Without a high -quality foundation, it is impossible to build a country house, summer kitchen ...

|

|

It is not always possible to connect to a centralized water supply, so ... |

After the completion of the construction of the log house, the grinding process follows, which ... |

FUM tape: how to wind on thread

The threaded connection in the current form appeared more than 3 centuries ago. The use of pipe threads made it possible to quickly mount water and gas supply systems, while the problem of good sealing the connection was solved for more than one year. And today there is also no universal remedy that can close this issue forever. Since the beginning of the 80s of the last century, FUM tape was supposed to become such a material.

Content

- FUM Tape: Main characteristics

- FUM tape for water supply video video

- FUM tape for gas pipes

- How to wrap the fum tape on thread

FUM Tape: Main characteristics

The first developments of the FUM tape began in the middle of the last century, since the late 80s it has already been successfully used in hydraulic systems of industrial equipment. Since the beginning of the 90s, it began to be used to seal various threaded formations, including at the household level.

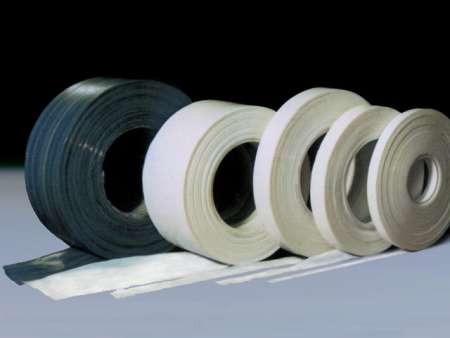

Fum tape is made of fluoroplast-4D and is thin threads fastened into a leisurely film. It is not toxic, heat -resistant, has anti -corrosion resistance. Fum tape, depending on use, produce three brands:

- mark 1 is designed to compact the threaded joints of industrial systems and systems with strongly active aggressive environments, contains a lubricant based on a petroleum jelly up to 20%;

- mark 2 is used for systems working on oxygen and other oxidizing agents, does not contain a lubricant;

- mark 3 is used for industrial and domestic systems, made from the regional parts of brands 1 and 2.

Regardless of the brand, the period of guarantee storage of the tape is 13 years.

The thickness of the FUM tape should not exceed 0.1 mm-0.2mm0.02mm, although specialists working with this product note that the tape of Soviet and Russian production is thicker than foreign analogues.

The width of the tape is in the range of 10-20mm, a different tape width is used for various pipes.

Important: it is worth remembering that pipes with a diameter of more than 6 inches (diameter of 150mm and more) cannot be connected using pipe thread, in which case pipes are welded.

Due to the high heat resistance of the working temperature range, the FUM tape is -60+200C.

Important: at a temperature above +260, fluoroplast from which the tape is made begins to release light volatile toxic fluoride compounds.

Although the water supply appeared more than 3 thousand years ago, the sealing of the compounds is also relevant. In the past few years, there has been a serious dispute that it is better than Fum or Len. Experts are zealously on both sides, supporting and justifying their choice.

The use of flax and sealants (in Soviet times, oil paints or olifa were used) makes the compound difficult to dissected, while the presence of excess material on the thread will lead to an increase in the voltage in the fitting and with, for example, a hydraulic impact can crack. It is necessary to work with linen carefully, knowing the characteristics of the thread, the amount of material necessary.

Foreign literature recommends using FUM tape as covering material for flax. In this case, it allows you not to sour the connection with its subsequent disassembly. After all, fluoroplast has a minimum friction resistance, less than melting ice.

Fum tape is easier in work. Following the basic rules and recommendations, everyone can work with it. Another advantage of this seal is the installation speed, it is good to use it for small and urgent repair.

Manufacturers of pipes and fittings, especially polypropylene, also recommend using only FUM with their products and prohibit the use of flax.

But as practice shows, the quality of the tape and its installation directly affects the quality of the connection. As a result of an insufficient amount of wound tape, there are frequent cases of leaks of threaded joints after several days of operation. At the same time, fluoroplast does not have shrinkage.

FUM tape for gas pipes

According to paragraph 10.221 of SP 42-101-2003, the use of FUM tape as other fluoroplastic seals for sealing is allowed if there is a certificate or passport of compliance.

And so, they figured it out. Fum tape can be used to seal threaded connections of gas pipes. For this purpose, it is necessary to use a special yellow tape. It is made with a width of 15-20mm and a thickness of 0.15-0.2 mm. But since this tape is made from fluoroplast-4D, like plumbing, for pipes that operate under low pressure, you can use a plumbing tape. It should be remembered that using the FUM tape is necessary when shaking the pipes by a barrel, installing a tee or tap. It is used in cases where the sealing of the compound is achieved only by compaction of the thread.

When installing flexible rubber hoses or metal bellows hoses, sealing is provided with a end paronyte laying. Also, with a well -polished surface of the hose, thin aluminum gaskets can be used. The installation of the sealant on the outer thread for the clamping nut will not only not seize the connection, but also does not allow the end laying to completely seal the joint.

How to wrap the fum tape on thread

Fum tape provides a reliable hermetic connection of pipe thread. But when working with it, several mandatory techniques must be observed.

They begin to wind the tape from the end of the thread to its beginning. The winding is carried out by clockwise for the right thread and counterclockwise for the left. Fum tape is applied in several turns. The number of turns depends on the diameter of the pipe thread, the quality of the thread itself and the quality of the tape. On average, 4-5 turns for the diameter of the pipe up to 20mm, 8-10 turns for pipes with a diameter of over 20 mm. On the last turn of thread, the tape is not laid to ensure a slight tightening of the element. It is necessary to lay the tape, otherwise it will subsequently move off the thread and you will not be able to tighten the fitting.

It should be remembered that after twisting the fitting the same fum tape cannot be used, it is necessary to replace it with a new piece and reproach the connection.