Plastic windows help to maintain heat in the room, do not let cold and sound. But...

|

|

There is a common problem in regions with snow winters ... |

The easiest and fastest way to transform the dwelling to glue the wallpaper. It... |

Glomagnetic sheet: characteristics, advantages, application

The use of glass -fruits is associated primarily with the internal and external decoration of the room. Thanks to such qualities as ease of installation, stability before moisture, strength and durability, the glass -deck leaf becomes quite popular material. We will talk about the features of the use of glass -fruits leaf.

Table of contents:

- Glass -fruity sheet - Features and production technology

- Glass -fruit sheet of characteristics, advantages and disadvantages

- Glamagnetic sheet application and selection of quality material

- Glomagnetic sheet Installation: Instructions for work

Glass -fruity sheet - Features and production technology

Glomagnium sheets are universal building materials that perfectly replace drywall, plywood, chipboard, flat slate, etc. For the production of this material, exclusively environmentally friendly components are used. Magnesitis is used as the main substance.

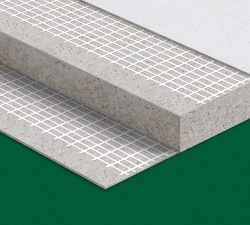

Glassnia sheets have a sandwich shape, one part of which consists of fiberglass, and the second is a filler. In addition, one part of the SML is smooth and mirror, and the second is texture on the contrary.

If we compare glass -fruits with drywall, then the first option is more harmless than the second - containing asbestos. Glomagnesium sheets are used in the process of performing internal finishing work in premises of any purpose.

Most often, glass -fruits are attached to the frame base, although they are possible to fix them directly on the surface of the wall. Glomagnium sheets are relevant in rooms with the presence of an aggressive environment. In addition, they are used in pools, saunas, showers. There is an option for laminating or rationing SML, after installation, such a material does not need additional decoration.

With the help of glass -deck sheets, enclosing and supporting constructions are built, in such situations they act as non -sewing formwork.

Glomagnetic sheets are distinguished in thickness:

- 0.4-0.5 cm - used to finish the ceiling;

- 0.5-0.8 is suitable for work on the walls;

- 1-2 cm - partitions, facade areas, performing the function of non -removable formwork.

Among the main features of this material, it should be noted:

- strength;

- flexibility;

- moisture resistance;

- simplicity of installation;

- lightness of the finish;

- small weight, less than that of drywall;

- Easy fixation with nails or screws.

This material refers to non -combustible or low -combat substances. It contains the presence:

- magnesium chloride;

- phosphoric acid;

- magnesium oxide;

- latex putty;

- water;

- non -woven canvas;

- perlite;

- fillers;

- plaster glasses.

Depending on the manufacturers, the composition varies. Its strength and quality depend on the amount of magnesium oxide in the material. Glomagnium sheets are of various shapes, sizes and thicknesses. Glass -fruit sheet sizes - length 122 cm, width 244 cm. Since the outer surface of the sheet is smooth, it is not required to align the surface again for decoration. It is enough just paint the sheet with paint or paste it with wallpaper.

The technology for the production of glass deck sheets consists of the following stages:

1. The procedure for forming a sheet from all of the above components.

2. Drying of glass deck sheets.

3. The process of output.

4. Pruning of sheets in accordance with previously specified parameters.

5. A set of strength characteristics.

Glass -fruit sheet of characteristics, advantages and disadvantages

Among the main advantages of the use of glass deck sheets, it should be noted:

- fire safety;

- stability before moisture;

- high strength characteristics;

- weight ease;

- duration of operation;

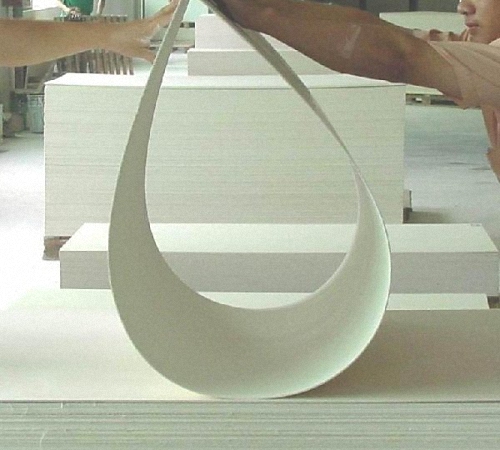

- flexibility;

- stability in front of temperature changes;

- frost resistance;

- biological resistance;

- harmlessness for human health;

- stability before the influence of chemical compounds;

- A wide range of use.

Studying about the glass -fruit sheet reviews, we note that its fire safety level is high. Since this material is practically not ignited.

The material begins to burn when the temperatures are exposed to more than 1000 degrees.

In addition, he is not inclined to swelling, relaxation, deformation and stable before moisture. Thanks to this, this material is used in rooms as saunas, baths, pools.

This property of glass -fruit leaf as biological stability contributes to its resistance before mold, fungus, bacteria and various kinds of insects.

The glass -fruit sheet is not amenable to the influence of alkalis, acids and other kinds of chemicals. In addition, this material is quite durable and light in the bend. Therefore, with its help, various kinds of structures are formed in the form of arches and voluminous asymmetric partitions. For cutting the material, it is not necessary to make great efforts, in addition, it does not crack and is not prone to crumbling. To fix it, the use of screws, nails or pneumatic pistol is enough.

Glomagnetic sheet photo:

The total mass of the structure made of glass -fruit sheet is forty percent less than the weight of the same plasterboard structure. Therefore, to install sheets, it will take less physical effort and time.

Glassnia sheets consist of fiberglass, which is a reinforcing element of this design. It is thanks to it that the material acquires the necessary elasticity. Thus, its easy transportation, simplicity of styling and the possibility of use on relief surfaces are ensured.

The duration of the operation of glass -deck sheets is more than twenty years. In addition, it does not contain harmful elements causing allergies, therefore it is used to decorate the premises of sanatorium, children's and medical purposes.

Keep in mind that the separation of glass deck sheets occurs into classes, so the material that belongs to the economy class has fewer advantages than the high -grade sheet of the highest class. Their cost also differs, for a lower price, the material has worsened operating properties.

Cheaper materials are capable of highlighting salt in the process of getting wet, so the use of steel screws leads to their corrosion. Low -quality glass -fruits are used exclusively for the interior decoration of rooms in which the appearance of temperatures or too high humidity is excluded.

Glamagnetic sheet application and selection of quality material

The scope of the use of glass deck sheets applies to:

- construction of wall, arched structures and partitions;

- in the process of installing suspended ceilings;

- when decorating slopes;

- when arranging underground space and floor decoration;

- in the process of decorating communication mines;

- like non -removable formwork;

- When decorating facade areas.

Most manufacturers of glass -fruits clearly indicate its belonging to a particular class on the product label. However, there are unscrupulous manufacturers who give out a low -quality glass -quality glass for premium material. On the glass -fruit sheet, the price is determined precisely by its belonging to a particular class. In this case, you should study several differences that will help you choose high -quality material:

1. The color of the material. Glomagnesium sheets that are of high quality are light yellow or beige. If the color of the products is white or grayish, then such sheets belong to a low quality class. If you draw a hand on them, then a small amount of dust flies from them.

2. The presence of brittle edges indicates the poor quality of the product and its tendency to crack.

3. If possible, the glass -fruit sheet is lowered into a container of water, if after two hours it was clouded, then it is better to refuse to buy such material.

4. The presence of a non -woven base indicates a low strength and a high level of fire of the glass magnesium sheet.

Glomagnetic sheet Installation: Instructions for work

In terms of strength characteristics, glass -fruits are significantly superior to drywall. For example, if a plasterboard sheet is used with a thickness of 1.2 cm, then for the same strength, a glass -deck sheet is enough, 1 cm thick.

Enough light weight of glass -deck sheets allows you to carry out work on its installation only one person.

Since the material was covered with hydrophobizing impregnation, which improves its adhesion with paint and varnishes, its finishing is as quickly as installation.

To prevent the formation on the surface of the glass magnesium plate of the fungus or mold, lime is used.

To install glass -deck sheets, the presence is required:

- metal profile;

- ribbons for reinforcement;

- putty;

- brackets for fixation;

- Self -tapping screws with a secret hat.

Glomagnesium sheets involve both transverse and longitudinal fastening. If it is planned to lay the sheets transversely, then on the walls they are attached horizontally, and transversely on the ceiling. Fixation of glass deck sheets according to the longitudinal attachment scheme is carried out vertically on the surface of the walls and in the longitudinal direction on the ceiling.

Before carrying out the installation of stlomagnium sheets, a supporting structure is installed. It will require a metal profile for its installation. To install the structure from the profile, the brackets and special kind of fasteners should be used.

Tips for the installation of a structure from a metal profile:

- If the thickness of the glass -fruit sheet is 1 cm, then the interval between the installation of vertical racks should be 61 cm;

- The supporting profiles are located at a distance of about 4 cm, with the thickness of the material at 0.8-1 cm (this rule is relevant for the installation of suspended ceilings);

- To improve sound insulation, it is recommended to use a special tape, which is glued with the back side of the profile installed near the wall, the main function of this profile is the distribution of the overall load.

Instructions for the installation of glass deck sheets for a construction of a metal profile:

1. The distance from the lower edge of the plate to the floor should be one centimeter. When the installation work is completed, it is filled with putty.

2. Fasteners are installed in a step of 250 mm.

3. The fixation of the sheet on the surface begins from its central part, gradually moving to the outer edge. If this sequence is violated, then there is a risk of deformation of the material.

4. Half of the thickness of one sheet is an interval between two sheets.

5. The distance between the edge and the screw should be at least 15 mm.

6. The hat of the screws is completely recessed in the stove for one two millimeters. If premium glasses that have increased density are used, then the sinking procedure should be carried out first.

7. Fixation of glass -deck sheets does not involve their interruption using brackets or screws, since the outer layer of fiberglass is deformed, the sheet mount is disturbed.

To fix a standard sheet, a size of 122 by 250 cm, weighing nineteen kilograms, the same fasteners are used as in the process of installing drywall sheets.

Please note that in accordance with the width of the sheet of 122 cm, the vertical racks are mounted with an interval of 46 cm.

Self -tapping screws are mounted on a surface with a step of 25 cm. It is best to use fasteners T N 25 or their analogues. If premium sheets are used, then it requires preliminary drilling holes for screws, its diameter is about two millimeters.

For putty sutures that form between the sheets, any plastering mixture is used, since the material is characterized by high adhesion to many finishing materials.

Acrylic sealant is used to accelerate the seaming of the joints. It is applied to the end sections of one sheet, and then the second sheet is installed. In this case, the gap between them is about 0.7 mm. The removal of the remnants of the sealant occurs after drying it.

Each of the surfaces of the glass -fruit sheet is working. For further decoration, any of the parties is used. If it is planned to paint or pour glasses sheets with wallpaper, then it is better to choose a smooth surface. The texture part of the sheet is perfect for its decoration using tiles.

Recommendations for installation work:

1. Keep in mind that in the process of installing the material it should be absolutely dry. Otherwise, it is subject to a change in the form, and its cutting is difficult.

2. The fibers on the surface of the glass deck sheets should be located in the vertical direction. This rule provides increased strength of the structure.

3. The screws used to install drywall will help to fix the glass -fruit sheet.

4. If the glass -fruits are cut, then it is carried out on a flat surface, while the smooth side of the material should be on top. An excellent material for this work will be an electric jigsaw. To carry out the incision, use a sharp knife, the ruler will play the role of a guide. Next, the sheet is broken off, and its edges are cleaned with sandpaper.

4. All the gaps between the sheets, as well as the fasteners of self -tapping screws, put up. Next, grouting and covering the base with a primer is made. In this case, the surface is cooking for the finish.

Glomagnetic sheet video:

Too many mistakes and

Too many mistakes and typos in the text itself. This spoils the impression of your portal.

Author Down, take this

Author Down, remove this [s] vyser [/s] Text do not disgrace.

Asbest in his drywall, then a person’s healthy person will no longer read.

And Magnesite is a rock that does not possess astringent properties, remember already "manufacturers" homegrown.