To maintain combustion process, as you know, oxygen is required, ...

|

|

By purchasing an interior door, it is impossible not to face the problem of choosing a door ... |

Arriving at the house, the guests immediately fall into the corridor and the first one received at the same time ... |

Aluminum composite panels. Characteristic and choice

Composite aluminum panels are modern building material, which is widely used for faces facing, decoration of premises, to create outdoor advertising structures, as well as in many other areas of life. The peculiarity of the material is that in its structure it is a heterogeneous, layer product consisting of several components. The basis of the material is aluminum panels (aluminum sheet, up to 0.5 mm thick), polymer sheets are located between them, and each panel is covered with special compounds that give additional strength characteristics to the product. The total thickness of such a product varies from 2 to 6 mm. The article will talk about the variety of aluminum composite panels.

Content:

- Characteristics and composition of aluminum composite panels

- Production of aluminum composite panels

- Advantages of aluminum composite panels

- The scope of aluminum panels

- Installation and delivery errors of aluminum composite panels

Characteristics and composition of aluminum composite panels

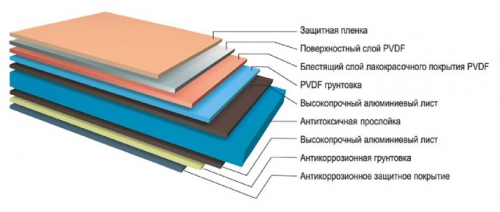

The design of aluminum panels is a multilayer structure, where aluminum sheets are taken as the basis, and polymer or mineral fillers are used as a layer. The most common type of product can be called the product with the following sequence of layers (starting from the lower):

- protective coating with anti -corrosion properties;

- primer, which also gives products to rusting;

- high -strength aluminum sheet (first);

- a layer of non -toxic plastic or other polymer material;

- high -strength aluminum sheet (second);

- a primer based on polyvinylendenfluoride resin (PVDF);

- pVDF -based paintwork;

- film to protect the product.

In addition, Goldstar aluminum composite panels and a number of other well -known manufacturers have a non -combustible base.

- The use of PVDF compatches provides many advantages of products, compared with the use of other types of funds. So, the enamel, which includes polyvinylendenfluoride resins with polymer acrylic resins, can be applied to only one layer and at the same time evenly stain the surface. Such a composition is not afraid of mechanical influences, resistant to ultraviolet radiation, resistant to acids, salts and alkalis, and increased humidity. In addition, it perfectly tolerates temperature fluctuations, as well as its high and low rates (-60 +120 degrees).

- Many manufacturers of aluminum composite panels try to improve this product, adding additional layers to the structure. So, for example, you can often see products with the presence of a carbide layer or antitoxic materials. Thus, manufacturers try to highlight their products and make it more competitive. But, of course, it is worth considering that the larger the layers in the product, the higher the price of aluminum composite panels becomes. For example, the cost of aluminum composite panels Bildex for M2 varies from 700 to 2000 rubles.

- The main characteristic of panels that allows you to use them in many areas where a large -scale size of the product is required is their mass. The weight of 1 m2 of aluminum composite panels is only 3-8 kg. Of course, such a product is not a heat -insulating product and when it is used to create ventilated facades, thermal extensions are necessarily laid between the panels and the wall based on paronite or plastic. The sheet itself has such precisely selected parameters that when heated the upper layer of aluminum (for example, under the influence of sunlight), the inner layer of polymer substance levels the temperature and that is why the product does not deform.

Aluminum composite panels photo

Each panel has standard dimensions that varies in certain parameters. An individual order is also possible, in this case, the manufacturer will cut the sheets for the measurements indicated by the client. The indicators are considered standard sizes:

- length 244 cm (the maximum possible indicator is 5.8 m);

- width 120 cm or 155 cm (depending on the manufacturer);

- thickness from 2 mm to 6 mm.

You can buy aluminum composite panels of different thicknesses, the number of layers can change here, as well as the thickness of the aluminum sheet itself, the most voluminous sheet will be 0.5 mm.

Production of aluminum composite panels

To make an aluminum panel with the required number of layers, three important stages are distinguished in production:

- preparation of aluminum and all components (chemiosynthesis).

- Painting and priming.

- Pressing.

So, first of all, aluminum should be prepared for further use. Metal enters the plants in rolls. To save the material from pollution, dust or fat film, it is subjected to chemical cleaning. That is, special chemicals are added to the washing solutions that do not spoil aluminum, but at the same time remove any dirt.

- The rectified aluminum is subjected to chemiosynthesis so that cleaning is carried out as high quality as possible. In addition to pollutants, the metal also gets rid of the impurities of silicone, iron, copper and magnesian precipitation. Also, it is at this stage that a special composition is applied to the sheets, which further greatly facilitates the staining procedure.

- After such preparation, the aluminum tape comes into further production, that is, the process of coloring in an isolated, hermetically closed chamber follows. Only high -quality enamel is used, since it depends not only the appearance of the finished product, but also the persistent characteristics.

- Painting products can be based on fluoroglerodes or polyester. The specific coloring composition depends on the further purpose of the finished panels. Thus, facade aluminum composite panels are covered with fluoroglerodic paints and have a thicker layer of metal. If the further purpose of the composite is an internal interior, then the paint is used on the basis of polyester, the metal is used more thin.

- To most qualitatively paint the sheets, the method of continuous staining is used. They can apply paint both on the one hand the front and both at once. The color is the most diverse, in addition, products are available, the surface of which resembles various natural materials.

- The third stage is the most responsible. Here, the thermoscopic and pressing procedure is carried out. The aluminum tape is again twisted into a roll. Aluminum of two rolls is simultaneously supplied to a special device, between which a synthetic polymer is squeezed out. The metal is connected to polymer or mineral material, necessarily the space is filled with non -combustible substances. The whole process is carried out at high temperature.

- Since polyethylene, placed inside the product, does not differ in high adhesion, some manufacturers additionally fix the layer. For this, a special film is placed between the layer of metal and polyethylene, which combines the two components of the products (metal and polymer) as firmly as possible.

Aluminum composite panels alukobond

- At the last stage of production of aluminum composite panels, a finish protective layer is applied, cut into the required sizes and sent to quality control.

Advantages of aluminum composite panels

- There are many advantages of aluminum composite panels. That is why this material has so quickly won the domestic market. Among the most important parameters can be called the following:

- ease;

- durability;

- fire resistance;

- reliability and strength;

- elasticity.

- Aluminum composite panels are distinguished by a variety of colors. In addition to aesthetics, this is a persistent coating that is characterized by a long period of operation. It can serve for more than 10 years and traces of fading or cracking will not be noticeable throughout the period. The coating remains just as persistent and bright. In addition, the used paints are almost immune to pollution.

- Since the surface does not have an adhesive and electrizing component, even when heated to high temperatures. Therefore, the settled dust is washed off with the first rain. If the product is used in the interior, then it is enough to wipe it 3-4 times a year with a soft cloth moistened with water.

- Aluminum composite panels can have a complex shape, that is, if you need to go around the angle, or renew the oval object, they will perfectly cope with the task. It is possible to bend the sheets at an angle of up to 180 degrees. Such flexibility and small weight greatly facilitate the installation process. Products are allowed to cut, saw, bend, pile and process in many other ways. In addition, it is possible to create a unique style and design to any structure.

- Aluminum sheets have sufficient resistance to external factors. They are not corroded and are not afraid of chemical reagents. Significant resistance to mechanical exposure is also manifested. They are not deformed when impacts and pressure.

- Aluminum panels withstand both high temperatures and low ones, while they are also not afraid of sharp temperature fluctuations. This allows you to use products under any climatic conditions, even in hot countries, even in regions with a harsh climate.

- Despite the small thermal insulation, the panels have noise -absorbing properties. So, when decorating walls made of concrete, its sound insulation increases approximately twice.

- Outwardly, this is quite attractive material, it is stylish and modern. That is why more and more gaining popularity, both when facing external walls, and for the decoration of the interior space. In addition, it is often used to create outdoor advertising designs. The resulting shields are durable and rather presentable.

The scope of aluminum panels

- The most common sphere of use of products was exterior of various buildings. The most popular are the ventilated facades. But this is far from the only area where aluminum panels have found their application. So, you can often find the internal space in public institutions trimmed with this particular materials. Most often, these are buildings of stations, airports, schools, automobile salons, shopping centers, cinemas and hospitals. That is, where the human flow is most intense and persistent, durable materials that can withstand a long process of operation in a constant state are required, and at the same time give attractiveness to the interior.

- Also very often, the panels can be seen in structures for outdoor advertising and in temporary pavilions for exhibitions or other events. Aluminum sheets are great for the restoration of old buildings, whose outer walls are already poorly amenable to restoration and renewal. The panels give modern design, attractive appearance and soundproofing properties.

Installation and delivery errors of aluminum composite panels

- In order for aluminum panels to really serve for a long time and do not have damage during operation, a number of rules must be observed at the stage of transporting them to the place of use. So, during delivery, be sure to ensure that the outer, front layer remains in integrity, is not damaged and not scratched with sharp objects.

- In order to prevent damage, it is important to lay cardboard or other material between several sheets with similar properties. You should also protect the panels from strokes on solid foundations or falls from a great height. This means that if it is planned to raise sheets above the ground by several meters, then special clamps should be used that will reliably fix the products.

- By mounting aluminum sheets, do not forget that when heated, they expand slightly, that is, it is necessary to leave small gaps between the panels, and make a hard clamp only on one side (corner), leaving the remaining edges with a small play.

- It is also important to remove the protective film correctly, since incorrect movements lead to curvature of the panels. They remove it at an angle of 180 degrees and necessarily after two weeks or even a month after production. This is necessary that the glue does not remain on the sheets, but removed completely.

Thus, we can say that aluminum composite panels are a wonderful building material that has a leading position in the modern market. It has excellent characteristics and various spheres of application. Having made the right choice of the product, it will serve as long years, during which it will require minimal care, but at the same time it will have an attractive appearance.

Hello, sales "Color

Hello,

Sales “Color with a coating of aluminum coil” ”Aluminum composite panel” ”, paint stone covered with metal tiles.” This is our site http://ru.jhct.cn/

Victor Zhu

Skype: kievrose@qq.com

Hello, sales "Color

Hello,

Sales "Color with a coating of aluminum coil"

Our company is the largest manufacturer in the north of China of the Yangtze River, specializing in production

with color coating of aluminum rolls, which is a medium

Industry and trade integration sizes .. Internal products are sold in 22 provinces, 120 cities, and exported

around the world in the Middle East, in Southeast Asia and Africa.

victor@jinhucorp.com

Where are the temperature regimes?

Where are the temperature regimes?