The long -awaited summer came, and many citizens hurry to summer cottages, gardens and sites to ...

|

|

The correct choice of insulation will reduce the heat loss of the insulated building and extend its term ... |

The first thing that outsiders see and evaluate the owner of the apartment or at home input ... |

DIY piece parquet laying

The wooden floor is always beautiful, original and warm. The created unique atmosphere of comfort is incomparable with other types of floors. To create an individual exquisite and noble flooring, parquet is used. From the piece parquet, you can form a fashionable unique pattern, which is why it is popular today, despite the fact that laying the piece parquet is complex and time -consuming. Nevertheless, it is not necessary to call a specialist by studying the technology and following all the rules and recommendations, all styling work can be performed independently. The task is also simplified by the fact that all modern parquet planks are made with a spike-paz system, which helps to firmly and without gaps to fasten the elements of parquet.

- Paul from piece parquet select wood

- We buy piece parquet pay attention to the quality

- Fitty parquet laying technology

- Preparatory work before laying parquet

- DIY piece parquet laying

- Grinding piece parquet

- Putty and priming piece parquet

- Opening the floor from piece parquet with varnish or oil

Paul from piece parquet select wood

Not only the color scheme of the parquet depends on the type of wood, but also its durability, since different wood species have different hardness and resistance to moisture. For example, pine and other conifers are not used for the production of parquet due to exceptional softness. On a pine parquet, even opened by several layers of varnish, there will be traces of heels and other sharp objects.

The most common rocks used for parquet are oak, nut, maple, cherry, ash, beech and others.

Oak parquet classics of the genre. It is solid, resistant to moisture, has a beautiful pattern, the color scheme of which can have various shades of brown. The only conditional disadvantage of oak is that it darkens over time. Otherwise, its operational characteristics are at a height. When buying oak parquet, pay attention to the duration of its drying, the accelerated option is not suitable.

Book parquet It has the same hardness as oak, but it has an even warm and soft yellowish or reddish tint, for which it is appreciated. Book is a capricious breed. Under the influence of temperature and humidity changes, it is limited and deformed, so it requires thorough care and observance of optimal operating conditions.

Maple parquet At first it seems white, but over time it turns yellows a little. In terms of hardness, it is practically not inferior to the oak, and in some breeds this indicator is even greater. Attention should be paid to the drying time, quickly dried maple wood is deformed over time.

Cherry parquet brown with a distant shade of pink, but over time it gets slightly darkened. It has less firmness than oak, however, is quite popular, as it is easy to process and pruning.

Parquet from Merbau Exotic option. He is valued for beautiful patterns in the context of the barrel and for the extensive color scheme of all shades of brown. Merbau is not afraid of moisture, but so saturated with resins that he can hardly lends itself to processing.

Choose wood for parquet based on operating conditions in a particular room. For example, cherries can be used in a children's room, maple in the office, and oak can be used everywhere. It is not at all necessary to perform the entire parquet floor from one type of wood, you can combine a unique pattern from breeds of different shades.

We buy piece parquet pay attention to the quality

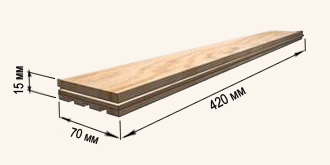

Parquet strips are available in various dimensional solutions. The length of the bar can be 15 40 cm, the width is 3 9 cm, and the thickness is 1.5 2.2 cm.

It is necessary to select the sizes in size taking into account the area of \u200b\u200bthe room: small strips will visually increase the room and decrease large. From the point of view of laying, the size of the planks is also of no small importance. If the parquet planks are large, then the number of connections will be less, but then the requirements for the quality of the drying of the material will be much larger. The larger the bar, the less its elasticity.

The optimal width of parquet strips is 5 cm. If you need to use larger planks, buy those that have cuts on the inside, they are more resistant to deformation.

What should you pay attention to when buying a piece parquet:

- There should be no knots, chips and cracks on the front surface.

- The upper layer (from the top to the start of the castle connection) should be large enough. The larger the thickness of the wear layer, the more times the parquet can be polished and updated.

- Products should be dried up to 8%. The drying duration is at least a month.

- It is necessary to check the quality of the spike and the groove. To do this, it is enough to add a square from 4 planks. If the strips join easily and the corners of 90 without cracks and gaps form between them, then the spike-paz system is made qualitatively.

- Sort the strips in the direction of the saw, the presence of the remains of sapwood and knots.

The most durable and valuable are the strips of the so -called radial sawing, i.e. dissolved along. A characteristic feature is straight lines on the surface and plain color. The radial variety of parquet is more expensive than other varieties.

Fitty parquet laying technology

All work on laying the parquet begins only after the ceiling and walls are completed, communications laying and checking them for tightness. In the process of laying the parquet, certain indicators of humidity and temperature must be observed. So the residual moisture of the walls should be no higher than 6 %, the moisture content of the floor is not higher than 5 %, the relative humidity of the air is 35 60 %. Optimum temperature 18 23 p.

Failure to comply with these conditions will lead to deformation of the coating. If you lay parquet with high humidity, it will swell and set moisture. And when all the work ends, over time it will dry out, begins to refer and the cracks between the dies will appear. Fixing this is much more difficult and more expensive than doing everything from the very beginning correctly.

The surface on which the piece parquet will be laid should be perfectly flat, the maximum error of 1 mm per 1 m2.

Fitty parquet laying technologyincludes such stages of work:

- Repair of the old concrete ceiling, if required.

- Waterproofing of a concrete base.

- Fill the aligning screed 4 5 cm thick. Or laying a lag for a wooden floor.

- The priming of the screed for glue.

- Gluing moisture -resistant plywood to screed or fastening plywood to lags.

- Gluing and nullifying parquet to the faner.

- Grinding the surface of the parquet.

- Parquet putty.

- Grinding parquet for varnish.

- Opening parquet with varnish from 3 to 9 layers.

All of the listed events are mandatory for implementation, otherwise the parquet will quarrel over time, begins to creak or fall off at all.

Preparatory work before laying parquet

Preparation of a strong and even foundation is perhaps one of the most important tasks in laying the parquet. The durability of the coating as a whole will depend on the quality of the fasteners. The cost of laying piece parquet, if you order it in specialized construction organizations, usually does not include preparing the base.

Preparation of a concrete foundation

If the parquet is laid on concrete overlap, then the first thing it is to be waterproof. To do this, the surface of the floor slab must be covered with a superdiffusion membrane or polyethylene film with 200 microns. The joints of the canvas of the film are made with an overlap of 15,100 cm and glued with construction tape. The waterproofing film is started on the walls by 10 15 cm and temporarily fixed on it with tape.

Then it is necessary to pour the leveling screed, which will also serve as a fastener base under the plywood. The thickness of the screed should be 4 5 cm. The horizontality of the coating and the absence of defects in pits, potholes, height changes and others are necessarily controlled.

Important! Before the start of subsequent work, the screed should completely dry. It will take about a month or two. Do not rush and continue to work on laying the parquet, since the wood will pull moisture from the screed, and this will lead to inevitable deformations.

When the screed dries, its surface is covered with special primers, which increase the adhesion of the base with glue and at the same time protrudes waterproofing.

Then the moisture -resistant plywood is taken with a thickness of 12 mm, cut into squares 50x50 cm or 75x75 cm.

Functions of moisture -resistant plywood under a piece bag:

- Protects parquet from shrinkage deformations.

- Perfectly levels the surface.

- Serves as thermal insulation and partially sound insulation.

- Provides strength.

- Serves as the basis for fastening the parquet planks. If you lay the parquet directly on the screed, then due to the destruction of the upper layer of the screed, the bar may disappear. Plywood holds them firmly.

Important! The thickness of the plywood should be 5 mm less than the thickness of the parquet bar. But using sheets less than 12 mm is inappropriate, they do not perform their functions. In this case, you can lay the plywood in two layers, rising.

Next, the surface of the screed is lubricated with glue and the squares of plywood are laid on it, tightly pressed and fixed with dowels-clavings or screws. Between the squares of the plywood, it is necessary to leave a minimum of 1 1.5 mm a gap to exclude parquet deformations if the plywood begins to expand.

It is also important to leave the gap between the wall and the plywood of 2 3 mm, it will be a deformation seam. You can insert special wedges into the gap so that the gap does not shift.

Laying plywood on the lags

It is not necessary to attach the plywood to the concrete base, you can make a floor on the lags along the old fashioned way. To do this, you don’t even have to level the concrete base. It is enough to waterproof it, spreading the waterproofing film.

Then the lags are laid with a step of 35 40 cm. As a lag, you can use a beam of 50x50 or 50x80 mm. Lags are fixed to the floor using corners and dowels. In the process of laying the lag, it is necessary to ensure that their surface forms an even plane. To do this, in the places of changes in the heights of the concrete base, you can put wooden stands or cut excess.

When the lags are equipped, plywood is nailed. Glue is no longer used here, only self -tapping screws. The step of fastening the squares of plywood to the lags is 10 15 cm. It is necessary to nail the plywood not only at the edges, but also in the middle to all the lags. The gap between the squares is also required.

Preparation of an old wooden floor

Before laying parquet on the old wooden floor, it must be checked for serviceability. Nowhere should there be creaks, failures or other defects. If, nevertheless, something similar is observed, it is necessary to partially disassemble the floor covering and repair the lags. After the repair is completed, the surface of the old wooden floor is polished. Parquet laying can be done directly on the wooden base of the floor, without plywood.

DIY piece parquet laying

Work on laying piece parquet is very responsible, you can’t rush here, reducing the time of repair. It is better to take a break of a day or two-week than then redoing all the work. After all, one error and the entire coating are a drain.

Methods of laying piece parquet

Parquet styling technology implies several ways to lay it:

- Floating way of laying.

- Parnish on parquet glue.

- Laying with fastening with nails or self -tapping screws.

- Laying on parquet glue and fastening with nails or self -tapping screws.

Floating way Laying involves fastening parquet strips only to each other using a spike-paz system. They are not attached to the base in any other way. So that such a floor does not creak, soundproofing material, for example, a cork, is put down under it. Parquet strips fixed in this way will freely expand and narrow depending on the temperature and moist conditions. It is enough to disassemble the floating floor of the repair -free and fold it again. But the strength of such a coating is very doubtful, it is enough for one castle connection to shake so that the entire floor begins to warp and deform.

Parquet laying on glue It is considered more durable, but also less repairs. The base is abundantly lubricated with glue, then parquet is laid, connecting with a spike-paz system. This method is considered more time -consuming and costly due to the flow of glue.

Laying on parquet glue with nail consolidation or self -tapping screws The most durable and demanded way. Such a floor is practically not subject to deformations, since they are restrained from all sides. But at the same time, it will not work to repair such a parquet. All hope for a long life.

How to lay a piece parquet stages of work

In order for the pattern on the floor to be even and beautiful, it is advisable to draw it on paper. At the same time, it is important to take into account the exact dimensions of the room and planes of the parquet. If suddenly according to the drawing it turns out that some row will not be whole, then the drawing must be redone so that there are cut rows along the edges of the room, and only even in the center.

The start of laying parquet also depends on the picture. Consider by the example of the Christmas tree.

- First we mark the room, find its middle. In the middle of the room from the wall to the wall we stretch the cord, along which we will navigate.

- We take two parquet strips and connect them with a Christmas tree, inserting the spike into the groove. On the spike, groove and ends of the planks apply glue.

- Then we smear with glue the base of plywood, starting from the far wall. We use a gear spatula for this.

- We put the lighthouse Christmas tree to the plywood so that the left edge of the planks presses the cord to the base, and the right edge of the planks rests on the cord.

- We press the planks to the fan so as to squeeze out the excess glue.

- Then we fix the bar with nails or self -tapping screws, screwing them into the groove of the planks at an angle of 45 and lingering the hat. On the bar 40 cm long, there should be at least 2 fasteners with nails.

Important! In the process of laying, the master should sit so that the spike of the planks is located to him.

- Next, lay the bar on the sample. We smear the base of plywood with glue on the width of the bar, 1 1.5 mm thick.

- We apply the bar, inserting it into the end and longitudinal groove of the previous one, we finish off with a rubber hammer. We fix the self -tapping screws in the groove.

- First, we lay the ranks of the planks on the model of the lighthouse Christmas tree, left and right.

- Then we lay a number of strips to the left of the lighthouse, then on the right. And so on we act, expanding the styling area, until we get to the walls.

- Narrow places near the walls are filled with slices cut to size.

- Between the wall and the last row of Parquet planks, we insert the wedges, performing a gap of 2 3 mm.

All further work can be done after at least a week so that the glue can dry well. Although some experts recommend waiting six months, then the Parquet planks themselves will take their final position.

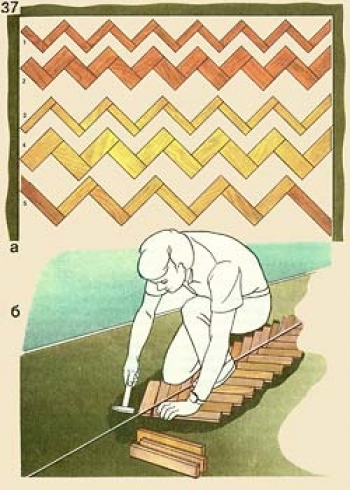

File parquet laying options

The piece parquet is good because it can be laid with various drawings, placing strips at different corners and in different sequences.

DeckThe easiest way to lay. The strips are located smoothly, parallel to each other, with a displacement of 1/3 or the length of the bar. The first bar is located near the wall, for a denser fit from it, the spike is sawn off.

Christmas tree - The strips are interconnected at an angle of 90. On the strips there should be two spikes one from the longitudinal side, the second from a narrow end. There should also be two grooves from the opposite sides. This styling method is quite complicated, since the ranks must be perfectly leveled.

Squares And the braid is formed quite easily. First, 2/3/4 of the Parquet strips are connected together and laid, then the other 2/3/4 strips are connected, but are laid perpendicular to the first. So the rows alternate, it turns out an organic geometric pattern.

Blade with inserts From different wood species.

Rombs They are laid from peculiar rhomboid planks of parquet.

Sheremetyevo star It is laid out of two types: rectangular planks and inclined diamonds.

In addition to the above options, there are their combinations with various figures and drawings.

The price depends on the laying of piece parquet on the layout of the planks. The simplest deck layout costs 7.5 8 cu For 1 m2, the Christmas tree will cost 9 cu per meter, and art parquet can cost from 17 cu Up to 35 cu and even more. All these prices are indicated without preparatory work and further finishing grinding and varnishing. The average cost of laying parquet with grinding and varnishing is 17 cu per 1 m2.

Grinding piece parquet

Grinding is necessary in order to make the surface as flat as possible and remove the defects that occurred during the work. Grinding can be done with special grinding machines or an ordinary grinder with a circle of sandpaper. Of course, the option with a grinder is more preferable, and there will be less dust.

The first and second time grinding is carried out large grainto cut big irregularities. Third time small grainTo achieve the smoothness of the coating and remove the roughness that arose after the first grinders. Then the floor must be thoroughly sprinkled, removing all fine dust.

Putty and priming piece parquet

It does not hurt to plunge all the cracks in the parquet, even if there are no visible large defects. The entire floor is wiped with a special putty on wood, all the cracks and irregularities are filled. After drying, the floor must be sanded again with small grain and remove the excess putty. Then the floor is vacuumed again. To improve the clutch of varnish with parquet and at the same time make the varnish do not penetrate deep into the structure of wood, the surface of the scalded parquet floor is covered with a primer.

Opening the floor from piece parquet with varnish or oil

The varnish protects the tree from moisture and mechanical exposure. There can be from 3 to 9 a total of varnish on the floor. The larger the layers, the deeper the image turns out. The varnish is applied to the entire surface at once, after which the floor is left to dry well for 24 36 hours. It is necessary to perform varnishing work in clean soft shoes.

Important! While the varnish dries, you can’t open the windows, leave the entrance doors open, turn on the air conditioner, ventilation or other methods to provide a draft. The varnish should dry in the maximum calm conditions.

All subsequent layers of varnish are also applied with a roller with an interval for drying 24 36 hours each layer. The last layer should dry at least a week so that you can carefully walk on it, and you can only put furniture into the room after at least a month, or even two.

Parquet varnish is glossy and matte. Glossy It makes the floor shine, makes the room bright and emphasizes the drawing. Matt lacquer Used to reduce the brightness of the pattern on wood and to create an atmosphere of warm comfort.

Laying piece parquet can do more than laying a massive board by about 2 4 times. But at the same time, the coating will turn out to be more refined and durable, also less the risk of creaking. The key to success in creating a beautiful prestigious parquet Patience of the master.