Metal is a rather popular material used in the manufacture of fences. It...

|

|

Plastic windows, innovative development of the German company HT Troplast AG, ... |

In order not to waste time and effort on the restoration of an old wooden floor, on ... |

Bitumen emulsion for waterproofing work: characteristics and application

The trends prevailing in the construction market, which is in a state of post -crisis revitalization, contribute to the confident development of the environmental construction industry. This is due not only to the desire of consumers to live and work in environmentally friendly conditions, but also by the desire of manufacturers in the process of technological chain to use only high -tech products that guarantee a long -term operational period of structures, during the installation of which the materials of a manufacturer were used. In this regard, despite the maturity and self -sufficiency of the Russian bitumen mastic market, noticeable changes are observed on it. This was not without the influence of Western colleagues. In Europe, for a long time, the production of bitumen waterproofing on water -based, the so -called bitumen emulsions, and in some countries of Europe, the production of bitumen mastic based on organic solvents is generally prohibited, which is due to changes in European legislation, according to which harmful emissions are prohibited into the atmosphere. But, since in our country, the problems of ecology have not been in the first place for a long time, they thought about the production of environmentally friendly bitumen waterproofing recently, no more than two years ago. In addition, this was due to trends reigning in the developing market of inexpensive waterproofing materials and increasing requirements for their quality and a circle of construction tasks solved with their help, the number of which grew exponentially. The result of this was the production of a mastic of cold use on a water -based bitumen emulsion.

Content

- What is a bitumen emulsion? The composition of the material

- The main varieties of bitumen emulsions

- Bitumen emulsion: Builder's look

- Why do experts recommend water -based waterproofing?

- Differences of bituminous emulsions and analogues based on solvents and hot mastics

- The scope of the bitumen emulsion

- Bitumen emulsion for waterproofing work: Procedure for use

- Bitumen emulsion of Technonikol No. 31: The main characteristics

What is a bitumen emulsion? The composition of the material

Before buying a bitumen emulsion, we suggest that you understand the basic concepts that are one way or another related to this material. From the point of view of physics, the bitumen emulsion is a dispersion system consisting of bitumen, water and an emulsifier that performs the function of a substance that gives the dispersion system stability. As for bitumen, it can act as a dispersion phase in the role of a dispersion environment. If we talk about the first case, then this is a direct emulsion (schematically this system is called oil in water), and if the second emulsion of the reverse type (schematically water in oil). The number and properties of the introduced emulsifier determine the type of bitumen emulsion.

The bitumen emulsion is characterized by stability in volume, which is realized during storage and transportation, and with this sensitivity, which is observed in contact with the surfaces of the processed materials. After applying to the surface, the bituminous emulsion decays into the component components of water and bitumen. In order for the bitumen emulsion to fully fulfill its purpose, it is necessary that after the breakdown it forms a continuous bitumen film that performs the waterproofing function.

The main varieties of bitumen emulsions

Bitumen emulsions characterized by various purposes are characterized by different decay speed, directly determined by the property and number of emulsifier. In addition, it is determined by environmental conditions, such as humidity and temperature.

Important! The decay index is an important parameter characterizing the density of the bitumen emulsion.

Depending on the reactionary ability, that is, the speed of decay, implemented in contact with the surface, the following varieties of bitumen emulsion are distinguished:

- Quick -ups of emulsions, the decay of which occurs immediately after contact with the purified stone surface. This can be seen when arranging surface treatment, applying a bitumen emulsion to the surface of crushed stone;

- Medium -falling emulsionsthe decay of which occurs after mixing with stone materials, which is used to prepare organomineral mixtures and black crushed stone;

- Slowing emulsions, which occurs after mixing with stone materials with a large specific surface. In some countries, these emulsions are designated as super -stabilized.

There is another classification of bitumen emulsions, which are based on the nature of the emulsifier used. In accordance with the type of emulsifier, the following types of emulsions are distinguished:

- Anion emulsions, for the production of which anionoactive emulsifiers are used;

- Catial emulsions, made on the basis of cationic emulsifiers;

- Nonal emulsionsmade on the basis of non -onogenic emulsifiers;

- Emulsion-paste, as an emulsifier for which powder materials of mineral origin are used.

The latest classification is based on a charge of bitumen emulsion particles. A particle of anionic bitumen emulsions are characterized by a negative charge. Their use is associated with a number of difficulties, which is due to the fact that the particles of most fillers are also characterized by a negative charge, which reduces the binder ability of waterproofing components.

In this regard, cationic emulsions were developed with bitumen particles, which are positively charged. This determines their effective compatibility with most fillers.

Bitumen emulsion: Builder's look

From a practical point of view, the bitumen emulsion represents a homogeneous dark brown fluid of insignificant viscosity, for which bitumen is finely crushed in a solution of water and emulsifier. Due to its moderate viscosity, the bitumen mastic of cold use based on water is used as a film -forming material that ensures the effectiveness of waterproofing work. The composition of the bitumen emulsion by 50-70 % is represented by bitumen, at 30-50 % with water and the binding component by the emulsifier, which accounts for no more than 0.6-1.6 %. Bitumen emulsions, the price of which is determined by the complexity of their production, are a material that is completely ready for use. It includes a water emulsion of oil bitumen, which has been modified with synthetic rubber, fillers and technological additives. Due to the fact that the process of production of bitumen emulsions is qualitatively excellent and more complicated, in contrast to the production of mastic of cold use on solvents and mastic of hot use, their price is appropriate.

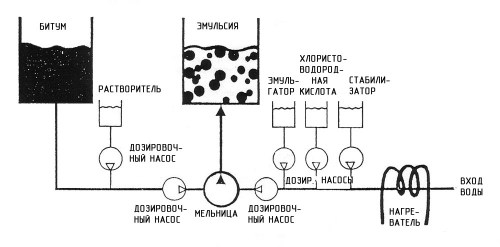

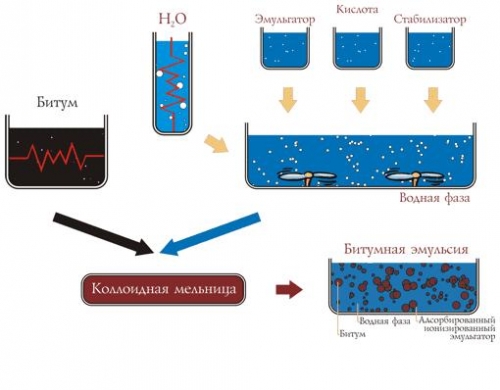

Features of the production of bitumen emulsion are determined by the method of emulsing bitumen. It can be carried out in several ways:

Emulsing using a colloidal millcalled a disintegrator. Despite the fact that this method is very popular, its use is limited to its significant drawback due to the high load on the mill very quickly, the wear of this mechanism occurs;

Emulsification by means of ultrasonic hydrodynamic cavitation It is a more progressive way of production. The method is based on the use of the ejection method and ultrasonic mixing system, which allows you to achieve maximum uniformity of the material by breaking bitumen particles and sharp pressure drops. This method is characterized by undeniable advantages, which are in the exact dosing of the components, the reduction in the temporal duration of the mixing cycles and the ability to abandon mixing containers. This method is based on the principle of a colloidal mill, but the load on it has significantly decreased.

Why do experts recommend water -based waterproofing?

Recommending certain building materials, specialists give a number of undeniable arguments in favor of water -based bituminous emulsions. Consider the main ones:

- Compliance with production standards. The use of water -based bituminous mastics during the installation of waterproofing systems allows you to reduce emissions of organic waste into the atmosphere, while fully corresponding to the most stringent environmental framework;

- Environmental Safety. Using water -based bituminous mastics (bituminous emulsions), you improve the conditions for the implementation of installation measures. By choosing this waterproofing material, you choose a technology that significantly reduces the negative impact on the environment and human health;

- Material benefit. Due to the fact that the production of bitumen emulsions is rapidly developing and increases in geometric progression, waterproofing materials made on a water -based are in a lower price category, however, their quality remains similar to the cold use of cold use on solvents;

- Waterproofing efficiency. Due to the fact that bitumen emulsions, unlike their analogues, are characterized by less viscosity, they penetrate much deeper and more efficiently into the pores of the concrete surface, providing better surface preparation for the final installation of the waterproofing system;

- Fire safety. Unlike their analogues based on organic solvents, bitumen emulsions are not inflamed material, which significantly reduces the risk of fire;

Differences of bituminous emulsions and analogues based on solvents and hot mastics

Unlike their analogues, bitumen emulsions are non -toxic, which allows them to be used to install waterproofing indoors;

- Bitumen emulsions are characterized by fire and explosion safety, which is another argument in favor of their use indoors;

- The use of bitumen emulsions allows you to create a more environmentally friendly waterproofing system formed after the decay of the emulsion and evaporation of water;

- Characterized by the best penetrating abilities and less drying time. Unlike analogues on solvents drying on average in 12 hours, the bitumen emulsion dries in 1 hour;

- Unlike mastic of hot use, working with bitumen emulsions is less labor -intensive, since the material does not need heating, and is not accompanied by the risk of fire;

- The bitumen emulsion is characterized by the best clutch with mineral material due to the presence of an emulsifier in its composition;

- Due to the high viscosity of the material, bitumen savings are at least 30-40 %.

Important! The only restriction that takes place when working with bitumen emulsion is the seasonality of this material. Emulsion mastics are prohibited from using at temperatures below +5 degrees. This is due to the fact that at lower temperatures, the water that is part of the emulsion goes into a solid aggregate state, which makes work with an emulsion impossible.

The scope of the bitumen emulsion

Since the bitumen emulsion is a high -tech material of the next generation, the possibilities opened when working with it are extremely extensive. Among the standard areas of application, the following areas of its use can be distinguished:

- Repair measures and the arrangement of mastic and roll roofs;

- With the help of a bitumen emulsion, you can equip the lottery roof, as well as a roof characterized by significant difficulties when using the fusion method, which is due to their complex geometric configuration;

- Separately, it is necessary to note the possibility of arranging roofs located in conditions where the arrangement of roofing systems with a firing method is prohibited, in view of the high risk of fire (gas storages, elevators, power plants);

- Arrangement of waterproofing structures in contact with water and buried in the ground.

Important! In addition to standard measures carried out using the bitumen emulsion, when working with it, new opportunities are opened, such as the arrangement of waterproofing indoors. In this case, we are talking not only about the prevention of the harmful effects of water on the structure, but also about the prevention of negative consequences for human health, which is due to the absence of harmful substances in the emulsion.

Bitumen emulsion for waterproofing work: Procedure for use

Due to the fact that the bitumen emulsion is a completely ready for use, working with it requires highly specialized skills.

- Before using the bitumen emulsion, the surface of the base (garage, basement, pool, floor in the bathroom or terrace) is cleaned of construction waste and the previous coating is removed. In the presence of cracks, chips and potholes with a width of more than 3 mm, they must be leveled with a primer. Sharp elements are also subject to removal. Experts advise paying special attention to removing from the surface of the base of all particles that reduce the degree of adhesion of the material with the base. These are dust particles, cement milk and fat;

- Before proceeding with the application of the bitumen emulsion, experts advise to primer the base with a bitumen emulsion primer, which must be thoroughly mixed until a homogeneous consistency before use;

- Application of a primer is carried out using a brush or fur roller made of any materials, for example, foam rubber. This is due to the fact that the primer does not contain solvents and does not corrode the material;

- Due to the fact that the bitumen-emulsion primer dries no more than 1 hour, waterproofing work can be continued almost immediately after applying the preparatory layer;

- The bitumen emulsion is also applied with a roller or brush in two layers, while the drying time of one layer does not exceed 5 hours;

- After the final drying of the waterproofing layer, you can continue to work on the arrangement of the system, and carry out the installation of a concrete screed and cladding with tiles.

Bitumen emulsion of Technonikol No. 31: The main characteristics

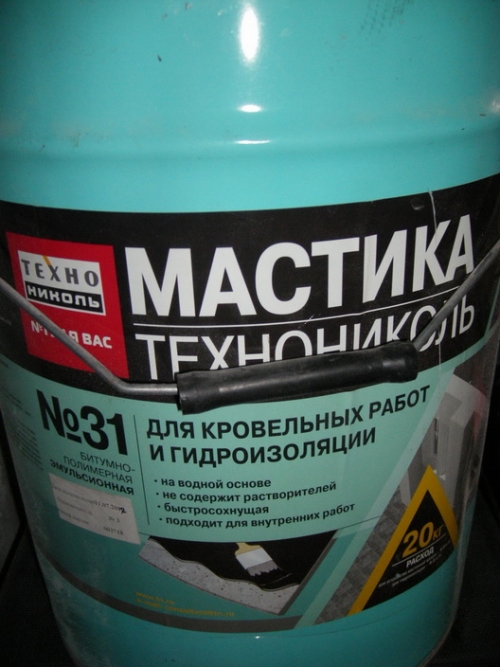

The leader in the market of modern water -based waterproofing materials is a promising technonic corporation, the key competence of which is the production of high -quality waterproofing materials. A representative of environmentally friendly water -based materials is a bitumen emulsion of Technonikol No. 31, the characteristics of which will be discussed later.

The bitumen emulsion of Technonikol is ready to use waterproofing material, which is a water emulsion of oil bitumen, which has been modified with synthetic rubber. Waterproofing coatings, for the installation of which used a bitumen emulsion of Technonikol, differ in the highest strength, elasticity and heat resistance. The scope of this material corresponds to the areas of the use of bitumen emulsions, indicated earlier.

Physical and technical characteristics of the Bitumen Emulsion of Technonikol:

Bitumen emulsion consumption Depends on the scope of use:

For the arrangement of the roofing system is - 3.8-5.7 kg/m2;

For the arrangement of internal waterproofing 2.5-3.5 kg/m2;

Adhesion strength with concrete surface corresponds to GOST and is at least 0.45 MPa;

The composition of the bitumen emulsion implies the content of the astringent and emulsifier at least 50-70%;

The specific gravity of the bitumen emulsion - 1.05 kg/dm3;

The operating temperature range located in the range from +5 to +30 degrees;

Subject to storage conditions (dry, premises protected from light) guarantee period It is no more than 6 months.