More recently, no one thought about the thermal insulation of the foundation, and that's it ...

|

|

To date, they use very popular in the field of low -rise construction ... |

In the event of a fire, the greatest danger to human life is not a fire ... |

DIY log house

Asking in the question of which house I would like to live in, for some reason the tower is remembered from children's fairy tales. Why not? The wooden house has a beautiful internal climate: in winter it is warm, and in the summer it is cool, always dry, even in a very wet area, a beautiful rich aroma of wood creates not only comfort, but also a beautiful atmosphere for life and creativity. In search of perfect housing, you inevitably come to the realization that no one came up with anything better than log houses. They are beautiful, practical, do not require decoration, perfectly retain heat and absolutely environmentally friendly, if not even healing. The construction of a log house is very responsible and laborious, although our ancestors overwhelmingly erected such houses on their own, everyone knew the technology that was passed down from generation to generation, but today the thread of knowledge has been interrupted. There are very few good architects left, but industrial methods of building wooden houses appeared. Of course, you can choose a turnkey log houses, but in the framework of this article, we will consider options on how to build a log house with your own hands.

- Escalled or strict (chopped) log which is better?

- Log houses: projects, technologies, cost

- How to choose the right wood for a log house

- DIY log house

Escalled or strict (chopped) log which is better?

In total, two types of buildings are called log houses: the first of the chopped log, i.e. Healing manually, he is also called a wild log house, the second of a log galinded on a special machine. Let's figure out which option is better.

Until the beginning of the twentieth century, all log houses were exclusively Wild log house. What does this mean? All the logs were manually processed, the upper layer of the bark was carefully removed from the newly sawed tree, while trying to keep the untouched bast layer, which protects the deeper layers of wood from moisture from the outside. This provided amazing resistance to fungi and mold. Obviously, the cut log is narrowing from the lower end, which is closer to the root, to the upper closest to the top. Even after processing, this difference in diameters remains, the closer to the top, the thinner the log. A fairly tall tree can be cut into 3 logs: the thickest one, whose end is located near the rhizome, is called the Middle Friends, and the upper Tretyak or the top. For construction, it was precisely the comel was used, as the most durable, thick and with a lower change in diameter. To compensate for the difference in thickness, when erecting a log house, the compel and the top always alternated. In one crown, the comel looks in one direction, and in the next in the opposite. The selection of manually chopped logs is not an easy task, because from logs of various diameters it is necessary to create an even strong design.

To this day, the technology for the construction of chopped houses has survived almost unchanged. Everyone also erects houses from a multibillian log, trying to fit them as perfectly as possible. Moreover, such houses are considered elite housing, and their construction services are much more expensive than houses from a beam or even a valued log. This is dictated by the complexity, duration and complexity of work. After the logging of the ruble logs, at least 1 1.5 years should be reached, during which time the wood will be sought out by about 5 7 %. Only after that you can finish the house: insert doors, windows, conduct communications, etc. In general, in addition to tremendous work on the preparation and individual fitting of logs, it will take a lot of time to wait.

Thanks to modern technologies, all the inconvenience using a strict log can be avoided. On special machines in industrial conditions, logs are processed to a perfectly cylindrical shape, also a groove is cut in them for further fastening in crowns. All sizes are verified to a millimeter. This greatly facilitates the work in the construction of a log house, they simply resemble the assembly of the designer according to the instructions and the drawing.

Escalled log Very light and convenient material for construction, but he lost all the advantages of a strict log in production. The fact is that in the process of production, not only the bark is removed from the log, but all the upper layers, including the sapel, only mature and nuclear wood, which is not protected from external factors. Therefore, when used, the logs are treated with special antiseptics and other antifungal and anti -ilenticular impregnations, as well as means that prevent insect damage. As a result, it turns out: convenient, beautiful, very evenly and less durable and environmentally friendly. In addition, the maximum diameter of such a log is less than 300 mm, while the chopped log can be of any diameter.

The price depends on already finished log houses on which log was used: chopped or galindowed. Chopped houses are more expensive. And although many say that they look less aesthetically aesthetic, in fact it is not so: from a manually strict logs you can create a masterpiece by a personal individual order that will not look like any house in the world. At the same time, the walls look primitive and unusual. The house made of a looped log is much easier, especially independently, since the human factor is almost completely excluded.

Log houses: projects, technologies, cost

Any construction begins with the creation of the project, and the construction of a log house is no exception. The project can be taken ready, or you can complete the individual by ordering it in a special bureau. You should not first fill in the foundation, and then think about which the house would like to build, because it will be quite difficult to adjust it to the size of the finished foundation.

The cost of a log house depends on its number of storeys, material and complexity. Houses can have one floor, or two or three can. The walls can be adjacent to each other at almost any angle, since in logs you can cut a bowl of any shape. Those. The wall in the form of a polygon for a log house is quite normal.

To date, log houses are built in two ways: they prepare logs directly on the construction site from the chopped forest or assemble the house according to the drawing from pre -made and fitted at the factory of allocated logs.

In the first case, the forest is always natural humidity, i.e. After the construction of the log house, they will be cone and left for a year and a half for shrinkage, and only then they continue to work. The installation of windows and doors is carried out according to two technologies: the first is to immediately cut the logs to the required length, leaving a place for a window or doorway, the second is based on first to give the wood evenly to dry, give a shrinkage and only then, to the next year, cut openings. The second option is preferable, as it provides the strength and durability of the log house, thanks to uniform shrinkage. But this is a loss of time. And the first option is faster, therefore it is used more often, albeit to the detriment of the log house itself.

Escalled logs are sold both natural humidity and dried in production. The designer always assumes that all logs already have the final length, it remains only to collect it. Companies engaged in the construction of houses from a galled log are extremely rare to build from an unprocessed log, almost always fitting and a complete assembly of the house is performed in production, then the log house is marked, disassembled and transported to the site where it is again assembled.

How much a log house costs, depends not only on the type of log, but also on its diameter, as well as on the accompanying works that the customer asks for. For example, the construction of only a log cabin of a log will cost about 280 350 cu. per 1 m2, from chopped logs in 350 450 cu per 1 m2. If you order the arrangement of the foundation in the construction company, communications, the finish of the house, in general, all-all, then count on 1000 cu per 1 m2.

How to choose the right wood for a log house

Most often, the construction of log houses is made of coniferous wood: pine trees, spruce, larch, cedar, but you can also use aspen, oak, ash and other deciduous ones. Pine and spruce are the most affordable material, so it prevails. It is necessary to purchase logs cut in winter, such wood has ideal indicators of moisture resistance.

If it is possible to choose, it is better to opt for the wood of northern conifers, it is more resistant to negative effects. A good option is pine from the Baltic coast and Canadian spruce. But the wood prepared in the middle lane is also not bad if all storage, drying and transportation conditions are observed.

Important! Pay attention when choosing wood that the forest grown in different climatic zones will have completely different characteristics and density level, despite the same processing conditions.

It is better to buy wood from a proven and reliable renewer. The strength of the whole house depends on this. I made a mistake with wood. The diameter of logs is selected depending on the project of the house and on the severity of winter colds. For example, if the temperature does not drop below -20 C in winter, 200 mm logs are enough, if up to -30 s, then 220 mm logs, and if up to -40 s, then 240 260 mm. Of course, these calculations are purely advisory. You can safely choose logs and larger thickness, up to 500 600 mm in diameter, or use 250 mm logs in a fairly warm climate, the tree compensates for temperature changes.

Having come to the sawmill or a base of wood, pay attention to the following features:

- The surface of the logs should be yellow or dark yellow.

- The cut should be dense and even, without blue spots.

- The core should occupy a cut and have an even dark shade.

- Smolly pockets should be absent.

- It is better if there are no bitch. But even if they are available, they should sit without gaps. If you observe such a picture, then the core is rotten.

- When the ax hit on the end of the log, there must be a ringing sound.

- The maximum depth of the permissible crack in the log should be 1/3 of the cut.

- The logs should not be twisted, in the construction of the house they can be used only for the sex boards and subtratiles, having previously dissolved into the bars.

Feel free to reject logs with the above shortcomings. If you buy a project house from a galinded log, be sure to provide an item that obliges the non -contact log at the expense of the company at the first request of the customer in the contract. Pay attention to what conditions the forest was stored, whether all the requirements were observed, or maybe after a couple of months mold will appear on the logs.

DIY log house

The easiest option for independent construction is a house made of a log. We will consider it further, since the chopped house will still require not only the ability to hold the tool in our hands, but also a decent experience in working with wood.

First of all, we order a project or house for an already finished project in a special company. After we discussed all the issues, the factory is made a full set of logs for our house, as well as beams for ceilings, lags and rafters. The house is collected for the first time there to make sure that all the logs are cut right. Then the house is disassembled.

Our participation begins with the inspection of a set of wood. Then we must prepare a place on the site for development for storage of wood, equipping it with a canopy so that the tree does not blow in the rain.

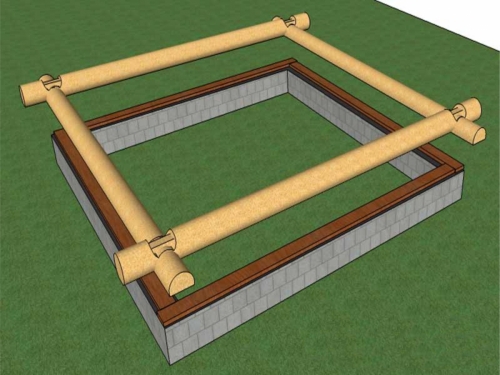

Foundation for a log house

Before you build a log house, it is necessary to equip the foundation on which it will stand. Since the wooden house is relatively light, then the foundation can be made finely packed. Most often, a pile-lental foundation, pile, slab and less often buried strip are used.

Consider the pile-lental foundation.

- Mark the site, then remove the upper fertile layer and put it up for landscape needs.

- On the width of the strip foundation, we make the excavation of the soil to a depth of 30 cm.

- Along the perimeter of the structure with a step of about 2 m, a well of a well with a diameter of up to 180 mm, to the depth of freezing of the soil, i.e. 150 cm.

- We fall asleep into the wells a layer of sand and crushed stone.

- We weld the frame from the reinforcement and lower it into the well.

- Pour the well with concrete, then we will trim it with a vibrator.

- We install a wooden formwork for the strip foundation. Above the level of soil, it should be at least 50 60 cm.

- We weld the frame for the strip foundation and connect it with the armature sticking out of the wells.

- Pour the strip foundation with concrete, compact and wait until it hardens.

After the foundation completely dried, you can proceed to its waterproofing. This is especially important, since our house is wooden. On the foundation we put the roofing material in 3 4 layers and additionally smear with mastic.

Building a log house made of a looped log: Elections of walls

Please note that this is extremely important, the first crown of the mortgage cannot be installed directly on the foundation. Although you can meet such a performance, but know, it threatens that the embedded crown will quickly become unusable.

So, for a start, we put the so -called linden board on the foundation on the foundation. It can be a beam with a thickness of about 50 100 mm, and at least 150 mm wide. Then we begin to collect a log house:

Important! In the lower embedded crown, an end of at least 150 mm should be cut off from below. This is necessary that the house is firmly relied on the plane of the end. If suddenly you notice that the logs of the embedded crown have the same groove as everyone else, contact the manufacturer and require replacement.

- The first two logs of the embedded crown are laid on the opposite walls of the foundation in parallel to each other, on a lining board. Carefully verify their even location.

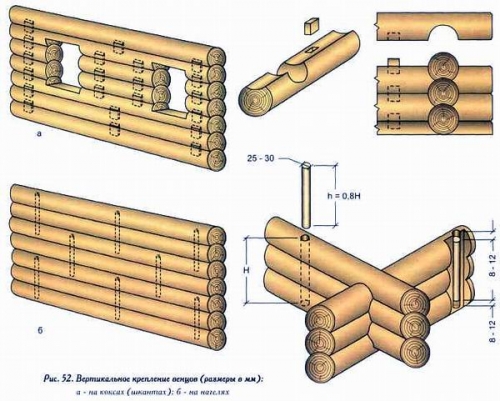

Important! All logs in the kit already have a PAZ for a longitudinal connection and a locking corner connection made at the plant. Most often it is a lunar groove and a connection in the bowl.

- On the logs that we will lay on the remaining two sides, we lay the insulation. We fill the entire groove and seizure of the bowl with material for the hemp. It can be moss, bag, hemp or jute. Most often, a jute or linen strip insulation with a width corresponding to the width of the groove in a log is used for hemp logs for hemp. We spread the insulation so that it hangs at the edges by 5 6 cm on each side. We fasten with the help of a construction stapler.

Important! The recess must be completely filled with insulation. When the jute ribbon is spread, it covers the entire longitudinal groove, but in the bowl it passes only in the middle. Therefore, in the area of \u200b\u200bthe bowl it is necessary to insulate with two segments.

- We install two logs on the transverse sides of the foundation, resting them on the embedded crown. The bowls should neatly connect. We check that there is a necessary angle between the logs, for example, 90. We control their horizontal level. The insulation should hang from the log.

- We install all other crowns according to the same scheme, collecting as a designer.

- For greater strength, some technologies involve the fastening of crowns with each other not only with the help of grooves and bowls, but also of the wades. These are wooden rails made of denser wood. A hole is drilled into the logs to a depth of more than one log and a wax is inserted into the hole.

- The last two crowns are not fixed. This is necessary for the correct shrinkage.

Important! All logs are necessarily treated with antiseptics, otherwise they will rot in the first winter.

Do not forget to constantly check the correctness of styling. The horizontality of logs and strict vertical of the log house are required. In the kit of the house from the galled logs, holes for window and door boxes are provided. Carefully put short logs and carefully fix them.

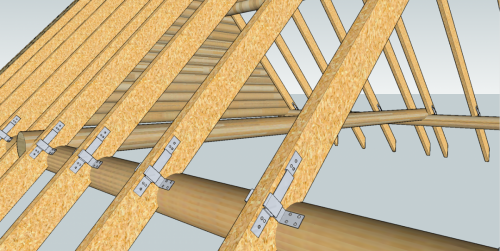

Installation of the roof of a log house

The log walls cannot be left without a roof, so immediately after the construction of the walls, we cover the log house. Rafters and floors are included in the kit. The rafters can be installed immediately on the logs of the upper crown, or you can first lay the Mauerlat (beam for rafters).

If the project provides a veranda, then we insert special in a vertical supporting log compensators of shrinkage, because Horizontally laid logs will dry out and decrease, but vertical no. To prevent the house from distorting, all vertical logs must be equipped with compensators.

We connect the ridge logs using metal studs. We install the rafters with a step of 600 mm. We use a beam of 50x200 mm for this. To the last crown of the rafters we fasten on sliding supports. On top of the rafters we lay the waterproofing film. Then we fasten the crate, the step of which depends on the selected roofing material. Lastly, we lay the roofing material.

The hemp of the log house

After the walls of the log house are ready and mounted, the entire insulation should be sneaked from logs, gently patch up. To do this, with the help of a hemp (tool), we wrap these 5 6 cm of insulation down, pour inside the crack between the crowns. Then we make a pushing movement at the top of the gap and in the middle.

In this state: with the roof and the first time the walls, we leave the house for the first time for a year for shrinkage.

A year later, we repeat the hemp, filling all the newly formed cracks and gaps of Pacley, hemp or jute.

Important! Sometimes it is advised to produce another hemp after the house will be operated with heating with the winter on winter.

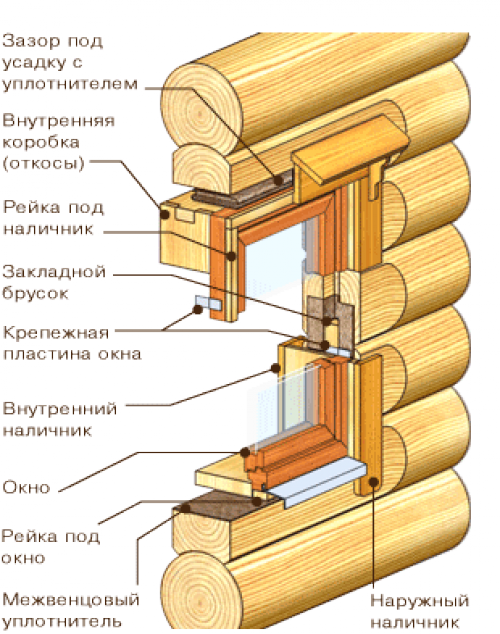

Installation of doors, windows, installation of ceilings and gender

All windows, doors and partitions are installed only after the maximum shrinkage of the log house, i.e. A year after the construction.

Neither doors nor windows are placed directly in the openings. First, wooden casing with compensation mount And they already have windows and doors in them. This precaution is due to the fact that the tree is plastic. It expands from moisture and refers to its deficiency, in addition, the shrinkage of a wooden house lasts 5 6 years. And although the loom is less subject to shrinkage, nevertheless, casing is necessary.

The floor of the first floor is cut into a embedded crown or subsequent. They must be firmly attached. Since the embedded crown should be well ventilated so as not to rot longer, it is recommended to mount the floor on the lags with a crown above.

At this stage, you can already mount the heating system and other communications, install internal doors, slopes, skirting boards, plumbing and perform another finish.

On this, the log house is ready, you can settled. In conclusion, I would like to note that logs of insufficient length can be joined, but it is important to perform a connecting groove, and there should not be many such compounds in one wall. The foundation should be provided for free ventilation of the underground. And do not forget, you can not leave the log house not with a covered roof or at least a film, as well as not treated with an antiseptic. A logs can spoil even in one season.

Important! All logs

"Important! All logs are necessarily treated with antiseptics, otherwise they will rot in the first winter."

Funny statement.

Very informative! Thanks

Very informative! Thank you!!!

To be honest, for me it

To be honest, it's difficult for me. Therefore, I chose the house that I liked in the same construction company - http://www.home-projects.ru/proekty_domov/brus/dovil/ and ordered its construction from specialists.

Hello.

Hello.