The kitchen and bath are special areas of the apartment requiring special care and, ...

|

|

The construction of a strip foundation is a rather complicated process, the correct implementation ... |

The simplest and most affordable way to perform a black coating for premises any ... |

We make arbolite blocks with our own hands. Equipment for the production of arbolite blocks

Arbolite is building blocks based on cement and wood chips. It has good characteristics that are significantly better than that of opilcoton. The article will talk about the areas in which arbolite blocks are used, about their advantages and disadvantages, as well as manufacturing technology.

Content:

- What are arbolite blocks

- Advantages and disadvantages of arbolite blocks

- Types of arbolite blocks

- Arbolite block production technology

- Manufacturers of arbolite blocks

- Arbolite block tool

- Preparation of chips for the manufacture of arbolite blocks

- Solution for arbolite blocks and pouring into forms

- Tips for the manufacture of arbolite blocks

What are arbolite blocks

Concrete is a universal building material. Its properties directly depend on the filler. It is easy to work with it, thanks to a liquid consistency. It is poured into the formwork or special shape and acquires the desired dimensions and design strength. Arbolite is also made of concrete, but due to sawdust in the composition it has a number of differences from the usual compositions.

- At the heart of the arbolite blocks is the wood sliver. To its size and quantity, strict requirements are applied to these two parameters affect the quality of the material and its brand. In addition, there are arbolite production that use cotton stalks, rice straw or bark.

- The astringent component is the brand cement not lower than the M300. Its brand affects the strength of the finished product and, therefore, on its marking.

- To improve the connection of the components of the mixture, special additives that provide quick hardening, etc. are added to it. In most cases, it is liquid glass, chloride salts of potassium or aluminum.

- Initially, the wood sliver and cement are poorly combined to finish the quality and uniform strength of the blocks, it is necessary to properly put production with a clear technological process. During which a long -term and thorough mixing of all components plays an important role.

- The sliver selected for manufacture should undergo hard control. Pine, spruce or beech are best suited. The nature of wood is also important or early or early workpiece. The size of the chip should not exceed 10 mm in width and 25 mm in length. Following these conditions, the material will turn out with high vapor permeability, but durable.

- To achieve the best thermal insulation indicators. The mixture is made of wood chips, astringent (cement with additives) and water in a proportion of 1: 1: 1.5. If you need a more durable block for a wall with a high loading load, then the proportions of the astringent accordingly change

Arbolite blocks video

Advantages and disadvantages of arbolite blocks

The most important thing is high energy -efficient indicators in the construction of the external walls of the house and the low cost of the material. But due to low strength, let's say only for the construction of low-rise buildings.

The advantages of arbolite

- In thermal insulation qualities, it is ahead of ordinary concrete or brick. Its thermal conductivity is only 0.08 W/(m*C).

- It has the best qualities of wood, but unlike it, it is fireproof. Arbolite is difficult to flammable material, which during the fire forms little smoke.

- When the house is heated and the heating system is subsequent, the heat in the room will remain for a long time even at a negative temperature outside.

- In its vapor permeable characteristics, it is second only to wood. Therefore, the room will always be a good microclimate, even with high humidity. That is why this material is chosen for the construction of a sauna or bath.

- Despite the low strength (the construction of buildings from arbolite blocks is not higher than 3 floors is allowed), it is well opposed to stretching loads. What is especially important when seasoning the soil when the house begins to walk. These properties of the material will protect the structure from the appearance of cracks.

- Frost resistance, depending on the brand of the product, can be within the F25 F50, but if humidity and negative temperature alternate in winter, the shelf life of the arbolite is significantly reduced.

- This inexpensive material is easy to adjust to the desired dimensions, fixed objects are sufficiently firmly kept in it. It will be the best option for small outbuildings or garages.

- The small weight of the blocks allows you to save on the foundation, since the latter will not be highly loaded.

The disadvantages of the arbolite

- Low strength puts the use of arbolite blocks in narrow frames. Only low -rise construction, interior partitions or as additional thermal insulation are allowed.

- The durability of the material depends on its quality. In addition to specializing large factories, today there are a lot of private small companies around the country that make blocks and sell them at lower prices. But, unfortunately, the quality of their products often remains low due to the desire to reduce the cost of the goods as much as possible and make it attractive to the buyer.

- The material made according to GOST has a cost almost equal to foam concrete. This is due to the fact that in its manufacture one cannot do without human labor.

- Due to the errors in the size of the blocks, during masonry, the seams are uneven. And the material itself does not differ in a beautiful appearance, so the finish decorative cladding of the facades of the house is required.

Types of arbolite blocks

In total, 2 main types are produced:

- Structural. It differs the highest density of 500-800 kg/cubic meter. It is proportional to the content of cement in relation to the chip. In terms of characteristics, it is suitable for laying load -bearing walls and supports. For greater strength, its reinforcement is allowed with rods or nets.

- Thermal insulation. Density in the range of 500 kg/cubic meter. It is intended for the construction of interior partitions for which there is no load and as a thermal insulation layer.

Arbolite can have 2 forms:

- In the form of blocks. This is already ready to use material of certain sizes. But due to the features of the material and its manufacture in sizes, there may be significant errors. Although they are regulated by GOST, in fact, more often inconsistencies exceed these parameters. This must be taken into account even at the design stage and calculation of the required number of materials. The blocks have a large size, so the construction rate is high.

- Monolithic. It is made immediately before use directly on the construction site. After kneading, they immediately use it completely. This method is suitable for creating a thin heat -insulating layer (when the arbolite is poured into a non -removable formwork of foam or foam). After pouring, you will have to stop the work during the setting of the composition. This is at least 7 days.

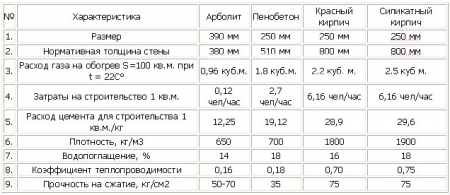

Technical characteristics of arbolite blocks

- Although in the arbolite there is wood on an equal for concrete, yet this class of material refers precisely to the construction stone. Therefore, it is marked and give a class of strength precisely as any other concrete product.

In shape, arbolite blocks can be:

- with a U-shaped recess. Convenient for door or window shoes with jumpers;

- wall blocks can be large, medium or narrow;

- rafts. But they necessarily have a layer of durable and dense concrete, since the characteristics of the arbolite cannot meet the necessary, in this case, requirements. The permissible length in accordance with GOST does not exceed 480 cm.

Arbolite block production technology

The technological process itself is quite simple, therefore, for small buildings, such as a barn or chicken coop, make a monbolytic block mono with your own hands. But due to slow hardening of the composition, manufacturing will take a lot of time, especially if there are few forms for filling. Especially provided that the arbolite will gain the necessary strength only at a temperature of 12 degrees and above. Of course, you can add special chemical components that will make possible work at lower temperatures, but this will lead to a rise in the cost of the material.

Stages of the technological process

- Obtaining wooden chips. For this, woodworking waste is suitable, which are available in large quantities on any sawmill. Almost all varieties of wood are suitable, except for larch and poplar. We must not forget about strict restrictions in the amount that are fundamental to the qualities of the arbolite. Therefore, manufacturers make chips on their own using various crushers (shreder, hammer, disk or rotary-noble).

- Proportions. If professionals use specialized dispensers, then with independent manufacture will have to be guided by weight or volume.

- Connection of the components. First, connect a sliver and cement. It is not possible to do this manually with a shovel, only a long -term kneading in a concrete mixer is allowed.

- Fill the form. The finished mixture on the gutter is supplied to special forms of metal or wood.

- Trombovka. This is a very responsible stage that cannot be missed. Manual labor is used here, since first the mixture must be pierced to remove air bubbles. Next, ramp is carried out in the vibrostol.

Tip: Due to poor adhesion of cement with chips, the ramp should last no more than 20 minutes, otherwise the concrete will begin to separate from the chip and compact at the bottom.

- Hardening. It occurs in ventilated warehouses, where there are no direct sunlight. Forms are removed in a day. Further transportation is possible after 2-3 weeks.

Manufacturers of arbolite blocks

Each city has more than one production of arbolite blocks. But most often they are produced in artisanal conditions and sold through announcements on local resources. If there is no large plant nearby, then it is better to contact the company that are engaged in the construction of arbolite houses. As a rule, they always have their own production at which all technologies are observed.

- The largest enterprise in Russia, engaged in arbolite blocks Ecodrev product. They supply their products to large building materials markets. On average, the cost of structural material is 5500 6000 rubles/m3, and thermal insulation 4500 rubles/m3.

- Lower prices of the manufacturer Arbolite Trade - 5300 rubles/m3 with delivery. They produce not only full -bodied, but also hollow brick.

- Vologda plant of Arbolit Also offers its products in most regions. The price of a structural block is from 4100 rubles/m3.

By buying large volumes directly from the manufacturer, you can always agree on an additional discount.

Arbolite block tool

Special equipment for arbolite blocks is not required, it is enough to prepare standard tools:

- concrete mixer;

- large metal pallet;

- form for filling the arbolite;

- separator. It is needed if it is planned to pour several smaller blocks or make voids in one form;

- a large sieve with vibration;

- vibration or hammer;

- forks, shovel and bucket;

- master OK.

Drawings of arbolite blocks

Preparation of chips for the manufacture of arbolite blocks

This is done in two methods.

Output in the open air

- At first, a large volume of chips or wood chips are acquired on any sawmill. As a rule, it is always given for free, you only need to pay for delivery.

- If there is no such possibility or the material there is of low quality, then with the help of a chopped machine (which can be rented), the material is prepared independently from lumber.

- Before use, the chips are kept in the open air for 2-2.5 months. During this time, the saw was cleaned of the sucrose present in it, which negatively affects the quality of the finished blocks (fermentation may begin). During this time, the chips are slowed several times and treated with calcium oxide, turned over. I wish this so that the air falls into the lower layer. This will prevent the decay of the material.

Limestone processing

- Limestone is mixed with water until a 1.5% solution is obtained. This will require a very large container. A sliver is poured into the resulting solution at the rate of 200 l/1m3 chips. Mix 2 times a day for 4 days.

- Then they sift through a large sieve to separate large garbage and leave to dry.

Solution for arbolite blocks and pouring into forms

- Sample proportions for arbolite blocks look like this: 25-30 kg of cement M400/25-30 kg of chips/1 kg of liquid glass/35-40 l of water.

- For kneading, you need an electric concrete mixer. First, the desired volume of water is poured, liquid glass is added and start to mix for several minutes, for high -quality mixing.

- Then the chips are filled and mixed. She must get wet all so that there are no dry areas.

- Next is the queue of cement. If you fall asleep at once the entire volume, lumps inevitably form. Therefore, it is necessary to fall asleep gradually in a working concrete mixer.

- Without stopping the work of the concrete mixer, all the cement is added until it forms a homogeneous mass with a chip. This is possible only if the wood chips are evenly wet.

- The finished arbolite mixture is laid out in detachable forms or formwork. If there is a vibro -resistant, then the process is very simplified. After filling out the forms, it only remains to wait for the result and remove the finished blocks.

- With the independent manufacture of arbolite blocks by a artisanal method, manual labor is most often used for compaction. To do this, prepare a ramily in the form of a sheet of metal in size with a handle.

- The shape is a box of metal or boards without a bottom. Install it on an absolutely even surface, pour a layer of the mixture and compact. The number of layers depends on the height of the shape. The more there are, the more high -quality and durable the block will turn out. On average, approximately 5 layers are poured. To remove excess air, the mixture after each fill is pierced with a fork or a metal rod.

- For the highest density, you need to trim in such a way that the retrief is smaller. It is best to alternately alternate strong and weaker pressure.

- At the end of the excess of the solution, they are cleaned with a trowel.

- The best strength is achieved by means of vibration. In this case, you do not need to be trampled manually. After pouring the mixture, it is pressed into the mold with a load and vibration is included for 15-20 minutes.

- Next occurs the moment of drying. If the strength of the arbolite solution is high, the shape is allowed to be removed immediately from raw blocks and send them to leisure. But with a more liquid consistency, this cannot be done. Since the block will lose its geometry.

- The technological process involves drying the blocks for 2 days at a temperature of 60C. But at home they are dried simply on the street for 2-3 weeks, previously covered with a film.

Production of arbolite blocks video

Tips for the manufacture of arbolite blocks

- Ready chips can be bought from small manufacturers of arbolite blocks.

- For easier extraction of the block from the shape, its inside is finished with smooth material, for example, by linoleum.

- For a set of strength, the blocks must undergo hydration. The first 10 days they must dry under the film at a temperature of 13-15 C.

- If arbolite blocks are needed only for insulation of load -bearing walls, then the technological process can be slightly simplified.

- You can immediately make finishing blocks. To do this, on a raw block, a layer of putty is applied with a spatula in the form and leveled.