If problems arise with a drain tank, it is not necessary to call a specialist on ...

|

|

Excellent appearance, excellent technical characteristics and enough ... |

Ceiling niche optimal solution of the cornice for curtains. The box allows ... |

How to make a door from the boards with your own hands

The construction of a wooden door from the boards is not a problem for a modern host. The process will not cause any difficulties, and the cost of a home -made product will be less than the purchase of the finished design. To competently make the door, you need to decide on its type, choose high -quality material and prepare a minimum set of tools. A step -by -step technology for manufacturing a door from the boards is described in the article.

- Features of wood doors

- Varieties of wood door doors

- Choosing wood for making doors

- How to make a door from the boards: step -by -step instructions

Features of wood doors

The construction market offers a wide range of entrance and interior doors. Despite the emergence of modern materials, wood products do not lose their popularity when arranging apartments, country houses, offices and public institutions.

Wood doors have a number of undeniable advantages:

- low sound and thermal conductivity;

- high frost resistance and good strength;

- low temperature expansion;

- durability of wooden structures with proper workpiece and processing of material;

- the environmental friendliness of wood, such doors fill the dwelling with positive energy and add natural harmony to the house;

- an excellent appearance and the possibility of implementing unusual design ideas doors made of wood look good in any style of interior.

However, wood, like raw materials for the manufacture of doors, is not devoid of some minuses:

- high hygroscopicity of the raw wood absorbs moisture, which subsequently worsens the physico-mechanical properties of the structure;

- the imperfection of the material on poor -quality wood may be present, resin pockets, cracks or knots may be present;

- combustibility.

Disadvantages of the wooden door The consequence of poor -quality material and violation of the technology of the workpiece. To reduce the absorption of the board, it is necessary to dry, treat with hot steam and special impregnations.

Varieties of wood door doors

Before you understand how to make a door from the boards, you need to decide on the nuances of the design of different types of doors and the features of their manufacture.

Massive doors They are made of strict or thick drooping boards interconnected in a single canvas. To strengthen the structure, inclined or horizontal jumpers are installed.

In the manufacture of a massive door, it is necessary to carefully approach the choice of wood. The input structure is best built from high quality dense material, for example: cedar, oak or larch. These types of wood are characterized by a dense structure and textured pattern.

If the question is about how to make a door to a bathhouse from boards, then you can use less expensive raw materials (pine, spruce, linden). The main condition for processing by water -repellent and antiseptic agents.

Filenced doors They are made of timber and boards obtained as a result of gluing wooden lamellas. Subsequently, the beam is covered with natural veneer, and the door acquires an aesthetic appearance. Depending on the idea of \u200b\u200bthe performer, the phylenka can have the same or various configuration, some wooden elements are replaced by glass.

High -quality phylene doors practically do not differ from a design of a wood array.

Transverse and vertical elements are often made of glued timber. To make the door, the floor board of the desired thickness is well suited for such work. Separate structural elements are fastened together with spikes or bastards. When creating a phylene door, it is necessary to take into account:

- the strength of the door depends on the quantity, the more of them, the more reliable the home -made structure;

- the frames are formed from a thick beam, and the fins-fins are made of MDF, thin boards or plastic with imitation of wood;

- the thickness of the phylenka, as a rule, is 1/3 of the thickness of the frame from glued beams;

- fixation of panels in frames using a natural or veneered stack.

Filenced doors have a small thickness, so they are usually installed between the rooms.

How to make a door from non -cut boards: video manufacture of a phylene design.

Shield doors A budget option made from inexpensive DVP materials lined with laminate or veneer. The shield structure is a frame of boards and internal filling (shield). Sheets of chipboard, fiberboard, dense cardboard or MDF are used as a shield.

In turn, the shield doors are classified into three types:

- Continuous structures are fully filled with a trimmed or not circumcised beam fastened with each other.

- Hollow doors consist of transverse and side bars. The frame is sheathed with lining, fiberboard or other material. Inside the design, vertical and horizontal crossbars can be installed.

- Small -empty door leafs have a different degree of filling.

Advice. To create a high -quality shield door, the frame is covered with glued plywood plywood or linden. The thickness of the cladding is 4-8 mm (two layers of 24 mm). Such material is not deformed and is a good basis for decorative decoration.

Choosing wood for making doors

The first stage in the manufacture of the entrance or interior door is the choice of suitable lumber. It is necessary to evaluate your own financial capabilities, determine the variety of wood and choose the material from which you can make the doors. Wooden boards must meet the following requirements:

- wood should not have a knot, in extreme cases, there should be very few of them;

- the residual moisture of the raw materials for the manufacture of doors should be about 12-15% - it is better to choose the material dried in a special chamber; Such drying guarantees the strength of wood and resistance to deformations;

- the evenness of the boards before buying the material must be laid on a flat surface and checked the fitness on the sides;

- the thickness of wooden boards for the manufacture of doors depends on the place of its installation for the input structure is optimally 5 cm, for the interior door, wood with a thickness of 2.5 cm is suitable;

- before using the boards, it is necessary to polish with sandpaper or a grinder.

For work, wood is suitable for both coniferous and deciduous species. Forest doors are more often made from oak and beech. A pine is suitable for interior models. The tarryness of conifers protects the wood from decay and fungal diseases.

When arranging a summer cottage, you can save on the material and not spend money on the purchase of wood to make the door. Boards of a barn or other building to be demolished are quite suitable for work. The main thing is to check them for the lack of marriage and mold.

How to make a door from the boards: step -by -step instructions

Let us consider in detail how to make a door from the boards yourself. The basis of any massive door is a plank shield, which must be correctly assembled and reliably fastened. The fence from a massive board is installed between the rooms, at the entrance to the bathhouse, a house or a household. Of course, in different cases, the appearance of the product will differ.

Necessary tools and materials

The work begins after preparing the tool kit and the harvesting of the necessary materials. It is advisable to have a stable vehicle table, on which the assembly of elements in a whole canvas will be carried out.

From the tools you will need:

- manual milling cutter to create grooves, holes, grinding surface, leveling of angles, etc.;

- hacksaw;

- shirts for grinding and aligning the door at the ends;

- coatings of different sizes;

- ordinary and rubber hammer;

- construction level, pencil, roulette, meter;

- grinding machine or sandpaper;

- squad.

Of the materials and consumables will be needed:

- shpunt boards with a spike-paz fastening choice of thickness and width depends on the purpose of the door structure, as well as its design;

- self -tapping screws of various lengths;

- the carpentry glue.

It is advisable to add purchased wood. Even if the material is ready for work, it is better to play it safe. Each board should not be laid on the gasket, they should not come into contact with each other. This is necessary that humidity freely exit the wood fibers. If the boards are not dry enough, then mold may form and ruin the finished product.

Drying time at a temperature of +25C takes about one to two months. The room where the wood is located should be well ventilated.

Important! Using a special chamber for drying, you can not exceed a temperature of +50C. Otherwise, resin from coniferous wood will flow out and the material will partially lose its strength.

Production of the door leaf

We will analyze step by step how to make a door from a dodgy board:

- Put the prepared boards and saw it on the segments of the desired length.

- Lay the boards on the table so that the image of the annual rings is headed in one direction.

- Collect the dinished boards in a single canvas, fastening them with a spike-paz with a lock connection. For additional fixation, the elements are glued with carpentry glue.

- From the extreme board of the shield, carefully cut the spike and process the end.

- Squeeze the canvas with clamps and leave until completely dry. The shield should be located on a flat surface.

- After drying, the surface of the canvas is treated with a mill and polish.

- Sometimes the design of the door is enhanced and assembled from several layers of boards. The shields are glued perpendicular to each other and clamped in the clamp. As a result of the work, a heavy powerful door leaf is obtained, suitable for installation at the entrance to the apartment or house. This technology is used if it is planned to apply a relief pattern on the finished product.

- Fixing the canvas with a binding consisting of two or three is transversely:

- prepare segments from the board with a length equal to the width of the door leaf;

- the shape of the crosses is best made to be trapezoidal so that the element is better into the groove;

- apply markings on the canvas under the placement of crossbars attach prepared boards and outline with a simple pencil;

- to note the depth of the groove, usually this size is half or a third of the thickness of the board;

- on the applied marks, cut out transverse grooves;

- make the groove with carpentry glue and push the crossbars into them using a mallet or rubber hammer.

Decorating a massive door

The next step is the processing and decorating of the door leaf. The work is performed in the following order:

- Treat the surface with sandpaper or grinding.

- To impregnate wood with an antiseptic. Apply the first layer and leave until completely dry. Repeat the processing. Antiseptic impregnation will protect the door from damage to harmful microorganisms and decay.

- Cover the canvas with putty this layer will hide small irregularities. The putty can be replaced with a primer. In this case, it is necessary to process the door twice, allowing each layer to completely dry. The drying of the primer, as a rule, occurs within one day.

- The finish processing of the door is performed with varnish, stain or paint the desired color. The stain is applied to the primed surface. The number of layers depends on how rich and intensive should a shade be obtained. Each layer should dry about 4 hours. To fix the result on top of the stain, apply two layers of varnish.

Important! The front door must be treated not only with an antiseptic, but also with a water -repellent composition. When creating the input structure for the apartment, it is advisable to cover the canvas with antipyletes.

The implementation of more complex decoration options (threads, milling, stencil, mosaics) are best entrusted to experienced craftsmen.

Installation of the door

The sequence of installation of the door leaf:

- To align the vertical and horizontal walls of the doorway.

- By the size of the opening, collect the door frame and check the evenness of its installation. The finished design should be stiff and durable.

- Try the canvas to the opening. If necessary, adjust the dimensions of the product.

- Fix the door structure in the opening, fixing the individual sides of the box in the opening with long self -tapping screws. Drown the fasteners of the fasteners into the material and close with plugs suitable in color.

- The gaps between the door frame and the walls are damped. Collect elements of cashing.

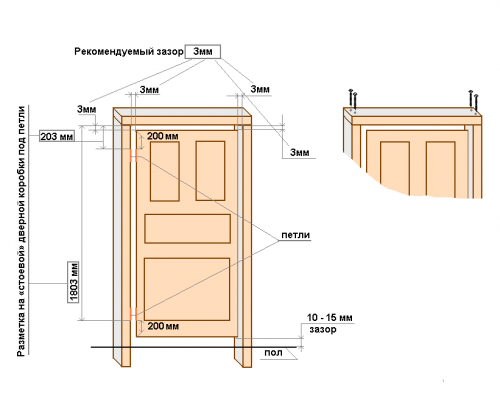

- Prepare the canvas for installation. Mount the handle, loops and cut the lock. On the finished shield, apply markings for placing hinged loops. Install the loops optimally if they are flush with the end side of the door leaf.

- On the door frame, indicate the installation sites of hinged loops and a place for a locking tongue. Make appropriate grooves according to the marks.

- Put the canvas on the hinges and adjust the structure. To enter the locking tongue on the box, it is necessary to fix the response plate.

How to make a door from the boards with your own hands: video

You are very good and clear

You very well and clearly told how to make the door, but how to make the front door is not indicated. Could you tell this https://rusremeslo.ru/dveri/vhodnye-dveri/ Example. I'll be very thankful.

http://interroro.ru/colors/go

http://interroro.ru/colors/goluboj-cvet-v-interere.html

cool http://strport.ru/

cool

http://strport.ru/

Doors in Korolev

Doors in Korolev www.stal-master.tt34.ru

8 (903) 715-91-15 Queens of the doors is vestibule.

8 (903) 715-91-15 Korolev Holling doors.

8 (903) 715-91-15 Korolev doors metal.

8 (903) 715-91-15 Korolev technical doors.

8 (903) 715-91-15 queens of the doors steel.

8 (903) 715-91-15 Korolev doors with MDF finishes, laminate.

8 (903) 715-91-15 Korolev doors with powder spraying.

8 (903) 715-91-15 Korolev doors with a photo seal.

8 (903) 715-91-15 Queens of the doors of the lattice.

8 (903) 715-91-15 Korolev doors with castles of Hardian.

www.stal-master.tt34.ru installation of the entrance doors in Korolev.