From an early age, the child needs personal space so that he can feel in ...

|

|

Not everyone knows that in addition to ordinary doors made of metal and wood on sale there are more ... |

How to make a bath for a bath with your own hands. Do -it -yourself furnaces for a bathhouse. Basic requirements and rules for the manufacture of a bathhouse for a bath with your own hands

To have your own bathhouse is probably one of the common desires of people. But as you know, the main element of this institution is the stove, which will be discussed in this article. How to make and install a stove constant and periodic heating in small baths? What are the advantages of masonry? What are the basic requirements for the manufacture of a bath heating device with your own hands? Look for these and many other questions further in the article.

Table of contents:

- Varieties of furnaces for a bathhouse

- Features and advantages of masonry of a stone

- Features of a metal furnace

- The stages of the manufacture of a metal furnace with your own hands

- How to build a brick stove with your own hands

- How to calculate the material, make a drawing for making a brick furnace with your own hands

- Stoves of constant and periodic heating for a small bathhouse

- Choosing a place and installing a bathhouse for a bath with your own hands

Varieties of furnaces for a bathhouse

A truly good bath is considered the one that has a high degree of heat, and this is impossible to achieve without a good furnace. So, there are several types of bath heater, the main of them are indicated in the table.

| Types of bath furniture | |

| Electric | Electric stoves for the steam room have a number of advantages. This is high thermal conductivity, affordable price, equipment compactness, etc. This type of heating equipment allows you to create the optimum temperature in the parlor room for the minimum time. |

| Wood | The traditional option and, moreover, the most popular. Such structures are both metal and brick. The components of such heating devices are: chimney, ashes, firebox and grates. District furnaces are characterized by a high efficiency of efficiency. |

| Finnish | Finnish stoves can be electrical or wooden structures, which, thanks to an attractive appearance, can decorate any bathhouse. Due to the well -thought -out device, such furnaces allow warm air evenly diverges around the steam room. One of the main advantages of Finnish furnaces is their high fire resistance. |

| Cast iron | Cast iron furnaces are considered significantly economical heating equipment for the bath, as they require minimal costs of combustible materials. Such structures are constant and periodic and characterized by high heat resistance. |

Having minimal building skills, each owner, having effort and purchased the necessary materials, will be able to equip the bath room with any of the types of furnaces.

Features and advantages of masonry of a stone

Kamenka is a type of bath stove that has a special compartment for placing stones. In turn, the stones are gaining heat during fuel combustion, water is heated and, as a result, a steam forms. The most popular today are stoves made of metal and bricks, and both have their pros and cons, which we will consider later.

So, brick heels have the following advantages:

- durability and practicality of the device;

- the ability to heat large rooms, while maintaining heat for a long time;

- simplicity of the mounting process;

- decent level of fire safety (due to the presence of a metal base);

- The practicality of operation, etc.

Along with the above advantages, brick stumps have their own disadvantages: they have a large weight, require enhanced cleaning, prolonged heating (more than 5 hours), etc. is required for productivity.

Metal stoves are considered no less popular in heating. They are characterized by the following features:

- differ in minor dimensions;

- have a compact design;

- multifunctional and ergonomic;

- They quickly gain temperature and hold it for a long time.

All the heels are divided into two groups: open and closed. Open stoves allow the use of stones for vaporization, water can be poured on them. Such steam is not harmful to people, it turns out dry and does not burn the body. In closed structures, stones are knocked inside, they can also be poured with water, but for this you need to open the door of the stove. The second type of furnaces retains heat much longer than the first.

As for the features of the masonry of the stone, certain skills and compliance with the instructions are required here. Here are some tips that just need to be taken into account in the work:

- The brick structure is best collected on a clay solution;

- The height of the department for stones should not exceed 7 brick rows;

- It is worth properly placed a ash, blown, and a smoke -sized pipe so that the steam room warms up as quickly as possible;

- When making the design calculations, remember the lower stones in the stove, the more productive the source of steam formation.

Features of a metal furnace

Metal furnaces for baths are used quite often: the material heats up quickly, quickly gives heat, and the structures themselves are light and small. However, such heaters quickly cool and require a huge amount of firm fuel (firewood). Many models of metal furnaces have a standard set of structural parts. Due to the presence of grates in such devices, it is virtually impossible to regulate the combustion process, therefore it is not possible to control (decrease degrees as necessary) temperature. Practitioners offer options for improving metal furnaces for baths. To do this, the design must be deprived of grates and firewood should be burned right on the basis, and in the meantime, in the doors for a blow, you need to make holes that will allow you to adjust the amount of penetrating air into the furnace. About the stages and features of the manufacture of metal furnaces with your own hands, we will talk further in the article.

The stages of the manufacture of a metal furnace with your own hands

For the manufacture of a metal stove for a bathhouse, amateur masters should do work in several stages.

Stage 1. Prepare a project with drawings, indicating all the necessary measurements of parts and their specific position.

Stage 2. Take the preparation of the necessary tools and material. Inalienable elements in the working process will be: welding machine, grinder, roulette, chimneine pipe, etc.

Stage 3. This stage can be called preparatory, since it is required to mark and clean the territory for the future structure.

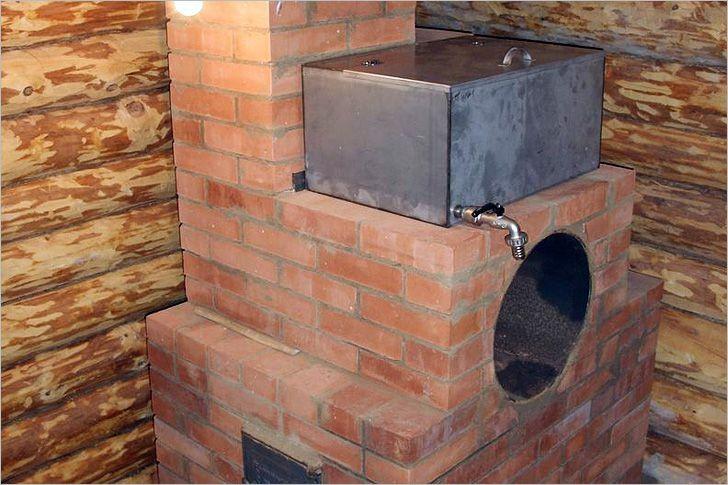

Stage 4. A water vessel is made. In the tank, a hole for a crane is given to replace water.

Stage 5. The firebox is created, the heater and blew. You need to install grates above the blower.

Stage 6. We work on the foundation for the furnace. It is best to make a brick base. Brick masonry on the solution must be done in two rows, this will be quite enough.

It is worth noting that metal stoves can be different in shape: curly, horizontal, rectangular, vertical. The most convenient in operation are rectangular structures. This form of the heater contributes to uniform heating of the room and retains the thermal balance in the steam room.

How to build a brick stove with your own hands

When planning the construction of a brick furnace for a bath with your own hands, you need to responsibly approach the issue of choosing the main material, on which the strength, reliability and productivity of the structure depends. Gritten brick is known excellent heat -resistant characteristics, and a red stove and ceramic brick, etc. are used with it.

The work regarding the construction of a bathhouse made of brick begins, as a rule, with a foundation filling, which can be a variety of type (stone, bottle, etc.). The classic option is a concrete base that should be supplemented with waterproofing layers of roofing material or felts.

Having started the laying of the furnace, it is important to constantly, in the process of work, check the horizontal rows on the errors and the verticality of the corners of the structure on inaccuracies. A brick stanger can be made both open and closed, in any case it is a painstaking work, which must be carried out strictly according to ordinal instructions. On the second row of masonry, holes are formed for the installation of a blower, most often it is blocked on the fourth row and is fixed in the design. At the door level blown in the stove, gols will be installed, which rely on the bricks of the previous row on the bricks. By laying the chamotomed brick in the future, you should pay attention to the presence of holes for the supply of secondary air. Next, the furnace furnace is built and the door is installed in it. Further, work boils over the creation of a stove. After the chimney is equipped, the valve is installed. A water tank is installed, taps are regulated, etc.

The above types of bricks are used in laying the stove at different stages regarding their physical properties, which we will talk more about in the next chapter of the article.

How to calculate the material, make a drawing for making a brick furnace with your own hands

So, as it turned out earlier for work, we need a ball (heat -resistant) and ordinary brick. It is not recommended to lay out the entire structure only from chamotical material, since such a stove will not last long and collapse. This species is best used for laying the internal environment of heating equipment. How to correctly and at what stages to alternate a brick should be indicated in the drawings. For inexperienced masters on the Internet, a huge number of already verified projects for creating this format for bath furnaces are presented.

When creating the drawing yourself, you should pay attention to the following points:

- Topa doors should be located opposite the entrance to the bathhouse;

- The foundation for the furnace should be more than 20 cm high;

- When creating a design project, it should be noted rows that are being built without a solution.

Drawings from professionals are posted on some construction sites imply the presence of ready -made numbers, calculations, the required number of materials. In general, we can say that all supplies to the construction of a brick furnace depend on its dimensions and the availability of additional equipment in it.

Stoves of constant and periodic heating for a small bathhouse

According to the principle of operation of the furnaces for baths, they are divided into constant and periodic heating devices. Designs of the first type, as a rule, have thin walls and are suitable for loading a small number of stones. The temperature in such heaters reaches 300 - 350 degrees. Such stoves are heated in various ways from electricity to liquid fuel, but gas is not used for the benefit of user safety.

Devices of periodic action, on the contrary, are characterized by thick masonry and the ability to use a large volume of stones. Such equipment has a high level of heat transfer. For heating such furnaces, firewood is most often used. In the lower section of the periodic action structures, the temperature reaches 1100 degrees. Such indicators are able to completely destroy soot on the stones, so at the finish they always remain clean.

At home, metal stoves of constant heating are most often made, the heat pressure of such structures is enough to provide small family baths. In addition, recently, more and more often collect combined devices that allow increasing the efficiency of heating equipment.

Choosing a place and installing a bathhouse for a bath with your own hands

The exact place for installing the furnace in the bath need to be determined at the design stage. For each construction, this is an individual territory, but still there are nuances the same for everyone:

- Carefully need to study the location of the beams and overlapping the roof;

- All details of the furnace should be thermal insulated from wooden surfaces;

- The firebox should be close to air access;

- It is best to install a stove between the dressing room and the steam room.

Before installing a furnace in a bathhouse, adjacent walls, you need to sheathe special protective material, for example, asbestos cardboard. Do not forget about the waterproofing and processing of metal structures with special products resistant to high temperatures. The distance from the wall to the heating equipment should be more than 26 cm. A properly placed furnace in the bath should not interfere with visitors, while the most effective ventilation in the room and a fluid pipe is functionally equipped.

Use the video as additional information: