The foundation is the main part of any structure, therefore, from the quality of its manufacture ...

|

|

Any repair work in the house requires material costs for the owner. Buy... |

One of the most prestigious coatings is a laminate. Stylish, practical and ... |

Epoxy glue: types, properties, application

To connect different parts, methods that do not require drilling holes or the use of hot welding are used. One of the simplest, affordable and reliable methods is the use of epoxy glue. The material has the necessary properties to solve any local problem.

- Epoxy glue inextricable compound

- The scope of epoxy glue

- Composition and properties of epoxy glue

- Varieties of epoxy glue and their characteristics

- Gluing technology: step -by -step instructions

- Precautions when working with adhesive composition

- Useful storage and use of glue

Epoxy glue inextricable compound

It can be safely argued that epoxy glue is the most popular type of glue among amateur masters and technical workers. Even with the advent of more stable and powerful compounds on the construction market, the epoxy has not lost its popularity and is used everywhere, where it is necessary to glue products from solid materials.

Epoxy resin (the main ingredient of glue) was invented in 1938, and starting in 1940, the mass production of glue began. The first commercial name of the epoxy glue Aralditis 1. This was a new sample of universal glue for household and wide industrial use.

Over the past decades, significant successes have been achieved in this industry, unique materials and bonding methods have been developed. Numerous types of epoxy compositions acting in a wide range of temperatures have been created, allowing to obtain high -strength joints with a long service life.

The scope of epoxy glue

The combination of the universal properties of epoxy glue is widely used in many areas of the national economy and industry:

- in construction, the connection of reinforced concrete structures of bridges, three -layer panels, filling cracks in concrete, gluing tiles, gluing metal with concrete, etc.;

- in the engineering industry, the production of abrasive tools, technological equipment, mounting brake pads, plastic parts to metal surfaces, carrying out repair work of the gas tank, car body, gearboxes, sheathing, brake boxes, etc.;

- aviation Designing Creation of Clay joints during the collection of aircraft, the manufacture of solar panels, fixing internal and external heat protection;

- in the field of shipbuilding, the assembly of fiberglass ships, the installation of highly loaded mounting nodes, the creation of a waterproof barrier to maintain stable humidity, processing the yacht housing and boats with epoxy with fiberglass reinforcement.

Epoxy glue - application for gluing a plastic frame.

In general, epoxy glue has become an indispensable assistant in everyday life. It is used to repair shoes, fine reconstruction of furniture, the creation of souvenirs, sealing pipes, etc.

Composition and properties of epoxy glue

Epoxy glue is a thermoreactive synthetic product. The material was created as a combination of epoxy resin and additional components: hardeners, solvents, fillers and plasticizers.

As hardeners Aminoamides (discyandiamide), di- and polyamins, polymer modifiers-modifiers (pheno-formaldehyde, rubber, silicon resin, polyamides based on fatty acids, etc.), organic acids, and lulis complexes with broadcasting and amines are used.

Secondary and primary amines usually account for 6-15% of the total amount of epoxy resin, tertiary amines of not more than 5%. Large concentrations of these hardeners can provoke the formation of simple polyester from epoxy resins.

Optimal physico-mechanical properties are achieved by using 40% phthalic anhydride or 30% maleine. Other acids and anhydrides are added to the glue in an amount of up to 0.85 mol/1 resin mol.

For epoxy adhesives, such solvents:

- acetone;

- kselol;

- alcohols;

- other organic compounds.

The number of solvents should not exceed 3-5% of the volume of dry resin. Exceeding the number of solvents is undesirable, since later they are difficult to remove from the adhesive compound. Alcohols and some other solvents accelerate the curing of epoxy adhesives.

Fillersepoxy resin-cell:

- powder substances (soot, aluminum oxide, vanadium, zinc or Berilia, silica, nickel and aluminum powder);

- glass, carbon fibers;

- glass fabrics/synthetic fibers.

The percentage of fillers on the mass of resin depends on the nature of the additive itself, and can be from 50% to 300%. Some fillers (zinc oxide, baril and vanadium) act as stabilizers and hardening grounds for thermo -acidic destruction.

Role plasticizers Perform the esters of phosphorus and phthalic acid. It is preferable to use polymer and oligomeric plasticizers, oligosulfides and oligamides, since their use allows you to regulate the physico-mechanical qualities of epoxy adhesives and increases the reliability of compounds of glued parts.

The connection of all components in one composition allows you to obtain an adhesive composition with the following qualities:

- heat resistance depends on the filler reaches +250C;

- frost resistance withstands up to -20s;

- glue seam tolerates oil/gasoline, atmospheric effects;

- glue does not decompose under the influence of household chemicals and detergents;

- the frozen composition has elasticity with minor displacements of parts of the seam gaping;

- resistance to shrinkage and cracks;

- water resistance, which gives the processed surface of waterproofing qualities;

- high adhesion with many materials, including cement screed, wood, drywall and plywood.

Disadvantages of epoxy glue:

- the inability to work with Teflon, silicone and polyethylene;

- the composition of the glue freezes very quickly to correct the small flaws of gluing time;

- it is important to adhere to safety measures, since after entering the skin it will be problematic to wash.

Varieties of epoxy glue and their characteristics

Epoxy glue is classified according to three main criteria: in composition, consistency and method of curing. Depending on the composition of the epoxy is divided into one -component and double -component.

One -component glue Epoxy transparent contains liquid resin or organic solvent with resin. The composition in the finished form is enclosed in a tube and does not need any preparation before use. Such glue is used to glue small details, sealing gaps and joints of pipes. For hardening, most one -component composition does not require pre -heating, and some adhesives are grasped under the influence of heat.

Most epoxy adhesives are produced two -component. Such glue is supplied with a set of two tubes. One container contains resin in the form of a paste, and in the second liquid or powder hardener. The ingredients are connected and mixed with a small spatula (usually attached to the kit). The finished mixture of glue of the two-component epoxy must be used for one or two minutes. Otherwise, the composition will lose its adhesive properties.

In consistency, two types of glue are distinguished: liquid and in the form of plastic mass.

Liquid glue - This is a gel squeezed out of the tube. The main advantage of the convenience of applying the composition on the glued surfaces, the saving of time on the preparation of the solution.

Plastic mass It resembles ordinary plasticine and comes in cylindrical tubes. To extract the glue, you will need to cut off part of the plasticine, knead it and moisten it with water. Apply a pasty mixture to the glued surface.

The method of curing glue depends on the hardener used. The compositions containing liquid epoxy resin, aliphatic polyama, plasticizers and fillers harden without heating for 24-72 hours, a temperature of about +20C. However, structuring such adhesives occurs longer. To increase the strength characteristics, such compounds recommend that the heat treatment is additionally subjected to.

Connections, cured without heating, are resistant to diluted alkalis and acids. However, with prolonged stay in water (up to 3 months), the connection strength is reduced especially when gluing hydrophilic materials, for example, wood.

Modified compositions of epoxy glue (curing temperature +60-120) are used to glue non-metals and metals, have shock viscosity, resistance to the action of oils, fuels and other organic solvents.

Particularly strong adhesives of hot curing (temperature +140-300C) have increased heat resistance and high electrical insulating qualities.

Among the most popular epoxy adhesives used in everyday life can be distinguished:

- Epoxy glue moment - is sold in any construction store at an affordable price. Glue packing small tubes, plastic masses weighing about 50 grams or voluminous packages for reusable use. The shelf life after opening several months at a temperature of up to +25C.

- Epoxy glue-plastilin Contact is suitable for repairing products exposed to moisture. Suitable for sealing pipe joints, gluing mild shelves in the bathroom. The glue hardening time is 1-2 minutes.

- Cold welding connects metal products in a matter of seconds. Often, the level of conjugation is not inferior to the reliability of heat treatment. Additional pluses: the edges of the metal product are not deformed, it becomes possible to glue alloys that cannot be connected by welding.

- Epoxy glue of the EDP fastenes different surfaces: from porcelain, glass products to metal. Many consider this composition to be optimal in price and quality. Epoxide universal glue is used for repairing automobile parts, shallowing cracks in plumbing, etc.

Gluing technology: step -by -step instructions

The entire gluing process can be divided into three main stages: cleaning the surface of the products, preparing adhesive solution and direct gluing.

Processing the surface of glued products is carried out in the first place. Since the finished adhesive solution requires quick application, and there will be no time to clean the parts. The surfaces are cleaned with sandpaper, degreased and dried. In conditions of production, processing is performed with shot, sand or ultrasound. Stone parts are subjected to etching in an acid bath and degreasing in organic solvents.

Preparation of adhesive composition:

- Squeeze the epoxy resin from the tube to the container for kneading.

- Add a few grams of hardener. The standard proportion of the hardener and epoxy resin 1:10. An overdose of the hardener is permissible (1: 5).

- Mix manually glue ingredients.

Gently apply the resulting mixture to the surface of one of the parts, tightly press objects to each other and fix it in this position for 8-10 minutes. After a few hours, the connection will acquire the desired strength, and the product will be ready for operation.

Epoxy glue: instructions for working with epoxy resin

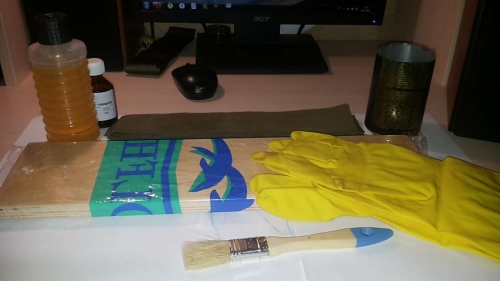

Precautions when working with adhesive composition

When working with epoxy adhesives, it is important to observe the usual precautions. To protect yourself from dust and harmful fumes, you should wear a protective mask with a coal filter, work should be done in a well -ventilated room.

It is important to adhere to all the safety measures indicated on the glue label.

People with sensitive skin must be worn during mixing and working with glue rubber gloves. When preparing the adhesive composition, you can not use dishes designed for cooking or storing food.

Useful storage and use of glue

- You can not use glue to repair objects that are in contact with food.

- If the glue hit the skin, it is necessary to quickly wash the damaged area with water and soap. If irritation occurs, consult a doctor.

- If the resin or glue is poorly squeezed out of the tube, then it should be heated on the battery or placed in hot water.

- To extend the expiration date of the glue, it is necessary to pump out air from the package and put the tube into the refrigerator.

idiots! Epoxy resin

idiots! Epoxy resin does not dry quickly

idiot you dry it quickly

idiot you, it dries quickly if you sprinkle with soda

idiots you finally do not do not

idiots you finally do not do not

Well, I don’t know what you have there

Well, I don’t know that it dries there for a long time and doesn’t glue ..... I have a perfectly sealed crack on the headlight and dried up for an hour completely!

Epoxy resin is used

Epoxy resin is also used for the manufacture of carbon fiber, so if ...

glue tanks for filtering

we glue the tanks for filtering the pool. Pressure 2 atmosphere will be an epoxy?

Kick, you are all idiots ...

Kick, you are all idiots ...

i warm up a little

i warm up the epoxy a little, placing the flask on a kettle or battery, then (having previously bought a syringe in a pharmacy for 20 cubes and 2 cubes), taking out the pistons into 20 cubic pouring an epoxy and in 2-wh cubic hardeners (so I fill 10 syringes and at the same way use the ratio is perfectly withstanding

this method of use

this method of use has never disappeared me, I stir out of the eggs in the half of the eggs under the chups and I need to mix very carefully and please without insults

Gn

Gn

Idiots, it does not dry

Idiots, it does not dry

Idiot, soda dries

Idiot, soda dries

The first thing to glue.

The first thing to glue. Naturally, we are trying to glue PVC with fat steel. This is not intended to glue. But steel with steel - no problem.

Or epoxy floors.

Epoxy for forty years, more

Epoxyk is forty years old, still Soviet, and he glues tightly, now I think they do worse. It will not go away right away, after gluing another day to wait

Epoxy resin should not

Epoxy resin should not dry quickly. Primary gelatinization should be from 25 minutes to 60 minutes. Primary hardening in 24 hours, but it is advisable to withstand for 72 hours under pressure. For the floor - 72 hours to the opportunity to walk on the floor.