Modern architecture and design capabilities allow you to equip at home and ...

|

|

The wooden floor serves as a finished coating. But, in case of any defects ... |

So that with the onset of winter it is always warm and comfortable in advance ... |

How to make a socket with your own hands. Rules for the installation of an outlet with your own hands. What to look for when installing a socket with your own hands

Electric devices are an integral part of modern life and, so that they work for a long time and reliably, are necessary, well mounted outlets. Typically, it is customary to attract professional electricians to such cases, but the installation of sockets is often practiced independently. How to work correctly with electric structures of this purpose and what is needed for this, we will analyze in more detail in the article.

Table of contents:

- Varieties and classification of sockets

- Basic requirements for installing sockets with your own hands

- The design of sockets

- DIY Old outlet dismantling

- Features of installing an outer outlet with your own hands

- Features of installing a double outlet with your own hands

- Features of installation of a do -it -yourself socket in brick concrete drywall

- The stages of work on installing sockets with your own hands

Varieties and classification of sockets

The main criterion according to which sockets are divided into species is the way they are installed. According to the above, they highlight:

- invoices;

- built -in;

- the sockets of hidden installation.

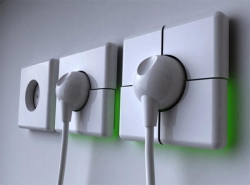

The first type does not provide for installation in the seat and is mounted directly in the wall. Falled outlets look quite unaesthetic and fit poorly into the interior, as they very protrude from the surface.

The second type is the most popular. Built -in sockets are mounted in special seats, due to which they do not stick out from the walls and are almost invisible in any decor.

The sockets of hidden installation represent the third type according to the installation method. Such designs are mounted in tables and, if necessary, simply hide. Most often, this species is used in kitchens.

To date, a large number of different types of outlets are known, which have a kind of marking that allows you to separate the designs in:

- plugs and connectors;

- germativity and degree of security;

- by the presence of additional capabilities, etc.

According to the above categories, the types of outlets differ in most countries, since the work of many foreign devices is played by indicators of the required current.

As for the additional opportunities that the outlets can be equipped, it may be designs:

- Equipped with backlight.

- Equipped with protection from children.

- With a built -in timer.

- With a thoughtful neutralization of moisture, etc.

This category also includes sockets in individual design, that is, to order suitable for elite interiors.

Based on the listed material, it is worth extracting the most important thing that when choosing a socket, it is very important to pay attention to the labeling of products so that the equipment can work safely and at full power.

Basic requirements for installing sockets with your own hands

Before, directly, to start the installation work of sockets, a non -professor needs to get acquainted with a whole package of documents on the specifics of structures of different types and their technical characteristics. This is what experts say and write about this.

Tips from specialists:

Tip 1. For each household appliance, it is better to plan a separate outlet, this will not only protect the equipment, but in the case of malfunctions it will save the detection time of the breakdown. A separate outlet for each device is the possibility of a trouble -free, simultaneous use of several powerful electrical appliances.

Tip 2. It is wrong to install sockets:

- Above the slab;

- Above the kitchen sink;

- Outside the body of the built -in device, etc.

Tip 3. When installing a socket for television, it is recommended to use a cable with a margin of at least 10 centimeters.

Tip 4. All installation work regarding sockets must be performed in special protective gloves.

Tip 5. The handles of the tools that are involved in work should be strictly isolated.

The design of sockets

Three main elements are included in the package of the outlet:

- base;

- conductive parts;

- Facial panel.

For what they are responsible and how they function, we will describe in more detail in the table.

|

Separately, it is worth writing about sockets with the presence of grounding and without it. It happens that when touching an electrical device, a person feels a pinch with a shock or even a blow more.

This means that a socket is used without grounding. But not everything is so extremely simple, because sometimes the use of sockets without grounding contact can lead to a death occasion. For example, a washing machine is one of those household appliances that can kill a person in the absence of a grounding contact.

When replacing the wiring in the house, experts recommend installing sockets, which initially provide for the presence of a third contact.

DIY Old outlet dismantling

One of the most important actions before the dismantling of the old outlet is the disconnection of electricity. For inexperienced masters, it is recommended to perform the work in stages, the correctness of the actions that is planned to be carried out depends on this.

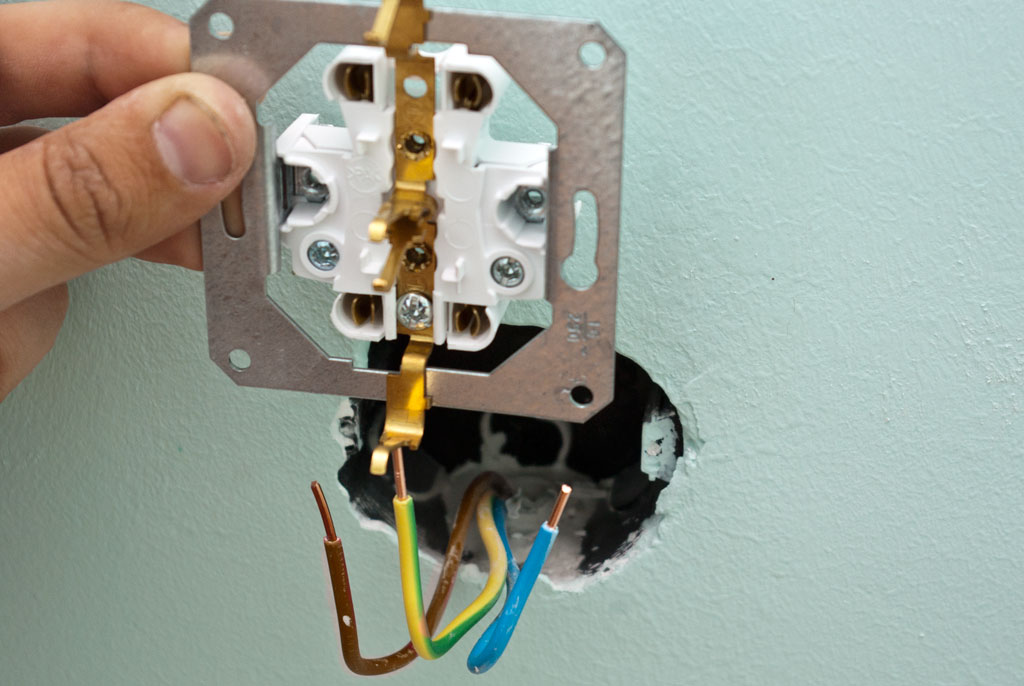

At the initial stage, a cover is removed, which is usually attached with special screws. Next, spacer paws are removed. Their unscrewing allows you to remove the entire mechanism of the old outlet.

The final stage of dismantling is, directly, the extraction of the outlet: by bending the contact screws, you can easily pull out all the components of the outlet and finish the disassembly of the old structure.

Features of installing an outer outlet with your own hands

External sockets are those about which we say that they are not aesthetic. But at times, safety is much more expensive than beauty. So, most often, external sockets are used in rooms where the walls are made of easily horn materials, for example, of wood. Installation of this type of socket consists of several steps.

- Having turned off the previously electricity, remove the main, top panel of the outlet.

- Using screws, strong base of the outlet to the wall.

- We clean the wires and place them in contacts.

- The head of the fasteners, you can start screwing the panel and, in fact, to the assembly of the outlet.

Features of installing a double outlet with your own hands

Double sockets differ in convenience in everyday life. Installation of this type is performed similarly to the previous one, only in this case it is necessary to connect the cables to different conductive plates.

Double sockets are of two types: prefabricated and stationary.

The first type is characterized by the complexity of installation. To install such outlets, additional wires are required, which stretch between the sockets. Auxiliary cables join the main using special clamps. In working with electricity, it is very important to monitor the procedure for the actions performed, because any inaccuracy can lead to a short circuit.

Features of installation of a do -it -yourself socket in brick concrete drywall

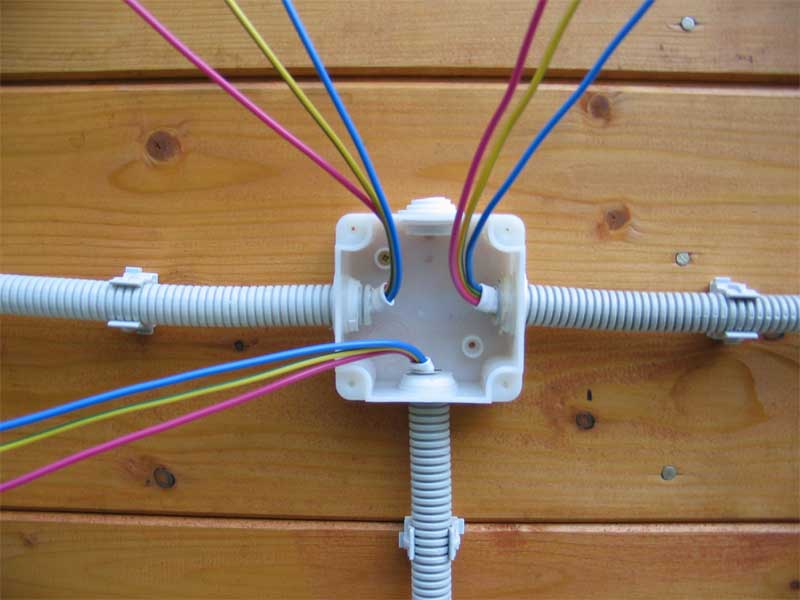

Installation work relative to sockets also depend on the surface of the walls. For installation in brick and concrete walls, you will additionally need a perforator (if the outlet is placed for the first time), as well as a solution for fixing the box.

The peculiarity of the installation of a do -it -yourself socket in a brick and concrete is to use a corrugated hose under the wires and its stroke. Installation boxes for sockets are inserted into the prepared holes in the wall, and wires are inserted down.

In order to fix the mounting box in the wall hole, a gypsum solution is most often used. In this case, it takes time to dry it.

As for gypsum walls, which are very popular in the modern world, special mounting boxes are thought out for them. The holes for them can be made using an ordinary electric drill. Under the gypsum sheet, wiring should be laid in advance, the wires of which are inserted through the hole into the mounting box. The box itself is attached to the gypsum tightly, screws.

The installation of sockets with your own hands is not so much complicated as a responsible matter, because we are talking about electric current, and therefore about a person’s life.

The stages of work on installing sockets with your own hands

Given all step -by -step instructions and advice of specialists, the whole process of installing sockets with your own hands can be described in stages and briefly. So,

- de -energization of the room;

- checking the absence of electricity;

- wiring;

- connecting a new outlet;

- installation in the socket;

- Cover fixation.

To check the lack of electricity, it is customary to use an indicator screwdriver. The final stage of work on the installation of sockets with your own hands is to connect machines and directly checking the performance of the installed design. For more information, watch the video: