.m. (per day) at a temperature of +23C;

- the tensile load at stretching is 250-300 N/5 cm.

- Anticondensat:

- the density of the antioxidant film is 135 g/sq.m.;

- vapor permeability per day is zero;

- the load on the gap is 400-450 N/5 cm.

The dimensions of the rolls are 1.5/50 meters. Waterproofing films for the roof can be bought at a price of 1500-1700 rubles/roll.

Waterproofing film UtaconFour-layer polypropylene membrane laminated on both sides and stabilized to UV radiation. Features of film waterproofing Utacon:

- on the one hand, there is a non -woven moisture -absorbing material;

- polypropylene tissue provides strength to material;

- non -woven material absorbs water vapor, preventing the condensation of the drops of moisture from steam;

- the stability of the film to UV radiation is 12 months;

- the higher cost of the waterproofing film (price for 1 roll 2000-2400 rubles).

Films are widely used in construction Ondutis:

- ARMIMENCE ANDDUTIS RS A waterproofer with good operational characteristics. The film provides wind and moisture protection, does not decompose in the sun and retains heat. The material is characterized by high strength and resistance to atmospheric influences. The price of the roll is 1850 rubles.

- Ondutis RV100 fabric environmentally friendly material. A distinctive feature of the presence of a UV stabilizer. Polymer tissue is not subjected to bacterial decomposition and has high strength strength. These characteristics allow the use of the film as a temporary roof for 1.5 months. The cost of the roll is 1200-1400 rubles.

- Ondutis RVM non -woven canvas with a heat -reflecting surface. In winter, the material protects the insulation from moisture, and in the summer it reflects heat and does not allow the roof to overheat. On the roof in winter, ice and icicles are not formed. The price of the roll is 2500 rubles.

Waterproofing film for the roof ondutis: video

Tips for choosing a waterproofing film

Here are some recommendations that will help determine the type of film waterproofing:

- The main criterion for choosing a film is the type of roof (pitched/flat, insulated/cold).

- I have high quality products in the production of Germany, Turkey and America. The cost of the material is justified by a long service life.

- A plastic film is suitable for any type of roof. An important condition for the installation of the arrangement of the ventilation system that provides normal air circulation.

- The room of the foil -based film isolated well, but its lack of low strength.

- The most universal and in demand is a two -layer film with an anti -Uftropiolet coating.

Basic requirements for the arrangement of the waterproofing layer of the roof

The roof waterproofing device should meet the following requirements:

- Film waterproofing is placed along the entire roof area, taking into account the overhang of the fronts and awnings.

- The film should fit tightly to the pipes and walls located on the roof.

- The waterproofing canvas is removed to the drain.

- The overlap between the canvases of the waterproofing material is about 15 cm. The junction of the docking must be covered with adhesive tape.

Important! The sides of laying the waterproofing film/membranes cannot be confused. Usually on the canvas there is a bright tape indicating the front side of the coating

How to lay a waterproofing film: installation sequence

The following tools will be needed for installation work:

- hacksaw;

- metal brackets (for fixing the rafters);

- construction knife and stapler;

- self -tapping screws;

- sealant;

- low -speed drill.

The entire installation process of the waterproofing film can be drawn into the following stages:

- Roll out the film and cut it over a layer of insulation.

- Installation is performed using horizontal paintings, tightly laid to each other (overlap 15 cm). Using a stapler, to fix the canvas on the rafters should be a slight sagging material (1-2 cm). The optimal distance between the rafters is 1.2 meters. The size of the overlap of paintings depends on the slope of the roof:

- Proppting the places of overlap with a mounting ribbon.

- On top of the waterproofing film, lay wooden boards pre -treated with an antiseptic. Reiki will distinguish between the rafter system and waterproofing. The size of one control river is 5 by 4 cm. The boards are attached with nails or other fasteners. The joints of the two paintings should be tightly pressed by the rail to the rafter system.

- When fixing the fasteners, the space should form between the outer side of the waterproofing film and the roofing. In this case, this distance is 4-5 cm. For the circulation of air vapor in the ridge area, a gap of 10-12 cm is left.

- In places where the antennas are located and the pipes are cut, and its edges are glued to the bars of the crate using adhesive tape.

- At the last stage, a context is mounted on which roofing material will be installed.

Notes on the installation of diffuse/superdiffuse membranes

Laying diffuse and superdiffuase membranes has some features:

- the membranes with high vapor permeability are laid on the insulation without a lower clearance;

- the membrane fastening to the rafters is performed by brackets of a mechanical stitch or galvanized nails with a flat head;

- membram installation occurs with an overlap 20 cm;

- membrane installation work begins after the crate dries completely if it was saturated with an antiseptic composition;

- the joints of membranes are desirable to connect a double -sided self -adhesive tape.

Work on laying volumetric diffuse membranes can be carried out at an air temperature not lower than -5C

Slust for the installation of the waterproofing layer: video

12

12