Due to the fact that the idea to transform the loggia into an additional dwelling is early ...

|

|

Protection of residential and industrial premises from insects, dust and poplar fluff ... |

The development of technology annually replenish the construction market with new materials with special ... |

Calibrated timber: Features of the material

Until the 19th century, residential buildings and household blocks were built without the use of nails, using dozens of fasteners and joints of logs. Of course, modern technologies do not stand still. Today you can build a country house or dwelling for permanent residence in a short time and small money using a calibrated timber. The article will talk about the varieties of a calibrated timber and the rules for working with it.

Content:

- Calibrated beam

- Calibrated

- Types of timber

- Production of a calibrated beam

- Properties and characteristics of a calibrated timber

- How to choose a calibrated beam

- Small but important nuances

- Forest processing

- Calculation of the number of timber at home

- Construction of a house from a calibrated timber

- We build from a calibrated profiled timber

- Ready -made houses from a calibrated timber

- Calibrated timber storage rules

Calibrated beam

- The exact dimensions allow you to build walls without preliminary fit. The absence of such additional works saves time, accordingly, financial costs are reduced. A dwelling built from a calibrated timber is reliable, practical.

- Siberian pine is the best operational properties. As a rule, the forest falls only in winter. In this case, it is important to know, the closer the power plant is located to the north, the better the products manufactured.

- For these purposes, a beam of natural humidity is selected, in rare cases, a forest that has passed forced drying can be used. But such processing significantly increases the price of the product.

- Special difficulties in building a house will not arise. As a base, its strip variety will be enough. At the end of the work, the structure must be given time for shrinkage, but not less than 1 year. Then hemp is carried out, grinding, processing impregnations and wiring communications.

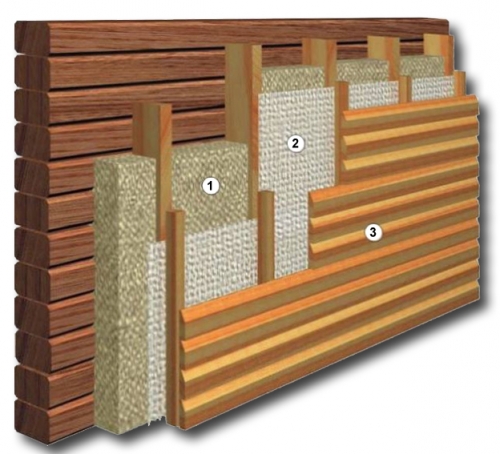

- Outside, the sheathing is made by siding or a chase product, with any option, a heater (mineral wool plates) should be used. Indoor work is carried out in the usual way: the surfaces are covered with varnish or plasterboard sheets are mounted.

- Experts recommend the lower rows from larch, and higher use pine bars.

Important: when burning, spruce and fir wood scatter sparkles, coals and pieces of resin at a rather decent distance. Therefore, if preference was given to these materials, then during construction with special attention should be taken to comply with all the rules and requirements for fire safety.

Calibrated

From ancient times in Russia, construction was carried out using wood. The choice of the tree of the tree depended on the purpose of the building, or rather its properties and characteristics.

- So, for example, a pine with a soft structure and a large content of resins, thanks to which it does not crack after drying, was mainly used for the construction of structures in conditions of high humidity.

- They ate dense wood hard to process, but its smell is known for its healing properties. The larch is of particular strength, which even naval water does not care. It is ideal for buildings in coastal areas.

- Among the deciduous wood of wood, the primacy holds oak. It is not subject to rot and damage to fungi. Linden with an excellent coefficient of heat saving in second place. It is rational to use it when erecting a bath.

- But it is better to build a steam room from aspen, because such characteristics as greater mechanical strength and high resistance to decay make this material the most suitable for these purposes.

Types of timber

This type of lumber is obtained from a conventional log by cutting. The course of work can be radial or tangential. Moreover, the final product obtained from a small log, where the central annual rings are located closer to the middle of the base of the beam, is considered the highest quality.

The product obtained by the Tangential method, where the incision of the fire occurs from the edge, is more susceptible to the appearance of cracks, deformation during the academician.

The processing of the tree trunk implies the output of the lumber of the 5-main species:

- raw timber The cheapest, not particularly high quality. The process of obtaining it is simplicity without significant time. The buildings of their material are subject to shrinkage. In addition, raw timber has a rather rough structure, so it needs additional processing, grinding;

- improved parameters are endowed calibrated beam. Its surface is smooth, and the dimensions are precisely verified. Modern technologies make it possible to produce this material of strict sizes, which, in turn, facilitates the construction of houses;

- profiled beam a kind of subspecies of calibrated wood, which has a spike-puzzle connection system;

- another version of this pilot is glued beamwith the properties of wood and the reliability of metal. It is 2-3 glued boards, where one of them is installed with the core out. This method can minimize the risk of cracks;

- a new product is offered in the building materials market glued beam from veneer. Distinctive characteristics, which have become such properties as lightness and greater strength. Unlike its analogue, gluing comes from lamellas. Due to this, the length of the beam may exceed the standard 6 m without losing quality.

Production of a calibrated beam

- The optimal materials for developers are calibrated or profiled bars, which make it possible to implement the most complex projects in a short period of time. Due to the clear geometric dimensions, an excellent socket between the crowns is performed.

- The harvested logs pass through the milling machines, cutting off 4 kanta. The top of the barrel is cut off, since it is inferior in strength to the middle part. At the output, the bars of a given type of size are obtained. The section of the material (140-250 mm) and length (2-6 m) are determined in accordance with technological norms.

- Finished products are checked for deviations. The inconsistency of the angles of the cut and the uneven lines is not allowed here. Also, the bars are inspected for the presence of lesions with a fungus or insects. Defective materials are not allowed to further processing or implementation.

- Next, drying is carried out in special cameras or naturally, but not less than 3 months. After processing the product, the humidity is about 22%, with chamber drainage, this indicator should not exceed 12%.

- The undercurrent drying of the lumber is endowed with the main advantage in the home can be entered almost immediately. Since the deformation and shrinkage is not relevant for such a house, because this indicator will not exceed 2-3 %. For example, a forest of natural humidity gives a shrinkage and shrinkage up to 10%.

- A calibrated timber is a certain workpiece for the production of a profiled product. It can be both simple with two crests, or complex with several grooves and ledges.

- Profile cutting is one of the most important stages of manufacture. The accuracy of geometry is achieved using machine tools with knives made of high -strength alloys of metals. Compliance with all parameters provides high -quality assembly of the structure.

- If the production of calibrated profiled bars is carried out for a finished project, then ending and manufacture of cups are performed. Any deviation in size or poor -quality wood will cause marriage in the construction of walls.

- The operational characteristics of the beam are determined depending on the forest used, complexity and duration of work. The cost of the finished product is determined by the same parameters.

Properties and characteristics of a calibrated timber

- As a result of production processing, high -quality lumber is produced, completely ready for installation. The woodworking technique produces forest cutting, prepares, if necessary, all the docking openings and joints. Thus, the beam is completely ready for styling.

- Thanks to the attractive (natural) appearance of the product, buildings often do not need additional decoration, both outside and inside.

- In addition, a calibrated beam with a prepared profile is arranged so that rainwater does not penetrate through the cracks, in this regard, the house is also provided from decay.

- The distinctive property of this building material, of course, is environmental cleanliness. It has resistance to humidity and is able to withstand significant temperature fluctuations.

- The low degree of thermal conductivity allows the house from a calibrated beam to hold and distribute heat in the winter, and in the summer to maintain coolness in the interior.

- The small weight of the structure allows you to save temporary and financial costs for filling the base. Here you can do with a columnar or pile foundation. However, for greater reliability, it is better to equip a strip base.

- The house from a calibrated beam guarantees the owner the presence of natural microvntilation. If the use of the house is supposed only in the warm period of time, then there is no need for additional insulation.

- The finished product allows you to carry out construction in a minimum short time. Based on the area and complexity of the structure, this process can take from several weeks to a couple of months.

- The thickness of the beam in 190 mm corresponds to 800 mm masonry made of brick and is equal to a log with a diameter of 320 mm.

Flaws

- poorly tolerates humidity;

- requires processing by bio -protective agents;

- for operation in the winter season, insulation is necessary;

- it is impossible to make a superstructure or redevelopment after the completion of construction.

How to choose a calibrated beam

The bar is ordinary or profiled, passed through the calibration machine has the exact dimensions and a relatively smooth surface. But do not forget about his living origin. It can be deformed due to violation of production technology, improper storage and other reasons.

When choosing trifles, it does not happen, carefully inspecting the products, you can save time, money and nerves. Therefore, before buying a calibrated beam, it is important to know about some nuances.

- Low cost must be afraid, but the high price of a calibrated timber, unfortunately, is also not an indicator of quality.

- In accordance with GOST, the moisture content of the wooden parts of the premises operated outside should be 15%. In some cases, this parameter may be 20%.

- It depends on the position of wood veins how the beam is deformed after drying. The more even they are, the better.

- Inspect the product for curvature. An evenness is the key to the quality of the structure.

- Ideally, annual rings should be located in the middle of the end part of the beam. And the denser they are, the better.

- The quality of the cut is an important indicator. The dimensions should be withstood along the entire length.

- The layers should have a minimum number of cracks. Deep cracks will lead to decay.

- Light blue first sign of the beginning of decay. The wormholes leading inside speak of the presence of bugs, such lumber should not be used.

- For a house with an area of \u200b\u200babout 100 m, built for seasonal residence, a beam with a width of up to 150 mm is suitable. The construction of cottages is recommended by lumber, the width of which is at least 190 mm.

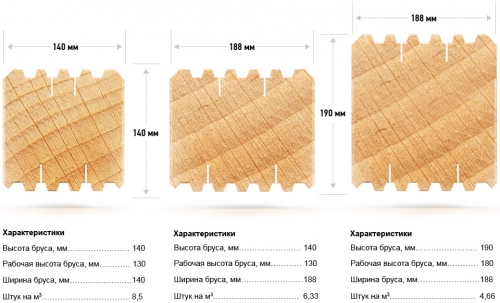

- Remember, the profiled beam has a working height. So, for example, if its height is 145 mm, then the working one will be 130 mm, at 195 mm 175 mm.

- The length of such products does not exceed 6 m.

- Of course, it is not always possible to conduct a visual inspection, but if the seller refuses this request, then this is an occasion to think about the quality of the goods.

Small but important nuances

Calibrated beam

- The use of a conventional timber during construction involves 2 stages. First, a box is being built, which is exhibited for at least 1 year. After that, communications are carried out, finishing is performed.

- This material is a segment of rectangular wood that does not have special recesses, grooves that would guarantee a tight connection of the crowns. Therefore, when dried, a sharp difference in temperature or high humidity when changing the season, it can be distorted. At the same time, no wax or nail will be able to keep it in place. In this regard, the whole house will be subjected to deformation, which will undoubtedly lead to the overhabitation of window frames, doorways and so on.

- Another important point is a way of insulation. If you ensure a tight fit of the bars to each other, then the house will be warm accordingly. This is achieved by laying special materials between the crowns.

- Many make a mistake using a linen-cancer verse insulation. The material itself holds heat perfectly, but it is hygroscopic. If it rains and a strong wind rises, water will flow along the walls, which will wet the edge of the insulation. Moisture on it will penetrate between the crowns and remain there for a long period. Since there is no access to sunlight and air flows, therefore, it will not dry soon. Thus, nothing will prevent the mushroom and mold from developing.

- Such consequences can be avoided by warming and skinning the structure outside with siding, lining. It will also be advisable to overlap the house with a brick.

Calibrated profiled beam

- If a calibrated profiled beam is used, then internal work is carried out immediately after the construction of walls, roof, and so on. Such material makes it possible to build a house in the 1st stage.

- There are more than 100 varieties of profile for a calibrated beam. They are united by one presence of a lock, which provides a dense connection of the lower and upper bars. He reliably fixes the crowns, thereby preventing their curvature.

- Often, capture is used as intervention insulation, but it, unfortunately, is not able to restore its shape. It should be explained here why this is so important. The beam is living material, depending on weather conditions, it expands or compresses. For example, under the influence of wet air in the spring-autumn period, the forest expands and presses on the insulation, which is compressed under its mass. In winter and summer, lumber gives shrinkage, respectively is compressed, while the insulation remains flattened. Therefore, there can be no talk of any tight fit or tightness.

- Today, the manufacturer offers lumber of this kind with 4 technological grooves, in which you can lay flax-cancer braids.

Forest processing

Unfortunately, the enemies of wood are a lot of fire, insects, fungi, and so on. The most dangerous of them is a white house mushroom, capable of turning a solid housing into dust in just a few weeks.

In the old days of the house, affected by this mushroom was burned so that neighboring buildings would not become infected. Today it, of course, is a radical measure, because it is enough to treat the bars with antiseptic solutions and no plague will be terrible.

- Home owners, confused in a huge assortment, simplify their task, acquiring a miracle tool 5 in 1. But not a single composition is able to protect the tree immediately from all misfortunes. Therefore, antiseptic should be carried out in stages.

- An ideal option would be to process all elements before the start of construction work. Because in the process, the beam is fragmentarily closed, and it is not possible to cover such areas.

- You can not ignore the cuts, saws, holes, grooves made after processing the entire product. Such places are most vulnerable.

- Prophetic products should be applied only after the beam is practically dried. After that, the result is necessarily fixed with glazing compositions. You can not use film -forming products for wet wood. The film will not allow to evaporate natural moisture, which will lead to deep cracks on the surface of the beam.

Calculation of the number of timber at home

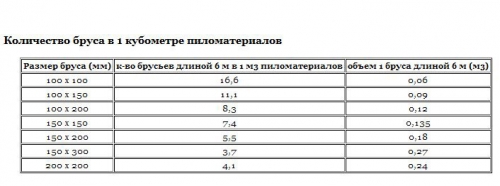

It is not so difficult to compose an approximate estimate for building a house. The initial data will be the cross -section of the beam and the dimensions of the future housing.

- The area of \u200b\u200beach wall is multiplied by the thickness of the bar used. The result is the number of cubes of the material. When calculating, the supporting walls should be taken into account if lumber of this cross -section also needs to be built. The data obtained are summarized, as a result, the general cubic meter of the forest is obtained. The load -bearing partitions are calculated in the same way.

- For example, the calculation of the material for one wall of the house 12x10 m using a beam of 200x200 mm looks like this:

- 12ˣ3ˣ0.2 \u003d 7.2 m

- 10ˣ3ˣ0.2 \u003d 6 m

- (7.2+6) ˣ2 \u003d 26.4 m - the amount of forest required for the construction of walls. Here, at least 20% of the final number of material per reserve is plused here. Remember, the result is approximate, it does not take into account the features of construction, such as the corner joints of the house, the beams of the ceiling and the like.

- You can calculate the quantity in pieces. So, for example, in 1 cubic meter of a calibrated beam with a cross section of 150x150 mm with a length of 6 m 7.4 elements; 150x200 mm 5.5; 200x200 mm 4.

Construction of a house from a calibrated timber

The construction of a building using a beam has the following advantages:

- rapidity. Since the product has accurate dimensions, accordingly labor -intensive work in the preparation of the beam is not required. A team of 4 people can raise the walls of the house 6x6 m in 4-5 days;

- simplicity. It is not necessary to have a special education or considerable experience. It is enough to observe the work once or it is better to participate in the construction process and you can already independently build a box.

Such work can be characterized as technical. The correctness of the marking, cut, saw, and also just just know the basic principles of construction. The more precisely it will be carried out, the better the home will turn out.

A house from a calibrated beam contrary to all opinions of an expensive pleasure, especially if it is intended for permanent residence. The saved products on the purchase of forests will easily go to the purchase of insulation and finishing materials.

Insulation of a house from a calibrated timber photo

1 thermal insulation material; 2-vapor barrier film; 3 facing material.

- A distinctive moment of the construction process is the use of fasteners. Many prefer nails or screws, but this is wrong. Thus, metizes help the forest more to tarash when shrinking, as they violate its integrity.

- Fasteners should be carried out using a naga, which is a wooden pin of a round section. For him, it is necessary to drill holes in the upper and lower beams. The length of wooden fasteners must be divided in half, and then the result is transferred to lumber. But it is always necessary to leave tolerance, for example, if the length of the bumber is 6 cm, then the holes should be 3.5 cm in a depth. The diameter of the drill should coincide with the diameter of this fastener element.

- They should be installed in a row (one over the other) vertically. On a wall of 6 m long, it is enough to install 4 pieces in the corners of the house and a pair of nagids is placed on the plane of the wall. If there is a window opening on the surface, then fasteners are placed around it.

- An important point is the installation of the so -called draft box in the window and doorways during the construction process. They prevent the curvature of the openings with a breeze.

- The angular compound is as follows: in one crown, a groove is selected 50 mm wide and 45 mm with a depth, in another timber, a spike of 50x50 mm is cut. Thus, during their docking, a gap is formed, which is later drunk.

- All rows are laid by jute. Thanks to the high coefficient of elasticity, the fiber reliably protects the wooden structure from heat loss even with severe academic.

We build from a calibrated profiled timber

- There are no special differences in the technology of laying such a product with a profile from a conventional forest. The only thing that the first crown is mounted on the foundation. The calibrated beam is mounted, and then the walls are built with profiled lumber. Corner compounds are cut into the same method as described above.

- The building does not need a hemp, since the crowns are tightly interconnected by means of a lock. But, nevertheless, for better fixation it is recommended to use the umbilia. Flax-foam braids are laid as insulation in the grooves.

Ready -made houses from a calibrated timber

- You can save time significantly through the purchase of a ready -made house. It is possible to purchase a home, both in standard performance and choose the layout, type and cross section of the profile at will.

- The project serves as the basis for creating residential real estate. It is on it that the material is marking. Computerized equipment makes a beam according to the specified parameters.

- The structure comes to the site in the kit, where it only needs to be assembled as a designer. All elements, details have the required recesses, grooves, therefore do not need additional fit or processing. The assembly is performed independently or ordered from specialized firms.

- The basic kit includes external and internal walls, beams, lags, rafters, lumber for the crate, fasteners and so on. Accompanying documents are also applied: certificate, warranty, assembly instructions.

Calibrated timber storage rules

- The acquired forest should not lie on the ground, for this, at a distance of 1.5-2 m from each other, 3 boards or others, for example, defective lumber, are laid. A beam stacked across them.

- In rainy weather, the forest is covered with a film, preventing moisture. But on sunny days, protection is removed, as it contributes to the formation of condensate.

If high -quality lumber has been acquired, construction technology was observed, then such a house will last at least half a century. Without fail, it is necessary to control the condition of the roof, at least 2 times a year clean the gutters, treat the surface annually with antiseptics and antipyrens.

Brill is excellent material, it

A beam is excellent material, it is environmentally friendly, so it is now very popular in construction. Last year I also built a house from a bar, more precisely, I built a company, my wife and I only chose a project from the options provided. Here is http://www.home-projects.ru/proekty_domov/brus/mons/ a nice and spacious house was built to us, we are very satisfied.