Today, a metal grid is a popular material used for any ...

|

|

The ceiling can be painted or pasted, equipped with drywall or plastic, but ... |

In any mixer, no matter how high -quality it is, sooner or later this is manifested ... |

DIY cornice

When the installation of the roofing is completed, work begins on the sheathing of the overhang of the roof. This is done not only to protect the facade and ensure the ventilation of the roof, but also to give a complete appearance to the structure. The article will talk about what materials are used for these purposes and how the cornice of the roof is made with your own hands with sofit, corners and wooden lining.

Content:

- The device of the cornice of the roof

- Creation of proper roof ventilation through cornices

- Selection of material for lugging roof overhangs

- Bearing roofing over rafters

- Bearing a roofing over a wooden box

- Bearing cornice overhangs with sofitis

- Bearing the cornices of the roof with corrugated board

- Bearing a roof overhang with a wooden lining or board

The device of the cornice of the roof

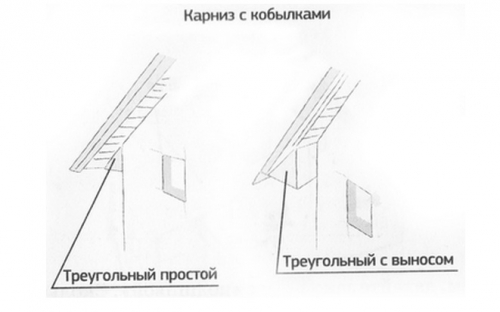

Cades is a ledge rafter outside the facade of the house. It can be either simple or with removal. The first is more easy to perform, and with a strong wind in it it will not be unpleasant to buzz, which can not be said about the second option.

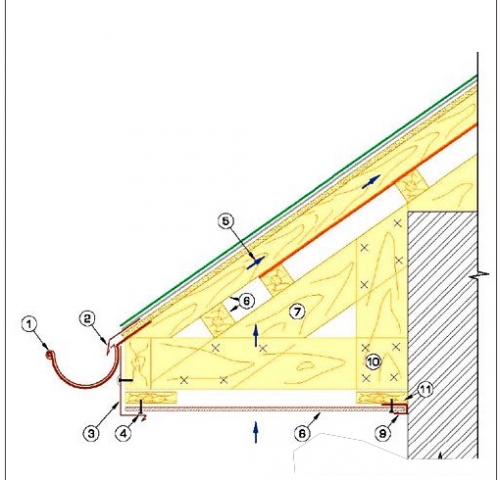

Roof overhang knot

1- gutter gutter;

2- dropper;

3-apron made of metal on a frontal board;

4- self-tapping screw;

5- direction by which air moves;

6- block 5x5 cm;

7- rafter leg (mare);

8- bearing material;

9- BREAK;

10- boards are the basis of the cornice overhang;

11- a supporting bar for fixing the break.

There are two types of cornice overhang - lateral and frontal.

The frontal cornice of the roof

Frontal is needed to protect the facade of the house. It is the side edges of the sloping slopes of the roof. Accordingly, they are absent in Valmova (four -sided) roof.

The device of the front overhang of an ordinary gable roof is performed by releasing the load -bearing crossbars fixed on the rafters. Often you can find when the front cornice is formed by the labels of the crate, which are laid on vapor barrier for roofing material. A cornice board is attached to them, which will subsequently be sheathed with corrugated board or Sofit.

The side cornice of the roof

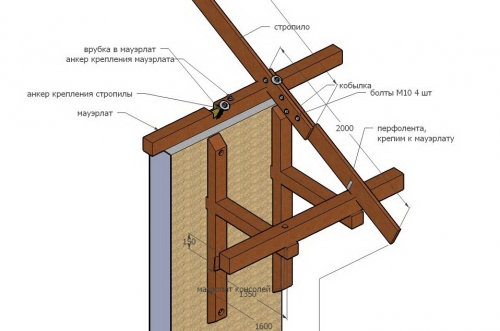

All inclined roofs have a side overhanx. It is formed by rafters, which are issued outside the walls of the house. Their distance is calculated from the height of the house and the width of the blind area, often it is about 50-70 cm.

Although it is believed that the minimum allowable overhang size is 50 cm, but more narrow are found.

- In this case, the wall of the house must have good wind protection, since in oblique rain it will get wet.

- The second option to fix the position to install the mares, thereby increasing the length of the rafters. But this is a rather laborious process, and with the roof already made, few people want to open everything and redo it again. Therefore, it is important even at the construction stage to provide for the necessary size of the roof overhang.

The rafters are interconnected by boards along the entire length of the cornice. In the future, they will be closed with facing material.

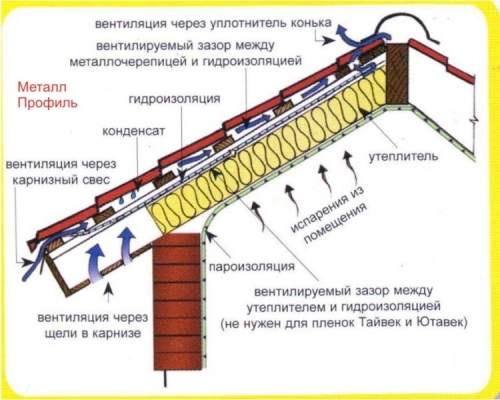

Creation of proper roof ventilation through cornices

The main function of any cornice is the protection of the roof from atmospheric influences. But at the same time, he should not interfere with the natural ventilation of the undercarriage. This is important not only for residential attic floors, but also for cold roofs. The warmer air rising from the Earth must pass through the cornice without hindrance and moving between vapor barrier and roofing material to go out through the horse. It is for this reason that when fading the cornice, it is forbidden to use various sealants and mounting foam. Otherwise, condensation will form, which will lead to the wet of the roof insulation.

But there are exceptions - the cornices are made with ventilated only under the slopes of the roof, and all front overhangs are closed tightly.

The selection of materials for lugging roof overhangs

To date, there is a wide range of materials for hearing a roofing cornice. Of course, each of them has its own advantages and disadvantages, but all of them perfectly protect it from humidity, provide insulation and ventilation of the roof. When making a choice in favor of a particular material, one should be guided not only by its beautiful appearance, but also by the duration of the operational period.

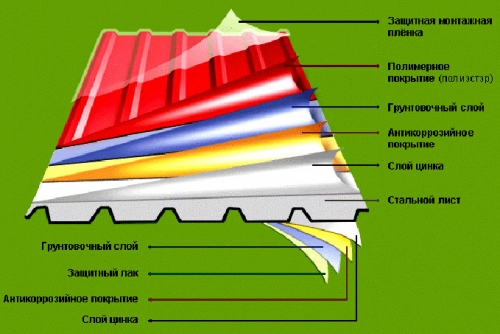

Corrugated board

This is galvanized steel with multi -colored polymer coating. It is resistant to mechanical damage and temperature changes, has the necessary rigidity, and is also not afraid of wind loads. To ensure the necessary ventilation, a gap between the corrugated board and the wall of the house is equal to the height of its wave.

Sofites

This is the most popular material specifically designed for hemding cornices. In fact, these are plastic panels that look like siding, but already having ventilation holes. Also, they differ from ordinary siding in that they contain UV stabilizers that protect sophites from the negative influence of sunlight.

Copper sofits

This is durable material, outwardly very aesthetic and presentable, but also quite expensive. Sofites made of copper have high fireproof and strength characteristics.

Aluminum sofitis

They are very light, fire -resistant, elastic, and if necessary, their repair will not be difficult. They also have high resistance of paint, so that color saturation does not change under the influence of ultraviolet radiation.

The disadvantage is only the scarcity of the color scheme of them is produced by white or brown.

Galvanized sofits

They are durable and do not need additional care. These are durable sofits that are not afraid of moisture and fire. But they have a fairly large weight, which to some extent makes their installation more time -consuming.

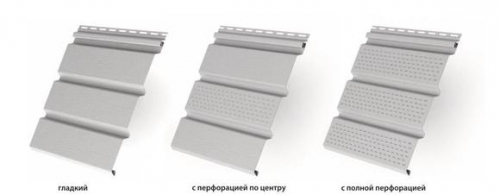

Vinyl sofites

This is an inexpensive and most popular option for sofitis for hearing roofing cornices. They have lightweight, perfectly protect against external influences, have a noble appearance, are easy to install, and also create a seamless canvas, providing full ventilation of the under -wrapping space.

To date, they are made of fire -resistant plastic, which, moreover, is able to withstand serious loads. Three types are produced:

- continuous three -lane without ventilated holes;

- fully perforated;

- three -lane with a perforated central strip (the most popular).

Regardless of the chosen material of the Sophies, all of them are quite easily mounted, and such work will not be difficult even for a beginner in construction. The main rule when installing them is that they are located perpendicular to the wall, and not along.

Wooden lining and trimming board

You can still often find that a real wood is selected for hemding the cornice overhang. Since it is installed outside the house and is subjected to aggressive influence of the environment, the choice of material must be approached responsibly. You can not save and buy too thin a lining, its optimal thickness is 2 cm. It should also be of medium humidity (it is not suitable too humid, since it can lead it, but very dry is also not the best option).

To ensure ventilation, the boards are nailed with an indent from the wall of 2 cm.

Bearing roofing over rafters

This method is rational for roofs with a small angle of inclination. The complexity of this execution of the sheathing is that all the edges of the rafters form a flat plane.

But this can be achieved forever, then small boards that are attached to the rafters will become a way out. Their length is equal to the distance from the wall of the house to the edge of the overhang. To install them evenly, at first it is screwed along one board from each edge of the cornice and the twine is pulled between them. All other segments of the boards are attached to the resulting guideline. The sheathing to such a frame is attached to metal corners or screws.

Bearing a roofing over a wooden box

This method is ideal for roofs with a large inclination. To arrange such a box, a wiped board is taken with a thickness of 4 cm and is attached between the wall of the house and the edge of the rafters. If its edge is installed directly to the rafter leg, then to fix the second edge, it will require installation of the board adjacent to the wall, which is screwed to the rafters from above.

The second option is also possible when, instead of an additional vertical board, a beam for dowels is attached to the wall of the house.

On this frame the box is finished, and you can attach the skin to it. To ensure the necessary rigidity of the entire structure, everything should be attached not on nails, but on screws or corners.

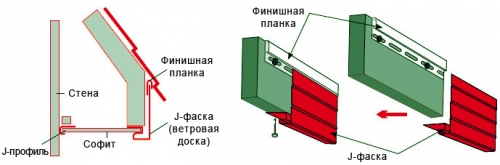

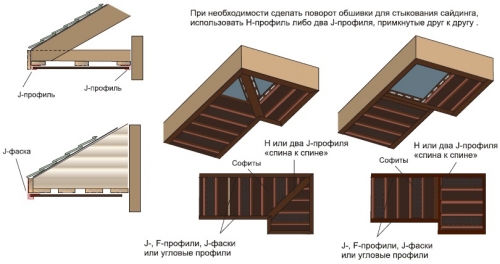

Bearing cornice overhangs with sofitis

Stages of work:

- Sofites are equipped with two special strips, which have the form of the letter J or F. It is attached to the wooden rail prepared on the wall, and the second from the side of the Svet. Self -tapping screws are used as mounts. All planks should be attached absolutely exactly in relation to each other, therefore it is recommended, first marking.

- Then the width of the cornice overhang of the roof is measured and 6 mm is deducted from the result. This is done in order to create the necessary gap, which compensates for the thermal expansion of the material. Sofites are cut into strips of the desired length.

- The prepared plates are slightly bent and inserted into the grooves of the installed profiles. Where they are fixed with self -tapping screws.

- In order to pick up the cornice angle, the length of the sofitis planks must be smoothly reduced, cutting off one of the sides at an angle of 45 degrees.

For their connection, H-profile or two J-profiles are used.

More detailed instructions on how to pick up the cornice of the roof with sophims can be viewed on the video presented below.

Important moments in working with sofitis

- Sofit is attached only at right angles and through special holes;

- there must be a gap so that the panel can freely expand or contract;

- the optimal size of the mounts: the length of the legs 3 mm, the width of the hat is 8 mm. They should not be fastened tightly, but have a gap between the hat and the surface of the sofit equal to 1 mm;

- the distance between the fasteners is 40 cm (more often);

- sofites are cut with a circular saw with a canvas on which the teeth are located in the opposite direction. You can also use scissors for metal or knife. In the latter case, it is best to draw a cut place for them, and bending the panel along it, break off the necessary segment;

- store and transport sofites on a flat surface with low piles (packs 10-15);

- despite the fact that the manufacturer is assured the possibility of installing sofitis even in winter, it is not recommended to carry out work if the temperature is below 15 degrees.

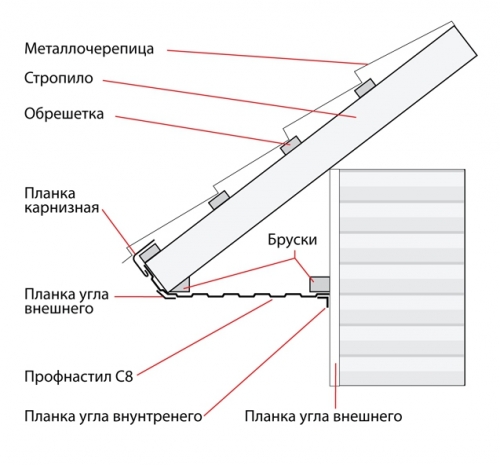

Bearing the cornices of the roof with corrugated board

- First, a bar is nailed on the wall in a horizontal position along the level of the overhang edge. At the same level, the second block is attached to it along the edge of the rafter legs;

- the corrugated board is cut off the desired length (not forgetting about the thermal supply of the material and the need for ventilation gap) and attached to the screws to the installed bars;

- the junction of the profiled sheet and the wall is closed by the bar of the inner angle, and the connection of the outer edge with the rafters is decorated with a similar bar of the outer angle.

On this installation of the corrugated board is completed.

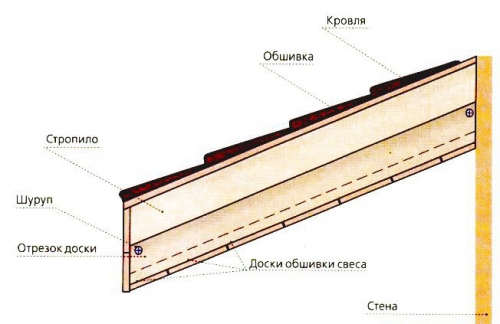

Bearing a roof overhang with a wooden lining or board

Bearing of roofing overhangs is most convenient to carry out from below, standing on construction forests or on a stepladder.

Important! The cornice should only be lined after the walls of the house are completely insulated outside, vapor barrier is made and the installation of facing material is completed.

Before sheathing the overhang, all rafters on the side cornices should be not only one length, but also to be precisely parallel to the wall of the house. Binding wind boards are attached to them.

When all this is completed, the installation of the mounting of the sheathing begins.

- At first, one board is screwed vertically to the wall, its lower edge should be at the level of the edge of the rafters - in the figure above (1).

- The second board is attached between the rafters and the board number 1 at their lower edges (2). It should be parallel to the earth. Thus, the basis on which the crate will be installed is obtained.

- When the frame is prepared, the installation of the sheathing itself begins.

- When lining the roofing cornice with boards, between them and the wall it is necessary to leave a small gap. The boards themselves are selected even, good quality and a thickness of 1-2 cm.

- To ensure the necessary ventilation of the undercarbon space when lining with wooden lining, it is recommended to install ventilation grilles with a step of 1.5 meters around the perimeter.

But often, relying on the properties of wood to breathe, most builders do not adhere to these rules.

A little more in my

A little more in my video about the sewing of the overhang lining ...)))

https://youtu.be/nujoocm5xko

There is a brigade for such a robot

There is a brigade for such a robot to leave