Polistyle foam is quite interesting material. The method of receipt was ...

|

|

From the sport of centuries, people equipped their house so that it was comfortable and warm ... |

Topping the goal of creating an unusual interior, using time tested by time and ... |

DIY waterproofing waterproofing

The foundation is the basis of the house. The durability of the entire structure as a whole depends on its strength and safety. The foundation affects rain, soil and capillary waters, as a result of which it sags and deforms. Concrete has the ability to gain moisture well, which, climbing up the capillaries, penetrates the walls and floor, providing ideal conditions for the occurrence of mold and other mushrooms. The problem associated with the operation of concrete foundations in the continental climate is also important, where water is freezing and thawing annually. Water that freezes and thaws inside, which has penetrated into the pores, leads to the destruction of the integrity of the foundation. To protect your structure from the destructive effects of water, timely waterproofing of the foundation is required. The waterproofing measures performed at the construction stage will ensure the safety of the house. If you are still tormented by doubts, to do it or not, keep in mind that in the future the repair of the foundation will cost more than the construction of the box at home, and you should not talk about the complexity and complexity of the work.

Content:

- The technology of waterproofing the foundation

- Horizontal waterproofing of the foundation

- Vertical waterproofing of the foundation

The main supporting element of the house requires extremely close attention at all stages of the structure, starting from calculations and installation and ending with the work on hydro- and thermal insulation. To say that the waterproofing of the foundation with your own hands is a simple matter is to listen. The technology itself requires certain knowledge and understanding of the processes occurring in the ground and in concrete, as well as in certain waterproofing materials. Experience is also of no small importance, therefore, before making the waterproofing of the foundation, it will not hurt to consult with a specialist and take into account his recommendations.

The technology of waterproofing the foundation

The first thing to do is to decide on a set of waterproofing measures. To do this, take into account a number of starting conditions:

- The level of groundwater;

- The force of swelling of the soil in the postparty period;

- Heterogeneity of the soil;

- The operating conditions of the building.

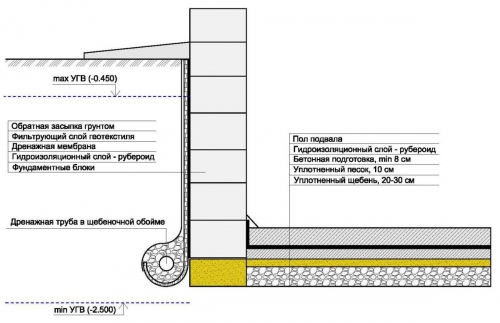

If the maximum level of groundwater is below the base of the foundation by more than 1 m, then it will be enough to perform coating vertical waterproofing and horizontal using roofing material.

If the groundwater level is higher than 1 m from the base of the foundation, but does not reach the basement level or is extremely rare, then a complex of measures will have to be expanded for high -quality waterproofing. Perform horizontal waterproofing in two layers with a mistake between them with mastic. For vertical insulation, both the coating method and the glimmer of rolled materials should be used. Depending on the budget, which is planned for materials for waterproofing the foundation, you can additionally process all the concrete elements of the foundation and the basement with penetrating waterproofing that stops the advance of water through the capillaries.

If the level of groundwater is above the base of the foundation and the level of the basement floor, or the area in which the house is built is famous for frequent and abundant precipitation, which long and difficult to seep in the ground, then in addition to the previous list of events, it is necessary to equip the drainage system around the entire house.

The price will depend on the waterproofing of the foundation on the surface area that must be processed, on a complex of measures, type and number of waterproofing materials. In the easiest case, you will have to spend money only on bitumen. And in the most difficult simultaneous for coating, rolled, penetrating waterproofing and on work on the arrangement of drainage or a clamping wall.

Horizontal waterproofing of the foundation

For tape and monolithic (continuous) foundation, horizontal waterproofing is carried out in two places:

- At a level or lower by 15,100 cm levels of the basement floor;

- In the basement and at the place of connection of the foundation with the wall.

Important! Horizontal waterproofing can only be performed at the stage of building a house, so take care of it on time.

Before starting all work on arranging the foundation and basement, it is necessary to fill the fat clay with a layer of 20 30 cm to the bottom of the pit, and then carefully compact. The concrete is poured with a layer of 5 7 cm on top. It is necessary in order to equip the waterproofing for the foundation. Before laying waterproofing, concrete should dry and well settled for at least 10 15 days. Further, concrete is carefully coated with bitumen mastic throughout the area, and the first layer of roofing material is laid on it. Then the surface is again coated with mastic and another layer of roofing material is laid. A 5 7 cm layer of concrete is poured on top, which must be leveled and lighted.

Important! Ironing also refers to measures that provide waterproofing. It is done according to this technology: on top of freshly laid concrete, after 2 3 hours, a layer of 1 2 cm is filled with cement, sifted through a thin sieve. Then leveled. After some time, cement should get wet from moisture contained in concrete. Further, they come with the surface in the same way as with an ordinary concrete screed from time to time moisten with water until the concrete reaches strength and dries.

After the arrangement of the strip or pile foundation is completed, it is also necessary to waterproof so that the moisture does not rise up into the walls. To do this, the surface is opened with bitumen mastic, and a roofing material or other molelnone material is laid on top. The procedure is performed twice to get two layers. The edges of the roller material hanging from the foundation are not cut, but starting down and then pressed with vertical waterproofing.

The device of the drainage system

Depending on the level of groundwater and the structure of the soil, the waterproofing device for the foundation may be assumed by the mandatory presence of a drainage system, which will collect and remove excess atmospheric and groundwater into a separate well. Basically, such a need occurs with high groundwater and poor soil permeability.

To arrange a drainage system, it is necessary to dig a trench around the perimeter of the object at a distance of at least 0.7 m from it. The depth depends on the level of the water mirror. The width is 30 40 cm. Trenches should be located with a light slope towards the collecting well or pit. We put geotextiles to the bottom, wrapping the edges on the sides of the trench by 80 90 cm. We pour gravel or crushed stone with a layer of 5 cm along the entire length of the trench. Then we lay perforated drainage pipes with a slope of 0.5 cm for each m. We fall asleep with a gravel layer of 20 30 cm, after washing it, so as not to clog the pipes. Then we wrap everything in the remaining edges of geotextiles. We take the pipes to the collecting well. We fall asleep with soil.

The drainage system can be performed after completing the construction of the house or even after some time during operation, if such a need is revealed.

Vertical waterproofing of the foundation

To perform waterproofing the vertical surface of the foundation, various materials can be used, combining them with each other. Of the options below, you can use one or more at once, depending on individual construction conditions.

Bitumen waterproofing of the foundation

The cheapest to this day is the option of coating waterproofing the foundation using bitumen resin. To do this, we get bitumen, most often it is sold in bars.

In a large container (pan, bucket, vat), we pour 30 % of the waste oil and 70 % bitumen. The container must be heated, for this we dilute the bonfire or put on a gas stove. When the bitumen is heated to the state of the liquid mixture, you can start applying it to the surface, which must be previously leveled.

We apply bitumen on the surface of the foundation with a roller or brush, trying to smear everything thoroughly. We begin to smear from the very sole of the foundation and end at 15,100 cm above the surface of the soil. Apply 2 3 layers of bitumen so that the total thickness is 3 5 cm.

Important! All this time, the battleship with bitumen should be hot so that it does not freeze.

Bitumen penetrates and fills all the pores of concrete, preventing moisture from entering it. It will last 5 years for relatively long. Then he will begin to collapse and crack, passing water into concrete.

To extend the service life of coating waterproofing, you can use bitumen-polymer mastics, they are deprived of the disadvantages of pure bitumen and more durable. The market can offer mastics of both hot and cold application, as well as polymer solutions with a rigid or liquid consistency. Methods of applying such materials can be different: using a roller, spatula, grater or spray.

Enough waterproofing of the foundation with roll materials

You can use roller waterproofing materials both separately and in addition to the coating method.

The most common and relatively cheap material for glow isolation is roofing material. Before fixing it on the surface of the foundation, it must be treated with a bitumen primer or mastic, as in the previous method.

Then we heat the roof roofs with a gas burner and apply to the vertical surface of the foundation with an overlap of 15 20 cm. This method is called survey. But it is also possible to fix the roofing material using special adhesive mastics. We again cover with bitumen mastic on top and glue another layer of roofing material.

Important! Before sailing, it is necessary to wrap the edges of the horizontal waterproofing down and press the edges of the horizontal waterproofing, giving the roll material on top.

Instead of roofing material, you can use more modern roller materials: technonic, glassizol, Rubitex, hydrostecloizol, technoelast or others. Their polymer basis is polyester, which increases elasticity, wear resistance and improves operational characteristics. Despite the higher price compared to roofing material, these materials are recommended to be used for waterproofing the foundation. But they will not be able to provide sufficient strength of the coating without processing with mastic, as they do not penetrate the pores.

Waterproofing of the foundation with liquid rubber

Instead of glow waterproofing, you can use liquid rubber, which has good grip with the base, durable and neo -hazardous. And most importantly, the surface is seamless, which provides better protection. If the waterproofing of the foundation is performed manually, on its own, then one -component liquid rubber, for example, elastopase or elastomix, is suitable.

The consumption of material per 1 m2 is 3 3.5 kg.

Elastopase It is applied in layers, in two layers, it will take at least 24 hours at a temperature of +20 C. Sold in buckets of 18 kg, cheaper than elastomyx. If the bucket is not fully spent, it can be tightly tightly closed and used later.

Elastomix It is applied in one layer, it will take no more than 2 hours at a temperature of +15 C. Buckets of 10 kg, more expensive than elastopase, will be required. If a bucket with elastomyx is not fully used, the mixture is not subject to storage, since the adsorbent activator, which is added to the mixture before use, will force the contents of the bucket to turn into rubber for 2 hours.

Which of the materials to choose depends on the preferences of the owner and the temporary framework for execution. Before applying liquid rubber, the surface must be exhausted and treated with a primer. An hour later, apply liquid rubber with a roller, spatula or brush according to the instructions on the package.

The surface treated with liquid rubber may require protection against external influences if the soil of the backfill contains stones or residues of construction waste. In this case, the foundation must be covered with geotextiles or equipped with a clamping wall.

Penetrating waterproofing of the foundation

Penetrating waterproofing is called materials whose substances can penetrate into the concrete structure by 100,200 mm and crystallize inside. Hydrophobic crystals prevent water from entering the structure of concrete and lifting it along the capillaries. Concrete corrosion is also prevented and its frost resistance increases.

Materials such as Penetron, Aquatron-6 and Gidrotx relate to penetrating anti-capillary waterproofing, differ in the depth of penetration and the application method. Most often, such materials process internal concrete surfaces of the foundation, basement or basement.

It is best to apply penetrating waterproofing to wet concrete. To do this, first clean the surface from dust, and then carefully moisturize. We apply the material in several layers. After it is absorbed, the outer film can be removed.

Plastering waterproofing of the foundation

To align and simultaneously waterproofing the vertical surface of the foundation, special plaster mixtures with the addition of moisture -resistant components: hydraulic concrete, polymer concrete or asphalt mastics can be used.

Plasting is carried out using the same technology as plaster walls according to lighthouses. So that the cracks do not appear for a long time, it is recommended to apply it hot. After drying, the plaster layer must be protected by performing a clay lock and a reverse filling with clay.

Screen waterproofing of the foundation

In fact, this method is a modern replacement for a clay castle. To protect the foundation from aggressive pressure waters, bentonite mats are used, which are based on clay. By the way, they can be used in addition to other waterproofing methods. Clay mats with dowels are fixed on the processed foundation. They are laid with an overlap of 15 cm. Then, a clamping wall of concrete is equipped nearby, which will serve as an obstacle that does not allow to swell the mats.

During operation, the paper component of mats is destroyed, and clay is pressed into the surface of the foundation, performing a protective function.

Clay castle

The clay castle is also designed not to let pressure water to the foundation. To do this, a trench is digging around it by 0.6 m. A layer of crushed stone falls on the bottom. Then the bottom and wall of the trench is trimmed with fat clay in several layers with breaks for drying. The remaining space is covered with either gravel or clay, and a blind area is equipped on top.

During spring floods, clay will not miss the water to the foundation, and the lower moisture will go through a layer of crushed stone.

The waterproofing of the foundation is responsible. Within the framework of this article, we examined only the most common methods. If you decide to do all the work yourself, remember, the main thing for the success of the case is to choose the right materials and necessary measures. Then the foundation will last a long time and will not require costly repairs.

The drainage of the land is the most important stage of preparation of the territory for construction. The use of drainage pipes significantly accelerates and simplifies the installation of drainage systems. Drainage pipes are necessary to drain water with a high level of groundwater.

I think it is necessary roofing

I think it is necessary to waterproof the roofing ground http://strport.ru/ - http://strport.ru/ - a very good resource

Penetron - money for

Penetron - Money is down!

Expensive, but no vapor barrier. There is always moisture in the ground, even if UC and below the floor. Moisture forms steam, which goes through the penetron into the wall of the foundation and the basement. The result is dampness.

Penetron can be waterproofed by the outer walls from getting wet with rain. At the same time, pairs from the wall will leave, which is useful for the preservation of the wall and microclimate in the house.

Any waterproofing should also be protected from damage when backfilling soil. The easiest way to paste EPS. But do not beat with dowels!

Ruberoid - last century! there is

Ruberoid - last century! There are a lot of new modern and good waterproofing materials for the foundation - Planter drainage membranes, Dorken, icopal coating mastics, and the same techno -nicol (by the way, they have an excellent catalog of all nodes).

Regarding the fastening of polystyrene foam to the foundation - it is necessary to fix the dowels, one glue is not enough.

The author is well done. Briefly and

The author is well done. Briefly and immediately about everything. I did and continue to do waterproofing work only with an element (penetrating waterproofing). Also, for fidelity, I also apply liquid rubber Element. Cheaper than analogues, and the indicators are higher. Since 2008, nothing has flowed yet. Here is their site by the way www.-golo-insulation-element.rf

And I made an element

And I made the foundation an element. Just as a supplement in concrete, I made the advance use. Quickly and inexpensively cost. The material is universal, easy to work, special tools and certain skills are not needed. Well, for the entire life of concrete, not like roofing material or other bitumen materials from the Stone Age

Now there are new ones

Now there are new waterproofing on without bitumen basis. Cat should not be protected from the ground, has a unique water resistance, including the vapor permeable, the name of this polymer waterproofing of the blockade. I tried it myself on different surfaces, I recommend it.

Great article! Big

Great article! Big Saved to the administrator of this blog. The waterproofing of the foundation is a very important stage in the construction of your home, many people are suppurate to the process of waterproofing, which I do not advise to do very much. Thanks again to the author for this information post. In addition, you can read this explanatory article on the topic: waterproofing of the tape foundation with your own hands!

http: //info-stroyka.ru/stroitelstvo/gidroizolyaciya-lentochnogo-fundamen ...

http://www.geozaschita.ru/

http://www.geozaschita.ru/

Moron

Moron

About the waterproofing of the blockade,

About the waterproofing of the blockade, I confirm- good material !!!