A country house cannot be represented without a fireplace or furnace, which means that necessarily ...

|

|

Private housing construction has not been complete for several years without arranging a transparent roof ... |

Consider the main components of this type of substrate and its properties. ... |

How to make a binding of the foundation with reinforcement

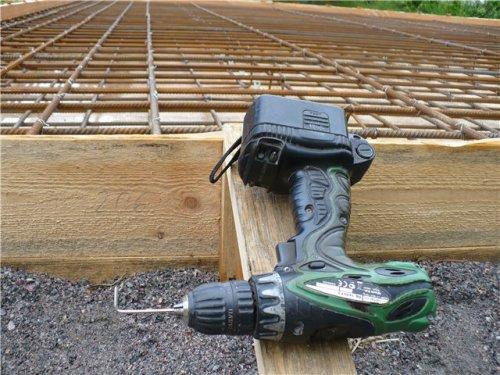

The number and quality of the laid reinforcement factor that directly determines the operational characteristics of the foundation of any type. The binding of the foundation with reinforcement has no less important functional value, since the reinforcing mesh of the proper quality is designed to maintain the spatial characteristics of the foundation in the process of filling it and after it. In 99 % of cases, the developer will have to encounter the reinforcement of the foundation, since it is possible to abandon it only in the case of ideal construction conditions, which, in principle, are not possible, but 1 % must still be left on them. In this regard, regardless of the dimensions of the building, whether it be a bathhouse of compact sizes or a large residential building, welding of reinforcement for these purposes is strictly prohibited, as this can lead to a violation of iron crystal and a decrease in the strength characteristics of the frame. Despite the fact that it is quite difficult to find information about how to make a binding of the foundation with reinforcement with a reinforcement of the foundation with a reinforcement. Given the relevance of this topic and a small amount of material on this issue, in this article we will reveal the technological nuances of binding reinforcing rods and help to make up for the existing gap of knowledge to builders who are not familiar with similar methods.

Content

- Functional purpose of the reinforcing frame

- Varieties of reinforcing frames depending on the type of foundation

- Basic rules for strapping the foundation with reinforcement

- Materials for strapping the foundation with reinforcement: what to prefer?

- The most popular methods of strapping reinforcement: step -by -step guide

- Frame welding: nuances that everyone should know

Functional purpose of the reinforcing frame

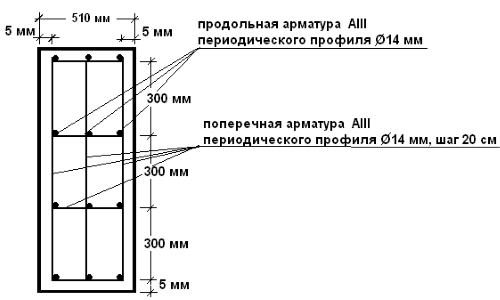

Despite the fact that the reinforcing frame for the foundation performing the supporting function is comparable to the human skeleton, its purpose is not limited to this. The metal elements of the foundation represented by reinforcing bars take on deformations and stretching loads, while concrete used in the construction of the foundation is able to resist only compression. For the manufacture of reinforcing binding, you will need reinforcing rods of various diameters, characterized by a ribbed or smooth surface. The rods with a smooth surface in most cases are characterized by a diameter of 6-8 cm and perform the function of elements designed to form the spatial structure of the frame. They can be laid vertically or across the main rods. The entire load that falls on the foundation is laid on the ribbed rods, and, depending on the qualitative characteristics of the soil, their diameter can increase from 12 to 16 mm or more. The ribbed surface of the rods, which are laid horizontally, provides the maximum degree of adhesion to concrete. Their main purpose lies in the perception of uneven deformation changes. Given the fact that the surface of the foundation is the place of occurrence of stretching zones, the most significant elements of the frame structure are located in the immediate vicinity of it (30-50 mm). Thanks to this approach, the effect of double protection is triggered: a protective layer of concrete is formed that prevents the corrosion of metal elements, as well as the most optimal conditions for the installation of the reinforcing frame.

Varieties of reinforcing frames depending on the type of foundation

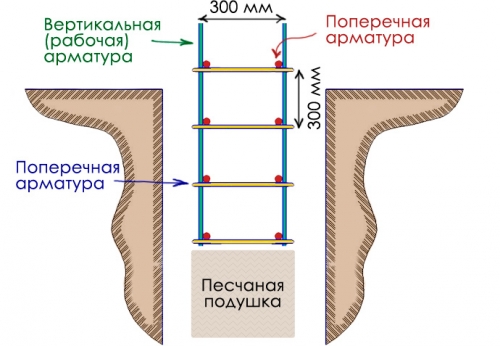

Despite the fact that the function of the reinforcing frame is one regardless of the type of reinforced concrete base, its design features are variable for the foundations of various types. The strip monolithic foundation necessitates the installation of a reinforcing frame consisting of two belts interconn by the transverse reinforcement, the plate foundation should be reinforced with a reinforcing mesh, and vertically installed reinforcing rods connected by a special wire are used to strengthen the pile brownish foundation.

Binding foundation with reinforcement photo

Basic rules for strapping the foundation with reinforcement

- Firstly, it is important to pay attention to the fact that welding is an unacceptable method of connecting reinforcement. This is due to the fact that the contact of the metal with the electrode helps to reduce the strength of the material, which, becoming fragile, is not able to withstand minimal loads that occur with a slight shrinkage of the foundation. This is the first reason for the appearance of cracks on a concrete base. To avoid this, experts recommend using the reinforcement of the reinforcement with wire.

Important! There are special varieties of reinforcement, for which, according to GOST, welding is the most acceptable way of fastening. The reinforcement of other varieties after welding will lose the calculated rigidity.

- Secondly, it is forbidden to install vertically oriented reinforcing rods, the function of which is to maintain the main fastening threads, directly into the ground. In the competence of experts, the lower horizontal series should be installed on plastic cup holders, while vertical rods must be screwed to the upper row, which is bent into clamps. Thanks to the reliable protection of the reinforcing frame with concrete, it does not contact the external environment, preserving its initial performance.

- Thirdly, it is important to ensure the strapping of the upper horizontal series from the inside, despite the certain complexity of this manipulation. Neglecting the fixation of the upper row, you make an irreparable mistake. If in the case of manual filling this error can be considered insignificant, however, if you use concrete pump in the process of filling, under the influence of pressure, reinforcing rods strive for extension, and the wire, not blessed into the clamps, is not able to hold them.

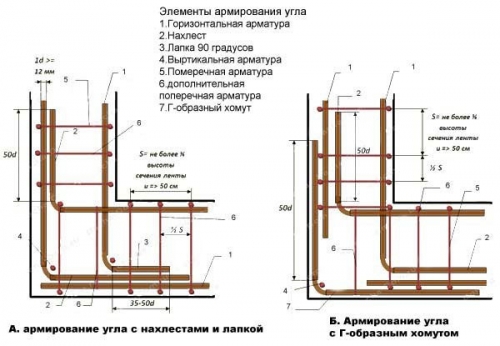

- Due to the fact that the corners, regardless of the design and the type of foundation, are most susceptible to mechanical loads, the basement of the foundation with reinforcement in these places must be carried out with special care, which will reduce their vulnerability. Some masters make an irreparable error, leaving segments of reinforcement abandoned at right angles. Ideally, all reinforcing rods should be bent, and as for the overlap of threads, it is recommended to hide it into the wall. At the same time, the threads located nearby should not carry out overlap in only one place.

Important! If you have binded the foundation with reinforcement in accordance with all the rules, the result of your work should be a rigid spatial frame that is able to withstand human weight. In order for the frame to realize all the tasks set before it, reinforcing rods should be used for its installation, the diameter and quantity of which is selected in accordance with preliminary calculations that take into account not only the weight of the structure and geological characteristics of the subject, but also possible loads that increase due to the occurrence deformation changes.

Materials for strapping the foundation with reinforcement: what to prefer?

In the process of preparing for the binding of the foundation, the question often arises: what to prefer? Knitting wire or modern plastic clamps?

Steel wire: Features of the material

For the manufacture of knitting wire, designed to strapping the foundation with reinforcement, an flowed low -carbon steel is used, characterized by softness and ease of use. The color scheme of the wire is different: from white galvanized to black, devoid of any coating. It is important to remember that, according to many masters, the use of galvanized wire to strapping the foundation will be excessive, since there is no oxygen access in concrete, and there can be no talk of any corrosion.

Important! If, after purchasing a knitting wire, you were surprised to note that it is poorly bending, do not rush to return it back. The misunderstanding that has arisen can be easily fixed if you warm it on the stake for half an hour, and then cool in the air.

As for the most suitable wire diameter, then, according to experts, it should be 1.2 to 1.4 mm. The use of knitting wire with a diameter of 2 mm requires large physical costs, and a wire with a diameter of 1 mm is considered extremely unreliable.

Plastic clamps: advantages and disadvantages

The strapping points of the reinforcement of the reinforcing frame can also be carried out using plastic clamps, firsthand familiar computer craftsmen and collectors of communication networks. Initially, they were used to fix the wires inside the case or switching cabinet. Despite the fact that they are gradually entering the builder’s use as a material for strapping the foundation with reinforcement, some masters still doubt their strength and reliability. However, the advantages of plastic clamps are obvious:

- A higher speed of the strapping and its simplicity;

- A democratic, albeit higher, compared to knitting wire, the cost of the material.

To date, there are plastic clamps of several varieties. The most popular as the materials used to bind the foundation with reinforcement (their price slightly higher) are plastic clamps, which are characterized by the presence of a heart from steel wire. They are more convenient to work and can be used in the process of installing perimeter protection systems.

Important! If, in the process of strapping the foundation with reinforcement, you use plastic clamps, after filling the structure, it must be left alone until the concrete is completely hardened.

Important! Thanks to the features of the material from which the plastic screed (clamps) is made, this material provides sufficient rigidity and fixation of the frame. Despite the fact that its cost is slightly higher, it is not subject to corrosion, which determines its longer operational period.

Foundation strapping with reinforcement scheme

The most popular methods of strapping reinforcement: step -by -step guide

In order to bind the reinforcement of the foundation frame, you will need specialized tools, which you can make with your own hands. To make an elementary hook to knit reinforcement, you will need a wire with a diameter of 3-4 mm. It can be a wire from an electrode or electric arc welding. Despite the fact that using this hook, you are unlikely to be able to bind the foundation with reinforcement quickly, but it is quite suitable for work. Some masters use the following cunning: they make a nozzle for a screwdriver from a nail, giving it a hook in a hook on a hanger for clothes, and use it to strapping the fittings of the foundation, the drawing for which will be presented below. Using this device, you can work twice as soon as possible, and your hands will get tired less.

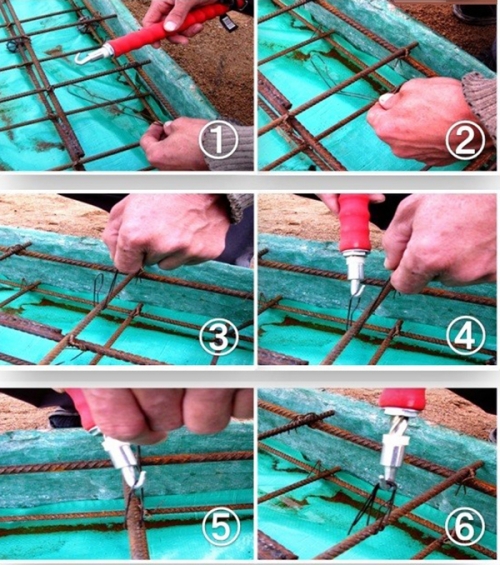

In order to quickly and efficiently carry out a binding of the foundation with reinforcement, it is enough to understand the technology of strapping, the essence of which is quite simple. First of all, it is necessary to perpendicularly place two rows of wire and use a home -made machine designed to squeeze the reinforcement using the boards. Next, the reinforcement is carried out. To do this, you can use a gun to knit reinforcement or conduct these manipulations manually. At the same time, it is important to ensure that there is no lowering rods to the bottom of the foundation. To prevent this, just put a brick or stick a grid directly into the ground. Subsequent measures for the binding of the foundation with reinforcement imply differences in how to bend the wire. Each master himself already chooses the most convenient way for him. Let us briefly consider the most common of them.

Option No. 1: step -by -step instructions

We will try to answer the question as briefly as possible: how to knit a wire with your own hands?

- Take the wire in your hands and fold it in half;

- Next, bend it around the finger by no more than one third from the loop;

- Put it on the reinforcement and insert the hook in the loop;

- Next, make the hook turns in such a way as to grab the end of the wire. The other end, while it is necessary to pull on yourself;

- Remove the hook and bend the ends. If they turned out to be long, they must be cut off.

- You can determine the number of revolutions for a high -quality binding of the foundation with reinforcement in practice. If they are not enough, the strapping will seem weak, and if you overdo it with the number of revolutions, the wire may break. In most cases, from three to five revolutions will be enough.

Option No. 2: step -by -step instructions

- The first step is similar to this for the first method and involves folding wire in half;

- Then it is pressed with their fingers to the reinforcing rod, and the ends are bent on themselves;

- After that, insert a hook, turn it, after which they bend the ends of the wire and take out the hook.

- This method involves a more reliable wire mount.

Important! The most common mistake that masters make in the process of knitting reinforcement are excessively long twisting. To prevent this, bending the wire must be carried out before the direct rotation of the hook. This must be done in such a way that it manages to do no more than 3-4 revolutions.

Option No. 3: step -by -step instructions

- Just as in the previous two versions, the wire is folded in half;

- Bring it from below and hook the loop;

- The tail left from the wire is bend through the hook;

- The loop that was formed in the process of this manipulation is twisted.

Method No. 4, who received the greatest recognition

- The hook must be inserted into a loop and captured the end that is in your hands;

- At the same time, the wire must be bent down, through the hook;

- Next, the hook is pulled on themselves and, making turns, twist the wire.

Important!An undoubted advantage of this method is that the left hand remains free and it can be used to hold the reinforcement.

Important! The foundation of the foundation with reinforcement can be carried out not only by hand, but also with the help of a special pistol. Their design is arranged in such a way that they are able to tighten the wire for a second and with a certain tension force. This avoids excessively weak knitting or wire rupture.

Frame welding: nuances that everyone should know

If you carry out the installation of the foundation designed to arrange a heavy, multi -storey building, experts recommend preference to welding the frame, which is carried out in exceptional cases. In order to assemble the reinforcing lattice for that base, quite large -sized reinforcing bars are used, the diameter of which is 12 mm or more.

The assembly of such a frame is as follows:

- On the bottom of the dug pits, it is necessary to lay reinforcing bars, observing a given step between them. The first transverse rod is mounted on top of the stacked rods;

- Using the welding apparatus of arc welding, the longitudinally laid rods and the first transversely located element are connected with point grades;

- Similarly, it is necessary to combine the last transverse rod with the longitudinal elements of the lower frame;

- After you have fixed the longitudinal elements, transverse rods with a given step are laid on them, grabbing them with point sutures;

- After the installation of the lower lattice has been installed, similarly to this method, assemble the upper reinforcing frame;

- After that, using calibrating inserts, the role of which is performed by wooden bars, the upper and lower lattices are separated. After that, starting from the corners, in opposite nodal elements it is necessary to weld pins called spacers.

- After you have finished with spacers, it is necessary to remove wooden calibrating elements and cover the boiled nodes with an anti -corrosion composition. After you have implemented all the described measures, the mounted frame is considered completely ready for use.

- Of course, the described method of knitting reinforcement is the most time -consuming, however, the use of this technique guarantees that the reinforcing cage made in this way provides the foundation of the greatest bearing capacity.

Binding foundation with reinforcement video