Many owners of apartments in multi -storey buildings live in conditions of square deficiency ...

|

|

High -quality roofing of your home a guarantor of reliable protection from ... |

High energy efficiency of buildings against the background of rise in price and obvious savings ... |

How to insulate the front door

Insulation of the front door contributes not only to minimizing heat loss, but also to improve sound insulation. In order to insulate the door leaf, you need to choose a high -quality thermal insulation material, and the doorbrooper insulation scheme will depend on its original design and on the material from which it is made. In the article, we consider how to insulate the front door with your own hands.

Content:

- Thermal insulation materials for entrance doors

- How to insulate the iron door

- How to eliminate the cracks

- Warming door from a solid sheet of metal

- How to insulate a wooden door

- Creating the thermal insulation of double doors

Thermal insulation materials for entrance doors

The modern construction market is replete with a variety of thermal insulation materials - from mineral wool to polypropylene plates used to warm the doors of business class.

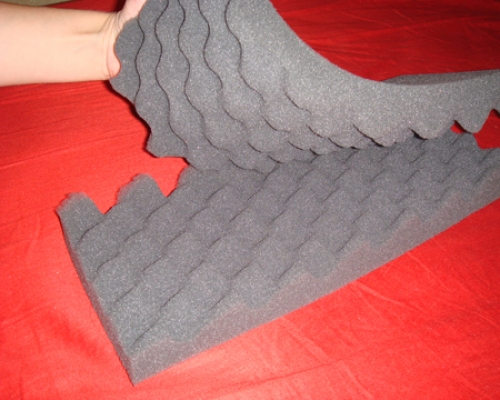

- Mineral woolThis is a material that provides excellent soundproofing and heat -protective indicators. Its unconditional pluses include cheapness and harmlessness. In addition, it is moisture resistant and is not exposed to temperature changes. Of the disadvantages of this material, one can distinguish its looseness, which contributes to the appearance of cold bridges in separate places of the door. In order to avoid such defects during insulation, special rails are installed that protect the material from subsidence.

- Corrugated cardboard– this is the second most popular material used in insulated doors for the house. It has sufficient rigidity due to the design in the form of bee soth and good resistance. As well as mineral wool, corrugated cardboard has low cost and low weight. This method of insulation of the door promotes effective sound insulation and significantly reduces heat loss.

- Styrofoam - This is a heater for doors, which is also used for economy -class products. Due to its low cost, high density and durability, the foam is very in demand as a material for door insulation. It has low thermal conductivity comparable to the indicators of expensive vacuum insulation. Such valuable properties are provided due to a homogeneous structure that does not have an open pore. The only serious minus of foam is its inability to resist the fire.

- Usage foamed polyurethane As a heat -insulating material, it has a lot of advantages. Polyurethane has low weight, sufficient rigidity and harmlessness. The high cost of the material is paid off due to excellent heat and soundproofing properties. And, unlike cheaper heater, it is moisture resistant, able to resist the fire and strong blows. Such high operational properties are achieved due to the special structure of polyurethane, consisting of the smallest cells.

- For thermal insulation of expensive doors, the most often used foamopylene panels. Of all the above insulation, they show the best characteristics of moisture resistance and sound insulation, as well as the minimum percentage of thermal conductivity. Foamopropylene plates have the property of counteracting stretching and compression.

- Wood fiber Another modern thermal insulation material. It is made of wood of coniferous trees. In the process of production, special substances are added to this material that provide its heat resistance. Wood fiber has a sufficient density, which has good sound insulation. The material is stiffness and strength. After installation, such panels do not shrink. It is harmless to human health and environmentally friendly. When installing wood fiber in a metal door, there is no need to use a vapor barrier film. Wood fiber has a special property to absorb moisture from the room if the percentage of air humidity is increased and to give moisture when it is reduced. The only minus of wood plates is the high price of material due to the complexity of production technology.

Tip: for insulation of a wooden door, it is best to use foam or isonon.

- Foamen. Its most significant plus as insulation is a good heat, hydro- and noise insulation. Foamen is also often used for insulation of metal door paintings as a replacement of mineral wool. It is a rather flexible and elastic material. Of the main shortcomings of foam rubber, its fragility is distinguished. The service life is no more than 3 years. In addition, in its production, toxic raw materials are used, which is why it is easily ignited and emits harmful substances during combustion.

- Isolon it has a higher cost than foam rubber, but its operational indicators are much higher. For example, according to thermal insulation criteria, this material exceeds mineral wool by more than 10 times. Isolon is moisture resistant and contributes to effective sound insulation. This material is not exposed to temperature changes, is able to withstand chemical influences. It is absolutely harmless to human health.

Thus, when choosing a thermal insulation material for the door, it is necessary to be guided by its operational properties. No need to chase the low cost of the insulation, since the high indicators of heat and sound insulation are often directly proportional to its price.

How to insulate the iron door

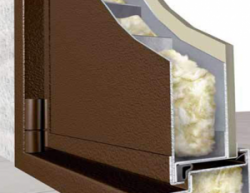

The method of insulation of the metal door depends on its design. Removable door boxes are usually assembled from an armored plate and sheet sheathing. They are fastened with each other with a metal support and stiffener ribs.

To create an insulated front door, it is necessary to prepare the following materials and tools:

- heat -insulating material (choice - mineral wool, polystyrene, corrugated cardboard, polyurethane);

- mounting foam;

- liquid Nails;

- drill.

Stages of work

- Before performing insulation work, the door is removed from the loops. From a metal frame, sheathing and armored plate is removed, carefully twisting screws.

- In the gaps between the stiffeners, the insulation is laid and it is strengthened with liquid nails.

- The joints between thermal insulation material and stiffeners are filled with mounting foam. When using mineral wool, a vapor barrier film is laid out on top.

- The metal sheet is screwed to the same place, and the door leaf is suspended back to the loops.

- At the end of the work, the presence of gaps between the door and the opening is checked.

How to eliminate the cracks

Often, even insulated doors continue to pass the heat outward. This is due to the presence of small cracks in the places where the door leaf and the opening are noted.

- They are plugged with cotton wool and rammed with a screwdriver, and then covered with a cement.

- It is better to fill the large gaps with foam with foam and putting it.

- For a denser adjustment of the door, special seals (rubber or foam rubber) are used to the opening. This material provides reliable sealing of the door leaf. This provides a minimum percentage of heat loss.

Warming door from a solid sheet of metal

Tools and materials for work:

- 2 DVP panels (or wooden lining);

- self -tapping screws;

- screwdriver (or screwdriver);

- wooden rails or metal professional pipe;

- file;

- mounting foam;

- heat -insulating film;

- sealant;

- liquid Nails.

Stages of work

- In order to fix the thermal insulation material on the door, a special frame of wooden rails is made. The resulting frame is attached along the perimeter of the door frame using self -tapping screws and three transverse rails are additionally installed that divide the door area into equal parts.

- After installing a wooden frame, the places around the screws are cleaned, covered with putty and oil paint.

- Instead of a wooden frame, you can use a metal frame made of 4 rectangular profile pipes. They are welded, cleaned and painted.

- 2 DVP sheets are measured in accordance with the size of the door, drill a hole for the eye and door accessories.

- Then thermal insulation material is laid and fixed with liquid nails. The joints are closed with mounting foam and at the end on the insulation is laid out a vapor barrier film.

- On the insulated door, sheets of fiberboard are placed, fixed and fixed using self -tapping screws.

- Self -tapping screws are inserted from the front side of the door frame so that the DVP panels are more even.

- They insert the door, fill it with sealant and put a valve.

- The door is suspended on the hinges, if necessary, glue the seals around the entire perimeter of the opening.

How to insulate a wooden door

The entrance wooden door is inferior to metal in its operational properties. If it is not insulated, then the owners of the apartment will have to suffer from drafts and heat loss. In addition, a non -insulated wooden door has low sound insulation.

Necessary tools:

- nails or screws;

- wooden rails;

- insulation;

- a fabric canvas prepared around the perimeter of the door with an allowance of 10 cm (in advance on the fabric you can apply a decorative pattern);

- decorative nails.

Stages of work

- A wooden door frame is removed from the hinges, remove the valve and door to the door.

- For its insulation, it is also necessary to make a wooden frame from the rails. Its cells must correspond to the size of the insulation. You can make them more often, but it should be remembered that they create cold bridges.

- A heater is inserted into it (preferably foil isonon).

- Pre -prepared fabric canvas is applied to the door and fixed with nails.

- The final stage of the work will be the decoration of the door leaf with decorative nails, which are nailed according to the intended scheme. Next, the door is installed in place.

- As with the installation of a metal door, the gaps between the door leaf and the opening are eliminated using seals attached around the entire perimeter.

Creating the thermal insulation of double doors

- If the apartment has two entrance doors, one of which is metal and the other wooden, there will be enough insulation of the door leaf made of metal.

- The wooden door frame is decorated with artificial skin, as thermal insulation will be achieved by creating air space between the doors.

- This will also significantly reduce noise and sounds.

- Double doors reduce the risk of freezing the metal door at very low air temperatures.

Thus, a high -quality heat -insulating material, properly mounted in a wooden or metal door, will provide a minimum loss of heat, protection against drafts and comfortable living conditions.