Enough part in the process of flooring, such a material as chipboard is used. Among...

|

|

In the process of laying paving slabs, a very important aspect is sand tamping ... |

If you want to equip an attractive, durable and inexpensive floor in your house ... |

Do -it -yourself modular parquet: styling technology, care, master advice

The modular parquet appeared on the domestic construction market relatively recently. Its main advantage is that the patterns of shields are collected in industrial conditions by highly qualified specialists. Unlike a piece analogue, it is easy and quickly mounted, which means it will not be difficult to perform the entire amount of work yourself. And the final result of the flooring from the modules will be almost impossible to distinguish from complex and expensive work on laying out piece elements. And this applies not only to the appearance, but also to its characteristics. The article will talk about the variety and way of laying a modular parquet.

Content:

- Types of modular parquet

- Laying a modular parquet

- Finishing the modular parquet

- Repair and restoration of modular parquet

- Modular parquet in the interior

Types of modular parquet

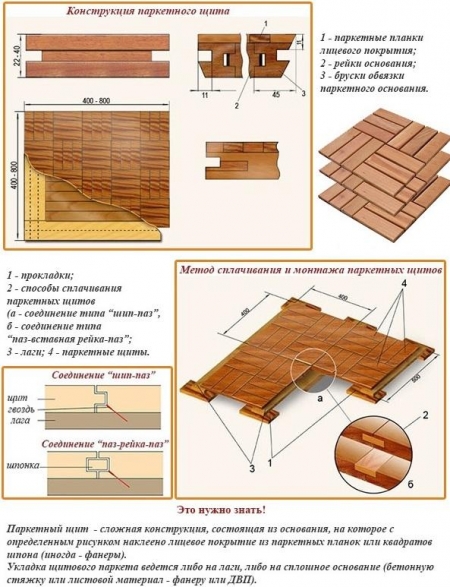

The modular parquet is a ready -made multi -layer shield consisting of a CSP or chipboard of a slab, a layer of plywood, wooden racks of their conifers (most often pine). This design is a basis that is made of a thin decorative layer (its thickness is on average 5 mm) from plywood, natural veneer or racks from noble varieties of wood. This is a general view of the module, but depending on the different bases, the modular parquet from the manufacturer is divided into several types:

- P3 The basis of chipboard is based, which has a bilateral cladding of veneer;

- PSh3 Based on the cement-stove:

- PSh1The frame is made in the form of a wooden frame with a rack base, the space is filled with wooden decorative rails;

- PSh2 also has a rack base with a frame, but a veneer is used as a cladding;

- Psh4 The most expensive type of modular coating. The shields are made with a double rack base, the location of the fibers of which is perpendicular to each other in different layers.

Decorative rails for art modular parquet are made of inexpensive wood: pine trees, birch, aspen or alder. But under order can be made of oak, nut or other type of noble wood.

In accordance with the type of facial coating, the parquet from the shields is divided into:

- modular parquet with plywood coated;

- modular parquet with veneer coating;

- modular parquet coating from parquet wooden rails.

Parquet shields can vary in size and thickness. On average, the side of the standard panel is 40-80 cm, and the width is from 2 to 4 cm.

Laying a modular parquet

- If ordinary piece parquet requires a very thorough preparation of the base, then its modular analogue is not so demanding. It is enough to perform black training to exclude strong changes or irregularities. This is due to the fact that individual elements are quite thin, and the shield is a multi -layer structure.

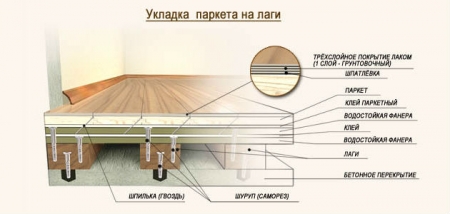

- But there are nuances here. Inexpensive modular parquet has a small thickness. Therefore, it is not recommended to lay it directly on the floor lags. To extend the service life, you need to make a concrete screed. If the thickness of the module is 3 cm or more, then installation is allowed directly through the lags.

Tip: on sale you can find a modular parquet made using extrusion pressing technology. Despite the fact that it represents a rather thick and stable flooring, its strength in the fracture is low. Therefore, it is allowed to mount it only on a flat continuous surface.

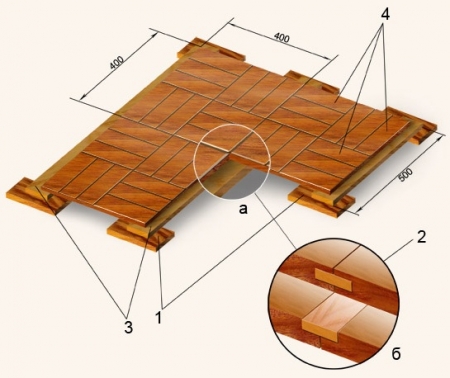

- The laying of modular parquet on the floor is quickly due to a special design. On each side of the parquet shield, there are grooves designed to hammer in them for this wooden wraps. They are sold complete with parquet, often made of coniferous wood.

- There are also models in which there are grooves on two sides on two sides, and from the other two protrusions. Thus, they can be immediately fixed without the use of additional connecting elements. Such flooring is less common, but it can significantly save assembly time.

- The modular parquet is produced on an industrial scale, there is always the opportunity to order an individual design. The location of the shields on the floor in this case will require more care. To create the right and beautiful drawing. But even with this work can be handled independently, without experience and additional skills.

Modular parquet walnut

- When choosing fasteners, you need to focus on the base of the floor. If the parquet is located on a concrete screed, then a parquet or mastic will be required. To fix shields to wooden lags or faner, screws are suitable.

Laying a modular parquet on wooden lags. Stages of work

This styling method is chosen if the existing base is very uneven, and there is no possibility or desire to make a screed.

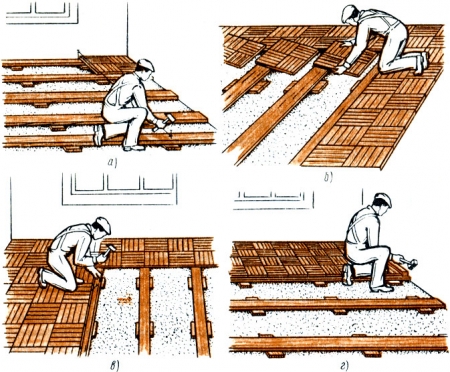

- First of all, they make a floor frame of wooden bars or rails of conifers with a cross section of 2-5 cm. Before laying, each bar must be checked for evenness from all sides. He should not have a review. Well, if they are treated with an antiseptic.

- To make the floor absolutely even, first it is necessary to mark the final level of the floor. To do this, fold the thickness of the module itself with the thickness of the gasket and the thickness of the lag. The total amount will be the desired height. Next, using a laser level, marking is made immediately on all walls.

- Lags begin to lay along the longest wall, retreating from it 1-2 cm. The step of their location is equal to the width of the shield, so that the joints of the elements fall on the frame, and there was the opportunity to fix them to it. But this applies to narrow models (up to 40 cm). If the parquet is 60 cm or more, then it must be placed on three logs. That is, the guides will pass along the edges and in the middle of the module.

- Lags are not put directly on the old screed, under them you need to put gaskets with a step of 50 cm. In these places, the lags are fixed to the floor on the dowels.

- It was the turn to make the first two lighthouse rows. They are located at the junction of two walls (long and short) in the opposite corner from the entrance.

- In the first method, the very first shield is attached in the corner, leaving a deformation gap from a wall of 1-2 cm. It is very important to put it evenly, since all further styling will depend on it. Before fixing it, you need to carefully check and align it using the level. After making sure that the module lies correctly, it is screwed with a self -tapping screw to the lag.

- From the first shield, you need to stretch along the twine along the long and narrow side. Focusing on these lighthouses, both starting rows along the walls are laid.

Tip: To speed up work, first you need to sort parquet shields. This is especially true for artistic modular parquet. Often, when ordering the size of the floor, special additional elements are made that differ in size. Therefore, they should immediately be put aside.

- Mounting the modules themselves is quite simple. If the model is already with the groove system provided for, then all subsequent elements are simply inserted into the lighthouses. For a tight connection, they are driven by a rubber hammer. If this is not at hand, then you can attach a cut of the shield with the corresponding fastening to the installed and knock on it with an ordinary hammer. If they are not tightly fastened, then gaps will appear during operation.

- In the case when the modules are fastened by means of a key, the circuit will be almost similar. It will only need to independently insert the veneer into the first fixed shield and stab it, after which the second shield joins and clogs with a rubber hammer.

- Having completed the laying of a row, it should be fixed. To do this, the wedges at the rate of 2 pcs are driven into the left deformation gap between the wall and the floor. To the module. Such spacers guarantee the integrity of the parquet, protecting it from the appearance of cracks.

- When the distance between the wall and the module is too large for the wedges, a preternal parquet element is installed there. Most often, they are made immediately according to the measurements of the customer. But if this was not done, you can saw it yourself with a disc saw or an electrician. The cut will turn out without a groove and spike, so it is placed to the wall.

Laying a modular floor on a screed. Stages of work

- First, check how flat screed. If necessary, it is easy to align with a bulk floor, which does not require a complex batch of solution, the establishment of lighthouses and subsequent leveling.

- The purified surface is primed with a waterproofing composition. After that, in a day you can start laying parquet.

Tip: If instead of screed it is planned to put a modular laminate on a black floor from plywood, then waterproofing must be placed under the plywood.

- The modules are sorted, preparing prefabricated elements in advance and placing them in a convenient place. When these works are finished, parquet glue is bred. By consistency, it should resemble a cement mortar.

- It is applied with a gear spatula to the floor surface in those places where styling will be directly carried out. It is not worth applying to a large area, as it dries quite quickly. As a result, the adhesive layer is wavy with a maximum height of 2 mm.

- The module is laid on top and pressed well, so that all air bubbles leave the solution. For additional strength, you can fix them on the dowel of nails in the grooves directly to the screed.

- Having laid the angular parquet shield, two lighthouses are pulled from it along the rope perpendicular walls. To make sure that it turns out smoothly, it is recommended to lay all the shields of the lighthouse rows on the dry.

- When connecting the plates with each other, you need to be careful, since if you are too strong a rubber hammer, you can remove the already glued shield. Therefore, if possible, after laying out one row, it is necessary to give him time to set the glue.

- Masters advise that the connection is especially durable, a spike or a key before fixing apply PVA glue. Excess glue that can occur when fastening elements should be removed immediately with a dry rag.

- As in the case of laying a modular parquet on wooden logs, it is necessary to take care of the deformation gap of 1 cm and the location of the wedges in it, which will later close the skirting board.

Finishing the modular parquet

- In most cases, the modular parquet, which is on sale in stores, does not need finish processing. It is already fully processed. But if old or unprocessed modules were laid, then they will need to be cycle, grind and cover with decorative parquet varnish.

- With a small area of \u200b\u200bthe room and the absence of a special cycle machine, the work is allowed to be performed by an electric rhuban. With its help, all the main irregularities from wooden rails are removed. You can grind with a grinder with a grinding circle.

- In conclusion, a special varnish for the floor is applied. It is most resistant to abrasion. When choosing a shade, it must be borne in mind that to create a durable layer it will be necessary to apply 3 layers, each of which will make the floor color more saturated. If you just want to emphasize the texture of a natural tree, then the first layer is applied to a water -based stain, and on top of 3 layer of transparent varnish. The work ends on this.

Repair and restoration of modular parquet

Unlike piece parquet, all elements of a wooden pattern are firmly glued to the base of the shield, so there are no problems with them. But with prolonged operation and inevitable aging of natural flooring, the cracks appear between the slabs themselves. It can be repaired in two most popular ways.

- The first way. Laborious, but guarantees a qualitative result. Complete shift of the entire floor is performed. To do this, the entire shields are separated from the base, not only a veneer or wooden rails, but a plywood with a substrate. Parquet glue is completely removed from them and mounted again on a fresh solution. This is advisable only if a large number of large cracks or swelling formed on the floor.

- The second method. It happens that the quality of styling over the years was not violated, and the parquet itself faded and covered with a network of small cracks. Then the restoration method is used. First, the old varnish is removed with a flat -grinding machine, and then the wood is treated with grinding. If there are deep cracks, they are filled with a compound. Subsequently, the entire floor is again polished and covered with varnish.

Modular parquet in the interior

Modular parquet will be a good solution for almost any room. Manufacturers offer a wide range of drawings and artistic designs, so it will not be difficult to choose the right option for themselves.

- Thanks to modern technologies that continue to develop and improve, it became possible to make a noble modular parquet for oak. But the combination of different wood in one module looks most exquisite. For example, such as nut, oak, red tree or ash. This flooring is suitable for an interior in a classic style.

- Inexpensive modular parquet consists of the same shields in the pattern, which are repeated over the entire area of \u200b\u200bthe floor. But, if desired, they can be supplemented with artistic elements. For example, in the center, place a pattern called a socket. Such an element can be made to order and make its own design on it, for example, the family coat of arms.

- By order, designers can offer individual projects of a modular parquet for specific premises. These can be real works of art, in the form of full -sized paintings or complex patterns. Today, such projects are done on the computer and are coordinated with the customer, if desired at the design stage, you can make changes and immediately make visualization how such a floor will look in the interior with furniture and decor. In addition, such a design project will allow you to accurately arrange all the shields of the modular parquet, so it will be easy to collect the finished drawing.

The modular parquet is certainly beautiful and durable. But because of the high price, not everyone is available. Yes, and requires periodic care. Therefore, in the construction market in a large assortment, a laminate is sold imitating modular parquet. If you buy such material of a commercial or semi -commercial class, then it will look very noble.