Metal -plastic windows have long become popular and popular products for ...

|

|

Fiber is an auxiliary building material, which are ... |

Due to the fact that composite tiles have such advantages as ... |

How to install and connect an electric hob and oven

The popular attribute of modern kitchen is a built -in hob and oven. In recent years, more and more consumers have preferred electric models, which are exceeding gas analogues in functionality. It will turn out to install household appliances with your own hands. The main thing is to correctly calculate the place for installation and take care of high -quality wiring, capable of withstanding high loading electric lines.

- Wiring requirements when connecting kitchen equipment

- Installation and commissioning of the hob panel

- Types of built -in cabinets according to the installation method

- The procedure for mounting and connecting an oven cabinet

- Choice of kitchen equipment: expert advice

- Job Electric Panel: DIY repair

Wiring requirements when connecting kitchen equipment

Before installing an oven or hob, special attention should be paid to the quality of the electrical wiring. It is necessary to take into account key points:

- Connecting the oven and the electrical hobs should be performed through grounding. It is easy to check in this condition in the device outlet/plug of the device should be three or five contacts for the power grid in 220V and 380V, respectively. In old buildings, this requirement was not always fulfilled. Therefore, it is necessary to lay a new cable. The wiring should be connected to the camshaft through the RCD (protective shutdown device).

- The connection of low -power equipment (about 2.5 kW) can be performed to the available network that satisfies the above requirements. Under the installation of the oven or high -power slab, it is desirable to draw a separate line.

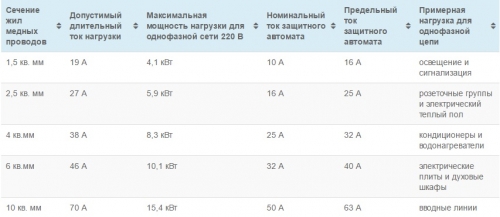

- Recommended cable section 6 mm. This conductor copes with a long load of 10 kW. The optimal class of protection of the machine with 32. When installing the oven or a hob of an electric built -in power of up to 8 kW, you can save a little and placed a cable with a thickness of 4 mm, an automatic machine from 25.

- Suitable type of cable NYM or VVGNG. When buying, you must check the diameter of the conductor. For a wire with a thickness of 4 mm, it should be 2.26 mm, for a cable of 6 mm 2.76 mm.

- The parameters of the RCD to one point should exceed the face value of the protective machine. For example, for a machine gun at 32 and you need to connect an RCD to 40 A.

Important! Grounding the electrical appliance provides safe operation of the device.

Installation and commissioning of the hob panel

Preparation of a place for installation

To insert the panel into the kitchen countertop, the following tools will be needed:

- electric drill;

- screwdriver;

- electric jigsaw;

- construction knife;

- ruler and pencil;

- silicone sealant.

The installation of an electric hob with your own hands is performed in the following order:

- To measure the main dimensions of the equipment or see the necessary information in the instructions attached to the equipment. As a rule, the documentation indicates the minimum sides of the countertop. It is extremely undesirable to reduce them, since during operation the material can break off.

- On the countertop, draw the contours of placement of the built -in slab.

- Drill the hole that will serve as the starting point of the cut.

- Install a saw with small teeth in a jigsaw, cut out by marking and polish the slice.

- Peel the surface from sawdust and attach the hob.

- Treat the cut with sealant or cover a self -adhesive seal. To protect the countertop from temperature fluctuations, it is additionally desirable to use the aluminum tape.

Further actions setting the surface in the prepared hole and the connection of the technique to the electrolyte according to the scheme.

For reference. A detailed connection diagram is depicted from the back of the electrical panel (fireproof, built -in).

Scheme and selection of the connection method

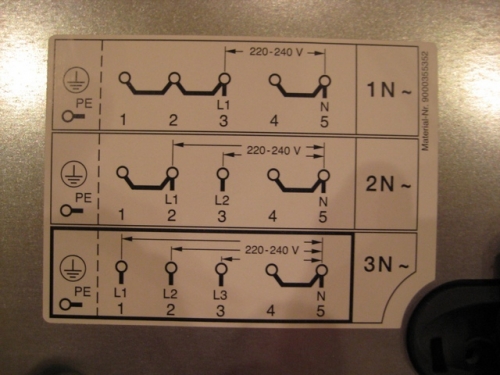

The commissioning schemes for the operation of kitchen panels and ovens in apartment buildings involve the use of one 220V network phase. In the private sector, it is sometimes advisable to equip a three -phase network. Such a connection redistributes the load during the functioning of several firewoods per 3 phases.

Designations on the diagram:

- 1L, 2L, 3L phases;

- N zero conductor;

- earth code or re grounding of an electrical appliance.

Connecting the hob to the power supply is performed in one of the methods: through a socket/power fork or using a terminal box.

In the first option, you need to correctly select a socket and a fork. The power of the plate of 7-8 kW corresponds to the current of 32-38 A. The fork must maintain wiring with a section of 4-6 mm. Often to connect the hob, the RSh/VS-32 connector is used. Such a ligament is applicable in a single, two- and three-phase network.

Advice. It is advisable to use the finished kit, since the fork of one manufacturer may not fit under the outlet of the other.

It is better to give preference to white plastic models, they are better than black carbolite. Structurally, the elements are no different, the connection order is the same.

Many consider the connection through the terminal more simple and reliable. On a plate of heat -resistant plastic there are several pairs of contacts and screw locks. The wiring is connected to two opposite sides, observing color marking. The terminal pads are selected according to the power of the electrical appliance.

Hobal panel connection instructions

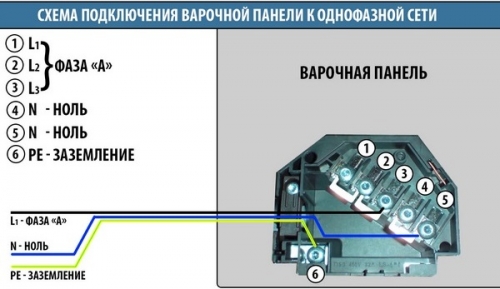

The commissioning of the electric panel through the box of terminal outlets depends on the number of phases of the network. If a three-wire wire is laid, then a 1-phase connection diagram is used:

- combine the terminals No. 1, No. 2 and No. 3 with copper jumper; connect a phase wire to them (black, white or brown);

- zeros (No. 4 and No. 5) connect with zero (blue) wire;

- connect the appropriate yellow-green wire to the re-re (grounding) terminal.

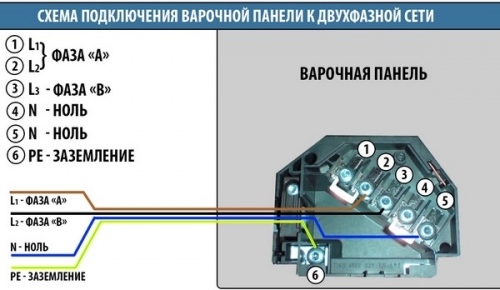

With two -phase connection, four wires are used. Their connection is performed according to the following scheme:

- combine wires No. 1 and No. 2 with a jumper, connect a phase conductor to them;

- to terminals No. 3 connect the second phase conductor;

- terminated terminals No. 4 and No. 5 together with a jumper, then connect the zero conductor to them;

- fix the grounding wire.

The five -core cable is used for a three -phase connection. In this case, the terminals No. 1, No. 2 and No. 3 are combined with three phase conductors, the subsequent procedure is similar to the previous one.

The algorithm for connecting a power fork to the hob:

- Disassemble the fork by unscrewing the fastener.

- Put the cable into the connector’s mechanism and clamp it with brackets.

- Remove the insulation from the wires by 1-1.5 cm and clean the veins.

- Fix the wiring in the forks of the fork according to the scheme. The veins of the conductor should not go beyond the terminals.

- Collect the plug body and tighten the screw.

DIY ELECTRAL BURDER BURNER: VIDEO

Types of built -in cabinets according to the installation method

According to the installation method, built -in ovens are divided into dependent and independent. Functionally, they do not differ among themselves, but the installation technology varies a little.

Dependent modelsthey are supplied with one set with a hob. The working zones are connected by wires, have a single control panel, which is usually located on the front of the oven. Dependent cabinets are compact, which is especially true for small kitchens. However, when buying, it must be taken into account that in case of failure of the control panel, both devices will stop working.

Independentthey have the ability to install separately from the hob. Such a device will be possible to place anywhere in the kitchen.

Distinctive features of independent models:

- unlimited choice of place for the installation of an oven;

- the ability to abandon the hob that modern models of ovens are equipped with steaming functions, defrosting, etc.;

- high cost of equipment.

The procedure for mounting and connecting an oven cabinet

Calculation of the dimensions of the box for the oven

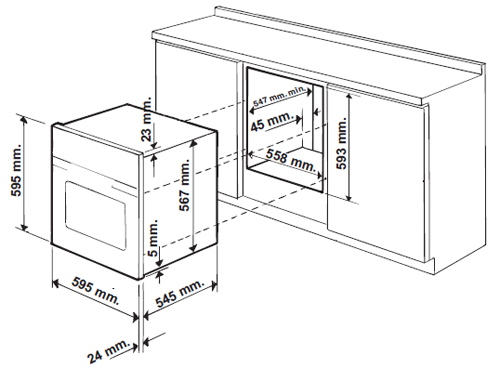

Manufacturers of kitchen equipment have developed a single standard that allows you to easily install the oven body in the designated section of the headset. The main thing is to adjust the evenness of the oven position during installation. Minor distortions can reduce the effectiveness of heating. Alignment is performed by adjusting the height of the legs, the construction level is used to control.

To protect the device from overheating and premature failure during installation, a number of nuances should be taken into account:

- the optimal distance from the base of the case to the floor is 8 cm, but not less than 5 cm;

- air gap around the perimeter of the oven 5 cm;

- distance to the rear wall 4 cm.

Important! Connecting an oven of an electric cabinet through an extension cord is prohibited. It is necessary to provide a separate outlet.

Installation and connection to the mains

After preparing the place and fitting the oven for installation, you can start connecting to the mains. If the power of the plate does not exceed 3.5 kW, then it can be connected through a conventional outlet. Otherwise, you will have to pay more attention to the new wiring and choosing a socket.

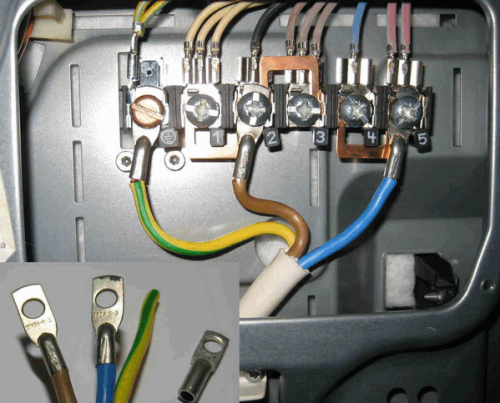

Connection procedure:

- Disconnect the power supply.

- If the cord is not extended from the oven, then it is necessary to remove the case cover, opening access to the terminal block.

- Choose a cable of the desired cross -section and connect the veins to the corresponding terminals. The connection is performed using jumpers. A detailed circuit of the wire connection is displayed in the instructions for the technique.

- Carry up a cable with a gun and RCD of these elements should be installed separately for an electric oven.

- To connect the oven to the RCD and the machine, a copper cable with a cross section of 4 mm will be required. Connection is performed according to the standard scheme.

Job Electric Panel: DIY repair

The most common electroanel malfunction does not heat up or one of the fireproof works. In this case, the independent elimination of the breakdown is reduced to the following actions:

- Check the voltage in the outlet. It is precisely this electric meter that comes out of the system.

- Inspect the fork and cord. If mechanical damage is detected, it is enough to replace the fork.

- If the previous actions did not solve the problem, then you will have to remove the hob. Previously, it is necessary to disconnect the wires and unscrew the fasteners.

- Check the functionality of the transformer and the heat -subject. This will need a multimeter. In the absence of voltage or its differences from the nominal, establish new elements.

- Check the reliability of the connection of the wiring at all points: switches, control unit, burner or thermoregulator.

Advice. Available alternative to the multimeter indicator screwdriver.

The most common reasons for the breakdown of the electrical hob of the 2nd, 3rd and 4th fireplace:

- frowning the fuse due to voltage jumps, the installation of a protective device of the network from overstrain will solve this problem;

- the cliff of the chain on the heater leads to a breakdown of one of the firewood;

- the failure of the sensor is the result of improper care and operation;

- overheating of the surface of the thermostat.

Choice of kitchen equipment: expert advice

When choosing a hob, it is necessary to compare the main parameters of technology:

- Decide whether a dependent or independent slab is needed. In the first case, the range of goods is significantly reduced.

- The second important point is the choice of the material of the manufacture of the plate in general and the fireplace in particular. Cast iron spirals are inexpensive, but they are warming up and energy -consumed for a long time. Many people believe that the best hobs are electric panels. Their main advantages: design creativity and high heating speed. The progressive version of glass ceramics induction surfaces, characterized by energy efficiency.

- Functional of the slab. The presence of additional options makes cooking faster and more convenient. It is good if the hob is equipped with a timer, heating function, waiting for the mode and protective shutdown.

- The number of firewood is determined based on the intensity of using tiles and kitchen dimensions. A hob is an electric panel 4-fire classic version, suitable for a family used to regularly eat at home. To arrange a small working area, you can choose a compact 2-fire model.

Electric hobs: which is better. Reviews and tips for choosing a working surface.

The masters connected the panel for us

The masters connected the hotpont panel for us, they took little time. I myself would have fiddled for inexperience for a long time.