Choosing a water warm floor is one of the economical options for heating the room, which ...

|

|

Everyone, even the most high -quality foundation, over time needs restoration ... |

Almost every person took a painting brush at least once in his life and what -... |

DIY formwork

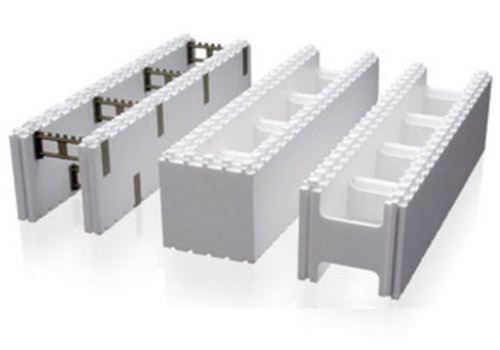

Domestic construction technologies are developing a rapid pace. And it pleases. Innovations not only greatly simplify the process of erecting buildings, but also allow you to create a solid base for any structure. The proof of this is a non -removable formwork for the foundation, which has many advantages compared to the traditional methods of arranging the base. Most often, such a formwork is made of ready -made polystyrene blocks, which minimizes the poor quality and influence of a person on the construction process.

Content:

- Advantages and disadvantages of the design

- Varieties of non -removable formwork

- Feeding formwork: construction technology

- Features of the performance of work

- DIY Fixed Formwork: Video

Advantages and disadvantages of the design

Construction of houses from non -removable formwork method used for about 15 years. It is noteworthy that the principles of the construction of the basis for the building have not changed, but the stages of work have almost doubled. If earlier it was necessary to purchase materials, collect the frame, install it in a trench dug in advance, and then dismantle it, then the technology of non -removable formwork involves only the assembly of ready -made elements.

Pros of non -removable formwork:

- forms for non -removable formwork do not absorb water;

- excellent seismic resistance;

- fire safety;

- ease of installation (everyone can master the nuances of construction);

- resistance to decay, the appearance of mold and fungus;

- equipment for the production of non -removable formwork guarantees the receipt of materials that have a minimum weight;

- due to the low density, non -removable formwork of polystyrene foam does not load the base;

- foam, performing the function of the heat insulator, allows you to get a warm foundation;

- quick terms of construction;

- tightness.

Cons of non -removable formwork:

As for the minuses, there are not many of them, but still it is worth knowing about them.

- non -removable formwork has a considerable price. On average, this indicator is 600-1000 rubles per square meter. However, the high cost of non -removable formwork with more than pays off the benefits that this innovative development carries with it;

- unknown transportation. Despite the light weight, the transportation of formwork forms will make it slightly fussing, choosing the optimal vehicle;

- the impossibility of secondary use of blocks.

Varieties of non -removable formwork

If you want to erect a house in the shortest possible time, then the construction of a non -removable formwork will become a competent exit from the situation. But everything is not so simple. After you decided to trust the trends of our time, you should decide which formwork is suitable for realizing the dream.

Due to the fact that non -removable formwork projects implements any complexity, then the material for its manufacture can also be different. Consider the most popular options.

- foam polystyrene. It has already become a classic, but not the only way to use the capabilities of the new technology. Polistyle blocks are durable, have increased thermal insulation qualities and at the same time pass the air, allowing the foundation to breathe;

- slice-cement forms. No less in demand, because characterized by excellent soundproofing properties. A distinctive feature of the presence of air bubbles located between wooden chips, increasing the reliability of formwork several times. Special chemical processing of wood prevents decay and makes the material immune to combustion and high humidity. Thus, the intricate-cement fixed formwork can be used without a doubt when pouring ceilings;

- fibrilite. Environmentally friendly and practical formwork. Fibrilite a mixture of caustic magnesite with wood chips. Sometimes, instead of magnesite, Portland cement is used. The main advantages should include bioforability, fire safety, high vapor permeability and frost resistance.

It is impossible not to say about the technology by rental concrete, which allows you to receive universal blocks according to the patented formula. This method of manufacturing non -removable formwork is recognized as the best solution for social construction, which provides a chance to build an intrinsic even with a modest budget. The essence of the method in the rental of masses using rollers and templates, compaction of the concrete mixture and the extraction of pores. Using concrete rental without special additives and plasticizers, you can give a profile any shape. Superflow material is allowed to operate in aggressive, moist media, as well as in conditions -50 degrees.

Feeding formwork: construction technology

The technology for the construction of a fixed formwork is simple to understand even a kettle, there would be a desire. The only thing that is necessary for marginal accuracy and maximum accuracy. So, where does it all start?

As with the classic development of events, the formwork is installed on the foundation covered with waterproofing. Forms are planted on the basics of the armatourins. After the installation of the first layer of blocks, horizontal reinforcing rods are threaded into the grooves. They should be laid and fixed with wire twisting. Installation of the first row is of particular importance. It is at this stage that in exact accordance with the project, door slopes and exterces of internal partitions are placed.

Forms, as a rule, are fixed during the installation of the second layer, which provides reliable fixation of vertical seams. Please note that the side sides of the layers must match. The technology resembles working with brick here, it is also necessary to shift each row relative to the previous one to ensure the rigidity of the walls.

The message of the forms vertically occurs using grooves, which easily closed with light pressure. When installing the third layer, do not forget about the control of the verticality of the seams. After the blocks are safely laid, concrete can be poured. This should be done with a thorough compaction of all voids. And the deep vibrators will help in eliminating holes. The working part of such equipment for non -removable formwork should not exceed 40 mm. If there is no professional equipment, the seal is carried out manually with a bayonet way. It is enough to choose a suitable segment of the reinforcement.

Features of the performance of work

The production of non -removable formwork has its own nuances. For example, many are concerned about the question of how to organize the process so that the walls turn out to be strong? Experts advise filling the upper layer half so that the concrete seam is inside the factory form for formwork. It is worth remembering that the bearing capacity of the walls directly depends on the class of the reinforcement and the brand of concrete.

During the construction of monolithic walls, it is necessary to worry about the wiring, sewer and water pipes, and ventilation holes. To do this, before filling the concrete mass in the forms, grooves are drilled. As a result, we get a pie in which reinforced concrete is located between layers of polystyrene foam. The walls are warm and no more thermal insulation is required.

There is an opinion that non -removable formwork with your own hands is a difficult matter. But this is not so. High -quality execution is provided if you observe a simple sequence:

- purchase good, elastic material;

- prepare fixtures of fixing nuts and fitting screws;

- install a fixed structure and secure it reliably.

Frighty formwork is a great opportunity to build a warm, solid house with your own hands, without resorting to outside help.

https://www.youtube.com/watch

https://www.youtube.com/watch?v\u003dPKZRO3QSR3W

https://www.youtube.com/watch

https://www.youtube.com/watch?v\u003dRF5T9Klyp08