Modern technologies and building materials allow you to make practical, reliable ...

|

|

An important step in preparing for the operation of a suburban site or house is ... |

Due to the widest range of materials for the arrangement of the roof, which today ... |

Ceramic facade tile laying technology

Building facade is an important stage of construction work. The face of the house should harmoniously fit into the surrounding development, so you should be attentive to the choice of materials for external decoration. There are currently a lot of ways of facing the external walls at present, one of them has become ceramic tiles. The article will talk about the technology of laying ceramic facade tiles.

Content:

- Differences from tiles for internal work

- Scope of ceramic facing facade tiles

- Advantages of ceramic facade tiles

- Disadvantages of ceramic facade tiles

- Types of ceramic tiles

- Technical characteristics of ceramic facade tiles

- Work tools

- Ceramic facade tile laying technology

- Installation of tiles on the frame

- Facade ceramic tiles from the manufacturer

Differences from tiles for internal work

In almost all apartments and houses for decoration of bathrooms and kitchens, a strong and waterproof ceramics are used. Facade tiles differs from it mainly by the method of fastening and the size of a separate part.

- For external work, products with large dimensions are used. The mount is performed using the installation on the frame, which allows you to additionally warm the outer wall. For small -piece elements, gluing is allowed.

- The usual tile for interior decoration most often has a smooth front surface. In turn, external cladding can imitate a variety of natural materials, such as brick, marble, natural stone.

Scope of ceramic facing facade tiles

Thanks to its characteristics, ceramic tiles are widespread in:

- restoration of facades of old buildings;

- external decoration for new construction;

- cladding of furnaces and fireplaces;

- imitation of brick and natural stone;

- prevention of mold and fungus in pools.

Advantages of ceramic facade tiles

Talking about the merits, it is most logical to compare ceramic tiles with another no less common material - facing brick.

- The front brick forms a layer with a thickness of 120 millimeters, the tile has a much smaller thickness. This allows you to reduce the load on the foundation, in addition, there is no need to bruise it to support decorative finishes.

- Variations in brick decoration can only be color. There is a facing brick with small textured frills, but its cost is higher. Ceramic tile gives the customer a scope for imagination, the design of the facade is practically unlimited.

- Simplicity of operation. Removing pollution is much easier from the wall with tiles with tiles.

- High resistance to moisture and temperature changes.

- The possibility of applying both in low -rise construction and high -rise constructiondue to increased resistance to wind loads and a high degree of wall protection from adverse atmospheric phenomena.

- Tiles, like brick, has a wide temperature range of use. It is equally good for harsh northern regions and for hot deserts. For example, a common finishing material - vinyl siding begins to bend and change its shape at temperatures above +50 degrees Celsius.

- Fire resistance and biological influences. The appearance of mold, fungus and other microorganisms harmful to humans does not occur.

Disadvantages of ceramic facade tiles

Before choosing a finish, you also need to find out its unpleasant sides and take measures to soften them in time.

- Most often, buyers repels high priceBut it is worth remembering that these are one -time costs. For decades, the facade will not require repairs, only cleaning of dirt and dust is enough.

- Facing does not miss moisture in both directionsboth outside and from the inside. To remove condensate from the insulation, there is a need for an air-ventilated layer. It is a gap of 10 centimeters between the thermal insulation layer and the finish. The volume of the layer should not be closed, but have a message with the outer air, otherwise its device is pointless.

- Ceramic tiles, of course, weighs less brick, but still refers to massive finishing materials. This must be taken into account when facing buildings made of light materials, for example, frame.

Ceramic facade tiles for a brick will become an excellent alternative to natural stone when facing a basement. Having lighter weight, outwardly it looks no less beautiful.

Types of ceramic tiles

Depending on the covering layer, matte and glossy ceramic tiles are distinguished. The glossy is covered with a thin layer of glass, which begins to shine. Matte, on the contrary, is characterized by a rough surface. For facade work, matte tiles are preferable, since it will allow the building to give the building a more presentable look. But in any case, it is important to choose a ceramic facade tile of GOST, which guarantees good product quality.

By the method of manufacture, facade coatings are distinguished by:

- porcelain tile. Tiles can be produced in various sizes. For manufacture, use several rocks of clays, field spaties, quartz and pigments to give color. First, the components are pressed, and then I burn;

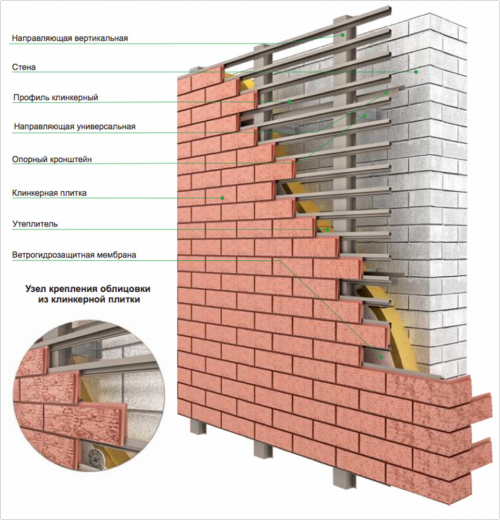

- clinker. After passing through the form, the material is subjected to temperature treatment. Thanks to the maximum temperatures, a strong and durable tile comes out of the furnace. It is possible to make pressing;

- cotto. Red clay is used as the source material. Like the clinker, it is passed through the shape and is burned. It is possible to obtain products of yellow, brown and pink shades;

- unglazed facade tiles. It is least often used in facing. This is due to the fact that it does not have a decorative surface. But the natural terracotta color of clay attracts adherents of all natural. When facing the house in combination with wooden lining or stone, it looks most advantageous. Its main disadvantage will be that for cleaning it will be necessary to use only special cleaners.

Technical characteristics of ceramic facade tiles

The indicated properties of ceramic tiles belong to physical and operational characteristics. To calculate the cost of work, you must familiarize yourself with the technical side of the question.

The main indicators include:

- thickness;

- form;

- consumption per square meter of area.

The thicker the material, the higher its price, but it is better to protect against negative external influences. Before buying, it will be necessary to determine the area of \u200b\u200bthe facing surface, and calculate the amount of material.

Work tools

During the installation of tiles, the worker will need tools for cutting it, since it is not always possible to smoothly fit the number of products under the facing surface. To do this, use one of the devices:

- roller or electric tile cutter;

- manual tile cutter;

- pachypes tiles;

- hacksaw with a diamond string;

- bulgarian;

- kusachki;

- ring saw.

The necessary control and measuring tools include:

- roulette;

- construction level and plumb line;

- pencil for marking.

The remaining devices and materials depend on the type of consolidation. When mounting on the adhesive composition, you will need:

- special tile glue;

- a toothed spatula for its application;

- a container for breeding a solution;

- fPFALL-LOBATION;

- facade spatula;

- crosses and corners for high -quality styling.

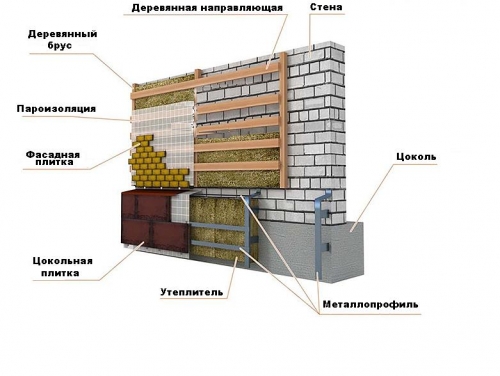

When erecting the frame of the ventilated facade, it is necessary to prepare:

- horizontal rack profiles, most often metal;

- fasteners and tools;

- waterproofing;

- when warming, thermal insulation material and wind protection are necessary.

Ceramic facade tile laying technology

For small -piece materials in the absence of insulation, it is not necessary to build a frame. You can use the same technology as for internal work.

- First, the processed surface is cleaned of dust and dirt. The quality of fixing the tile depends on the evenness of the base, so you need to apply a layer of plaster, primer and concrete contact, which contains sand to increase adhesion of materials with each other.

- To avoid falling off individual parts, you should not save on the solution. The use of cement-sand mixture is not recommended, since it cannot guarantee strength. It is best to purchase glue for tile work, having polymer components in their composition. Thanks to them, the screed quickly sets and has resistance to moisture and temperature differences.

- On average, one glue bag for 400-500 rubles is enough for a cladding of 7-8 m2 of the surface. To reduce costs, you can make an adhesive solution yourself. The ratio of cement and sand is used 1: 3. To increase the characteristics, plasticizers are introduced that are sold in liquid form. A 100 kg of cement will need 1 liter of plasticizer, which costs 100-150 rubles.

- Installation of tiles begin with installation around the perimeter of the starting profile building. It is fixed from below and ensures the support of the overlying rows of tiles. The cladding parts are first fixed in the corners, and then the whole row is performed. To provide the same joint thickness, special plastic crosses are used.

- After the upper row is completed, the crosses are removed, and the seams are grinded. The result should be a neat flat surface.

Installation of tiles on the frame

This method is used for large tiles. It allows you to carry out additional work on the insulation of the facade. The most important stage of work in this case is the assembly of the frame. He perceives the main load from the cladding. Ideally, a set of supporting profiles from one manufacturer is purchased.

- Before installing the supporting structure, marking for the starting profile and brackets is performed. After that, a waterproofing layer is applied. For example, when using a membrane, it is glued over the brackets, providing slots under them.

- The next step is the installation of vertical racks. Between them, if necessary, a heater is laid, which is rigidly fixed with glue and plastic dowels. So that the insulation does not sag, it is based on a metal profile.

- If the insulation is carried out, then before the installation of a transverse supporting profile, a windproof film is laid. It remains only to hang the facing layer, and the work is finished.

- Fixing depends on the type of ceramic tile and manufacturer. For example, porcelain tiles are attached with metal clamps. Some manufacturers provide fasteners, and in other cases, the tile is made with holes for special screws.

Facade ceramic tiles from the manufacturer

Tiles are produced by both domestic companies and foreign companies. Different countries become the leaders in production depending on the starting raw materials.

Porcelain tile

- Leaders can be called Italy and Spain. The main manufacturers in this segment are Keramamarazzi, Keranit, Italon, Estima Hitom. Most materials are made in Russia on foreign equipment. The quality of such tiles is not inferior, produced directly in Italian factories. Domestic products are in demand from buyers, guarantees a long service life and excellent operational characteristics.

- The material of these companies allows you to perform wood, concrete, brick, stone, marble. Prices of ceramic facade tiles varies from 600-800 rubles per square meter.

Clinker

- The clinker tile market is represented mainly by Germany. In the production of materials for external cladding, Korzilius, Feldhausklinker, ABC Klinkergruppe, Strher are specified. The location of the main suppliers is due to the stalls of clay suitable for manufacture. In Russia, production is concentrated in the Leningrad region.

- Average prices for products are in converters 750-1500 rubles/m2. Many manufacturers guarantee a high service life - from 25 years.

Cotto

- Cotto is less well -known than the previous two. Leading suppliers are engaged in the production of this tile. Keramin (Belarus), DelConca (Italy), Cir & Serenissima (Italy), Cersanitia are delivered to the Russian market.

- The cost in this case is almost the same as that of the clinker and porcelain. It is worth noting that the high price is completely compensated during the operation of the building.

Ceramic tiles for facing cladding will provide reliable protection of external walls from atmospheric phenomena that are unfavorable for the building. In addition, it will give the facade a unique look, which will last for several decades. All types of ceramics in this case have excellent characteristics.

When choosing a finish material, you should not save, because everything is known for the phrase: the stingy pays twice. The insufficient quality of the material or inattention, when performing work, can be unusable not only of the facing layer, but also the supporting structures. Repair of the external walls of the building is a technically complex and very expensive process, which can only be avoided with a responsible attitude to the construction and finishing process.

Inexpensive and high -quality

Inexpensive and high -quality porcelain tiles for ventilated facades of Russian production - http://grasaro.ru/gres/