Due to the widest range of materials for the arrangement of the roof, which today ...

|

|

Modern doors are equipped with a special device that saves households from ... |

It is pointless to prove that for a comfortable year -round residence in the cottage in ... |

How to insulate a concrete floor

In the system of heat exchange of the house, floors are one of the places of large heat loss. This is especially true for concrete floors, which, despite all their excellent operational qualities, have one serious drawback of concrete very cold material. And for a comfortable living in a house with concrete floors, high -quality, multilayer thermal insulation is required. The insulation of the concrete floor in the house, especially if it is the gender of the first floor, is a strict necessity, but the implementation of all work is not particularly difficult. The main thing is the observance of insulation technology and the presence of skills in handling the tool.

Concrete floor insulation

Reliable and high -quality thermal insulation of the concrete floor directly depends on the thermal insulation materials used, which differ in operational characteristics, as well as the place and operating conditions. The choice of the correct material should be done first when finding an answer to the question of how to properly insulate the concrete floor.

When choosing thermal insulation, you need to pay attention to the following characteristics:

- density is responsible for the total weight of the material. The smaller this indicator, the more porous material and the more heat it can keep indoors;

- strength material, can be either bend and compress. For insulation of the concrete floor, materials with a high strength indicator due to large loads on the floor surface are required;

- coefficient of thermal conductivity Shows the ability of the material to pass through heat through itself. The lower this indicator, the better;

- moisture resistance the material should be very high, otherwise the material located between the concrete screed and the soil will quickly lose its properties;

- moisture permeability, unlike moisture resistance, should be minimal. Otherwise, the material will quickly gain excess moisture and lose its thermal insulation qualities;

- durability. With this indicator, everything is simple: the more it is, the better;

- environmental friendliness. This characteristic will be useful for those who seek to build an environmentally friendly house using natural materials.

The following materials are often used to warm the concrete floor:

- mineral and basalt cotton wool. These thermal insulation materials are very popular. They have low thermal conductivity and density (although there is a slab position with a high density), as well as excellent sound insulation. Unfortunately, cotton wool is unequal, perfectly absorbs moisture, does not tolerate the moist environment. The use of cotton wool as a heater for the concrete floor is justified only if the false floor is insulated;

- styrofoam. The second name is polystyrene. Today, the insulation of the concrete floor with foam is the usual business. This material has excellent indicators of thermal conductivity, moisture resistance and moisture permeability. It has the following shortcomings: non -excessive and rather fragile;

- extruded polystyrene foam. This material is a derivative of the material of ordinary foam and has a number of significant differences. Firstly, extruded polystyrene foam is much stronger. Secondly, the durability of EPS is greater than that of ordinary foam. Thirdly, thermal conductivity, water absorption and water resistance is an order of magnitude higher in EPS.

- poliuretan foam. This material has excellent thermal conductivity indicators, resistant to moisture and temperature changes. Perfectly tolerates mechanical loads without losing thermal insulation properties, durable. The only drawback is non -elected;

- keramzit. This material is more often used as a substitute for crushed stone in concrete and for insulation of the latter. The heat -insulating properties of expanded clay allow you to reduce concrete thermal conductivity several times. Despite the low thermal conductivity and environmental friendliness, expanded clay has a number of significant disadvantages. Firstly, a fairly large total weight of the thermal insulation layer from expanded clay. Secondly, expanded clay absorbs and holds moisture perfectly;

- foam -glass. As a heat insulator, the foam glass has a number of undeniable advantages. These include low thermal conductivity and specific gravity, the ability not to absorb moisture, the environmental purity of the material, the inevitability of moisture, and a very great durability. The only serious drawback is the certain fragility of the material that is poorly tolerate mechanical loads;

- cork. Absolutely natural insulation with excellent thermal insulation characteristics. The only thing that should be noted is better to use the cork for insulation of the false floor and as a thermal insulation layer for the finish flooring;

- perlit. This thermal insulation material is similar in the method of its use with expanded clay. The difference lies in the characteristics of perlite, which are an order of magnitude better than that of expanded clay.

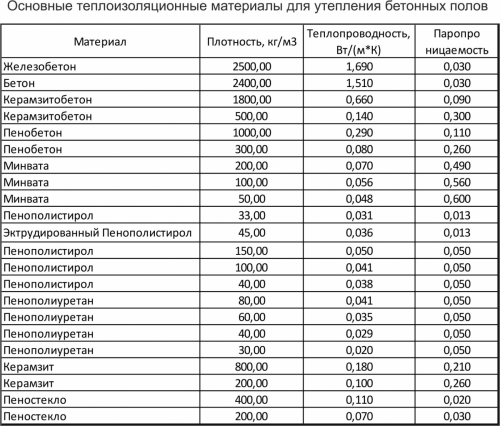

The table below indicates the main characteristics of thermal insulation materials, which will have to be focused on when choosing them. Especially the thermal conductivity of various types of concrete with different fillers should be noted. This little secret will help answer the question, the better to insulate the concrete floor.

Table 1.

Features of concrete floor insulation

Before proceeding directly to the work on insulation of the concrete floor, you need to deal with the technology of insulation, as well as choose the most suitable option of insulation from the existing ones.

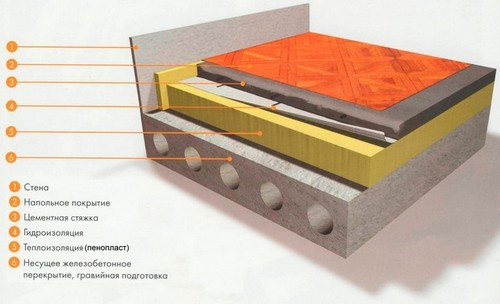

The technology of insulation of the concrete floor is to create multilayer thermal insulation and consists of several stages of work. The first stage of insulation of the concrete floor is performed before pouring a black screed. The second stage of insulation occurs during the creation and pouring of the concrete mixture. At the third stage, the insulation of the concrete floor is performed during the creation of the flooring. It should be noted right away that it is best to warm the concrete floor when it is created from scratch. This is the only way to ensure a qualitative level of insulation.

There are only a few ways of warming the concrete floor. Each of them is performed at one time as the floor is created. In more detail, each of these methods is considered below.

- Laying of insulation under the concrete screed. Such insulation is performed during the creation of a concrete floor from scratch. Therefore, if there is a desire to insulate the floor in an already built house, you will first have to completely destroy the old concrete screed to the base. With this method of insulation, materials with high strength indicators, resistance to mechanical loads, moisture resistant and durable are used.

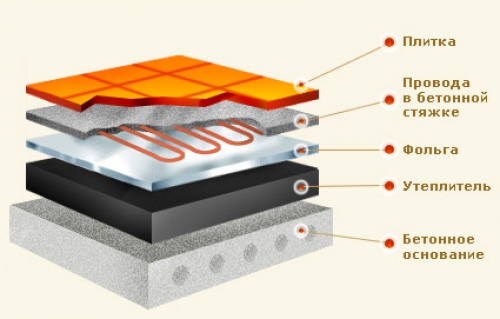

- Today is especially popular the system is a warm floor, which allows you to create active heating of the concrete floor throughout its area. Such a system is placed on top of the insulation layer and poured with a concrete screed. Warm floor can be water or electric. In any case, the use of a third -party energy source will be required to heat the floor using such a system. Concrete warm water floors or electric warm floors are more related to the active heating system. But in general, they are perfect for insulation.

- Another option for insulation of the concrete field is adding such fillers to a mixtureLike expanded clay or perlite, instead of crushed stone familiar to everyone. Due to its thermal insulation characteristics, these materials can reduce the coefficient of thermal conductivity of concrete several times. Concrete with expanded clay or perlite can be used both to create the basis on the ground and for screed.

- One of the common options for insulation of concrete floors of the upper floors is creating a false floor. This method of insulation provides for the arrangement of wooden lag and filling the space between them with a heater. This approach is useful in that it reduces the overall load on the foundation of the house, and is useful for those who do not want to mess with the filling of a concrete screed.

- You can insulate the finished concrete floor with the help of flooring. To do this, just use insulated floor materials. For example, warm linoleum or carpet. In addition, when creating the finish flooring, you can lay a layer of cork, foamed polyethylene or other thin -layer insulation under it.

All these methods of insulation, depending on the situation, can be used both in complex and separately. So, for example, if it is impossible to lay the insulation under the screed, you can limit yourself to the use of expanded clay and the creation of a multilayer finish coating. Or when creating the system, the warm floor is not equipped with a multi -layer warm finish coating.

How to insulate a concrete floor

There is nothing complicated in how to make a warm concrete floor. The first thing to do is to carry out a number of preparatory work. And depending on whether the floor insulation will be on the ground or on the inter -story floor, choose the methods of insulation and materials.

As previously noted, it is possible to insulate the concrete floor on the ground in several ways. Below we will consider in more detail two most often used. This is the creation of multi -layer thermal insulation and the system of warm floor.

Concrete floor insulation multilayer pie

Regardless of the method of insulation, first it is necessary to make the following:

- if you have to repair and insulate the concrete floor in the already built house, you will have to remove the old screed to the base. Re-spover from a cave mixture, and then carefully compact it;

- a layer of skinny concrete is poured over the resulting pillow, which is the base for waterproofing and insulation;

- after the base from concrete hardens and gains strength, lay on top of the waterproofing layer. At the same time, we strive to make it as reliable as possible. Errors or flaws at this stage can entail the penetration of moisture into the insulation, which will reduce its operational characteristics, and over time the moisture will reach the finish screed. As a result, increased humidity in the room and constantly cold floors. To prevent this from happening, we will overlap the waterproofing, and glue the joints with tape;

- now that the waterproofing is ready, we lay a layer of thermal insulation. For these purposes, you can use polystyrene foam, extruded polystyrene foam, foam glass, polyurethane foam. Materials in the form of mats or plates are laid on an adhesive composition. We place the materials themselves into a run, thereby reducing the likelihood of the appearance of cold bridges and increasing the strength of the thermal insulation layer. On the perimeter of the heat -insulating layer between the wall and the edge of the material we lay the damper tape;

Important! A layer of thermal insulation from polyurethane foam can be equipped from plates, or it can be drowned. In the second case, a seamless coating will turn out. Another important point is the optional arrangement of steam and waterproofing when using polyurethane foam.

- having arranged the main layer of thermal insulation, we lay another layer of waterproofing over it, after which we install the reinforcing mesh and pour the black concrete screed. At this stage, you can also additionally insulate the concrete floor. To do this, we use clay or perlite instead of crushed stone as a concrete filler.

Important! Due to the specific operational characteristics of expanded clay and perlite, it is best to use in a screed of semi -dry solution. Another OSawareness is the use of a filler of various fractions, which will provide a more dense filling of the screed and its strength.

- by giving a completely screed to dry and gain strength, you can proceed to the arrangement of the finish flooring. At this stage, you can also insulate the concrete floor. For this, a special insulation substrate and floor materials with good heat conductivity indicators are used. As a substrate, you can use a cork or foamed polyethylene. It is worth noting that under a certain type of flooring, it is necessary to use your type of substrate. So, foamed polyethylene does not fit linoleum, instead you need to use a cork. Therefore, before laying the insulation substrate, you must verify its compatibility with the flooring.

Warm floor arrangement

To make the concrete floor on the ground really warm, so much that it will be pleasant to walk barefoot on it, you will have to equip a water or electric warm floor system. It should be noted that concrete water warm floor is somewhat more complicated in the arrangement, since in addition to pipes with water placed under the screed, it will be necessary to install equipment for heating and forced circulation, which will affect the volume and complexity of the work.

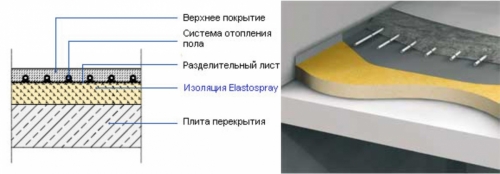

Such a system is laid directly on a layer of thermal insulation. But there is one important feature of the thermal insulation material should have a foil coating to reflect most of the heat inside the room. Of course, you can use any suitable thermal insulation material, but on top of it you should definitely lay a reflecting foil barrier.

After laying and checking the system’s performance, we lay the reinforcing mesh and fill the concrete screed. To equip the system, a warm floor, concrete solution can be done without crushed stone or expanded clay.

The arrangement of the false floor

The insulation of the concrete floor in the house with several floors is carried out in one of the above methods, as well as by creating a false floor. Such a floor can be easily equipped in any room of the upper floors.

Important! It should be noted that if the floor on the ground can still be deepened relatively painlessly in order to maintain the height of the room, then when warming the upper floors, it is necessary to carefully monitor the thickness of the floor with the insulation.

Close concrete overlap using a false floor can be as follows:

- clean the surface of the ceiling from dirt and, if necessary, level it;

- using a wooden beam 50x100 mm, equip the lags over the entire area of \u200b\u200bthe room. Step between the lags take 50 60 cm;

- we lay on top of the waterproofing layer. We lament the edges and glue with tape;

- inside we lay the insulation. It can be cotton wool, polystyrene, EPPS, expanded clay, perlite or other insulation;

- on top of the lag we lay a moisture -resistant plywood or chipboard, after which you can equip the finish flooring.

Important! The raft can significantly reduce the height of the room. Therefore, before warming the concrete overlap with the help of a false floor, you need to make sure that this method of insulation is appropriatened.

Performing the insulation of concrete floors, the main thing is to choose the right method and materials that work will be done. And compliance with technology will create a really reliable insulation that prevents heat loss. It should also be remembered that the insulation of concrete floors is only part of the general thermal insulation of the house. Of course, a lot of heat is lost through the floors, but, having insulated only them, you can not get the desired effect. Therefore, it is so important to warm the whole house in the complex.