Camping wallpaper for walls is one of the most beautiful and environmentally friendly materials, ...

|

|

The technology for the construction of ventilated facades in Russia appeared relatively recently ... |

After the thermal insulation layer is laid, it is necessary to form a reinforced ... |

Installation of PVC membranes

Modern industry offers a membrane to cover the PVC roof, which has high technical indicators, and is also easily operated and used in construction work. In this article, we will consider the features of the installation of this material with different technologies.

Table of contents:

- Characteristics and components of PVC membrane

- Features of using the membrane

- The advantages and disadvantages of PVC membranes

- The parameters of the device of the membrane roof

- Additional materials for laying the membrane

- Methods of installation of a membrane coating

Characteristics and components of PVC membrane

For the first time, the membrane on the market appeared about 40 years ago, and still holds its position among other building materials. Many consumers choose PVC a membrane that owns high insulating and warmths. There are different options and technologies for fastening this material that will be described in the article.

The PVC membrane is a roofing material that owns excellent waterproofing properties. It is made on the basis of polyvinyl chloride. The membrane consists of several components that determine its quality:

1. The surface of the material is quite resistant to different temperature differences, as well as to the effects of ultraviolet rays. The upper layer has different colors, so choosing a roof that would correspond to the general architecture of buildings is not difficult.

2. Next, there is a layer of polyester grid, which is reinforced. Such a component is not in every material.

3. The lower part of the roof PVC of the membrane has dark shades, which is very important for this type of product. This is necessary so that when the upper layer of the membrane is ruptured, it is easy to find the damage site and repair it.

The main feature of the PVC membrane are special stabilizers that are present in the upper area of \u200b\u200bthe material. They allow you to protect the roof from external exposure and other damage. It is worth noting that ultraviolet rays dangerous for PVC membrane roofs. Therefore, in the building material there are absorbers that form a barrier, which prevents destruction from ultraviolet radiation.

Modern manufacturers provide customers with a guarantee for 8-12 years, however, the shelf life of such a coating may have 50 years. The peculiarity of the manufacture of the material is to combine the voltage technology, using hot air flows. This method allows you to create a membrane with a holistic surface, as well as with reliable seams. The installation of the material can be carried out at any time of the year without unnecessary effort.

Features of using the membrane

Laying a PVC membrane can be done for buildings that are operated or not used. As a rule, this material is consulted for a flat roof, and is used in the construction of multi -storey buildings, industrial buildings, shopping centers, and so on. The installation of a membrane roof is rarely used in the construction of ordinary residential buildings. This is determined by high prices for such products, as well as a feature of roof architecture, which are made gable and so on.

The membrane is advised to use for the construction of buildings with a flat roof. The characteristics of such a roof and the correct design will allow you to equip a roof that does not need to be repaired. In this case, you will need to constantly clean the drainage system, as well as check the roof for damage.

The characteristics of the production of PVC membranes and technologies of modern industry make it possible to create material of small weight. Such a roof does not have a high load on the supporting elements of buildings and foundation. The thickness of the membrane can be from 0.8 to 2 millimeters, the average weight of which has 1.5 kg per square meter. A similar material is offered in stores in rolls of different widths and lengths, so choosing the required number of roofs without residues is quite easy.

The advantages and disadvantages of PVC membranes

Experts distinguish a number of advantages of the membrane as a roofing material that are:

1. The quick process of installing and installing all elements of the product.

2. The membrane has a long life.

3. The surface of the material has a large level of resistance to the external environment, while the product withstands very low temperatures up to -60 degrees.

4. PVC membrane has a solid structure that is distinguished by elastic properties.

5. The material is vapor permeable, which eliminates moisture and condensate on the surface of the product.

6. The product is easy to mount on a different roof, even with an uneven surface.

7. The membrane is considered non -combustible material, which complies with all fire safety rules.

According to the above advantages, this material has some disadvantages that are important to consider when choosing a product. First of all, the membrane is considered expensive material, because not everyone can allow such a coating for the roof. Such a drawback is quite compensated by the durability of the product. For example, bitumen tiles need to be repaired after three years, and the membrane coating will last at least 40 years.

The parameters of the device of the membrane roof

The roofing should not only protect the surface from external exposure, but also save heat in the room, remove excessive moisture and the like. All properties must determine the durability of PVC

membranes. Technonikol is a company that offers a membrane coating around the world.

Experts use a special concept of a roofing pie for this type of product. This is due to the fact that the membrane has three main layers, namely vapor barrier, insulation and waterproofing. Of course, in some products there may also be additional layers that depend on the purpose of the material used.

The standard roof diagram from the PVC membrane has the following parts:

1. The first layer is thorough and consists of a profiled sheet.

2. Further, vapor barrier is laid, which is a film that prevents the appearance of moisture and condensate formation.

3. The lower area is considered thermal insulation. The most popular insulation material is mineral wool. A great substitute can be polystyrene or glass wool.

4. For such a roof, it is necessary to create another layer of thermal insulation. The second row is intended to distribute the load on the roof. Mineral wool can be used as insulation materials, but with the highest percentage of density.

5. Next, telescopic fasteners are installed.

6. On top of all layers, PVC membrane is installed.

Additional materials for laying the membrane

The modern market offers a wide selection of additional materials that are necessary for the installation of a membrane coating. They allow you to form a dense layer of roof, which will own high waterproofing and thermal insulation properties. Manufacturers offer several types of roof membranes, which differ in certain parameters.

1. PVC membranes also produce polyvinyl chloride, which is strengthened by a reinforcing grid of polyester. To make this product more plastic, it is recommended to add plasticizers. PVC membranes are quite durable and reliable, which is determined by special technologies for soldering components. Therefore, all joints of the product are strong enough and have a holistic structure. The only drawback is volatile compounds, as well as a low level of resistance to different oils, solvents and bitumen.

2. EPDM membranes are also produced, the main component of which is a synthetic rubber. This product is additionally reinforced using polyester threads. Such material has a low cost, and among the main properties, a long service life and high elasticity can be distinguished. The main disadvantage is the use of glue for the installation of such products, which excludes other methods of fastening. The most problematic area is the joints between the sheets, which must be periodically checked and repaired.

3. TPO membranes are made on the basis of thermoplastic olefins. There are different variations of the product that differ in the presence of a reinforcing grid or its absence. The technology of connecting the elements of the material is determined by the method of hot welding of components, which forms strong and reliable seams. One of the disadvantages can be called the smaller elasticity of the product.

Methods of installation of a membrane coating

Features of the roof installation are determined by the consumption of the PVC membrane, as well as the technology of attaching parts. Further, we will describe all the methods of installing a similar type of roof for buildings with the recommendations of specialists.

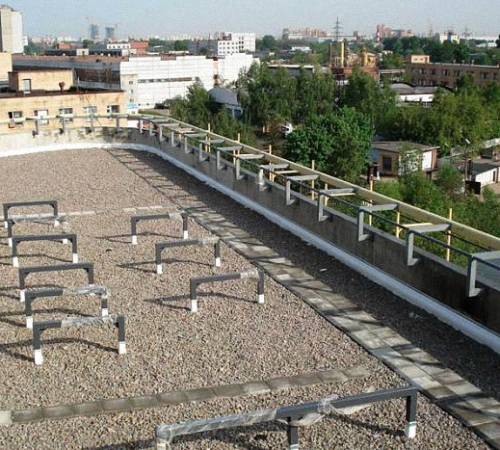

Ballast installation technology:

When fastening a membrane roof in this way, it is necessary to adhere to the following instructions:

1. With a small slope of the roof, it is recommended to use the ballast technology for fastening roofing material. First of all, the product is laid on the roof, after which the membrane is leveled and attached to the surface. The sheets of the material must be fixed with the assistance of glue or special welding technology around the entire perimeter of the roof.

2. On top of the membrane layer, you need to put ballast. The optimal material for this is river pebbles, which has fractions from 25 to 40 millimeters. Experts advise using gravel and gravel. The approximate mass of ballast is determined by 50 kg per square meter.

3. If non -rounded materials were bought for the coating, then in order to avoid surface damage, it is necessary to use mats or a special canvas. The density of the material should be 50 grams per 1 square. meter.

Mechanical fastening of a membrane roof:

Additional details for the installation of the membrane are the holder, rail and telescopic fasteners. At first, it is necessary to calculate the load of all parts of the roof, which are important for fixing the membrane coating. Mechanical fastening of the roof is important when waterproofing for PVC membranes cannot be fixed with glue.

As a basis for fixing elements, wood, corrugated board, reinforced concrete and the like can be used. For reliable fastening of parts, it is necessary to choose the edge rails that are mounted around the entire perimeter of the roof. The main device in the work is telescopic fasteners, which is an umbrella made of plastic. They should have a wide hat and metal anchor, which is quite possible to replace with disk holders. The last detail is advised to use if the roof slope angle has an indicator 100.

Features of mechanical fastening are the placement of a membrane in the way of overlap. The approximate step of fixing the fasteners should be 20 cm. With a slope of the roof, more than 2-40, it is necessary to equip an additional mounting strip.

It's important to know! With the mechanical installation of a membrane roof, especially to the plane of the roof, it is necessary to attach another layer of geotextile material. This will avoid violation of the integrity of the surface of the product.

Method of installation using glue for PVC membrane:

The technology of gluing a membrane is used very rarely, since this method is uneconomical. This option of attaching the roof is unreliable and does not have a sufficient level of strength of fixation of the product on the surface. Most often, glue is used only in those options where other methods of fixing membranes are impossible.

As a glue, a mixture, the strength of which should not exceed the strength of the compound of the layers of the membrane coating, can be used. Experts do not advise applying glue over the entire area of \u200b\u200bthe roof. It is best to choose a mixture around the perimeter, as well as at the points of fixation of the sheets and in the areas of the adjacency of the membrane to ventilation or chimney.

PVC welding technology:

Most membrane coatings are attached to the surface by thermal welding. To do this, it is necessary to use a special apparatus, which creates an air flow with a temperature of 450-600 degrees. The approximate width of welding seams should be from 2 to 10 cm.

The technology of fastening the seams in the same way will create the tightness of the roofing. At the same time, all places of joints fastened with welding are not amenable to the effects of ultraviolet rays, which differ from the bonding option. In the modern world, welding methods allow you to form a reliable and strong coating, however, it is almost impossible to do such work yourself.

All technologies and options for fastening the membrane coating presented in this article can be applied, both for huge buildings and for ordinary houses. If you correctly approach the choice of roofing material and use a reliable technology for fixing the product, then you can make a strong coating that will have a long service life.